Brass Ekubunjweni

Izinsizakalo Zokulingisa I-Brass - Izingxenye Zenkampani Yokulingisa I-Brass Custom China Inkampani

IATF 16949 UKWENZIWA KOKWENZIWA KOKUSAKAZA KWEBHORA LOKUTHOLA

Kuyini Ukulingiswa Kwethusi? Ingxubevange yethusi ene-zinc njengoba isici esiyinhloko se-alloying ngokuvamile sibizwa ngethusi. I-copper-zinc binary alloy ibizwa nge-brass ejwayelekile, kanye ne-ternary, quaternary noma i-multi-element yethusi eyakhiwe ngokungeza inani elincane lezinye izinto ku-alloy yethusi-zinc ibizwa nge-bronze ekhethekile. -Zn ingxubevange kanambambili. Isikhathi sayo sokushisa se-crystallization sincane futhi ukusebenza kwaso ekubunjweni kungcono. Uma kuqhathaniswa ne-tin bronze, ithusi lethusi linezinto eziphakeme zemishini. Ngaphezu kwalokho, ngoba ithusi liqukethe inani elikhulu le-zinc, izindleko ziphansi. Lezi yizizathu zokuthi kungani insimbi yethusi isetshenziswa kabanzi.

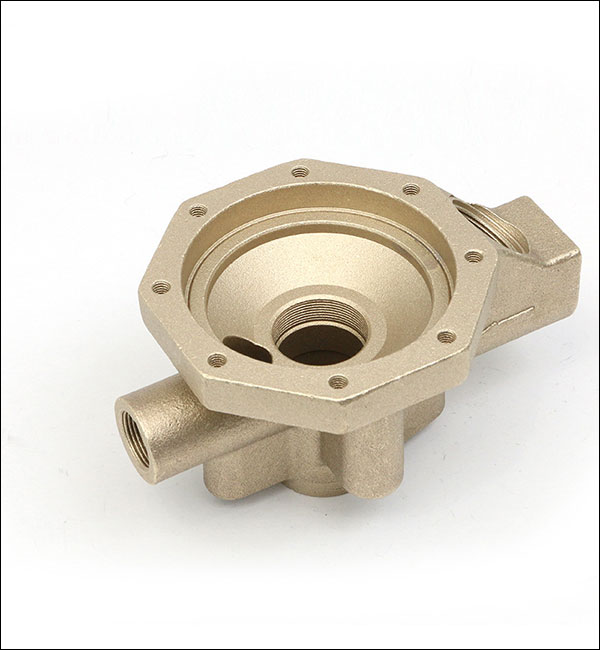

Ithusi lokusakaza lisetshenziselwa ukukhiqiza ithusi lokusakaza. I-Brass castings isetshenziswa kabanzi ekukhiqizeni imishini, emikhunjini, emabhanoyini, ezimotweni, ekwakheni nakweminye imikhakha yezimboni, futhi ithatha isisindo esithile ezintweni ezisindayo zensimbi ezingekho zensimbi, zakha uchungechunge lwethusi lwensimbi. izindleko, inqubo eguquguqukayo ephezulu, ukwakheka okuyinkimbinkimbi nokuqoshwa okukhulu kungatholwa, futhi kuhlala ingxenye enkulu ekukhiqizeni ngomshini, njengamathuluzi wemishini abala ama-60 kuye kuma-80%, izimoto zibala ama-25%, kanti ogandaganda babala ama-25%. 50 ~ 60%.

