Ukuphonsa Ingcindezi Ephansi

Kuyini Ukuphonsa Ingcindezi Ephansi

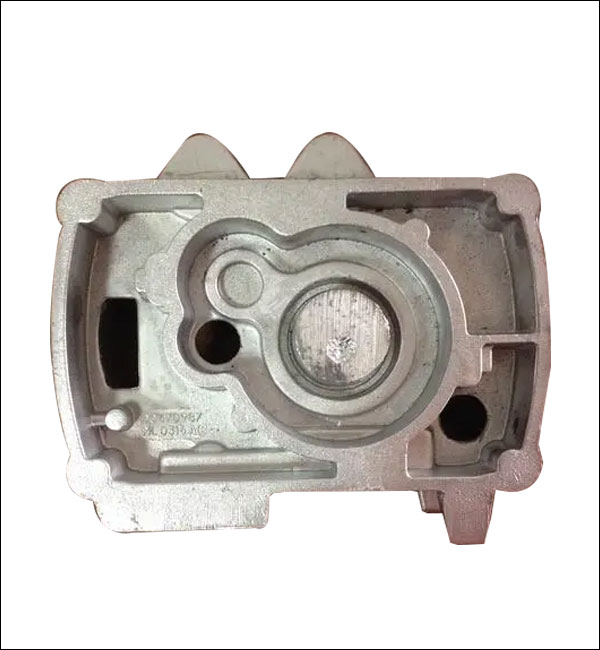

Ingcindezi ephansi ekubunjweni kusho ukuthi isikhunta ngokuvamile sibekwe ngaphezulu kwesibambo esivaliwe, futhi umoya ocindezelweyo wethulwa ku-crucible ukudala ingcindezi ephansi (0.06 ~ 0.15MPa) ebusweni bensimbi encibilikisiwe, ukuze insimbi encibilikisiwe ivuke ipayipi elikhulayo lokugcwalisa isikhunta nokulawula Indlela yokusakaza eqinile. Le ndlela yokulingisa inesondlo esihle nesakhiwo esihlangene. Kulula ukusakaza ukusakazwa okuyinkimbinkimbi okukhulu nokuncane ngaphandle kokuphakama, futhi isilinganiso sokuthola kabusha sensimbi singafinyelela kuma-95%. Akukho ukungcola, okulula ukukuqaphela ukuzenzekelayo. Kodwa-ke, izindleko zemishini ziphakeme futhi ukusebenza kahle kokukhiqiza kuphansi. Ngokuvamile isetshenziselwa ukusakaza ama-alloys angenayo i-ayoni.

Ukuphonsa ingcindezi ephansi kuyindlela yokusakaza lapho i-alloy liquid icindezelwa emgodini wesikhunta kusuka phansi kuya phezulu ngaphansi kwengcindezi, futhi kwaqina ngaphansi kwengcindezi ukuthola ukusakazwa. I-crucible evaliwe igcwele umoya omile ocindezelweyo noma igesi engenayo. Ngosizo lwengcindezi esebenza engxenyeni yensimbi encibilikisiwe, insimbi encibilikisiwe igcwalisa isikhunta ngokushelela eceleni kwepayipi eliphakamisayo kusuka phansi kuye phezulu ngomgijimi. Ingcindezi yokugcwalisa imvamisa ingama-20- 60kPa. Lapho ukusakazwa kuqina ngokuphelele, kukhishwa ingcindezi yegesi ebusweni obuketshezi, ukuze insimbi encibilikisiwe engaxutshiwe epayipini le-riser bese umgijimi egelezela ku-crucible ngesisindo sayo, khona-ke isikhunta siyavulwa bese kusakazwa kukhishwe.

Inqubo ukukhiqizwa ongaphakeme ingcindezi thusi kuhlanganisa izinqubo ezine eziyisisekelo ezilandelayo:

- - Ukuncibilikisa kwensimbi nokulungiswa kwesikhunta noma isikhunta sokuphonsa.

