Insimbi Engagqwali

Izinsizakalo Zokulingisa Insimbi Engagqwali - Izingxenye Zokuphonsa Izinsimbi Zensimbi Engagqwali zeChina

IATF 16949 UKWENZIWA KOKWENZIWA KOKUSAKAZA KWABASEBENZI BOKUPHOSA

Kuyini Ukuphonsa Insimbi Engagqwali? Insimbi engagqwali ngokunemba ekubunjweni noma ekubunjweni kokutshalwa kwezimali, inqubo ye-silica sol. Kuyinqubo yokusika ephansi noma engasiki. It is a omuhle kakhulu inqubo ubuchwepheshe embonini Foundry. It has anhlobonhlobo izicelo. Akulungele kuphela ukusakazwa kwezinhlobo ezahlukahlukene nama-alloys, kepha futhi kukhiqiza ukusakazwa ngokunemba okuthe ngcembe, Izinga lobuso liphakeme kunezinye izindlela zokuphonsa, futhi ngisho nokusakazwa okuyinkimbinkimbi, okushisa kakhulu futhi okunzima ukucubungula kunzima ukusakaza ngezinye izindlela zokulingisa kungafakwa ngokulingisa utshalomali.

Izinzuzo Zensimbi Engagqwali (Ukulingisa Izingxenye Zensimbi Engagqwali):

