Ukulayishwa kweSand

Kuyini Ukuphonsa Isihlabathi

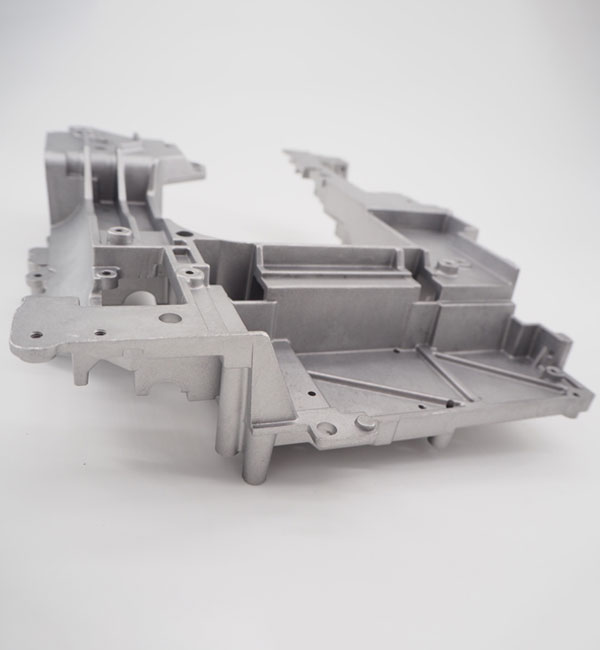

Ukusakazwa kwesihlabathi kusho indlela yokulingisa lapho kukhiqizwa khona ukukhiqizwa kwesihlabathi. Insimbi, i-iron nokuningi okungafaki i-alloy castings kungatholakala ngezindlela zokuphonsa isihlabathi. Ngoba izinto zokumodela ezisetshenziswa ekubunjweni kwesihlabathi zishibhile futhi zitholakala kalula, futhi isikhunta kulula ukusikhiqiza, singakwazi ukuzivumelanisa nokukhiqizwa okukodwa, ukukhiqizwa kwe-batch nokukhiqizwa kwabantu abaningi. Isikhathi eside, bekuyinqubo eyisisekelo ekubunjweni komkhiqizo.

Izinto zokusetshenziswa eziyisisekelo zokwenza isikhunta sesihlabathi ziyisihlabathi se-foundry nesihlabathi. Isihlabathi se-foundry esisetshenziswa kakhulu isihlabathi esinosilika. Lapho ukusebenza okushisa okuphezulu kwesihlabathi se-silica kungakwazi ukuhlangabezana nezidingo zokusetshenziswa, kusetshenziswa isihlabathi esikhethekile njengesihlabathi se-zircon, isihlabathi se-chromite, nesihlabathi se-corundum. Ukuze wenze isikhunta sesihlabathi esiqediwe nomgogodla ube namandla athile futhi kungakhubazeki noma konakaliswe ngesikhathi sokuphathwa, ukubunjwa nokuthelwa kwensimbi engamanzi, ngokuvamile kuyadingeka ukwengeza isibopho sesihlabathi ekusakazeni ukubopha izinhlayiya zesihlabathi ezikhululekile isihlabathi. Isibopho sesihlabathi sokubumba esisetshenziswa kakhulu ubumba, kanye namafutha owomayo ahlukahlukene noma amafutha owomisa kancane, ama-silicates ancibilikiswa ngamanzi noma ama-phosphates nezinhlaka ezahlukahlukene zokwenziwa nazo zingasetshenziswa njengezihlanganisi zokubumba isihlabathi. Isikhunta sangaphandle sesihlabathi esisetshenziswa ekubunjweni kwesihlabathi sihlukaniswe izinhlobo ezintathu: isihlabathi esiluhlaza sobumba, ubumba isihlabathi esomile futhi isihlabathi esiqinile samakhemikhali ngokusho kwe-binder esetshenziswe esihlabathini nangendlela eyakha ngayo amandla ayo.