- - Amalungiselelo ngaphambi kokuthulula: kufaka phakathi ukubekwa uphawu kokubethelwa (ukumbozwa okufanelekile), ukususwa kwe-slag epayipini le-riser, ukukala izinga loketshezi, ukuhlolwa kokufaka uphawu, ukufanisa isikhunta, ukuqinisa isikhunta noma isikhunta, njll.

- - Ukuthela: kufaka phakathi ukuphakamisa uketshezi, ukugcwalisa, ukucindezela, ukuqina, ukukhululeka kwengcindezi nokupholisa, njll.

- - Demoulding: kuhlanganise udini okuxekethile nokukhipha.

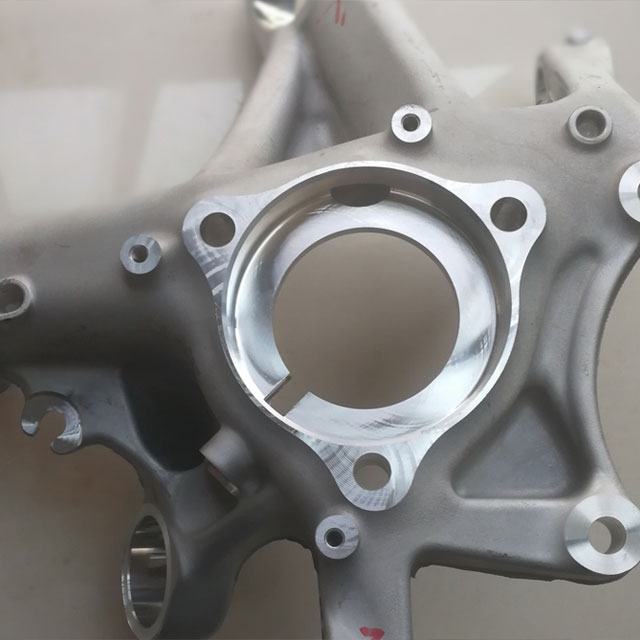

Isicelo Of okuphansi Pressure Ekubunjweni

Low-ingcindezi thusi ubuchwepheshe bokuqala anti-adonsela phansi ekubunjweni, futhi iye yasetshenziswa ekukhiqizeni izimboni kusukela ngawo-1940. Ingcindezi okuphansi ekubunjweni kuyinto ezejwayelekile die thusi, futhi izingxenye non-wagcizelela angasebenzisa le nqubo. Kulezi zinsuku, ukusakazwa okuphansi kwengcindezi kusetshenziselwa ukukhiqiza izingxenye ze-aluminium alloy nezingxube ze-magnesium, ezinjengamasondo emoto embonini yezimoto, amasilinda amasilinda, amakhanda wesilinda, ama-piston, amagobolondo e-missile, ama-impellers, amasondo omoya omoya nezinye izinto zokulingisa ezinemilo eyinkimbinkimbi futhi Izidingo ezisezingeni eliphakeme embonini yezimoto.Ukuphonsa okuphansi kwengcindezi kusetshenziselwa ukukhiqiza insimbi, njengamasondo wensimbi, ipayipi le riser lidinga ukwenziwa ngezinto ezikhethekile zokuphikisa. Ukuphonsa ingcindezi ephansi kungasetshenziswa nasekuphonsweni kwe-alloy yethusi encane, njengokufakwa kwamapayipi, ompompi beqhude ezindlini zangasese, njll. Ubuchwepheshe busetshenzisiwe phesheya.