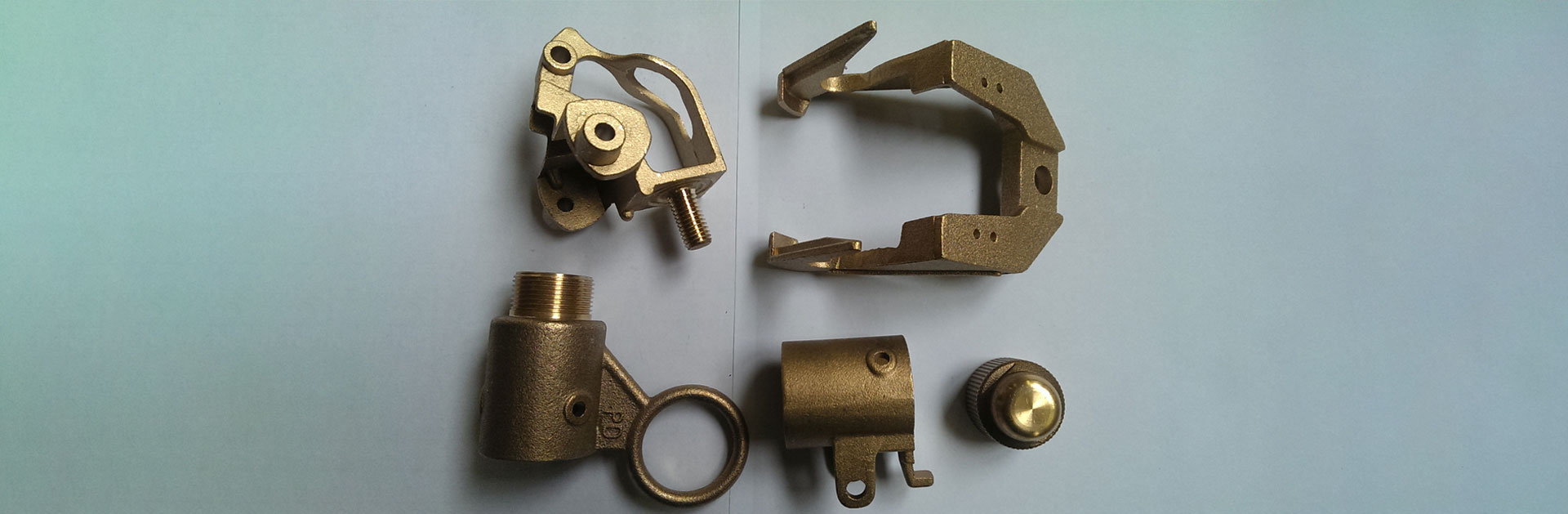

Ufuna izingxenye zethusi ezenziwe ngezifiso ngumenzi wezinto zokulingisa onolwazi futhi onokwethenjelwa? Izinsizakalo zokusakaza zethusi ezenziwe ngokwezifiso zikaMinghe zingaba ukukhetha kwakho okuhle. Sineminyaka engaphezu kwengu-30 sinesipiliyoni sokuphonsa, sinamandla okwenza ngobuningi imikhiqizo elula noma eyinkimbinkimbi yethusi kufaka phakathi izingxenye zethusi zokufa zekhwalithi ephezulu, izingxenye zethusi zokutshala izimali zethusi, izingxenye zethusi ze-centrifugal zokulingisa, izingxenye zethusi zokukhipha isihlabathi nethusi elahlekile izingxenye zokuphonsa amagwebu ukuhlangabezana sifuna opharetha abathembekile, imishini eyindida nemishini esinayo. Zonke izingxenye zethu zokusakaza zethusi zingaphansi kombuso wethu wokuhlola onzima nabahloli abaqokiwe, ukuhlolwa okuqhubekayo kanye nokuhlolwa okuphelele okugcwaliswe kuzo zonke izingxenye.

Xhumana nonjiniyela wethu wethusi oyingxenye yanamuhla ukuze uxoxe ngokuningiliziwe kwamaphrojekthi akho anzima.

Ukuqhathaniswa kokuSebenza kokuSebenza phakathi kweBrass neBronze

Uma kuqhathaniswa nethusi nethusi, ukuncibilika okuqinile kwe-zinc ngethusi kukhulu kakhulu. Ngaphansi kokulingana okujwayelekile kokushisa, cishe i-37% ye-zinc ingancibilika ngethusi, futhi cishe i-30% ye-zinc ingancibilika ku-as-cast state, ngenkathi i-tin bronze Esimweni se-as-cast, ingxenyenamba eqinile yokuncibilika kwethini ku ithusi liyi-5% kuphela ukuya ku-6% kuphela, kanti ingxenye eqinile yokuncibilika kwensimbi ye-aluminium bronze ne-aluminium ethusi ingama-7% kuya ku-8% kuphela. Ngakho-ke, i-zinc ibaluleke kakhulu ngethusi. Umphumela omuhle wokuqinisa isixazululo. Ngasikhathi sinye, izinto eziningi ezihlanganayo nazo zingancibilika ngethusi ziye emazingeni ahlukahlukene, kuqhutshekwe kuthuthukiswe izakhiwo zayo, ezenza ithusi, ikakhulukazi ithusi elithile elikhethekile, libe nezici zamandla aphezulu, futhi intengo ye-zinc Iphansi kune-aluminium, ithusi nethini, futhi inezinsiza ezicebile.