I-Clay Wet Sand

Ubumba nenani lamanzi elifanele lisetshenziswa njengesibopho esikhulu sokubumba isihlabathi. Ngemuva kokuthi isihlabathi senziwe, sihlanganiswa ngqo bese sithelwa esimweni esimanzi. Ukusakaza okumanzi kunomlando omude futhi kusetshenziswa kabanzi. Ukuqina kwesihlabathi esiluhlaza kuncike odakeni lobumba olwakhiwe ngokuxuba ubumba namanzi ngesilinganiso esithile. Lapho isihlabathi sokubumba sesihlanganisiwe, sinamandla athile. Ngemuva kokushaywa ngesikhunta sesihlabathi, ingahlangabezana nezidingo zokubunjwa nokuthelwa. Ngakho-ke, inani lobumba nomswakama esihlabathini sokubumba kubaluleke kakhulu kunqubo yenqubo.

Indlela yokusakaza lapho kusetshenziswa khona isihlabathi sokubumba nesihlabathi esiyinhloko njengezinto zokubumba ukwenza isikhunta, futhi insimbi engamanzi igcwele isikhunta esingaphansi kwamandla adonsela phansi ukukhiqiza ukusakaza. Insimbi, i-iron nokuningi okungafaki i-alloy castings kungatholakala ngezindlela zokuphonsa isihlabathi. Ngoba izinto zokubumba ezisetshenziswa ekubunjweni kwesihlabathi zishibhile futhi zitholakala kalula, futhi isikhunta kulula ukusikhiqiza, singakwazi ukuzivumelanisa nokukhiqizwa okukodwa, ukukhiqizwa kwe-batch nokukhiqizwa kwabantu abaningi. Isikhathi eside, bekuyinqubo eyisisekelo ekubunjweni komkhiqizo.

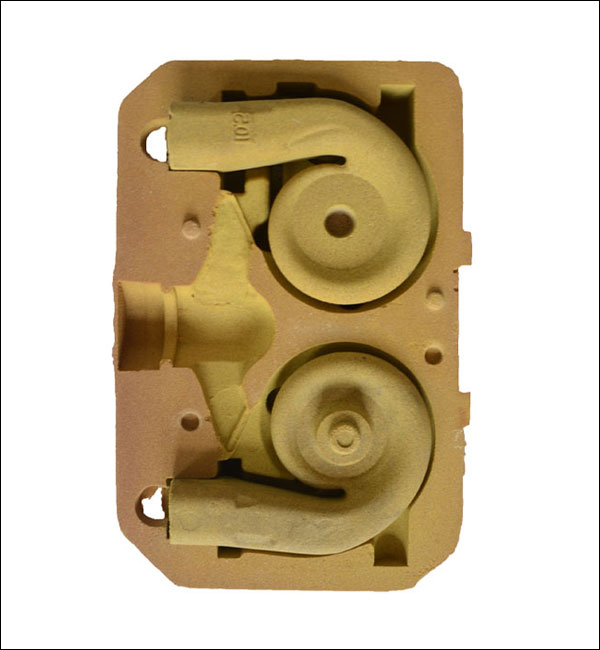

Isikhunta esisetshenziswa ekusakazweni kwesihlabathi ngokuvamile sakhiwa inhlanganisela yesikhunta sangaphandle sesihlabathi nengqikithi. Ukuze uthuthukise ikhwalithi ephezulu yokusakazwa, ungqimba wepende uvame ukufakwa ebusweni besikhunta sesihlabathi nomgogodla. Izingxenye eziyinhloko zokumbozwa yizinto ze-powdery kanye nezibophezelo ezine-refractoriness ephezulu nokuqina okuhle kwamakhemikhali emazingeni aphezulu okushisa. Ngaphezu kwalokho, othwala (amanzi noma amanye ama-solvent) nezinye izithasiselo ezahlukahlukene zengezwa ukuze zisetshenziswe kalula.

Ubuhle bokubumba isihlabathi esiluhlaza okotshani yilawa:

- - Ubumba lunothile ngezinsizakusebenza futhi ngamanani aphansi.

- - Iningi lesihlabathi esisetshenzisiwe sobumba olumanzi singaphinde sisetshenziswe futhi lisetshenziswe ngemuva kokuphathwa kahle kwesihlabathi.

- - Umjikelezo wokwenza isikhunta mfushane futhi ukusebenza kahle komsebenzi kuphezulu.

- - Isihlabathi sokubumba esihlanganisiwe singasetshenziswa isikhathi eside.

- - Ngemuva kokuthi isikhunta sesihlabathi sikhishwe, sisengakwazi ukubekezelela inani elincane le-deformation ngaphandle kokulimala, okuzuzisa kakhulu ekubhaleni nasekusetheni okuyisisekelo.