Izici Zokuphonsa Ingcindezi Ephansi

Ukuphonsa ingcindezi okuphansi kungasebenzisa isihlabathi, insimbi, i-graphite, njll. Inqubo yokugcwalisa ihlukile ekubunjweni kwamandla adonsela phansi njengokuphonsa insimbi nesihlabathi, futhi kuhlukile ekuphonseni ingcindezi ngokucindezela okuphezulu nokugcwaliswa kwejubane elikhulu. Inezinzuzo ezilandelayo:

- - Ukugcwalisa ngensimbi encibilikisiwe kuthuthukisa ubumsulwa be-castings. Njengoba i-slag encibilikile ivame ukuntanta ebusweni bensimbi encibilikisiwe, ukusakaza okuphansi kwengcindezi kugcwaliswa ngensimbi encibilikisiwe engxenyeni engezansi ye-crucible ngepayipi le-riser, evimbela ngokuphelele ukuthi kungenzeka ukuthi i-slag encibilikisiwe ingena embotsheni yesikhunta .

- - Ukugcwaliswa kwensimbi okusamanzi kuzinzile, kunciphisa noma kugwema ukuwa, umthelela nokuchaphazeleka kwensimbi engamanzi ngesikhathi sokugcwaliswa, ngaleyo ndlela kuncishiswe ukwakheka kwe-slag ene-oxidized.

- - Ukusakazwa kunesakhiwo esihle. Insimbi encibilikisiwe igcwaliswa ngaphansi kwengcindezi, engathuthukisa uketshezi kwensimbi encibilikisiwe, evumelana nokwakhiwa kwama-castings anemigqa ecacile nezindawo ezibushelelezi, futhi inenzuzo eyengeziwe yokwakhiwa kwe-castings enkulu ebiyelwe ngodonga.

- - Ukuphonsa kukhanya futhi kuqinise ngaphansi kwengcindezi, okungafakwa ngokugcwele futhi isakhiwo sokulingisa siminyene.

- - Thuthukisa isivuno sensimbi encibilikisiwe. Ngaphansi kwezimo ezijwayelekile, asikho isidingo sokwenyuka, futhi insimbi engenamalayisense epayipini le-riser ingaxhunyaniswa ne-crucible ukuze isetshenziswe kaninginingi, okuthuthukisa kakhulu isivuno sensimbi encibilikisiwe. Ngokuvamile kufika kuma-90%,

- - Ukukhiqizwa nokusebenza okulula, izimo zokusebenza ezinhle, ukusebenza kahle kokukhiqiza, okulula ukubona imishini nokuzenzekelayo,

- - Ukuphonsa ingcindezi okuphansi nakho kunamaphutha athile, imishini nokutshalwa kwemali kwesikhunta kukhulu kakhulu; ekukhiqizweni kwe-aluminium alloy castings, ipayipi le-crucible kanye ne-riser lixhumana nensimbi encibilikisiwe isikhathi eside, okungahle kube nokugqwala nodoti, okuzophinde kudale ukuthi insimbi encibilikisiwe inyuse insimbi futhi yehle ukusebenza.