- Amandla aqine kakhulu

- Ukugqoka okuhle kakhulu nokumelana nokugqwala

- Ukuqina okuhle nokuqina

- Inhlanzeko enokuhlanzeka okuhle kakhulu

- Ukusebenza okuhle emazingeni okushisa aphezulu / aphansi

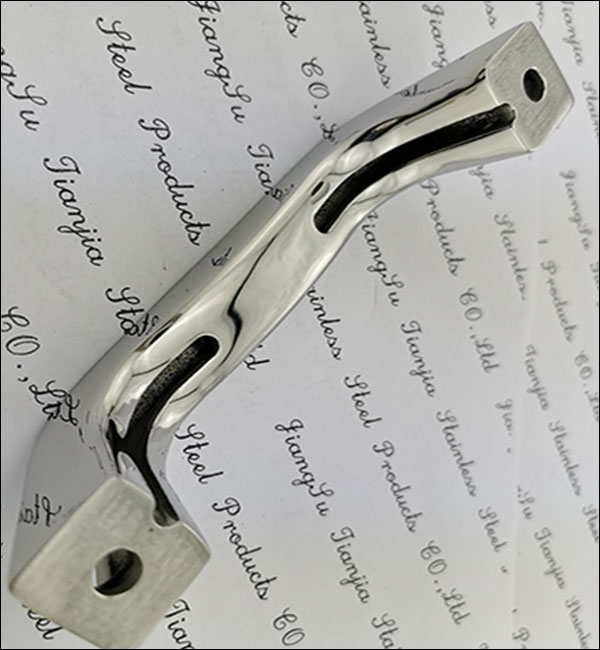

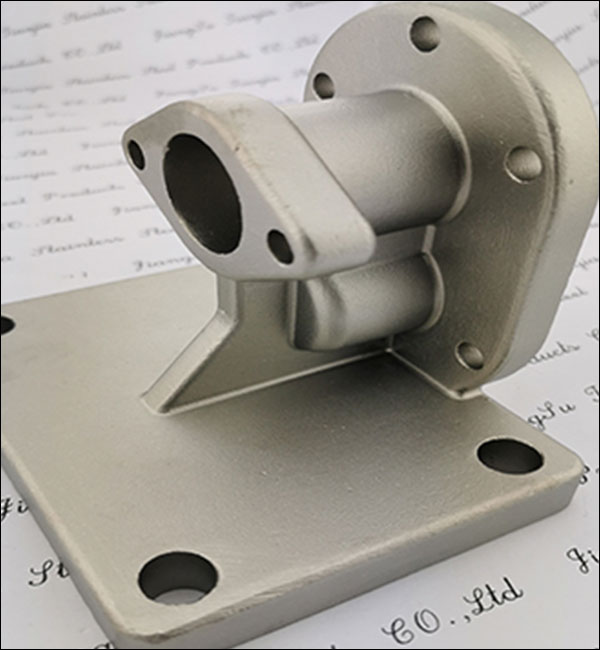

Uma ufuna uchwepheshe wokulingisa umphakeli ukuhlinzeka ngezinga eliphezulu lokutshala imali ekubunjweni okungagqwali izingxenye ze-Stainless, uMinghe ungomunye wabakhiqizi abangabizi kakhulu futhi abanekhono, abasebenza ngenqubo yokulingisa i-Stainless Steel ekusetshenzisweni kwemishini esezingeni eliphakeme. Ngolwazi olukhulu nolwazi olubanzi, imishini yethu yokusakaza ingafinyelela ukubekezelelana okuqinile kakhulu ekukhiqizeni izingxenye zensimbi engenazinsimbi ezingenalutho nemikhiqizo. Onjiniyela bethu bephrojekthi abanolwazi nabasebenza ngemishini bazohlaziya iphrojekthi yakho ngokucophelela bese beyicubungula ngenqubo ephumelela kunazo zonke yokulingisa ukutshala imali ukuhlangabezana nemininingwane yakho yokuklama, ngenkathi usebenzisa isikhathi sakho nezindleko zakho.Sisebenza ngokukhetha okukhulu kwezinhlobo zensimbi engagqwali ukukhiqiza konke inkambiso elahlekile ye-wax ekubunjweni ezingxenyeni zensimbi ezingenasici ezimbonini eziningi. Sicela uxhumane nathi ukuthola izinto ezithile ze-sus ekubunjweni nasekusebenziseni imishini.

Thintana nonjiniyela wethu wensimbi engagqwali namuhla ukuze uxoxe ngokuningiliziwe kwamaphrojekthi akho anzima.

Ukulingiswa Kwensimbi Engagqwali

Ngasekuqaleni kuka-1910, kwatholakala ukuthi lapho okuqukethwe kwe-Cr kusimbi kungaphezu kwe-12%, kunokumelana okuhle nokugqwala. Ngaphezu kokuqukethe ngaphezu kuka-12% Cr, insimbi engagqwali ejwayelekile iqukethe into eyodwa noma ngaphezulu yokuhlanganisa izinto, njenge-Ni, Mo, Cu, Nb, Ti, ne-N2.

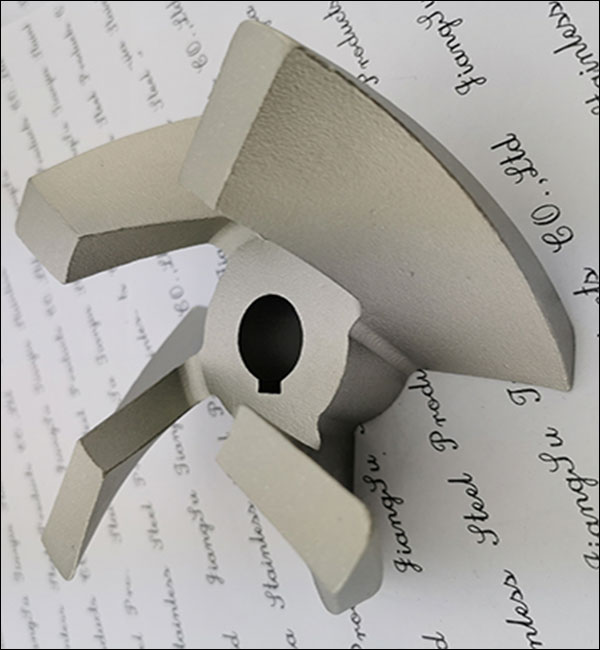

Ukulingiswa kwensimbi engagqwali akulungele kuphela ukusakazwa kwezinhlobo ezahlukahlukene nama-alloys, kodwa futhi kukhiqiza ukusakazwa okunemba okuphezulu nobukhulu bekhwalithi kunezinye izindlela zokulingisa. Ngisho nezinye izindlela zokulingisa kunzima ukusakaza okuyinkimbinkimbi, ukumelana nokushisa okuphezulu, futhi kunzima ukucubungula ukusakazwa. , Ingaphonswa ngokusakazwa kokutshalwa kwezimali.