Ubuthakathaka ngukuthi:

- - Ukuze ugqoke i-viscous slurry slurry ebusweni bezinhlamvu zesihlabathi ngesikhathi sokuhlanganiswa kwesihlabathi, kudingeka imishini yokuxuba isihlabathi esinamandla ngesenzo sokuxova, kungenjalo akunakwenzeka ukuthola isihlabathi esezingeni elifanele.

- - Njengoba isihlabathi sokubumba sinamandla aphakeme kakhulu ngemuva kokuxubeka, isihlabathi sokubumba akusilula ukugeleza ngesikhathi sokumodela futhi kunzima ukusiklina. Kuyasebenza futhi kudinga amakhono athile lapho kwenziwa imodeli ngesandla, futhi okokusebenza kuyinkimbinkimbi futhi kukhulu lapho kumodeliswa ngomshini.

- - Ubulukhuni besikhunta abuphakeme, futhi ukunemba kobukhulu bokuphonsa kubi.

- - Abalingisi bavame ukuba nezinkinga ezifana nokuwasha isihlabathi, ukufakwa kwesihlabathi kanye nama-pores.

Izikhunta zesihlabathi ezomile zinomswakama omanzi ophakeme kancane kunalowo osetshenziswayo ekukhiqizeni lesi sikhunta sesihlabathi.

Umgogodla wesihlabathi sobumba ungumgogodla olula owenziwe ngesihlabathi sobumba.

Isihlabathi Sobumba Olomile

Umswakama omanzi wesihlabathi sokubumba esetshenziselwa ukwenza lesi sikhunta sesihlabathi siphezulu kancane kunesihlabathi sokubumba esimanzi. Ngemuva kokuthi isikhunta sesihlabathi senziwe, ingaphezulu lomgodi kufanele ligcotshwe ngopende okhanyayo, bese lifakwa kuhhavini ukuze lome, futhi ngemuva kokuthi selipholile, lingabunjwa futhi lithelwe. Kuthatha isikhathi eside ukomisa isikhunta sesihlabathi sobumba, kudla uphethiloli omningi, futhi isikhunta sesihlabathi sikhubazeka kalula ngesikhathi senqubo yokumisa, okuthinta ukunemba kokuphosa. Izikhunta zesihlabathi ezomile zivame ukusetshenziselwa ukwenza ukusakaza kwensimbi nokuphonsa okukhulu kwensimbi. Njengoba isihlabathi esenziwe lukhuni samakhemikhali samukelwa kabanzi, izinhlobo zesihlabathi esomile zivame ukuqedwa.

Isihlabathi Esenziwe Ngamakhemikhali

Isihlabathi sokubumba esisetshenziswe kulolu hlobo lwesihlabathi sibizwa ngesihlabathi esiqinile samakhemikhali. I-binder imvamisa iyinto ekwazi ukwenza i-polymerize ama-molecule futhi ibe yisakhiwo esinezici ezintathu ngaphansi kwesenzo se-hardener, futhi izinhlaka eziningi zokwenziwa kanye nengilazi yamanzi zivame ukusetshenziswa. Kunezindlela ezi-3 zokuqina kwamakhemikhali ngokuyisisekelo.

- - Ukuzilimaza: Isibopho kanye ne-hardener zombili zengezwa ngesikhathi sokuhlanganiswa kwesihlabathi. Ngemuva kokuthi isikhunta sesihlabathi noma umgogodla wenziwe, isibopho siphendula ngaphansi kwesenzo se-hardener ukwenza ukuthi isikhunta sesihlabathi noma umgogodla uqine ngokwawo. Indlela yokuzenza lukhuni isetshenziselwa ukumodela, kepha isetshenziselwa nokwenza ama-cores amakhulu noma ama-cores ngamaqoqo amancane okukhiqiza.

- - Ukuqina kwe-Aerosol: Faka isibopho nezinye izithasiselo ezisizayo lapho uxuba isihlabathi, ngaphandle kokungeza i-hardener kuqala. Ngemuva kokumodela noma ukwakheka okuyisisekelo, vuthela nge-generous hardener noma i-liquid hardener eyenziwe ku-carrier ukuze uyihlakaze kwisikhunta sesihlabathi noma emgogodleni wokubangela isikhunta sesihlabathi ukuba siqine. Indlela yokuqina kwe-aerosol isetshenziselwa ukwenza ama-cores, futhi kwesinye isikhathi isetshenziselwa ukwenza isikhunta sesihlabathi esincane.

