Usebenzisa oksijini okokushisa okumsulwa ukunciphisa ukusetshenziswa kwamandla we-ladle preheating

I-Wu Steel Works inezingxoxo zokucobelelana ngolwazi ezimbili, i-workshop eyodwa yokwenza izinsimbi kanye nomhlangano wokusebenzela wensimbi wesibili. Iworkshop yesibili yokwenza izinsimbi ikhiqiza insimbi ejwayelekile, kanti ishabhu lokuqala lokwenza izinsimbi lenza ikakhulukazi amaqoqo amancane amabanga ensimbi afana nensimbi ekhethekile. Izinqubo zokukhiqiza zifaka ukwelashwa kwensimbi eshisayo, isiguquli, neRH. Ukusakaza okweqile kanye nokuqhubeka kukhiqiza okhonze elingaba ngu-20 lensimbi encibilikisiwe ngosuku.

Ukusetshenziswa kweyunithi kaphethiloli osindayo we-ladle preheating ku-workshop yokuqala yokwenza insimbi kuphakeme kakhulu kunalokho okwenziwa e-workshop yesibili yokwenza insimbi. Uma i-workshop yokuqala yokwenza izinsimbi ingu-100, khona-ke umhlangano wokusebenzela wensimbi wesibili ngu-6.8. Ngakho-ke, ukunciphisa inani lamafutha asindayo asetshenziswa esitsheni sokushisa amalitha eworkshop yokwenza izinsimbi sekuyinkinga ebalulekile. Ukuze kuncishiswe ukusetshenziswa kwamandla we-ladle preheating, i-Wu Iron & Steel Institute yethule ama-burner oxygen amsulwa.

Ngokuya ngokuqhathanisa amandla omlilo nezimpawu zomlilo we-oxygen burner kanye ne-burner yomoya, kungabonakala ukuthi lapho kusetshenziswa umshisi wokushisa umoya, i-nitrogen engadingekile (ebala u-79% womoya) ishaywa, ngakho-ke izinga lokushisa lomlilo lizokwehliswa. , Khulisa inani legesi yokukhipha futhi wandise ukulahleka kokushisa. Lapho usebenzisa okokushisa okumsulwa kwe-oxy-fuel, ngoba i-burner isebenzisa kuphela umoya-mpilo odingekayo emlilweni, izinga lokushisa lomlilo lingakhuphukela ku-3000 ℃, futhi nenani legesi yokukhipha lehla kakhulu, ngakho ukulahleka kokushisa kungacindezelwa futhi ukushisa okusebenzayo kungakhuphuka. Nciphisa ukusetshenziswa kukawoyela osindayo futhi wehlise izindleko zikaphethiloli.

Umthamo wokushisa odingwa umshiseli womoya-mpilo omsulwa uyafana nowesishisi somoya, futhi kuyadingeka ukukwazi ukufudumeza izinga lokushisa kukalayini ophikisayo kusuka ku-600 ° C kuye ngaphezu kuka-1000 ° C cishe ku-20 imizuzu. Lapho kusetshenziswa isibhengezo somoya esivamile, umthamo omkhulu womlilo ngu-520L / hr, kanti okokushisa okumsulwa kwe-oxy-fuel kwandisa ukushisa okusebenzayo, ngakho-ke umthamo omkhulu womlilo ngu-350L / hr, owanele.

Lapho kusetshenziswa isibasi somoya esivamile, amandla okushisa abe ngu-20 ° C / iminithi lapho inani lamafutha asindayo lishisiwe lingu-450L / hr, futhi lapho kusetshenziswa umshiseli womoya-mpilo omsulwa, ukushisa okusebenzayo kuyanda, nenani lamafutha asindayo okushile kungu-200 ~ 250L. Endabeni ye / hr, kungatholakala umthamo ofanayo wokushisa njengesigesi somoya.

Ngemuva kokwethulwa kwesibhengezo somoya-mpilo esihlanzekile, ukusebenza kahle komlilo kuyathuthukiswa. Ngakho-ke, ukukhuphuka kwezinga lokushisa kwe-ladle ngaphambi kokugcwalisa insimbi encibilikisiwe kanje. Ngemuva kokushisa imizuzu eyi-15, izinga lokushisa le-refractory lizofinyelela ku-75 ° C, futhi ngemuva kokushisa imizuzu engama-20, lizofinyelela ku-100 ° C, lizofinyelela ku-125 ° C ngemuva kokushisa imizuzu engu-25.

Uma kuqhathaniswa ne-burner yomoya, ukusetshenziswa kwamayunithi kaphethiloli osindayo kuncishiswa ngama-46% ngemuva kokutholwa kwesitofu somoya-mpilo esihlanzekile, nomphumela wokonga amandla ubaluleke kakhulu.

Ngokuya ngokuqhathanisa izindleko zikaphethiloli ngaphambi nangemva kokuthuthuka kwesibaseli, lapho kusetshenziswa umshisi oshisayo we-oxy-fuel, yize izindleko zomoya-mpilo sezinyukile, inani eliphelele likaphethiloli lehle cishe ngama-37%. Ngasikhathi sinye, yehlisa ukukhishwa kwe-CO2 futhi ineqhaza ekuthuthukiseni imvelo.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Usebenzisa oksijini okokushisa okumsulwa ukunciphisa ukusetshenziswa kwamandla we-ladle preheating

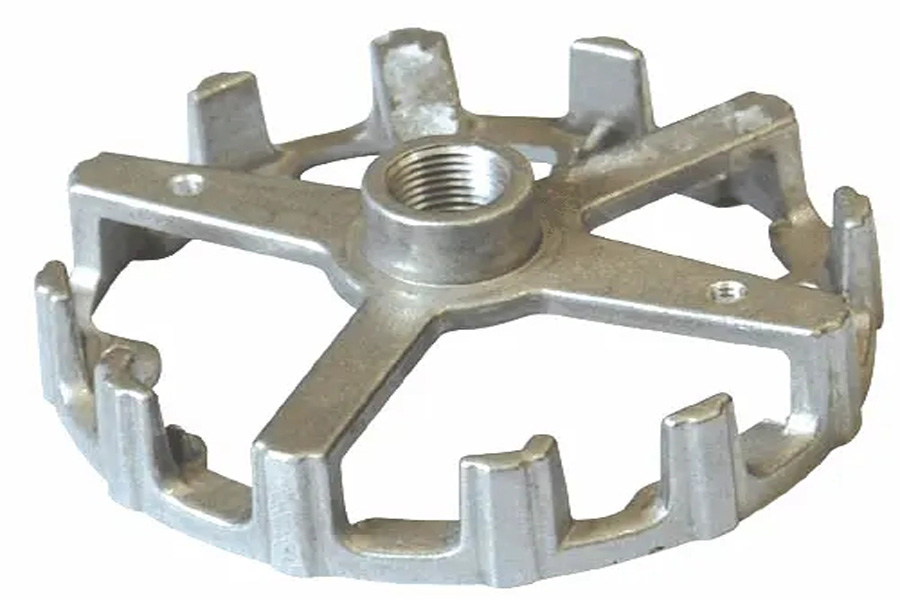

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off