Ukulingiswa kweBronze

Izinsizakalo Zokulingisa i-Bronze - Inkampani Yezinkampani Zokulingisa I-Bronze Custom Custom Company

IATF 16949 UKWENZIWA KOKWENZIWA KOKUSAKAZA UKUFAKA IBHOLA

Kuyini Ukulingiswa Kwethusi? Ama-bronzes asendulo amaShayina ekuqaleni ayenziwe ngethusi lemvelo. Esikhathini sokuqala se-Shang Dynasty, kwakungenzeka ukusebenzisa umlilo ukwenza izinsimbi zethusi ezenziwe nge-alloy-tin alloy. Njengamanje, izindlela zokukhiqiza ezaziwa ngama-bronzes asendulo ama-Chinese zisebenzisa kakhulu izindlela zokuphonsa abalandeli, futhi inani elincane lamabronze anezakhiwo eziyinkimbinkimbi namaphethini ayinkimbinkimbi nawo asetshenziswa yindlela elahlekile ye-wax, indlela yokukhipha, indlela yokushisela, njll. amamaki ahlukene ezitsheni.

I-cast bronze ekuqaleni ibibhekiswa kuphela ku-tin bronze. Kamuva, ngenxa yokwamukelwa kwezinto ezahlukahlukene zokuxubanisa, kwavela izinhlobo ezintsha zethusi ngaphandle kwethusi lethusi, njenge-aluminium bronze, i-silicon bronze, i-manganese bronze, i-chromium bronze, i-beryllium bronze ne-lead bronze.

I-cast bronze yithusi elisetshenziselwa ukukhiqiza ukusakaza. Ukufakwa kwebronze kusetshenziswa kabanzi ekukhiqizeni imishini, emikhunjini, ezimotweni, ekwakheni nakweminye imikhakha yezimboni, kwakheka uchungechunge lwethusi lwezinsimbi ezintweni ezisindayo ezingezona ezensimbi. Ama-bronzes ajwayelekile asetshenzisiwe yi-tin bronze, i-lead bronze, i-manganese bronze ne-aluminium bronze.

Udinga ukusakazwa kwempahla yethusi ngumkhiqizi wezinto zokwenziwa ngobuningi onokwethenjelwa futhi onokwethenjelwa? UMinghe inkampani yokukhipha nokukhiqiza ephezulu yaseChina, ihlinzeka ngensizakalo yethusi engcono kakhulu, futhi inikela ngezifiso ezisezingeni eliphakeme zezingxenye zethusi zezinhlelo zokusebenza zezimboni ezifana ne-elekthronikhi, ezokwelapha, ukudla, i-semiconductor, imishini, izimoto, ezokuthutha nokuningi. Ngaphezulu kweminyaka engama-35 yesipiliyoni, sinobuchwepheshe bokukhiqiza nokukhiqiza ukukhiqiza ngokunemba izingxenye zethusi ezenziwe ngokwezifiso eziyohlangabezana nezidingo zakho zokufaka isicelo. Siphinde sibe namandla okunikela ngezingxenye zethusi zokufa, ukusakaza ukutshalwa kwezimali, ukukhishwa kwesihlabathi, ukusika okufa, ukugaya, ukugoba, i-CNC machining, kanye ne-welding.

Xhumana nonjiniyela wethu wokulingisa ingxenye yethusi ukuze nixoxe ngokuningiliziwe kwamaphrojekthi akho anzima.

Ukulingiswa Kwethusi Lethusi

I-shrinkage yevolumu ye-Cu-Sn alloy incane kakhulu (isilinganiso sokuncipha komugqa singu-1.45% ~ 1.5%), futhi kulula ukukhiqiza ukusakazwa okuyinkimbinkimbi ngobukhulu obunembile nobuciko obunamaphethini acacile. Ukulingisa i-tin bronze ngokuvamile kunezela izinto ezifana ne-zinc, lead, ne-phosphorus. Ama-Phosphates anokuqina okuphezulu, ukumelana nokugqoka, nezakhiwo ezinhle ezilimazayo. Kuma-tin bronze amelana nokugqoka, okuqukethwe kwe-phosphorus kungafinyelela ku-1.2%. I-Zinc ingathuthukisa uketshezi kwe-alloy futhi yehlise ukuthambekela kokulwa nokuhlukaniswa kwethusi lethusi. Ukuhola kuthuthukisa kakhulu ukumelana nokugqoka kanye nokungasebenzi kahle kwe-alloy. I-cast tin bronze isetshenziswa njengezingxenye ezingagqoki futhi ezingamelana nokugqwala.