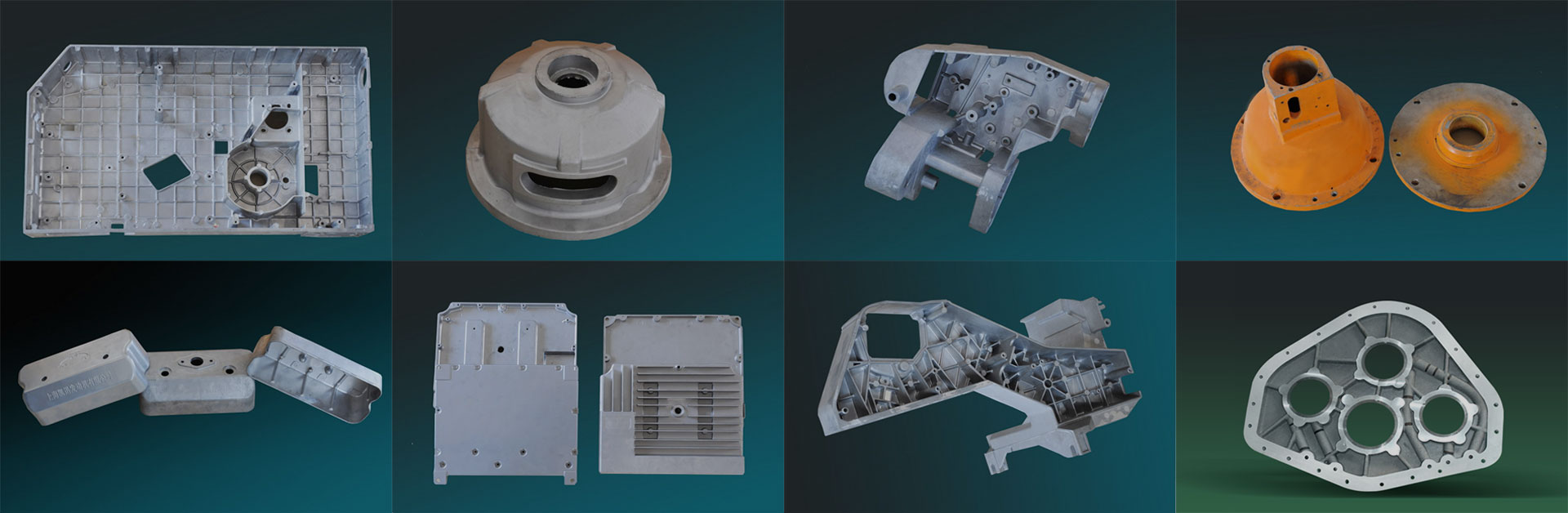

Izinhlobo Ezihlukahlukene Zokukhiqiza Isimo Sokuphonsa Ingcindezi Ephansi

UMinghe uhlala enamathela kuzidingo zamakhasimende kanye namazinga wenkonzo yenkampani. Kunoma yikuphi ukuxhumana kokuklanywa kwesikhunta, ukuhlangana kwesikhunta, ukulungisa iphutha lesikhunta, ukukhiqizwa kwesilingo, inqubo yokusakaza, njll., Kukhona onjiniyela abazinikele bokukugcina ocingweni;

