Ukwelashwa Kwensimbi Yokulingisa Insimbi

Kuyo yonke inqubo yokukhiqiza yokusakaza kwensimbi, ukusonteka kwenzeka cishe kuzo zonke izinqubo. Izimbangela zokusakazwa kwe-deformation zihlukaniswe kakhulu ngezigaba ezimbili. Esinye sezizathu zangaphakathi, ezivezwa ikakhulu njengokusakaza ukuguquguquka kwengcindezi kanye nokuguquguquka kokucindezelwa ngokwelashwa kokushisa.

Ukulingisa ukusonteka kokuxineka kubhekisela ekucindezelekeni kokulingisa okubangelwa ukulandelana okuqinile kokuqina nokuqina kokuqina kwezingxenye ezahlukahlukene kunqubo yokuqinisa yokusakaza. Lokhu kucindezelwa kuzokhishwa ngenqubo ethile ngemuva kokufakwa kwesibhakela, okuzoholela ekusonjululweni kokuphonsa. Ukwelashwa kokushiswa kokushisa ikakhulu kungenxa yokwehla kwamandla okusakaza ngemuva kokunwetshwa okushisayo nokuthamba phakathi nenqubo yokwelashwa kokushisa, ukusonteka kokuphonsa okubangelwe amandla adonsela phansi alo, nokusonteka okubangelwe ukukhululwa kwengcindezi okunqwabelene isakhiwo ngesikhathi sokuguqulwa kwesakhiwo.

Ngokuvamile, eyokuqala inethonya elikhulu kusayizi nasekwakhekeni kokuphosa.

Kunezizathu eziningi zokuguqulwa kwe-castings, futhi ukusonteka kungenzeka kuzo zonke izinqubo zenqubo yonke yokukhiqiza. Uma ukwakheka nohlelo lwenqubo lungenangqondo, ukumodeliswa okungafanele, isibhakela, ukuhlanza noma ukwelashwa kokushisa, njll., Konke kungadala ukuthi ukukhishwa kukhubazeke. Okunye kokukhubazeka okusakazwayo okubangelwe yizizathu ezibalulwe ngenhla kungancishiswa noma kugwenywe ngokwenza ngcono ukwakheka, kubuyekezwe inqubo, kuthuthukiswe izinga lokusebenza kanye nokuqinisa ngokuzithoba umqondo wokuzibophezela. Kodwa-ke, kunzima ukugwema ukusonteka kokunye ukujula ezingeni lobuchwepheshe lamanje, ukuze umsebenzi wokulungisa owenziwe ngabakhubazekile uvele.

Ngokuvamile, izindlela zokulungisa ukusakazwa kwe-deformation zihlukaniswe izigaba ezimbili, okungukuthi, ukuguqulwa kokuphonsa kuyindlela yokulungisa ukucindezela noma umthelela ekamelweni lokushisa (okubizwa ngokuthi indlela yokubanda ebandayo); indlela yokulungisa ukushisa ukusakaza kuthempelesha ethile, ukucindezela noma ukukhama, nokusekela (Kubhekiswa njengendlela yokulungisa ezishisayo).

Indlela Yokulungisa Okubandayo

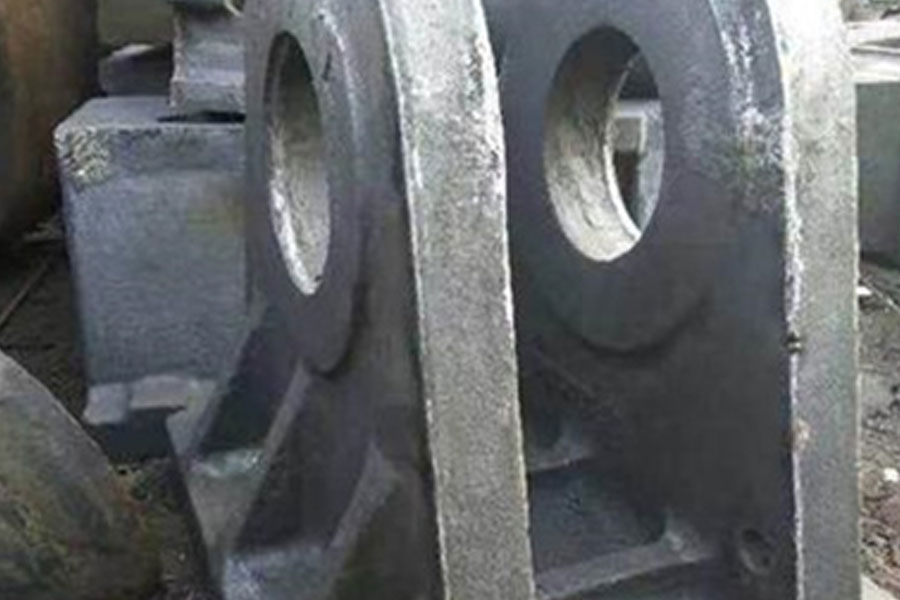

Indlela ebandayo yokuqondisa isuselwe kusayizi wokuphonsa okhubazekile nobukhulu besigaba. Ingashaywa ngesando, ithintwe noma icindezelwe ekamelweni lokushisa ngokusebenzisa isando sesandla, umshini omkhulu nophansi wokuqondisa, umshini wamanzi (kawoyela) noma enye indlela elula yokucindezela. Indlela yokulungisa.