Inani le-zinc elifakwe ngethusi lingaphezulu, ngakho-ke izindleko zethusi ziphansi kune-tin bronze ne-aluminium bronze. I-Brass inebanga lokushisa eliqinile elincane, uketshezi oluhle, nokuncibilikisa okulula. Ngenxa yokuthi ithusi linezici ezishiwo ngenhla zamandla aphezulu, amanani aphansi nokusebenza kahle kokuphosa, ithusi linezinhlobonhlobo eziningi, okukhiphayo okukhudlwana nokusetshenziswa okubanzi ukwedlula ithusi lethusi ne-aluminium yethusi kuma-alloys ethusi. Kodwa ukumelana nokugqoka kanye nokumelana nokugqwala kwethusi akukuhle njengethusi, ikakhulukazi ukumelana nokugqwala nokugqokwa kokumelana nethusi elijwayelekile kuncane kakhulu. Kuphela lapho kufakwa ezinye izinto ze-alloy ukwakha ubhedu okhethekile, ukumelana nokuqina kwayo nokumelana nokusebenza kwe-Corrosion sekuthuthukile futhi kwenziwa ngcono.

Izici Zokulingisa Zokusebenza Zethusi

Izici zokulingisa ukusebenza zethusi yensimbi yilezi: i-zinc ekubunjweni kwethusi yiyona nto eyinhloko ethinta ukusebenza kokulingiswa kwethusi lethusi. Iphoyinti le-vaporization le-zinc cishe lingu-907 ℃, futhi iphuzu lokuncibilika lethusi le-cast cishe liyi-900 ℃. , IZinc inokuthambekela okukhulu kokuhwamuka kanye ne-oxidize. Ithusi lokuphonsa line-fluidity enhle, kepha ithusi le-manganese lincipha kakhulu, futhi livame ukuncipha, ukuqhekeka okubandayo kanye nokusonteka.

Ngenxa yezici ezingenhla, izinyathelo zenqubo ezilandelayo kufanele zithathwe ngesikhathi sokusakaza:

- - Khetha umgogodla wesihlabathi onemvume enhle yokwehlisa ingcindezi yokuphonsa futhi uvimbele imifantu nokukhubazeka.

- - Misa isikhuphukeli sokuqinisa ukudla.

- - Uhlelo lwesango kufanele lusethelwe ukuqinisekisa ukuqiniswa kokuqina kokuqondisa, ukuqoqwa kwe-slag kanye nesakhiwo sokugcina kufanele kusethwe, futhi ukugeleza ketshezi kufanele kugcwaliswe kahle. Isakhiwo somgijimi wangaphakathi kufanele senze ukusakazwa kupholiswe ngokulinganayo.

- - Inqubo yokuthela inciphisa izinga lokushisa elithululwayo le-cast zethusi ukunciphisa ukuncipha koketshezi nokuvikela ukuphefumula.

Izindlela zokulingisa zethusi ezisakazwayo ikakhulukazi zifaka i-die casting, i-sand casting, i-centrifugal casting, i-casting eqhubekayo kanye ne-investment casting. Ama-alloys ahlukene adinga ukukhethwa ngendlela eqondisiwe.

Ukulingisa ithusi kuyingxubevange yokusakaza isuselwa ku-Cu-Zn alloy kanambambili. Isikhathi sayo sokushisa se-crystallization sincane futhi ukusebenza kwaso ekubunjweni kungcono. Uma kuqhathaniswa ne-tin bronze, ithusi lethusi linezinto eziphakeme zemishini. Ngaphezu kwalokho, ngoba ithusi liqukethe inani elikhulu le-zinc, izindleko ziphansi. Lezi yizizathu zokuthi kungani insimbi yethusi isetshenziswa kabanzi.

Kodwa-ke, uma kuqhathaniswa ne-tin bronze ne-aluminium bronze, ithusi lethusi linokumelana nokugqwala okungalungile. Ngenxa yesimo samakhemikhali esisebenzayo se-zinc namandla we-electrode aphansi, ithusi kungenzeka livuselelwe. Ikakhulukazi emanzini olwandle nakweminye imithombo yezindaba ebhubhisayo ene-electrolyte, i-interphase yamanje yenziwa phakathi kwesigaba esine-copper kanye nesigaba esine-zinc esakhiweni sethusi, esiqinisa ukugqwala kwesigaba esine-zinc esinamandla aphansi e-electrode, ebizwa ngokuthi ukugcwala kwe-dezincification.

