Ukuhlanganisa Nokuhlola

UMHLANGANO NOKUHLOLA

I-Advance Of Minghe Assembly

IMinghe Die Casting inikeza izixazululo eziguqukayo, ezingabizi kakhulu zokwenza i-turnkey ngemikhiqizo ehlanganisiwe yomhlangano omncane kanye nemihlangano ekulungele ukukhiqizwa.

Thina eMINGHE CASTING sinezinsiza nobuchwepheshe bokwenza izinhlobo eziningi zokuhlangana nokuhlola. UMkhandlu Womkhiqizo uyaqinisekiswa ukugcina izinga eliphakeme kakhulu lekhwalithi, kanye nezikhathi ezikahle zokujika usebenzisa imigqa yomhlangano ngobuningi.

Kusuka kumhlangano olula womshini nokuhlolwa kwengcindezi, ukuya enhlanganweni kagesi nokuhlolwa nge-analyzer yenethiwekhi. Lokhu kuzokuvumela ukuthi uthenge umkhiqizo ophelile kunokuba nje into ethile.

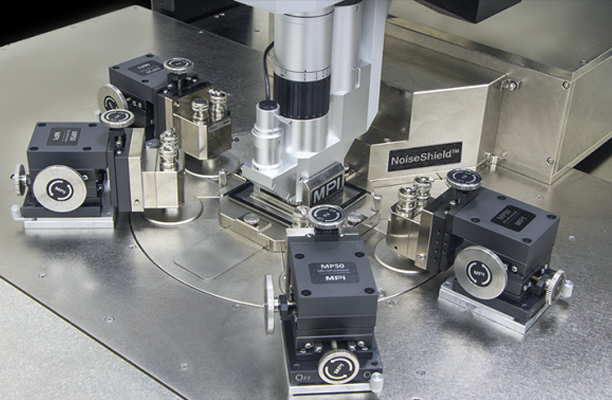

Imishini yokuhlola ye-elekthronikhi isetshenziselwa ukudala amasiginali ezikhuthazo nokubamba izimpendulo kusuka kumadivayisi we-elektroniki. Ukusebenza kahle kukadivayisi we-elekthronikhi kungaqinisekiswa noma kunamaphutha ocingweni, okungalandelwa kulungiswe. Ukusetshenziswa kwemishini yokuhlola kagesi kubalulekile kunoma yiluphi uhlobo lomsebenzi kuma-elekthronikhi.

|

|

|

|

Imizamo Yethu Nemizamo Yethu Yokuthola Umhlangano Okulula Kakhulu

Noma ngabe udinga ukufaka okulula kwe-Hardware noma ukuhlangana okuyinkimbinkimbi kwemishini, iMinghe Die Casting inganikeza ngokonga isikhathi, izinsizakalo ezisebenza ngempumelelo zeprojekthi yakho. Siphatha iphrojekthi yakho ephelele kusuka ekukhutsheni prototyping, die casting, machining, stock procurement, and Assembly. Futhi singanikeza ngokukhishwa kwezingxenye ezihlanganiselwe ulayini wakho wokukhiqiza nokulungisa amakhithi. Ukusuka emihlanganweni emincane yemishini kuya kokuvalekile okuyinkimbinkimbi kwemishini, sihlela izixazululo zomhlangano kuzidingo zakho ngqo.

1. Isakhiwo se-Die Casting

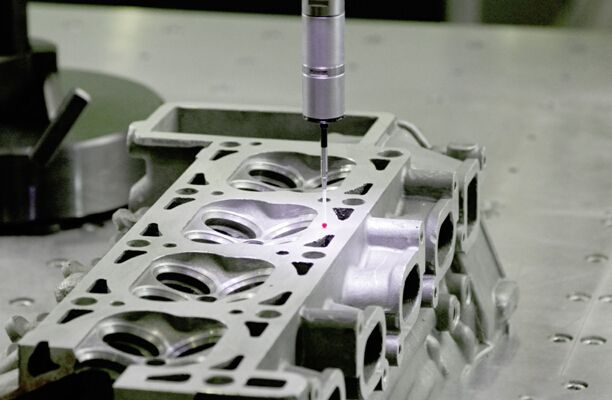

Ngokusetshenziswa okubanzi kwe-CNC machining technology, ubunzima besakhiwo se-die castings buqhubeka nokukhula. Ekucutshungulweni kokuphonsa okuthile okufa, ukubeka nokubamba kunzima kakhulu, futhi akulungele ukubekwa nokuqiniswa okuningi. Isikhathi esisodwa ukwakha ubuchwepheshe machining jikelele ukushintshanisa bese uvula worktable ngokuvumelana engela enezingqimba noma mpo-enezingqimba ukuguqulwa machining isikhungo umshini ithuluzi ukucubungula bonke ubuso nezimbobo ingxenye die-thusi ngesikhathi esisodwa, futhi bese uhlangabezana nazo zonke izidingo zokubekezelelana kwejometri zomdwebo. Ingxenye exhunywe nesibambo senqubo igqinsiwe futhi yashiswa ukuze kwehlukaniswe isibambo senqubo nendawo yokusebenza.