- - Tin phosphor yethusi. I-Phosphorus iyi-deoxidizer enhle yama-alloys ethusi, angakhuphula uketshezi kwe-alloy, ithuthukise inqubo nezakhiwo zomshini we-tin bronze, kepha inyuse izinga lokuhlukaniswa okuphindayo. Ukuncibilika kokugcina kwe-phosphorus ngethini lethusi ngu-0.15%. Uma kuningi kakhulu, kuzokwakhiwa i-α + δ + Cu3P ternary eutectic, enendawo yokuncibilika engu-628 ℃. Kulula ukukhiqiza ubukhali obushisayo ngesikhathi sokugingqika okushisayo futhi kungasetshenzelwa amakhaza kuphela. Ngakho-ke, okuqukethwe kwe-phosphorus ku-tin bronze okhubazekile akufanele kube ngaphezu kuka-0.5%, kanti i-phosphorus kufanele ibe ngaphansi kuka-0.25% ngesikhathi sokushisa. I-phosphorus equkethe i-tin bronze yinto enwebeka eyaziwayo. Ngesikhathi sokucubungula, kuyadingeka ukulawula usayizi wokusanhlamvu ngaphambi kokusebenza okubandayo nokufakwa kokushisa okuphansi ngemuva kokucubungula. Amandla, i-modulus nokunwebeka nokukhathala kwamandla okusetshenzisiwe okusanhlamvu okusetshenzisiwe kuphakeme kunokwenziwe ngezinto ezisetshenzisiwe zokusanhlamvu okusanhlamvu, kepha ipulasitiki iphansi. Izinto ezisetshenzisiwe ezibandayo zifakwe emazingeni okushisa aphansi ka-200-260 ° C amahora angu-1 kuya kwangu-2 ukukhiqiza umphumela wokuqinisa, ongathuthukisa amandla, i-plasticity, umkhawulo wokunwebeka kanye ne-modulus yomkhiqizo, futhi kwandise ukuzinza kokuqina.

- - Tin-zinc ithusi. Inani elikhulu le-zinc liyachithwa ku-alloy yethusi, futhi inani le-zinc elifakwe kubhulonzi we-tin elicwengekile ngokuvamile alikho ngaphezu kwe-4%. I-Zinc ingathuthukisa uketshezi kwe-alloy, inciphise ibanga lokushisa nge-crystallization, futhi inciphise ukwehlukaniswa okuguqukayo.

- - Tin-zinc-lead bronze. Umthofu awuncibiliki empeleni ku-alloy-tin alloy. Isatshalaliswa phakathi kwama-dendrites njengesigaba esisodwa, ukufakwa kwabantu abamnyama. Ukusatshalaliswa komthofu ku-ingot akulula ukufana, imvamisa ukufaka inani elincane le-nickel kungathuthukisa ukusatshalaliswa kwayo futhi kucwenge isakhiwo. Ukuhola kunciphisa ukungqubuzana kokushayisana kwe-tin bronze, kuthuthukisa ukumelana nokugqoka nokusebenza kwemishini, kepha kunciphisa kancane izakhiwo zemishini. I-3% kuye ku-5% we-zinc ivame ukungezwa ku-alloy-lead-lead alloy ukuqhubekisela phambili ukwenza ngcono izakhiwo zemishini. Ukungeza i-0.02% ~ 0.1% i-zirconium noma i-0.02% ~ 0.1% i-boron, ikakhulukazi ukungeza i-0.02% elements 0.2% izakhi zomhlaba ezingavamile zingacwenga izinhlayiya eziholayo futhi zizenze ngokulinganayo zisatshalaliswe, ukuze kuthuthukiswe ukwakheka, ukusakaza kanye nezinto zomshini zomthofu- equkethe ithusi lethusi.

Ukulingiswa Kwethusi Ngaphandle Kwethini

- - I-casting lead bronze inezakhiwo eziphezulu zemishini, ukumelana nokugqwala, ukugqoka ukumelana, ukushaqeka okuhle, futhi kungaphonsa ukusakazwa okujiyile.

- - Ukulingisa ithusi le-manganese ngokuvamile kufakwa nge-aluminium, i-iron, i-nickel nezinye izinto, ezingamelana nokugqwala futhi ezingamelana nokushisa, futhi zilungele ukwenza izingxenye ezisebenza emazingeni aphezulu okushisa.