- - Ukushisa Ukuqina: Faka i-binder ne-latent hardening agent engasebenzi ekamelweni lokushisa lapho uxuba isihlabathi. Ngemuva kokuthi isikhunta sesihlabathi noma umgogodla wenziwe, kuyashiswa. Ngalesi sikhathi, i-hardener efihlekile iphendula ngezingxenye ezithile ku-binder ukuze ikhiqize i-hardener ephumelelayo engaqinisa isibopho, ngaleyo ndlela iqine isikhunta sesihlabathi noma umgogodla. Indlela yokuqinisa ukushisa isetshenziselwa ukwenza ama-cores ngokungeziwe ekwakhiweni kwesikhunta esincane sesihlabathi esinoqweqwe oluncane.

Umlando We-Minghe Sand Casting Workshop

I-Minghe Sand casting workshop yengezwe ku 2005 ngokufakwa kwesihlanganisi sesihlabathi esisogwini Ukulingiswa kweSand kuyincomo enkulu ku-Rubber Plaster Mold, inqubo inkampani eyasungulwa kuyo. Ukusakazwa kwesihlabathi okwamanje kwenza cishe uhhafu webhizinisi lethu lesisekelo.

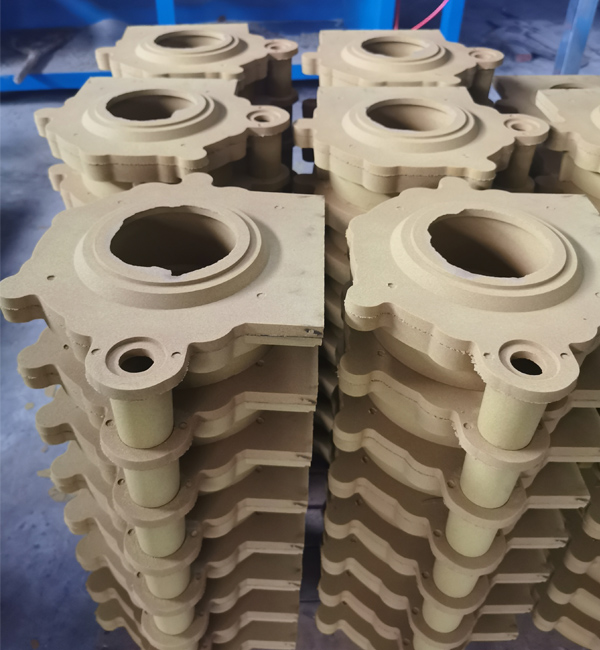

In 2016, UMinghe Casting ukhulise kakhulu umugqa wokusakazwa kwesihlabathi ngokufakwa kwesihlanganisi esikhulu sesihlabathi esiqhubekayo esine-hopper embaxambili, izilawuli ezizenzakalelayo, nokubuyiselwa kwemishini. Lokhu kuvumela iMinghe Casting ukuthi isuke enanini eliphansi kakhulu iye kunani lokukhiqiza, ngenkathi igcina ikhwalithi ephezulu ifunwa yindawo yemakethe. Ukutshalwa kwezimali kuphinde kumele ukuzibophezela kwePrototype Casting ukunciphisa iminyango yayo yokusebenzisa imithombo yemvelo, ikakhulukazi isihlabathi se-silica esisetshenziswa ekubunjweni kwesihlabathi. Ngenxa yezimakethe zesibili zesihlabathi esibuyisiwe, kanye nokukwazi ukusebenzisa kabusha isihlabathi esingu-80% kule nqubo, ukumoshwa kwesihlabathi ezindaweni zokulahla udoti kuzoqedwa ngokuphelele !!!

Minghe isihlabathi ekubunjweni workshop imayelana 8000 square metres. Noma ngabe iphrojekthi yakho yokusakaza incane noma inkulu, singakunika isikhathi esihle sokuhola nekhwalithi enhle. Esisekelweni sethu, izingxenye ezingaphezu kuka-60% ze-Cast Aluminium zithunyelwa kwamanye amazwe. Ngakho-ke sinokuhlangenwe nakho okuningi ngamaphrojekthi akho.