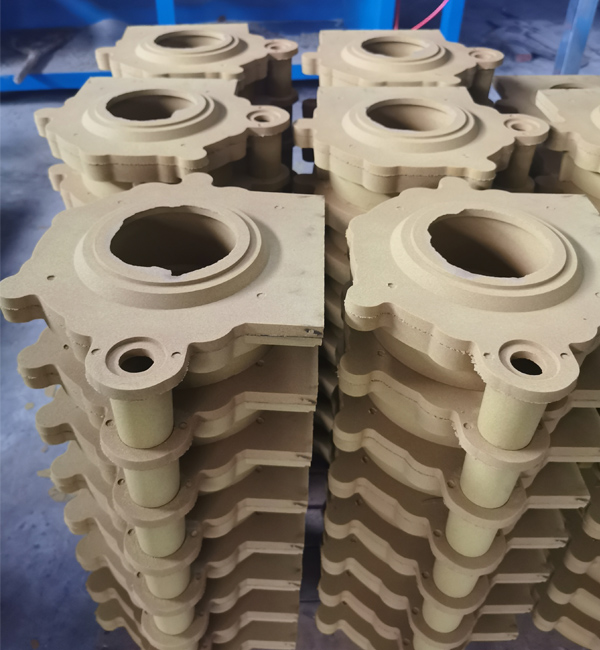

Inqubo okuthiwa yokusakaza utshalomali ukumane usebenzise izinto ezi-fusible (njenge-wax noma ipulasitiki) ukwenza imodeli yefusible (ebizwa ngokuthi utshalomali noma imodeli), faka izingqimba eziningana zokumboza okukhethekile kuyo, bese uyomisa futhi uyiqinise . Ngemuva kokwenza igobolondo elihlanganayo, sebenzisa umusi noma amanzi ashisayo ukuncibilikisa imodeli egobolondweni, bese ufaka igobolondo ebhokisini lesihlabathi, ugcwalise isikhunta ngesihlabathi esomile esizungezile, bese ekugcineni ufake isikhunta esithandweni sokuwosa ngokushisa okuphezulu (uma kusetshenziswa isikhunta esinamandla amakhulu, igobolondo lesikhunta ngemuva kokudilizwa lingasuswa ngqo ngaphandle kokumodela). Ngemuva kokukhishwa kwesikhunta noma isikhunta, insimbi encibilikisiwe ithelwa kuyo ukuthola ukulingiswa.

Ukunemba ntathu of utshalomali castings kuyinto kuqhathaniswa eliphezulu, ngokuvamile kuze kufinyelele CT4-6 (CT10 ~ 13 for sand sand casting and CT5 ~ 7 for die casting). Vele, ngenxa yenqubo eyinkimbinkimbi yokusakazwa kotshalo-mali, kunezinto eziningi ezithinta ukunemba kobukhulu bokuphosa, okufana nesikhunta. Ukuncipha kwento, ukuguqulwa kwesikhunta sokutshala imali, ushintsho oluqondile lwegobolondo kunqubo yokushisa nokupholisa, ukuncipha kwe-alloy kanye nokusonteka kokuphonsa ngesikhathi senqubo yokuqinisa, njll, ngakho-ke ukunemba okuyisisekelo ukusatshalaliswa okujwayelekile kokutshalwa kwezimali kuphezulu, kepha ukuvumelana kwayo kusadinga ukwenziwa ngcono (ubukhulu bokuvumelana kokuphonswa ngama-wax wokushisa okuphakathi naphakathi kufanele kuthuthukiswe kakhulu).

Lapho ucindezela isikhunta sokutshala imali, uhlobo lwengcindezi olunobushelelezi obuphezulu bomgodi luyasetshenziswa, ngakho-ke ubushelelezi bendawo yesikhunta sokutshala imali buphezulu kakhulu. Ngaphezu kwalokho, igobolondo lenziwe ngengubo ekhonjiwe eyenziwe ngcina ekhethekile enamazinga okushisa aphezulu kanye nento ekhombayo, eboshwe kusikhunta sokutshala imali, nengaphezulu langaphakathi lomgodi elixhumana ngqo nensimbi encibilikisiwe bushelelezi high. Ngakho-ke, ukuphela kobuso bokuphonsa utshalomali kuphakeme kunalokho kokuphonsa okujwayelekile, ngokuvamile kufinyelela kuRa. 1.6 ~ 3.2μm.