- - I-Cast aluminium bronze ngokuvamile ifakwa nge-iron, i-manganese, i-nickel nezinye izinto, ezilungele ukwenza izingxenye ezinamandla amakhulu nezimelana nokugqwala.

Ukwakheka Kwamakhemikhali Nokusetshenziswa Kwethusi Elisetshenziswa Ngokuvamile

| Brand | Ukwakheka okuzenzakalelayo /% | Isicelo |

|

|

|

|

|

|

|

|

|

|

|

|

IMinghe Casting, etholakala eDongguan, eChina, inokuhamba okulula. Ikakhulu babandakanyeka ekusakazeni nasekucubunguleni amamaki akhethekile ama-alloys ethusi nama-aluminium alloys. Amakilasi we-Copper alloy afaka i-aluminium bronze, i-silicon bronze, i-aluminium yethusi, i-aluminium nickel bronze, ithusi yethusi, ithusi le-manganese, ithusi elibomvu, ithusi, njll. C94400, C95800, C83600, 10-2, 9-2, CuAl5Sn5Zn5, CuAl9, CuAl9Fe njll., Ngemishini yokuhlola i-spectrum analyzer yokusebenza ngobungcweti ukuqinisekisa ukunemba kokwakheka kwamakhemikhali kwalolo daba. Imishini yokucubungula ifaka isethi ephelele yemishini yokucubungula enjengemishini ejwayelekile, imishini yokugaya, i-CNC, izikhungo zemishini, njll.

Izifundo Zamacala WakwaMinghe Zokusakaza I-Bronze

Izinsiza zokukhiqiza ze-Minghe ziyatholakala kukho konke ukuklama zibe ngokoqobo futhi ziphansi kuya ekukhiqizeni ivolumu ephezulu yezingxenye zakho zokuphonsa i-aluminium, izingxenye zokukhipha i-zinc, i-magnesium casting, izingxenye zokukhipha i-titanium, izingxenye zokuphonsa insimbi engagqwali, izingxenye zokuphonsa ithusi, izingxenye zokukhipha izinsimbi, ukulingisa ithusi izingxenye nokuningi.

Iya Kokubuka Izifundo Eziningi Zezingxenye Zokulingisa >>>

Khetha Umhlinzeki Ohamba Phambili Wethusi

Njengamanje, izingxenye zethu zethusi zethusi zithunyelwa eMelika, Canada, Australia, United Kingdom, Germany, France, Sout Africa, nakwamanye amazwe amaningi emhlabeni jikelele. Singabantu i-ISO9001-2015 ebhalisiwe futhi eqinisekiswe yi-SGS.

Insizakalo yethu yokwenziwa kwethusi yethusi ihlinzeka ngemishini ehlala isikhathi eside futhi engabizi kakhulu ehlangabezana nemininingwane yakho yezimoto, ezokwelapha, i-aerospace, i-elekthronikhi, ukudla, ukwakhiwa, ezokuphepha, ezasolwandle nezinye izimboni. Ngokushesha ukuthumela uphenyo lwakho noma uthumele imidwebo yakho ukuze uthole isilinganiso samahhala ngesikhathi esifushane.Xhumana nathi noma nge-imeyili sales@hmminghe.com ukubona ukuthi abantu bethu, imishini kanye namathuluzi kungaletha ikhwalithi engcono kakhulu kunani lentengo engcono kakhulu yephrojekthi yakho yokusakaza ithusi.

Sinikezela Ngezinsizakalo Zokulingisa Faka:

Izinsiza ze-Minghe Casting ezisebenza ngesihlabathi, i-casting yensimbi, ukusakazwa kwezimali okutshalwayo okulahlekile, futhi okuningi.