Izinzuzo Zenqubo Yokuphonsa Isihlabathi

Imisebenzi yokusakaza utshalomali ingafingqwa kanjena:

- - Izingxenye zokugqoka ezingamelana nesihlabathi zokukhipha isikhunta zisasetshenziswa kakhulu eChina, njengamapuleti omhlathi, izando eziphakeme ze-chromium, izindonga ezichotshozwa, izindonga zodaka ezigingqikayo, njll. , Uma kuqhathaniswa, ukunemba akukona okuphezulu kakhulu. Ikakhulukazi emihlathini, imikhiqizo eqediwe cishe ayipholishiwe nge-lathe. Udonga oluphukile, udonga olugingqikayo, isikhumba sokugoqa kanye nokunye okunjalo kudinga ukupholishwa nge-lathe, ngakho-ke kufanelekile ikakhulu ekubunjweni kwesihlabathi. Ngoba izingxenye ezingagqokiwe zomhlabathi ophonsa imihlathi, izando eziphezulu ze-chromium, izindonga eziphukile, izindonga zodaka ezigingqikayo, izikhumba zokugoqa, njll.

- - Sand ekubunjweni uhlobo inqubo ekubunjweni. Isikhunta sokulingisa esisetshenziswa ekubunjweni kwesihlabathi ngokuvamile sakhiwa isikhunta sangaphandle sesihlabathi nengqikithi. Ngoba izinto zokubumba ezisetshenziswa ekubunjweni kwesihlabathi zishibhile futhi zitholakala kalula, futhi isikhunta kulula ukusikhiqiza, singakwazi ukuzivumelanisa nokukhiqizwa okukodwa, ukukhiqizwa kwe-batch nokukhiqizwa kwabantu abaningi. Isikhathi eside, bekuyinqubo eyisisekelo ekubunjweni komkhiqizo. Njengamanje, emhlabeni jikelele, ekukhiqizeni konke ukusakaza, ama-60 kuya kuma-70% wabalingisi akhiqizwa ngesikhunta sesihlabathi, futhi cishe ama-70% abo akhiqizwa ngobumba besihlabathi sobumba.

- - izindleko eziphansi

- - Inqubo yokukhiqiza elula

- - Umjikelezo wokukhiqiza omfushane

- - Ngakho-ke, ukusakazwa okufana namabhulokhi we-injini yemoto, amakhanda amasilinda, ama-crankshafts, njll konke kukhiqizwa ngenqubo yesihlabathi esiluhlaza. Lapho uhlobo olumanzi lungakwazi ukuhlangabezana nezidingo, cabanga ukusebenzisa uhlobo lwesihlabathi sobumba olomile lomhlabathi, uhlobo lwesihlabathi esomile noma ezinye izinhlobo zesihlabathi. Isisindo sokuphonsa esenziwe ngesihlabathi esiluhlaza sobumba singahle sisuke kumakhilogremu ambalwa siye kumashumi amakhilogremu, kuyilapho ukusakazwa okwenziwe ngobumba olomile kungaba nesisindo samathani amaningi.

Inqubo Yokukhiqiza Yezingxenyekazi Zomsebenzi kaMinghe Yokuphonsa Isihlabathi

Inqubo eyisisekelo yenqubo yokulingisa isihlabathi se-Minghe inezinyathelo ezilandelayo:

- Isiteji Sokuxuba Isihlabathi: Ukulungiselela isihlabathi sokubumba kanye nesihlabathi esiyisisekelo sokumodela, ngokuvamile sebenzisa isihlanganisi sesihlabathi ukufaka ebalazweni lakudala kanye nenani elifanele lobumba ukuxuba.