| Isitolo Sokucindezela Okuphansi 1 ▶ |

| Isitolo Sokucindezela Okuphansi 2 ▶ |

| Isitolo Sokucindezela Okuphansi 3 ▶ |

| Isitolo Sokucindezela Okuphansi 4▶ |

| Isitolo Sokucindezela Okuphansi 5▶ |

| Amatebhe wokubhola nokuthepha umshini▶ |

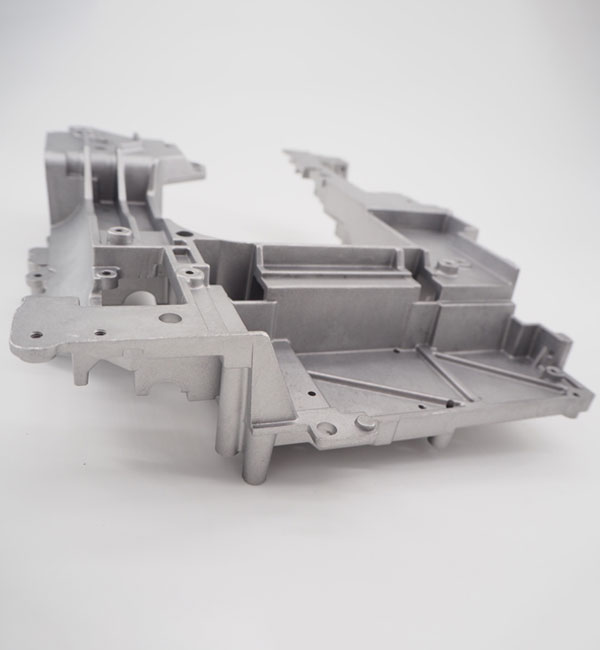

| Imikhiqizo ye-Aluminium alloy imishini yokuqeda umoya ▶ |

| Umshini wokucindezela we-De-gate▶ |

| Ifenisha▶ |

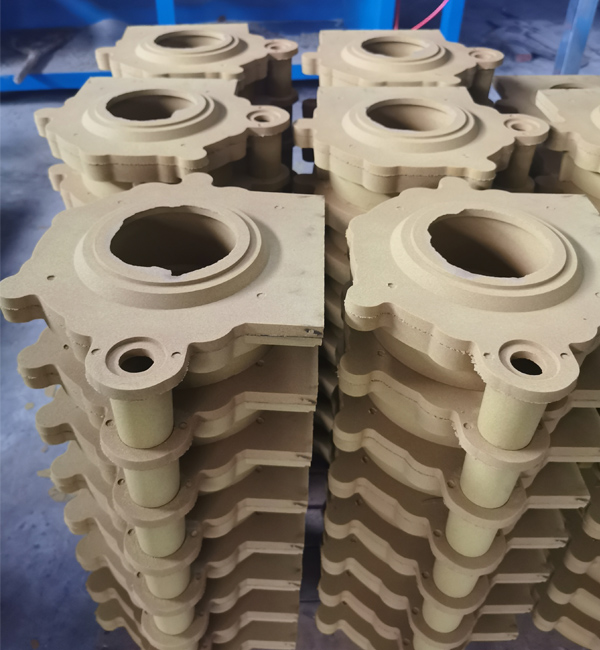

| Ingcindezi ephansi ethululela imishini-core shell shell▶ |

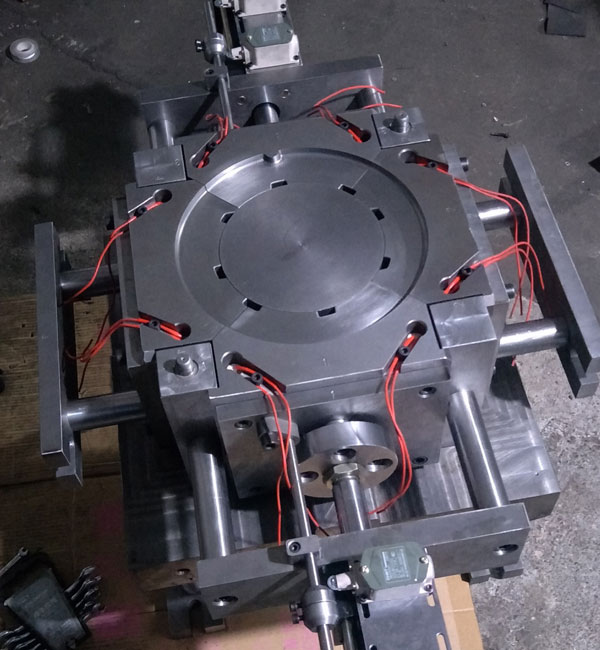

| Ingcindezi okuphansi ethela umshini▶ |

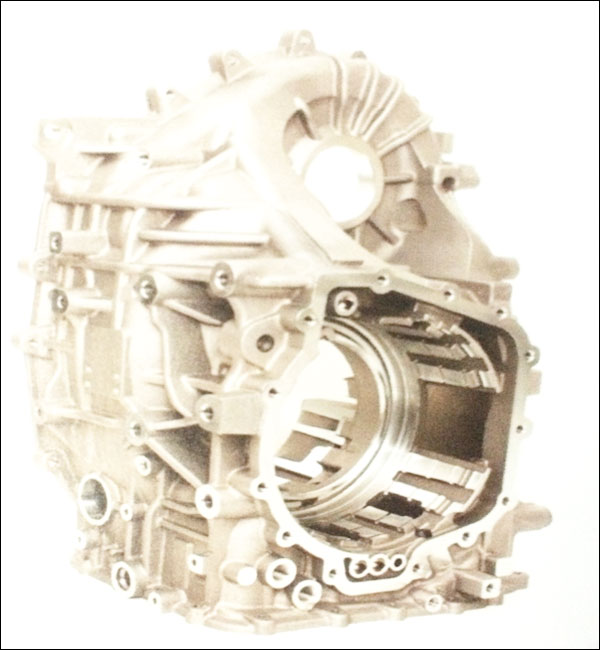

| Umzimba we-gearbox womshini ophansi▶ |

Izifundo zeMinghe Case Zokuphonsa Ingcindezi Ephansi

Izinsizakalo zeMinghe Casting bumbela ziyatholakala kuzo zombili ukwakheka zibe ngokoqobo futhi ziphansi kuya ekukhiqizeni ivolumu ephezulu yokukhiqiza izingxenye zakho zokufa, isihlabathi sokulingisa, izingxenye zokukhipha utshalomali, izingxenye zensimbi, izingxenye ezilahlekile ze-foam nokuningi.

Iya Kokubuka Izifundo Eziningi Zezingxenye Zokulingisa >>>

Khetha Umhlinzeki Ohamba Phansi Wokucindezela Okuphansi

Njengamanje, izingxenye zethu eziphansi zokuphonsa izingxenye zithunyelwa eMelika, Canada, Australia, United Kingdom, Germany, France, Sout Africa, nakwamanye amazwe amaningi emhlabeni jikelele. Singabantu i-ISO9001-2015 ebhalisiwe futhi eqinisekiswe yi-SGS.