2. Isimiso sokucubungula

Zisebenzise ngokugcwele izinzuzo zokucubungula ama-multi-angle ne-omni-direction of the CNC machining centre, sebenzisa izici zomsiki we-carbide milling ukucubungula izingxenye nge-deformation ephansi ngesivinini esikhulu nokuphakelayo okuncane, sebenzisa ingxenye eyinsalela yengxenye yephrofayela njenge isibambo senqubo yokuma nokucindezela, bese usebenzisa isoftware ye-UG ukwenza ngokuzenzakalela Umsebenzi wokuhlela uqinisekisa ukuvumelana kwezingxenye ezisetshenzisiwe kanye nokuhlangana okuhle kwazo zonke izinhlangothi.

3. Umphumela Wokusetshenziswa

Izingxenye Die-ekubunjweni zamukele machining ebalulekile futhi okukodwa-ukwakha ubuchwepheshe. Lapho izingxenye zokufa zenziwa ngobuningi, ngemuva kokuhlolwa kokuxhumanisa kathathu, idatha yezibalo zokuma nokuma kwesimo imi ngale ndlela elandelayo: K indiza indiza flatness ≤ 0.012mm, M base indiza flatness ≤ 0.01mm, M backside parallel Izinga le ≤0.015mm, ubukhulu be-φ30mm kusisekelo se-M ngu-.0.013mm, ubukhulu be-φ32mm kusisekelo se-K ngu-.0.015mm, impambana yomgwaqo engu-φ30mm ne-eksisi ka-φ32mm ingu -0.014mm. Ekukhiqizweni ngobuningi, ukuma nokunemba kwesimo sezingxenye kuzinzile, futhi ukusebenza kahle kokukhiqiza kuthuthukiswe kakhulu.

4.Ukusetshenziswa Nokunwetshwa

Isikhathi esisodwa ukwakha inqubo ubuchwepheshe machining ebalulekile izingxenye zingasetshenziswa hhayi kuphela enezingqimba machining izikhungo, kodwa futhi mpo futhi mpo-enezingqimba ukuguqulwa machining izikhungo. Izingxenye ze-Die-casting zingacutshungulwa futhi zakhiwe ngesinyathelo esisodwa esikhungweni semishini ye-axis emihlanu, futhi izibambo zenqubo zingagaywa ngezendlalelo; izingxenye zokufa zingacutshungulwa yipuleti eliguquliwe esikhungweni semishini enama-eksisi amathathu. Ukususa ipulatifomu yenqubo eseleyo.

5. Isicelo Of Machining sekukonke

Isikhathi esisodwa sakha inqubo yobuchwepheshe bemishini ebalulekile yezingxenye ikakhulukazi isetshenziselwa ukucubungula izingxenye ezinokuma okunzima nokubamba. Izinqubo zokucubungula zingahlanganiswa ukwenza ngcono ukusebenza kahle komsebenzi nokuqinisekisa ukunemba kokuma nesimo; ingasetshenziselwa ukusika okubhangqiwe kwezingxenye zesakhiwo sokulinganisa ukunciphisa inani lokuqinisa, Ukulondoloza izindleko zokukhiqiza zamathuluzi; ifanele isendlalelo sokucubungula ukusheshisa okukhulu nokuncane, ungqimba, amandla okusika mancane, ukushisa okusika kuncane ngesikhathi sokucubungula, futhi izingxenye zokuphonsa azithambekele ekucindezelekeni. Lo mqondo wokucutshungulwa ukhuthazwa kancane kancane emafemini okusakaza okufa.

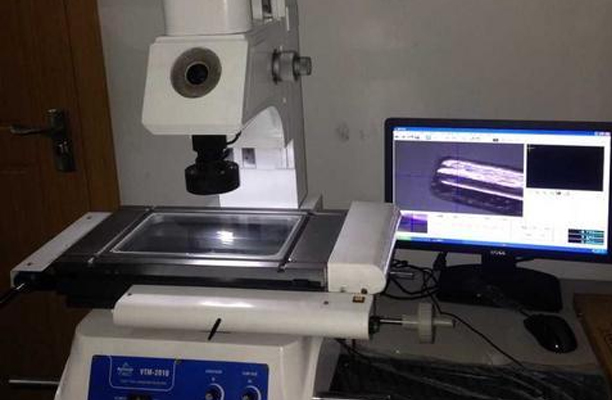

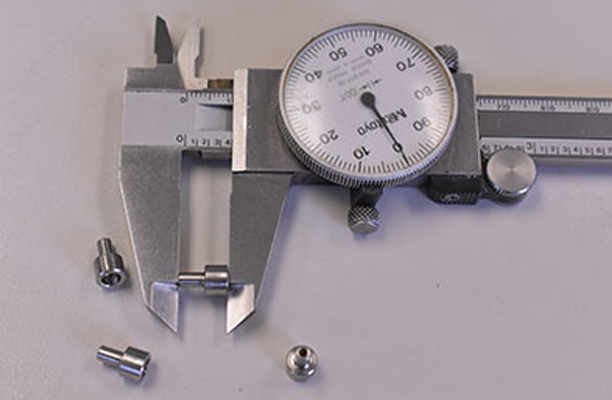

Uhlu lwethu lwezinto zokulinganisa

|

|

|

|

|

|

|

|

|

|

|

|