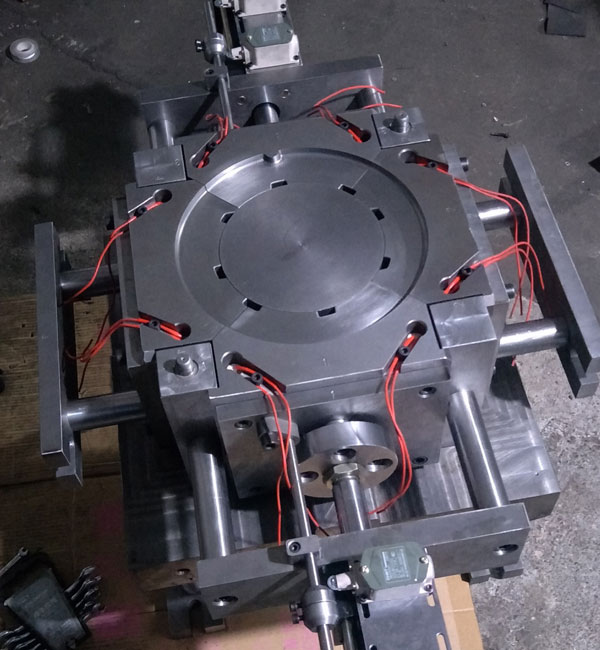

- Isikhunta Sokwenza Isiteji: Yenza isikhunta namabhokisi ayinhloko ngokuya ngemidwebo yezingxenye. Ngokuvamile, ucezu olulodwa lungenziwa ngesikhunta sokhuni, ukukhiqizwa ngobuningi kungasetshenziselwa ukwenza isikhunta sepulasitiki noma isikhunta sensimbi (esaziwa kakhulu ngokuthi isikhunta sensimbi noma isikhunta sensimbi), futhi ukusakazwa okukhulu kungasetshenziswa ukwenza amapuleti ephethini. Manje isikhunta imishini yokuqopha ngokuyisisekelo, ngakho-ke umjikelezo wokukhiqiza ufinyezwe kakhulu, futhi ngokuvamile kuthatha izinsuku ezi-2 kuye kwezi-10 ukwenza isikhunta.

- Ukumodela (Ukwenza Okubalulekile) Isiteji: kufaka phakathi ukumodeliswa (ukwakha umgodi wokusakazwa ngesihlabathi sokubumba), ukwenza okuyisisekelo (ukwakha isimo sangaphakathi sokuphonsa), nokufaniswa kwesikhunta (ukubeka ingqikithi emgodini, nokuvala amabhodlela aphezulu nangaphansi)). Ukumodela isixhumanisi esiyinhloko ekusakazeni.

- Isigaba Sokuncibilika: Ngokuya ngensimbi edingekayo, ukwakheka kwamakhemikhali kuyafana, kukhethwa nesithando esincibilikayo esifanele ukuncibilikisa ingxubevange yokwakha uketshezi lwensimbi oluwuketshezi olufanelekile (kufaka phakathi ukwakheka okufanelekile nokushisa okufanele). Ukuncibilikisa ngokuvamile kusebenzisa i-cupola noma isithando somlilo sikagesi (ngenxa yezidingo zokuvikelwa kwemvelo, ama-cupolas manje asevinjelwe ngokuyisisekelo, futhi kusetshenziswa amafutha kagesi).

- Kuthelwa Isiteji: Sebenzisa ukhamba ukuthela insimbi encibilikisiwe esithandweni sikagesi kwisikhunta esiphelile. Kuyadingeka ukuthi unake ijubane lokuthela insimbi encibilikisiwe, ukuze insimbi encibilikile igcwalise wonke umgodi. Ngaphezu kwalokho, ukuthela i-iron encibilikisiwe kuyingozi kakhulu, ngakho-ke naka ukuphepha!

- Isiteji sokuhlanza: Ngemuva kokuthela nokulinda ukuthi insimbi encibilikisiwe iqiniswe, thatha isando ukususa isango bese uxukuza isihlabathi sokuphonsa, bese usebenzisa umshini wokuqhafaza isandblasting, ukuze ubuso bokusakaza bubukeke buhlanzeke kakhulu! Okokuphonsa okungadingeki ngokuqinile Ngemuva kokuhlolwa, kulungele ukushiya ifektri.

- Icubungula Ukulingisa: Kwabanye ukusakazwa abanezidingo ezikhethekile noma ukusakazwa okuthile okungakwazi ukuhlangabezana nezimfuneko, kungadingeka ukucubungula okulula. Ngokuvamile, isondo lokugaya noma i-grinder lisetshenziselwa ukucubungula nokupholisha ukususa ama-burrs nokwenza ukubola kube bushelelezi.