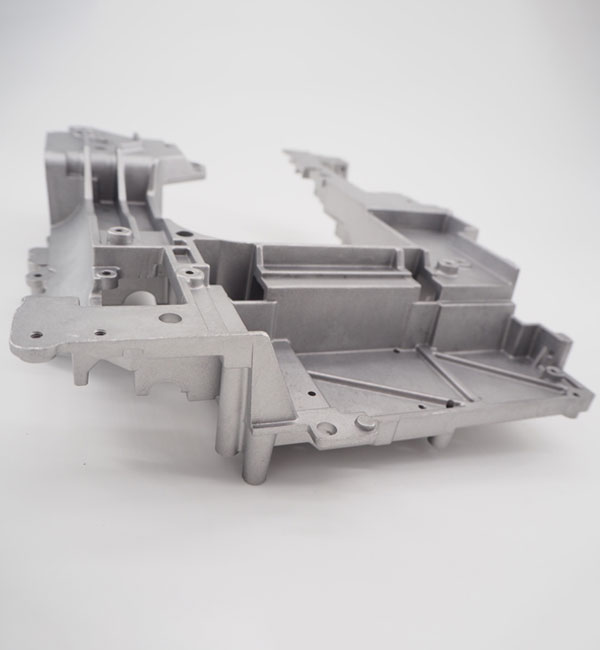

Inzuzo enkulu yokusakazwa kokutshalwa kwezimali ukuthi ngenxa yokuthi ukusatshalaliswa kwezimali kunokunemba okuphezulu nobuso obuphezulu, umsebenzi wemishini ungancishiswa, kepha kuphela inani elincane lesabelo semishini esingashiywa ezingxenyeni ezinezidingo eziphakeme, futhi abanye abaphosayo baneKhefu kuphela isabelo sokugaya nokupholisha, futhi singasetshenziswa ngaphandle kokulungiswa kwemishini. Kungabonakala ukuthi ukusetshenziswa kwendlela yokutshala imali kungagcina imishini eminingi yamathuluzi womshini nokucubungula amahora omuntu, futhi kugcine kakhulu izinto zokusetshenziswa zensimbi.

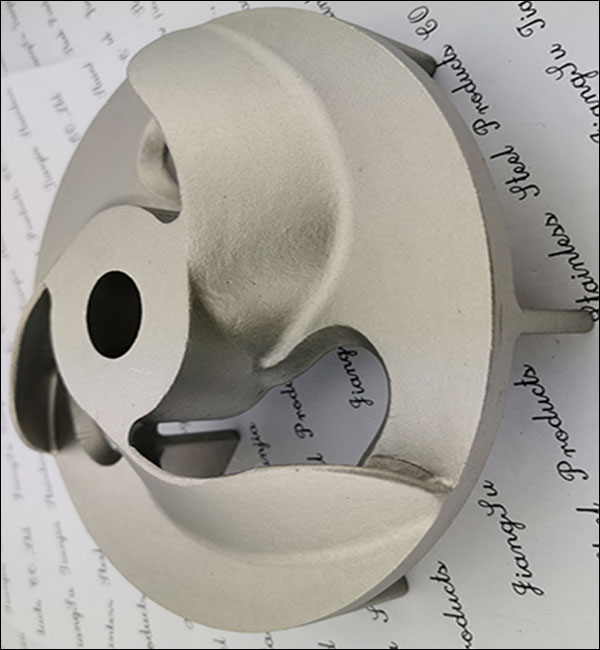

Enye inzuzo yendlela yokulingisa utshalomali ukuthi ingaphonsa ukusakazwa okuyinkimbinkimbi kwama-alloys ahlukahlukene, ikakhulukazi ama-castings alloy aphezulu. Isibonelo, i-blade yenjini ye-jet, iphrofayili yayo ehlelekile kanye nomgodi wokupholisa, akunakwakhiwa ngobuchwepheshe bemishini. Ukukhiqizwa ngenqubo yokukhipha utshalomali akukwazi kuphela ukufeza ukukhiqizwa ngobuningi, ukuqinisekisa ukuvumelana kokuphonswa, kepha futhi kugweme ukugxila kokucindezelwa kwamamaki wommese osalile ngemuva kokuchofoza.

Izinto Zokulingisa Zensimbi Engagqwali

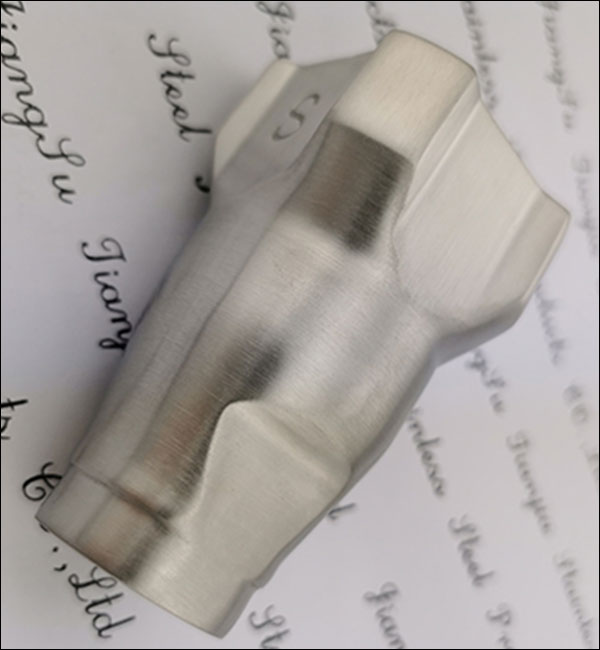

Insimbi engenasici ingahlukaniswa ngezigaba ezintathu, okungukuthi, insimbi engagqwali yamandla aphakathi nendawo namandla amakhulu wezakhiwo zobunjiniyela, insimbi engagqwali emelana nokugqwala nensimbi engagqwali ukushisa.