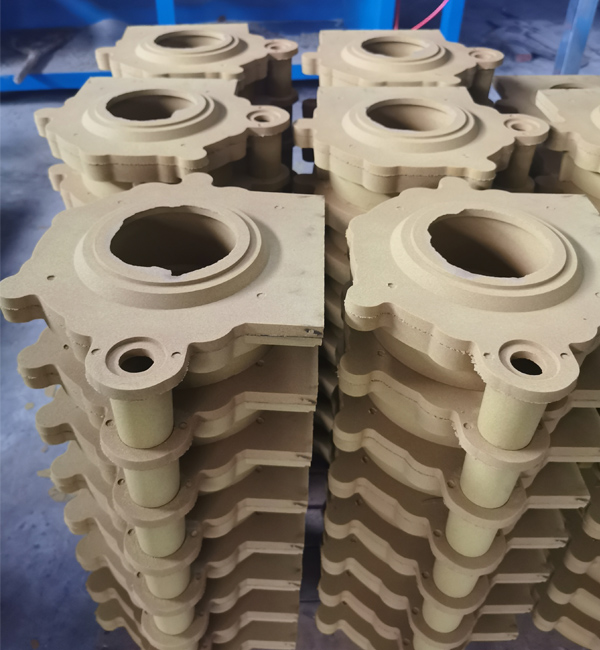

Ukulayishwa kweSand

Ukulayishwa kweSand inqubo yokulingisa yendabuko esebenzisa isihlabathi njengezinto eziyinhloko zokumodela ukwenza isikhunta. Ukuvuthwa kwamandla adonsela phansi kuvame ukusetshenziselwa isikhunta sesihlabathi, nokuphonsa ingcindezi ephansi, ukusakaza kwe-centrifugal nezinye izinqubo kungasetshenziswa uma kunezidingo ezikhethekile. Ukusakazwa kwesihlabathi kunezinhlobonhlobo zokuzivumelanisa nezimo, izingcezu ezincane, izingcezu ezinkulu, izingcezu ezilula, izingcezu eziyinkimbinkimbi, izingcezu ezilodwa, nobuningi obukhulu bungasetshenziswa.

Permanent Isikhunta Ukulingisa

Permanent Isikhunta Ukulingisa unempilo ende nokusebenza kahle kokukhiqiza, hhayi nje ukuthi unokunemba okuhle nobuso obushelelezi, kepha futhi unamandla aphakeme kunokusakazwa kwesihlabathi futhi mancane amathuba okuthi alimale lapho kuthululwa insimbi efanayo encibilikisiwe. Ngakho-ke, ekukhiqizweni ngobuningi bokuphonsa izinsimbi eziphakathi nendawo nezincane, inqobo nje uma iphuzu lokuncibilika kwento yokuphonsa ingekho phezulu kakhulu, ukukhishwa kwensimbi kuvame ukukhethwa.

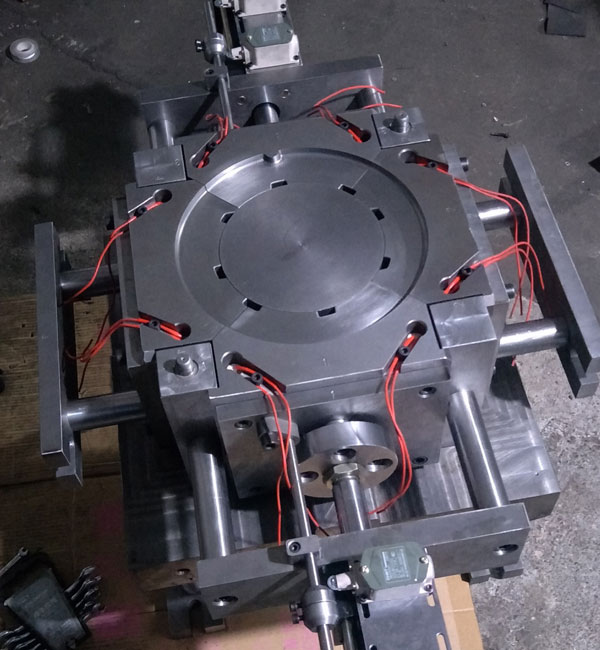

Ukutshalwa Kwezimali

Inzuzo enkulu ye- ukukhipha utshalomali lokho kungenxa yokuthi ukusatshalaliswa kokutshalwa kwezimali kunokunemba okuphezulu nobuso obuphezulu, banganciphisa umsebenzi wemishini, kepha bashiye isabelo esincane semishini ezingxenyeni ezinezidingo eziphakeme. Kungabonakala ukuthi ukusetshenziswa kwendlela yokutshala imali kungagcina imishini eminingi yamathuluzi womshini nokucubungula amahora omuntu, futhi kugcine kakhulu izinto zokusetshenziswa zensimbi.

Lost Foam Ekubunjweni

Ilahlekile i-foam ekubunjweni ukuhlanganisa i-parafini wax noma amamodeli we-foam afana nosayizi wokuphonsa nomumo ube ngamaqoqo ezimodeli. Ngemuva kokuxubha nokomisa okubhangayo okukhanyayo, bangcwatshwa esihlabathini esomile se-quartz sokumodela kokudlidliza, futhi bathelwe ngaphansi kwengcindezi engemihle yokufaka imodeli amandla. , Insimbi ketshezi ithatha isikhundla semodeli futhi yakha indlela entsha yokusakaza ngemuva kokuqina nokupholisa.