- Ukuhlola Ukulingisa: Ukuhlolwa kokulingisa kuvame ukwenziwa ngenqubo yokuhlanza noma ukucubungula, futhi okungafaneleki kuvame ukutholakala. Kodwa-ke, abanye abaphosayo banezidingo zomuntu ngamunye futhi badinga ukuhlolwa futhi. Isibonelo, okunye ukusakazwa kudinga ukuthi kufakwe i-shaft engu-5 cm emgodini ophakathi nendawo, ngakho-ke udinga ukuthatha u-5 cm shaft bese uyazama.

Ngemuva kwezinyathelo ezingenhla eziyi-8, ukwenziwa kwakhiwa ngokuyisisekelo. Okokuphonsa okudinga ukunemba okuphezulu, imishini iyadingeka.

| Ukuthuthukiswa Kwesikhunta Nokwakhiwa ▶ |

| Isigaba seSand Mxing ▶ |

| Ukuhlolwa Kwe-Wax Okulahlekile ▶ |

| Isihlahla Seqembu Le-Wax▶ |

| I-Silica Sol Shell ▶ |

| Ukuqinisa Ingilazi Yamanzi▶ |

| I-Steam Dewaxing ▶ |

| Ukuthosa-Ukuthulula▶ |

| Susa iSand Sanding ▶ |

| Akunalutho Okuhle▶ |

| Qedela i-Precision Castings▶ |

| Pakisha Nomkhumbi▶ |

Izifundo zeMinghe Case Of Sand Casting

Izinsizakalo zeMinghe Casting bumbela ziyatholakala kuzo zombili ukwakheka zibe ngokoqobo futhi ziphansi kuya ekukhiqizeni ivolumu ephezulu yokukhiqiza izingxenye zakho zokufa, isihlabathi sokulingisa, izingxenye zokukhipha utshalomali, izingxenye zensimbi, izingxenye ezilahlekile ze-foam nokuningi.

Iya Kokubuka Izifundo Eziningi Zezingxenye Zokulingisa >>>

Khetha Umhlinzeki Ohamba Phambili Wesihlabathi

Njengamanje, izingxenye zethu ze-Sand Casting zithunyelwa eMelika, Canada, Australia, United Kingdom, Germany, France, Sout Africa, nakwamanye amazwe amaningi emhlabeni jikelele. Singabantu i-ISO9001-2015 ebhalisiwe futhi eqinisekiswe yi-SGS.

Insizakalo yethu yokwenziwa kwe-Sand Casting inikeza ukusekelwa okuqinile futhi okungabizi okuhlangabezana nemininingwane yakho yezimoto, ezokwelapha, i-aerospace, i-elekthronikhi, ukudla, ukwakhiwa, ezokuphepha, ezasolwandle nezinye izimboni. Ngokushesha ukuthumela uphenyo lwakho noma uthumele imidwebo yakho ukuze uthole isilinganiso samahhala ngesikhathi esifushane.Xhumana nathi noma nge-imeyili sales@hmminghe.com ukubona ukuthi abantu bethu, imishini kanye namathuluzi kungaletha kanjani ikhwalithi engcono kakhulu ngentengo engcono kakhulu yephrojekthi yakho yokuphonsa isihlabathi.

Sinikezela Ngezinsizakalo Zokulingisa Faka:

Izinsiza ze-Minghe Casting ezisebenza ngesihlabathi, i-casting yensimbi, ukusakazwa kwezimali okutshalwayo okulahlekile, futhi okuningi.

Ukulayishwa kweSand

Ukulayishwa kweSand inqubo yokulingisa yendabuko esebenzisa isihlabathi njengezinto eziyinhloko zokumodela ukwenza isikhunta. Ukuvuthwa kwamandla adonsela phansi kuvame ukusetshenziselwa isikhunta sesihlabathi, nokuphonsa ingcindezi ephansi, ukusakaza kwe-centrifugal nezinye izinqubo kungasetshenziswa uma kunezidingo ezikhethekile. Ukusakazwa kwesihlabathi kunezinhlobonhlobo zokuzivumelanisa nezimo, izingcezu ezincane, izingcezu ezinkulu, izingcezu ezilula, izingcezu eziyinkimbinkimbi, izingcezu ezilodwa, nobuningi obukhulu bungasetshenziswa.