Insizakalo yethu yokwenziwa kwengcindezi ephansi ngokwezifiso ihlinzeka ngemishini ehlala isikhathi eside futhi engabizi kakhulu ehlangabezana nokucaciswa kwakho kwezimoto, ezokwelapha, i-aerospace, i-elekthronikhi, ukudla, ukwakhiwa, ezokuphepha, ezasolwandle nezinye izimboni. Ngokushesha ukuthumela uphenyo lwakho noma uthumele imidwebo yakho ukuze uthole isilinganiso samahhala ngesikhathi esifushane.Xhumana nathi noma nge-imeyili sales@hmminghe.com ukubona ukuthi abantu bethu, imishini kanye nokusetshenziswa kwamathuluzi kungaletha ikhwalithi engcono kakhulu kunani lentengo ephansi yephrojekthi yakho yokusakaza ingcindezi.

Sinikezela Ngezinsizakalo Zokulingisa Faka:

Izinsiza ze-Minghe Casting ezisebenza ngesihlabathi, i-casting yensimbi, ukusakazwa kwezimali okutshalwayo okulahlekile, futhi okuningi.

Ukulayishwa kweSand

Ukulayishwa kweSand inqubo yokulingisa yendabuko esebenzisa isihlabathi njengezinto eziyinhloko zokumodela ukwenza isikhunta. Ukuvuthwa kwamandla adonsela phansi kuvame ukusetshenziselwa isikhunta sesihlabathi, nokuphonsa ingcindezi ephansi, ukusakaza kwe-centrifugal nezinye izinqubo kungasetshenziswa uma kunezidingo ezikhethekile. Ukusakazwa kwesihlabathi kunezinhlobonhlobo zokuzivumelanisa nezimo, izingcezu ezincane, izingcezu ezinkulu, izingcezu ezilula, izingcezu eziyinkimbinkimbi, izingcezu ezilodwa, nobuningi obukhulu bungasetshenziswa.

Permanent Isikhunta Ukulingisa

Permanent Isikhunta Ukulingisa unempilo ende nokusebenza kahle kokukhiqiza, hhayi nje ukuthi unokunemba okuhle nobuso obushelelezi, kepha futhi unamandla aphakeme kunokusakazwa kwesihlabathi futhi mancane amathuba okuthi alimale lapho kuthululwa insimbi efanayo encibilikisiwe. Ngakho-ke, ekukhiqizweni ngobuningi bokuphonsa izinsimbi eziphakathi nendawo nezincane, inqobo nje uma iphuzu lokuncibilika kwento yokuphonsa ingekho phezulu kakhulu, ukukhishwa kwensimbi kuvame ukukhethwa.