Ukuncibilika okuqinile kwe-zinc ngethusi kukhulu kakhulu. Ngaphansi kokulingana okujwayelekile kokushisa, cishe i-37% ye-zinc ingaqedwa ngethusi, ngenkathi kukhiqizwa uqobo, cishe i-30% ye-zinc ingancibilika ku-as-cast state. Ngakho-ke, i-zinc inomphumela omuhle wokuqinisa isixazululo ethusi. Yize ithusi elijwayelekile linamandla athile, ubulukhuni nenqubo enhle yokusakaza inqubo, inokuqina kokugqoka okuncane nokumelana nokugqwala, ikakhulukazi ngokugeleza kwamanzi olwandle, umusi ne-acid engaphili. Ngakho-ke, inani elincane lezinye izinto ezihlanganisa izinto (ikakhulukazi i-Mn, Al, Fe, Si, Pb, njll.) Zivame ukungezwa ukwenza ithusi ukwenza ngcono izinto zalo zemishini, zomzimba nezamakhemikhali, ngaleyo ndlela zakhe ithusi elikhethekile elingahlangabezana nokusebenza okuhlukahlukene izidingo. , Njengethusi elisika mahhala, ithusi lasolwandle, ithusi elinamandla amakhulu nethusi elifeziwe.

Ibanga lokushisa le-crystallization lethusi lincane kakhulu (cishe ngo-30-40 ℃). Lapho okuqukethwe kwe-zinc kwanda, izinga lokushisa kwe-liquidus lehla ngokushesha futhi iphuzu lokuncibilika lincipha ngokufanele. Ngakho-ke, ithusi linamanzi amaningi futhi lakha izimbotshana ezigxile ekunciphiseni. , Akulula ukwakha i-porosity nokuhlukaniswa kwangaphakathi. I-Brass inendawo yokuncibilika ephansi futhi iqukethe inani elikhulu lezinto ezilula zokuhwamuka ze-zinc. Lapho ihwamuka, ingavimbela ingxubevange ekutholeni igesi futhi isuse igesi kuluketshezi lwethusi, ukuze kube khona igesi encane kunqubo yokuncibilikisa. Ngakho-ke, ukusakazwa kwethusi ngokuvamile akukhiqizi iStomata.

Ngasikhathi sinye, lapho kuncibilikiswa ithusi, i-zinc uqobo inomphumela oqinile we-deoxidizing, futhi awekho amanye ama-deoxidizing agents adingekayo. Ngakho-ke, ithusi kulula ukulenza lincibilike kunamanye ama-alloys ethusi futhi linezindawo zokuphosa ezingcono. Ngenxa yokusondelana okuphezulu phakathi kwe-zinc ne-oxygen, i-oxide ZnO yakhiwa kalula ngesikhathi senqubo yokuncibilikisa ithusi, kepha ngokungafani ne-Al2O3, ihlukaniswa kalula kusuka kuketshezi lwethusi lube yi-slag. Uma nje kuthathwa izinyathelo zokuvimbela i-oxidation yesibili ye-alloy, ukukhubazeka kokufakwa kwe-oxidation ngokuvamile kungagwenywa. Izinga lokuncipha lethusi likhulu, futhi izimbotshana ezigxile ekunciphiseni zakhiwa kalula ngesikhathi sokuqina. Ngakho-ke, ukukhuphuka okukhulu kokudla kungasethwa ngokuya ngomgomo wokuqina okulandelanayo. I-Brass inezici zokuqina okufana negobolondo futhi ayizweli kangako ekusakazweni kwesilinganiso sokupholisa, ngakho-ke izakhiwo zayo zomshini nazo azizweli kangako kuzinguquko ekubunjweni kodonga.