Permanent Isikhunta Ukulingisa

Permanent Isikhunta Ukulingisa unempilo ende nokusebenza kahle kokukhiqiza, hhayi nje ukuthi unokunemba okuhle nobuso obushelelezi, kepha futhi unamandla aphakeme kunokusakazwa kwesihlabathi futhi mancane amathuba okuthi alimale lapho kuthululwa insimbi efanayo encibilikisiwe. Ngakho-ke, ekukhiqizweni ngobuningi bokuphonsa izinsimbi eziphakathi nendawo nezincane, inqobo nje uma iphuzu lokuncibilika kwento yokuphonsa ingekho phezulu kakhulu, ukukhishwa kwensimbi kuvame ukukhethwa.

Ukutshalwa Kwezimali

Inzuzo enkulu ye- ukukhipha utshalomali lokho kungenxa yokuthi ukusatshalaliswa kokutshalwa kwezimali kunokunemba okuphezulu nobuso obuphezulu, banganciphisa umsebenzi wemishini, kepha bashiye isabelo esincane semishini ezingxenyeni ezinezidingo eziphakeme. Kungabonakala ukuthi ukusetshenziswa kwendlela yokutshala imali kungagcina imishini eminingi yamathuluzi womshini nokucubungula amahora omuntu, futhi kugcine kakhulu izinto zokusetshenziswa zensimbi.

Lost Foam Ekubunjweni

Ilahlekile i-foam ekubunjweni ukuhlanganisa i-parafini wax noma amamodeli we-foam afana nosayizi wokuphonsa nomumo ube ngamaqoqo ezimodeli. Ngemuva kokuxubha nokomisa okubhangayo okukhanyayo, bangcwatshwa esihlabathini esomile se-quartz sokumodela kokudlidliza, futhi bathelwe ngaphansi kwengcindezi engemihle yokufaka imodeli amandla. , Insimbi ketshezi ithatha isikhundla semodeli futhi yakha indlela entsha yokusakaza ngemuva kokuqina nokupholisa.

I-Die Casting

Ukufa kwe-die kuyinqubo yokusakaza yensimbi, ebonakala ngokusebenzisa ingcindezi ephezulu kwensimbi encibilikisiwe isebenzisa umgodi wesikhunta. Isikhunta ngokuvamile senziwa ngama-alloys anamandla aphakeme, futhi le nqubo icishe ifane nokubunjwa komjovo. Iningi lokufa kwabantu alinansimbi, njenge-zinc, ithusi, i-aluminium, i-magnesium, i-lead, i-tin, ne-lead-tin alloys kanye nama-alloys awo. UMinghe ubelokhu ehamba phambili eChina die inkonzo ekubunjweni kusukela 1995.

I-Centrifugal Casting

I-Centrifugal Casting kuyindlela nendlela yokujova insimbi ketshezi kwisikhunta esigijimayo esinejubane, ukuze insimbi engamanzi inyakaze nge-centrifugal ukugcwalisa isikhunta futhi yenze ukusakaza. Ngenxa yokunyakaza kwe-centrifugal, insimbi eyiketshezi ingagcwalisa isikhunta kahle esiqondisweni se-radial bese yakha indawo yamahhala yokusakaza; kuthinta inqubo ye-crystallization yensimbi, ngaleyo ndlela ithuthukise izakhiwo zemishini nezomzimba zokusakaza.

Ukuphonsa Ingcindezi Ephansi

Ukuphonsa Ingcindezi Ephansi kusho ukuthi isikhunta ngokuvamile sibekwa ngaphezu kwesibambo esivaliwe, futhi umoya ocindezelweyo wethulwa ku-crucible ukudala ingcindezi ephansi (0.06 ~ 0.15MPa) ebusweni bensimbi encibilikisiwe, ukuze insimbi encibilikisiwe inyuke isuka kumbhobho ophakamayo iye gcwalisa isikhunta nokulawula Indlela yokusakaza eqinile. Le ndlela yokulingisa inokuphakelwa okuhle nesakhiwo esinyene, okulula ukusakaza ukusakazwa okuyinkimbinkimbi okunamapulangwe amancane, akukho risers, kanye nesilinganiso sokutakula kwensimbi esingu-95%. Akukho ukungcola, okulula ukukuqaphela ukuzenzekelayo.