Ungayibala Kanjani Ingcindezi Yokudonsa Amakhonco

Ifomula Yokubala

Ifomula yokubala yokukhethwa komshini wokuphonsa okokufa: Amandla wokuphonsa umshini wokuphonsa umshini (t) = 1.4 * ukusakaza indawo ehlongozwayo * isilinganiso sendawo ekhonjisiwe yensimbi yokulingisa indawo ebhalwe phansi ye-die casting * imodyuli (CM2).

Ubukhulu bomshini wokuphonsa ngokufa bukhonjiswa ngamandla okuqinisa umshini.

Njengoba ingxubevange yokufa ifakwa ngesibhakela esimweni "esinejubane eliphezulu nengcindezi enkulu", uma umshini wokuphonsa ungavaliwe ngokuqinile, ukundiza okubucayi kuzokwenzeka, kubangele izingozi ezifihliwe zokulimala emsebenzini, indawo engcolile nekhwalithi embi yabasiki.

Ifomula yokubala yokukhethwa komshini wokulingisa wokufa wezingxenye zokufa kanjena:

- Amandla okubopha umshini wokuphonsa umshini (t) = 1.4 * indawo yokuphonsa * ingcindezi ethile

- Isakaza indawo eqageliwe-i-orthographic ekhonjisiwe yendawo yokuphonsa i-die casting * modulus (CM2)

Uma ukhetha umshini wokuphonsa ngokufa ngokwahlukana ngokwesisindo noma ngosayizi

Ungakwenza lokhu:

Usayizi: Ngokuvamile indawo yokusakazwa komkhiqizo (kufaka phakathi uhlelo lokuthela), iyunithi ibalwa ngo-cm, ihlukaniswe ngo-2.5, futhi isibalo esitholakele yisidingo esiphansi samathani.

Isisindo: Kuyadingeka ukwazi inani eliphakeme lokuthela lomshini. Imingcele eminingi yomshini yehlukile kulungiselelwa komshini wangempela wepayipi lezinto nomshini wesobho. Isibonelo, umthamo othululwayo wethiyori wamathani ayi-1250 ngu-13-25.4kg. Eqinisweni, imishini eminingi yokuphonsa ifa inenani eliphakeme lokuthela elingu-10-12kg; ipharamitha yefektri yamathani ayi-1600 ingu-17-32kg wokuthela ivolumu, empeleni okungaba ngu-16-20kg (kuya ngokuhlelwa ngakunye kweFektri).

Ubukhulu bomshini wokuphonsa die ungamandla okuqinisa umshini wokuphonsa die, hhayi amandla wokuqinisa. Amandla okuqinisa umshini wokuphonsa ufewa ngamandla okuqinisa we-clamping cylinder kanye ne-toggle force extension mechanism, hhayi amandla e-clamping cylinder. Ngokuqondene no-tonnage womshini wokulingisa, uhlobene nendawo ephikisiwe yenxenye yokulingisa (kufaka phakathi indawo ephikisiwe yengxenye yokufa, isikhwama se-slag, umgijimi wokuwela, i-sprue nekhekhe ), kungcono ukubala indawo eneprojekti enembile esikhundleni sokusebenzisa i-coefficient. Ngoba i-coefficient yomkhiqizo wezingxenye ezinkulu ayinakuphakama kakhulu, futhi i-coefficient yomkhiqizo wezingxenye ezincane iphakeme, kunembe kakhudlwana ukubala amandla okubamba ngokususelwa endaweni yangempela ebonwayo yesikhunta. Ngokuqondene nokukhethwa kwengcindezi yokusakaza, kuya ngobunzima bokusakaza, imvamisa kusuka ku-500bar kuye ku-800bar.

Njengoba ingxubevange yokufa ifakwa ngesibhakela esimweni "esinejubane eliphezulu nengcindezi enkulu", uma umshini wokuphonsa ungavaliwe ngokuqinile, ukundiza okubucayi kuzokwenzeka, kubangele izingozi ezifihliwe zokulimala emsebenzini, indawo engcolile nekhwalithi embi yabasiki.

Ngakho-ke, umshini wokuphonsa unganikeza i-160t isikhunta amandla, futhi umshini wokuphonsa ufe ubizwa nge-160t.

Ukusebenza Kwangempela Kokubala Ingcindezi Ye-Die Casting Tonnage

Umkhiqizo wami ngu-xx amagremu kanti usayizi ngu-xx * xx mm. Ngisayizi kabani womshini okufanele ngiwuprinte? "——Lokhu kuyinkinga ejwayelekile ekukhetheni imishini yokusakaza ifa.