Cishe alukho ubhedu olunambambili olusetshenziswayo ekusakazweni komkhiqizo. Ukuze uhlangabezane nezidingo zokusebenza ezikhethekile futhi uthuthukise ukusebenza kwenqubo, izingxenye eziningi zethusi zisetshenziswa kabanzi

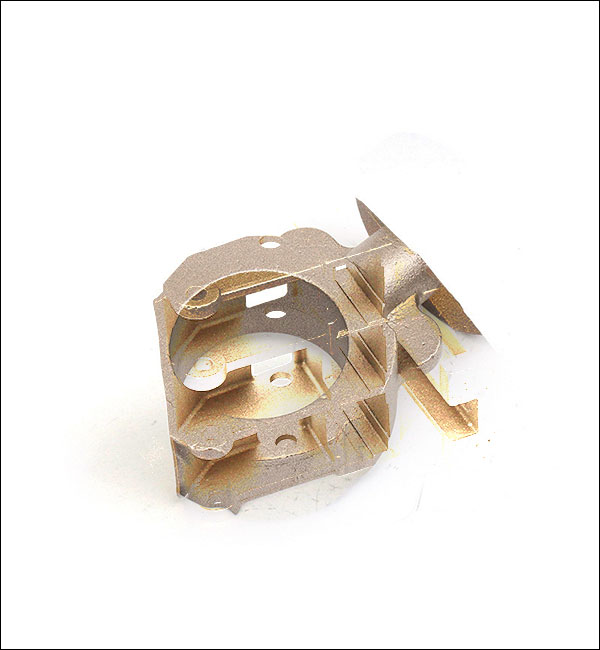

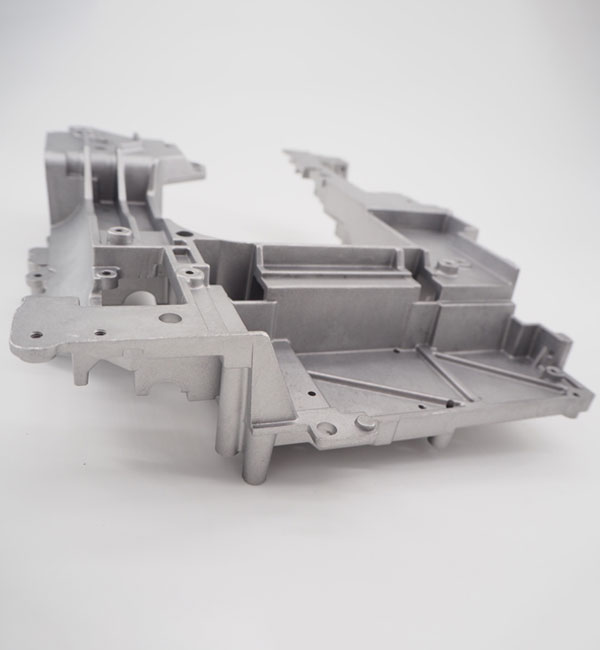

Izifundo zeMinghe Case Of Brass Casting

Izinsiza zokukhiqiza ze-Minghe ziyatholakala kukho konke ukuklama zibe ngokoqobo futhi ziphansi kuya ekukhiqizeni ivolumu ephezulu yezingxenye zakho zokuphonsa i-aluminium, izingxenye zokukhipha i-zinc, i-magnesium casting, izingxenye zokukhipha i-titanium, izingxenye zokuphonsa insimbi engagqwali, izingxenye zokuphonsa ithusi, izingxenye zokukhipha izinsimbi, ukulingisa ithusi izingxenye nokuningi.

Iya Kokubuka Izifundo Eziningi Zezingxenye Zokulingisa >>>

Khetha Umhlinzeki Ohamba Phambili Wethusi

Njengamanje, izingxenye zethu zethusi zokukhipha zithunyelwa eMelika, Canada, Australia, United Kingdom, Germany, France, Sout Africa, nakwamanye amazwe amaningi emhlabeni jikelele. Singabantu i-ISO9001-2015 ebhalisiwe futhi eqinisekiswe yi-SGS.

Insizakalo yethu yokwenziwa kwethusi yethusi enikezela ngokwezifiso ihlinzeka ngemishini ehlala isikhathi eside futhi engabizi kakhulu ehlangabezana nemininingwane yakho yezimoto, ezokwelapha, i-aerospace, i-elekthronikhi, ukudla, ukwakhiwa, ezokuphepha, ezasolwandle nezinye izimboni. Ngokushesha ukuthumela uphenyo lwakho noma uthumele imidwebo yakho ukuze uthole isilinganiso samahhala ngesikhathi esifushane.Xhumana nathi noma nge-imeyili sales@hmminghe.com ukubona ukuthi abantu bethu, imishini kanye namathuluzi kungaletha ikhwalithi engcono kakhulu kunani lentengo engcono kakhulu yephrojekthi yakho yokusakaza ithusi.