Ukutshalwa Kwezimali

Inzuzo enkulu ye- ukukhipha utshalomali lokho kungenxa yokuthi ukusatshalaliswa kokutshalwa kwezimali kunokunemba okuphezulu nobuso obuphezulu, banganciphisa umsebenzi wemishini, kepha bashiye isabelo esincane semishini ezingxenyeni ezinezidingo eziphakeme. Kungabonakala ukuthi ukusetshenziswa kwendlela yokutshala imali kungagcina imishini eminingi yamathuluzi womshini nokucubungula amahora omuntu, futhi kugcine kakhulu izinto zokusetshenziswa zensimbi.

Lost Foam Ekubunjweni

Ilahlekile i-foam ekubunjweni ukuhlanganisa i-parafini wax noma amamodeli we-foam afana nosayizi wokuphonsa nomumo ube ngamaqoqo ezimodeli. Ngemuva kokuxubha nokomisa okubhangayo okukhanyayo, bangcwatshwa esihlabathini esomile se-quartz sokumodela kokudlidliza, futhi bathelwe ngaphansi kwengcindezi engemihle yokufaka imodeli amandla. , Insimbi ketshezi ithatha isikhundla semodeli futhi yakha indlela entsha yokusakaza ngemuva kokuqina nokupholisa.

I-Die Casting

Ukufa kwe-die kuyinqubo yokusakaza yensimbi, ebonakala ngokusebenzisa ingcindezi ephezulu kwensimbi encibilikisiwe isebenzisa umgodi wesikhunta. Isikhunta ngokuvamile senziwa ngama-alloys anamandla aphakeme, futhi le nqubo icishe ifane nokubunjwa komjovo. Iningi lokufa kwabantu alinansimbi, njenge-zinc, ithusi, i-aluminium, i-magnesium, i-lead, i-tin, ne-lead-tin alloys kanye nama-alloys awo. UMinghe ubelokhu ehamba phambili eChina die inkonzo ekubunjweni kusukela 1995.

I-Centrifugal Casting

I-Centrifugal Casting kuyindlela nendlela yokujova insimbi ketshezi kwisikhunta esigijimayo esinejubane, ukuze insimbi engamanzi inyakaze nge-centrifugal ukugcwalisa isikhunta futhi yenze ukusakaza. Ngenxa yokunyakaza kwe-centrifugal, insimbi eyiketshezi ingagcwalisa isikhunta kahle esiqondisweni se-radial bese yakha indawo yamahhala yokusakaza; kuthinta inqubo ye-crystallization yensimbi, ngaleyo ndlela ithuthukise izakhiwo zemishini nezomzimba zokusakaza.

Ukuphonsa Ingcindezi Ephansi

Ukuphonsa Ingcindezi Ephansi kusho ukuthi isikhunta ngokuvamile sibekwa ngaphezu kwesibambo esivaliwe, futhi umoya ocindezelweyo wethulwa ku-crucible ukudala ingcindezi ephansi (0.06 ~ 0.15MPa) ebusweni bensimbi encibilikisiwe, ukuze insimbi encibilikisiwe inyuke isuka kumbhobho ophakamayo iye gcwalisa isikhunta nokulawula Indlela yokusakaza eqinile. Le ndlela yokulingisa inokuphakelwa okuhle nesakhiwo esinyene, okulula ukusakaza ukusakazwa okuyinkimbinkimbi okunamapulangwe amancane, akukho risers, kanye nesilinganiso sokutakula kwensimbi esingu-95%. Akukho ukungcola, okulula ukukuqaphela ukuzenzekelayo.