Ukukhethwa umshini die ekubunjweni cishe kuhlanganisa izici ezintathu:

- 1. Ubukhulu bomshini wokulingisa uhlobene nokuthi impahla izondiza yini

- 2.Usayizi wesikhunta, ohlobene nokuthi isikhunta singafakwa emshinini wokuphonsa u-die

Inani lokuthela, elihlobene nokuthi umkhiqizo ungakheka yini

Ungayibala kanjani i-tonnage yomshini womkhiqizo?

Mayelana nenkinga yokubalwa kwamathani womshini wokuphonsa odongeni, kunzima ukusho ukuthi akunzima, kepha akulula ukusho ukuthi kulula. Uma nje ubuqonda ubudlelwano, kulula ukubala ithani lomshini elidingekayo kumkhiqizo.

Okokuqala nquma umqondo onjalo

Ubukhulu bomshini wokuphonsa ufe ubhekise emandleni okuqinisa umshini wokulingisa

Ukuqinisa amandla yipharamitha yokuqala ezonqunywa lapho kukhethwa umshini wokuphonsa u-die. Indima yamandla okubamba ikakhulukazi ukunqoba amandla aqhamukayo emgodini, ukukhiya isikhunta, ukuvimbela insimbi encibilikisiwe ekushayeni, nokuqinisekisa ukunemba okuyisisekelo kokusakaza.

Ngakho-ke buyela embuzweni wokuqala, ukuthi ungawabala kanjani amandla okuqinisa umshini wokuphonsa? Okokuqala bheka ifomula elandelayo:

Umshini wokuphonsa umshini wokuphonsa umshini> amandla okuvula isikhunta F1 × 1.1

Ngakho-ke, yini amandla okuvula isikhunta nokuthi ungawabala kanjani?

Isikhunta sokuvula amandla sisho amandla asebenza emgodini ukwenza isikhunta sandise ngesikhathi sokukhiqizwa kokufa. Amandla okuvula isikhunta angatholakala ngale ndlela elandelayo:

Ekubunjweni indawo × ekubunjweni ingcindezi

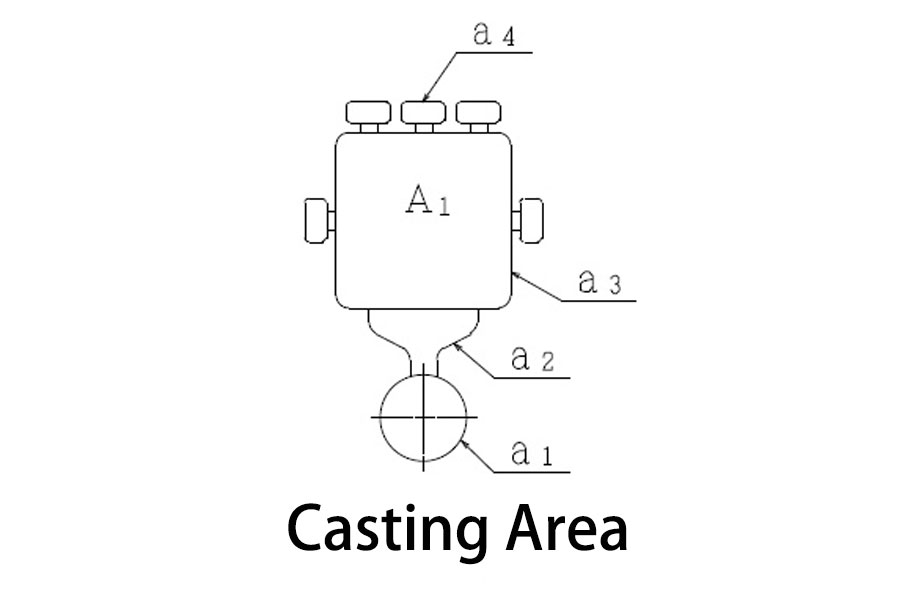

Indawo yokusakaza A1 = a1 + a2 + a3 + a4 = indawo yekhekhe + indawo yomgijimi + indawo yomkhiqizo + indawo yesikhwama se-slag

Ukulinganiswa kwendawo Lapho isikhunta singaklanyelwe ngokuphelele, sazi kuphela indawo ehlongozwayo a3 yomkhiqizo, futhi siyilinganisela