Sinikezela Ngezinsizakalo Zokulingisa Faka:

Izinsiza ze-Minghe Casting ezisebenza ngesihlabathi, i-casting yensimbi, ukusakazwa kwezimali okutshalwayo okulahlekile, futhi okuningi.

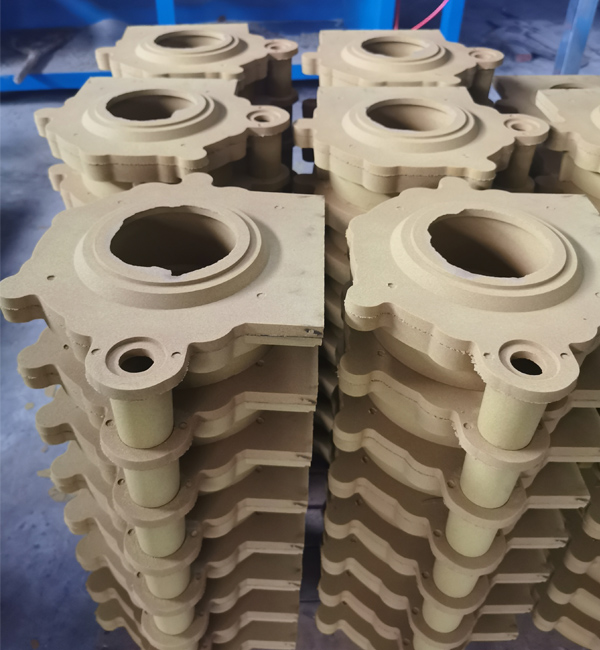

Ukulayishwa kweSand

Ukulayishwa kweSand inqubo yokulingisa yendabuko esebenzisa isihlabathi njengezinto eziyinhloko zokumodela ukwenza isikhunta. Ukuvuthwa kwamandla adonsela phansi kuvame ukusetshenziselwa isikhunta sesihlabathi, nokuphonsa ingcindezi ephansi, ukusakaza kwe-centrifugal nezinye izinqubo kungasetshenziswa uma kunezidingo ezikhethekile. Ukusakazwa kwesihlabathi kunezinhlobonhlobo zokuzivumelanisa nezimo, izingcezu ezincane, izingcezu ezinkulu, izingcezu ezilula, izingcezu eziyinkimbinkimbi, izingcezu ezilodwa, nobuningi obukhulu bungasetshenziswa.

Permanent Isikhunta Ukulingisa

Permanent Isikhunta Ukulingisa unempilo ende nokusebenza kahle kokukhiqiza, hhayi nje ukuthi unokunemba okuhle nobuso obushelelezi, kepha futhi unamandla aphakeme kunokusakazwa kwesihlabathi futhi mancane amathuba okuthi alimale lapho kuthululwa insimbi efanayo encibilikisiwe. Ngakho-ke, ekukhiqizweni ngobuningi bokuphonsa izinsimbi eziphakathi nendawo nezincane, inqobo nje uma iphuzu lokuncibilika kwento yokuphonsa ingekho phezulu kakhulu, ukukhishwa kwensimbi kuvame ukukhethwa.

Ukutshalwa Kwezimali

Inzuzo enkulu ye- ukukhipha utshalomali lokho kungenxa yokuthi ukusatshalaliswa kokutshalwa kwezimali kunokunemba okuphezulu nobuso obuphezulu, banganciphisa umsebenzi wemishini, kepha bashiye isabelo esincane semishini ezingxenyeni ezinezidingo eziphakeme. Kungabonakala ukuthi ukusetshenziswa kwendlela yokutshala imali kungagcina imishini eminingi yamathuluzi womshini nokucubungula amahora omuntu, futhi kugcine kakhulu izinto zokusetshenziswa zensimbi.

Lost Foam Ekubunjweni

Ilahlekile i-foam ekubunjweni ukuhlanganisa i-parafini wax noma amamodeli we-foam afana nosayizi wokuphonsa nomumo ube ngamaqoqo ezimodeli. Ngemuva kokuxubha nokomisa okubhangayo okukhanyayo, bangcwatshwa esihlabathini esomile se-quartz sokumodela kokudlidliza, futhi bathelwe ngaphansi kwengcindezi engemihle yokufaka imodeli amandla. , Insimbi ketshezi ithatha isikhundla semodeli futhi yakha indlela entsha yokusakaza ngemuva kokuqina nokupholisa.