Ukuzijwayeza kufakazele ukuthi kunzima ukufeza umphumela olindelekile wokulungiswa kokuphosa okujwayelekile ngokulungiswa okubandayo. Kodwa-ke, ukulungiswa kokuguqulwa kwe-castings ephezulu yensimbi ye-manganese, ukulungiswa okubandayo kungamukelwa kuphela (kunqunywa yizinto ezibonakalayo).

Indlela Yokulungisa Okushisayo

Indlela yokulungisa eshisayo ukushisa ukusakaza okhubazekile kube ngaphezu kwendawo yokushisa ye-elastoplastic yento, futhi ubuyise ukuguqulwa kokuphonsa ngamandla angaphandle afana ne-extrusion ne-bracing, ukuze kuzuzwe inhloso yokulungiswa.

Izinga lokushisa lokushisa lendlela yokulungisa okushisayo lihlukaniswe cishe ngezinhlobo ezimbili. Elinye izinga lokushisa eliphakeme (okungukuthi, izinga lokushisa elinamandla); okunye ukushisa okuphansi, okushisa okushisa kokushisa okuphansi okunciphisayo noma ukushisa okuphezulu. Amazinga amabili okushisa anezinzuzo nezinkinga zawo. "Ukushisa okuphezulu" kudinga izidingo eziphakeme ku-opharetha futhi ukusebenza kunzima, kepha isikhathi sokulungisa sifushane; "izinga lokushisa eliphansi" alidingi izidingo eziphakeme ku-opharetha, ukusebenza kulula, futhi izinga lokuphumelela lokulungisa liphakeme, kepha isikhathi sokulungisa side kakhulu. yinde. Ngokuya ngobuhle nobubi bawo, izinga lokuphumelela lokulungisa yilona eliyinhloko, ngakho-ke sihlala sisebenzisa ukulungiswa okushisa okuphansi.

Ngokusho kwezingxenye ezifudumele zabalingisi abakhubazekile, umbhali uhlukanisa indlela yokulungisa ukushisa ibe yizinhlobo ezimbili: indlela yokulungisa kanye nendlela yokulungisa yendawo.

Ukusebenza kwendlela yokulungisa kulula futhi kulula, futhi umphumela wokulungisa muhle; ngenkathi indlela yokulungisa yendawo inezidingo eziqinile endaweni yokulungisa, kwesinye isikhathi kuyadingeka ukwakha isitofu, kwesinye isikhathi usebenzise isibhamu sokusika igesi ukuze usebenze ngesandla, isikhathi eside ubhaka, izimo zokusebenza ezingezinhle, futhi ungaphephile, ukulungiswa kuyanelisa kakhulu (ngokwethiyori, ukwelashwa kokuqeda ukucindezeleka kufanele kwenziwe ngemuva kokulungiswa). Ngakho-ke, ekukhiqizweni kwangempela, sisabheka indlela yokulungisa, bese sizama ukungasebenzisi indlela yokulungisa yendawo (ngaphandle kokuphonsa ngakunye okungenakusetshenziselwa indlela yokulungisa).

Umphumela wokulungisa wendlela yokulungisa uncike ekulungiseni kwesithando somlilo kanye nendlela yokushisa. Njengendlela yokulayisha isithando somlilo sabakhubazekile abakhubazekile (kufaka phakathi ukuzimisela kwenani legebe lokulungisa lengxenye ekhubazekile, ukulungiswa kwesisindo nendawo yengcindezi, ukukhethwa kwesisindo, isitobhi, ukwesekwa, i-shim, ipulatifomu, i-wedge, njll.), Ukulungiswa kokushisa kokushisa (Ukushisa okuphezulu noma ukushisa okuphansi) ukuzimisela. Inani legebe lokulungisa (ngemuva kwalokhu elizobizwa njengenani legebe) yisimo sokunquma somphumela wokulungisa.

- (1) Akunandaba ukuthi hlobo luni lwe-deformation, alunakususwa ngokuphelele. Nguchungechunge lwezinyathelo kuphela ezingathathwa ukunciphisa inani lokusonteka nokulawula inani lokukhubazeka ebangeni elamukelekayo.

- (2) Ukugxila kokukhubazeka kulele ekuvikeleni: kusukela kokumodela, ikakhulukazi ukwakheka kwenani lokulungisa ngenqubo yokuguqula kabusha; ukuqala kwisici se-welding, ukwakheka kwe-welding anti-deformation brace, ukukhethwa kwemingcele ye-welding, njll .; ukuqala kwisici sokwelashwa kokushisa, kugxile ekutadisheni ukusakazwa Ukubekwa kwesithando somlilo nokukhethwa kwemingcele yokwelashwa kokushisa.

- (3) Ukulawulwa kokukhubazeka kubandakanya yonke inqubo yokusakaza nokwenza izinto, futhi idinga ukwenza izinqubo ezahlukahlukene, ikakhulukazi ukulawulwa kwezinqubo ezisemqoka, ukuze yenze umsebenzi wangempela wokulwa nokukhubazeka.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ukwelashwa Kwensimbi Yokulingisa Insimbi

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off