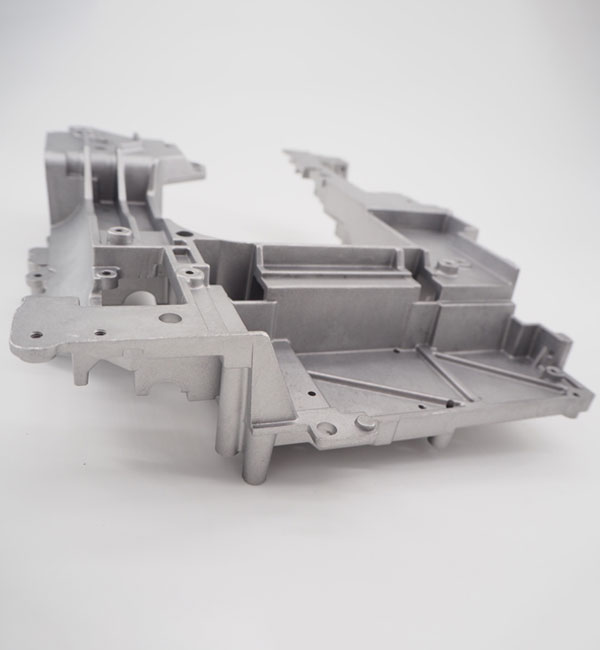

I-Die Casting

Ukufa kwe-die kuyinqubo yokusakaza yensimbi, ebonakala ngokusebenzisa ingcindezi ephezulu kwensimbi encibilikisiwe isebenzisa umgodi wesikhunta. Isikhunta ngokuvamile senziwa ngama-alloys anamandla aphakeme, futhi le nqubo icishe ifane nokubunjwa komjovo. Iningi lokufa kwabantu alinansimbi, njenge-zinc, ithusi, i-aluminium, i-magnesium, i-lead, i-tin, ne-lead-tin alloys kanye nama-alloys awo. UMinghe ubelokhu ehamba phambili eChina die inkonzo ekubunjweni kusukela 1995.

I-Centrifugal Casting

I-Centrifugal Casting kuyindlela nendlela yokujova insimbi ketshezi kwisikhunta esigijimayo esinejubane, ukuze insimbi engamanzi inyakaze nge-centrifugal ukugcwalisa isikhunta futhi yenze ukusakaza. Ngenxa yokunyakaza kwe-centrifugal, insimbi eyiketshezi ingagcwalisa isikhunta kahle esiqondisweni se-radial bese yakha indawo yamahhala yokusakaza; kuthinta inqubo ye-crystallization yensimbi, ngaleyo ndlela ithuthukise izakhiwo zemishini nezomzimba zokusakaza.

Ukuphonsa Ingcindezi Ephansi

Ukuphonsa Ingcindezi Ephansi kusho ukuthi isikhunta ngokuvamile sibekwa ngaphezu kwesibambo esivaliwe, futhi umoya ocindezelweyo wethulwa ku-crucible ukudala ingcindezi ephansi (0.06 ~ 0.15MPa) ebusweni bensimbi encibilikisiwe, ukuze insimbi encibilikisiwe inyuke isuka kumbhobho ophakamayo iye gcwalisa isikhunta nokulawula Indlela yokusakaza eqinile. Le ndlela yokulingisa inokuphakelwa okuhle nesakhiwo esinyene, okulula ukusakaza ukusakazwa okuyinkimbinkimbi okunamapulangwe amancane, akukho risers, kanye nesilinganiso sokutakula kwensimbi esingu-95%. Akukho ukungcola, okulula ukukuqaphela ukuzenzekelayo.

Ukuphoswa Kokuqothula

Ukuphoswa Kokuqothula inqubo yokuphonsa lapho insimbi incibilikiswa khona, ithululelwe futhi ifakwe emgodini we-vacuum. Umshini ekubunjweni kunganciphisa okuqukethwe kwegesi ensimbi futhi kuvimbele i-oxydation yensimbi. Le ndlela ingaveza ukufunwa kwensimbi ekhethekile efunwa kakhulu kanye nokufakwa kwe-titanium alloy castings okulula kakhulu. UMinghe Casting unendawo yokukhipha umshini ongaphansi, okwanele ukuxazulula zonke izinkinga ezihlobene nokulingiswa komshini