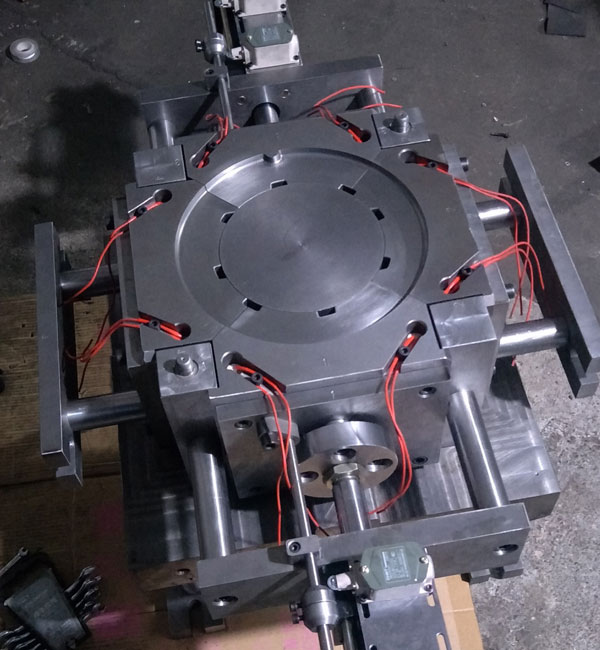

I-Die Casting

Ukufa kwe-die kuyinqubo yokusakaza yensimbi, ebonakala ngokusebenzisa ingcindezi ephezulu kwensimbi encibilikisiwe isebenzisa umgodi wesikhunta. Isikhunta ngokuvamile senziwa ngama-alloys anamandla aphakeme, futhi le nqubo icishe ifane nokubunjwa komjovo. Iningi lokufa kwabantu alinansimbi, njenge-zinc, ithusi, i-aluminium, i-magnesium, i-lead, i-tin, ne-lead-tin alloys kanye nama-alloys awo. UMinghe ubelokhu ehamba phambili eChina die inkonzo ekubunjweni kusukela 1995.

I-Centrifugal Casting

I-Centrifugal Casting kuyindlela nendlela yokujova insimbi ketshezi kwisikhunta esigijimayo esinejubane, ukuze insimbi engamanzi inyakaze nge-centrifugal ukugcwalisa isikhunta futhi yenze ukusakaza. Ngenxa yokunyakaza kwe-centrifugal, insimbi eyiketshezi ingagcwalisa isikhunta kahle esiqondisweni se-radial bese yakha indawo yamahhala yokusakaza; kuthinta inqubo ye-crystallization yensimbi, ngaleyo ndlela ithuthukise izakhiwo zemishini nezomzimba zokusakaza.

Ukuphonsa Ingcindezi Ephansi

Ukuphonsa Ingcindezi Ephansi kusho ukuthi isikhunta ngokuvamile sibekwa ngaphezu kwesibambo esivaliwe, futhi umoya ocindezelweyo wethulwa ku-crucible ukudala ingcindezi ephansi (0.06 ~ 0.15MPa) ebusweni bensimbi encibilikisiwe, ukuze insimbi encibilikisiwe inyuke isuka kumbhobho ophakamayo iye gcwalisa isikhunta nokulawula Indlela yokusakaza eqinile. Le ndlela yokulingisa inokuphakelwa okuhle nesakhiwo esinyene, okulula ukusakaza ukusakazwa okuyinkimbinkimbi okunamapulangwe amancane, akukho risers, kanye nesilinganiso sokutakula kwensimbi esingu-95%. Akukho ukungcola, okulula ukukuqaphela ukuzenzekelayo.

Ukuphoswa Kokuqothula

Ukuphoswa Kokuqothula inqubo yokuphonsa lapho insimbi incibilikiswa khona, ithululelwe futhi ifakwe emgodini we-vacuum. Umshini ekubunjweni kunganciphisa okuqukethwe kwegesi ensimbi futhi kuvimbele i-oxydation yensimbi. Le ndlela ingaveza ukufunwa kwensimbi ekhethekile efunwa kakhulu kanye nokufakwa kwe-titanium alloy castings okulula kakhulu. UMinghe Casting unendawo yokukhipha umshini ongaphansi, okwanele ukuxazulula zonke izinkinga ezihlobene nokulingiswa komshini