- a2 = 0.21a3

- a4 = 0.12a3

Indawo yekhekhe isuselwa ku-punch

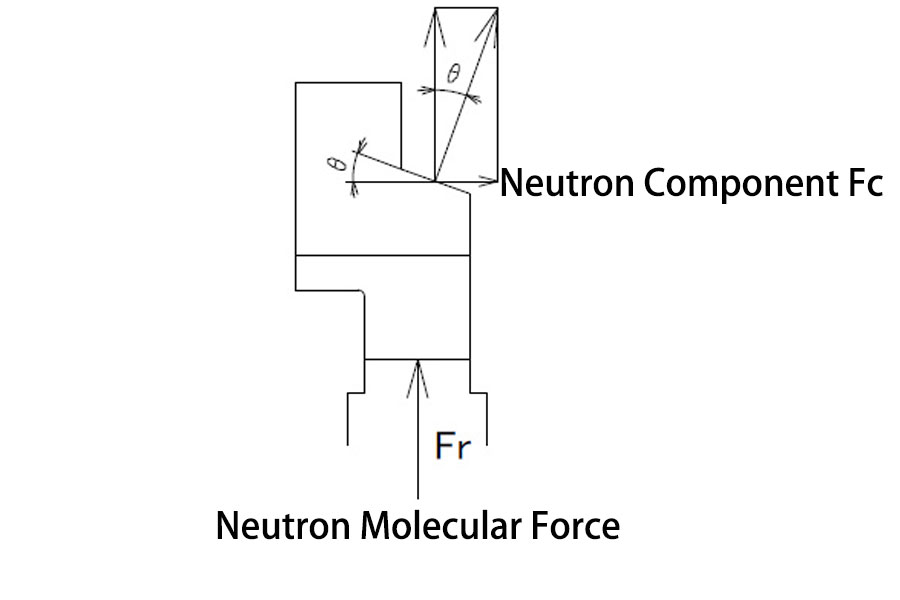

Isikhunta sokuvula amandla F1 = ingcindezi yokusakaza i-Pp × indawo yokuphonsa i-A1 + neutron element force Fc (ukubalwa kwamandla okuvula isikhunta ngesilayida)

Lapho kune-neutron eshelelayo, ama-molecule we-neutron adinga ukubalwa

Amandla okubuyisa i-neutron Fr = indawo yomkhiqizo i-Ac × ebalwa ingcindezi yokusakaza × 75%

I-neutron element force Fc = amandla okubuyisela i-neutron Fr × tanθ

Mold opening force F1=(a1+a2)×Pp+a3×Pp×0.75+a4×Pp×0.25+Fc

Ekubunjweni ingcindezi ukusatshalaliswa:

Ngoba izinga lokushisa kwesikhunta alifanele futhi ukudluliswa kwengcindezi akufani, ingcindezi esetshenziswa engxenyeni ngayinye ihlukaniswa futhi ibalwe ngokulandelayo:

- Umnyango womkhiqizo = ingcindezi yokubalwa ebaliwe × 75%

- Isigaba sesikhwama seSlag = ingcindezi yokubalwa ebaliwe × 25%

- Ikhekhe, ingxenye yomgijimi = ingcindezi yokubalwa ebaliwe × 100%

Ekubunjweni ingcindezi ukulinganisa:

I-Aluminium: Imfuneko yokuqina komoya ngokuvamile ingaphezu kwe-80MPa, enye i-60MPa

I-Zinc: cishe i-30MPa

Amandla okubamba kudingeka abe yizikhathi eziyi-1.1 noma ngaphezulu kwamandla okuvula isikhunta. Uma amandla okuvula isikhunta emkhulu kunamandla okubamba, ukukhanya (ukudubula okufishane) nokusetshenziswa ngokweqile kungenzeka kwenzeke, futhi umkhiqizo wangempela awukwazi ukwenziwa.

Ngokufingqa, ifomula lokugcina lokubala le-die casting machine tonnage lingatholakala:

Amandla okubopha> amandla okuvula isikhunta × 1.1 = indawo yokulingisa × ingcindezi = (ikhekhe indawo + umgijimi + indawo yomkhiqizo + indawo yesikhwama se-slag) × ukucindezela ukuphonsa × 1.1

I-die casting machine tonnage = clamping force / 10, iyunithi yokuqinisa amandla yi-KN

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Ungayibala Kanjani Ingcindezi Yokudonsa Amakhonco

Inkampani kaMinghe Casting inikezelwe ukukhiqiza nokuhlinzeka ngekhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zifeza ububanzi zifaka ikakhulu I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off