- Insimbi Engagqwali Namandla Ephakeme Ephakathi Namandla: kufaka phakathi i-martensitic insimbi engagqwali nemvula eqinisa insimbi engagqwali. Kuzicelo zobunjiniyela, izakhiwo zemishini ziyizinkomba eziyinhloko, futhi ziyamelana nemidiya esemkhathini kanye nemidiya enobungozi enobungozi (njengamanzi nezinto ezithile eziphilayo) Ukugqwala okuhle. Isakhiwo se-metallographic siyi-carbon lath martensite ephansi.

- Corrosion-Resistant Engagqwali: eyaziwa nangokuthi insimbi engagqwali futhi engamelana ne-asidi. Ihlola kakhulu ukumelana kwayo nokugqwala. Ingahlukaniswa ngezigaba ezimbili: i-chromium insimbi engagqwali ne-nickel-chromium insimbi engagqwali. Izici eziyinhloko ezithinta ukumelana nokugqwala kwensimbi engenasici okuqukethwe kwekhabhoni nenani lama-carbides aqhamukile. Ikhabhoni ngokuvamile iphansi kakhulu, imvamisa iba ngaphansi kuka-0.08%.

- Insimbi Engagqwali Ukushisa: Ensimbi engagqwali engamelana nokushisa, ngoba izakhiwo ezinamazinga okushisa aphezulu zincike esigabeni sokuzinza se-carbide ensimbi, okuqukethwe kwekhabhoni kuphakeme kunokwensimbi emelana nokugqwala, cishe u-0.20% noma ngaphezulu. Ukushisa okumelana nokushisa kwe-high-alloy insimbi engamelana nokushisa kungafinyelela ngaphezu kuka-650 ℃

Precision utshalomali ekubunjweni izingxenye zensimbi engagqwali ziba ukukhetha ezimbonini eziningi ngenxa yezakhiwo zayo ezifiselekayo zomzimba! Insimbi Engagqwali ingenye yama-alloys ezimboni athandwa kakhulu ngamaphrojekthi amaningi okusakaza, ngenxa yezakhiwo zawo ezinhle kakhulu zomzimba. Izinzuzo ezingezansi zenze izingxenye nemikhiqizo ye-Stainless Steel yaba yinto efanelekayo ezimbonini eziningi nasezinsizeni, yize zithandwa kakhulu emkhakheni wezokwelapha, owezimoto, owasemkhathini, owezempilo nowabathengi. Ngenkathi indlela engcono kakhulu futhi esheshayo yokwenza izinsimbi zeNsimbi Engagqwali ukulingisa ukutshalwa kwezimali ikakhulukazi ukusakaza ngensimbi engagqwali engamelana nensimbi kufinyelela kude naseduze.

Izifundo zeMinghe Case Zokusakaza Kwensimbi Engagqwali

Izinsiza zokukhiqiza ze-Minghe ziyatholakala kukho konke ukuklama zibe ngokoqobo futhi ziphansi kuya ekukhiqizeni ivolumu ephezulu yezingxenye zakho zokuphonsa i-aluminium, izingxenye zokukhipha i-zinc, i-magnesium casting, izingxenye zokukhipha i-titanium, izingxenye zokuphonsa insimbi engagqwali, izingxenye zokuphonsa ithusi, izingxenye zokukhipha izinsimbi, ukulingisa ithusi izingxenye nokuningi.

Iya Kokubuka Izifundo Eziningi Zezingxenye Zokulingisa >>>

Khetha Umhlinzeki Wokuphonsa Insimbi Engcono Kakhulu

Njengamanje, izingxenye zethu zensimbi ezingenasici zithunyelwa eMelika, Canada, Australia, United Kingdom, Germany, France, Sout Africa, nakwamanye amazwe amaningi emhlabeni jikelele. Singabantu i-ISO9001-2015 ebhalisiwe futhi eqinisekiswe yi-SGS.

Insizakalo yethu yokwenza insimbi engagqwali yokwenza insimbi ihlinzeka ngemishini ehlala isikhathi eside futhi engabizi kakhulu ehlangabezana nokucaciswa kwakho kwezimoto, ezokwelapha, i-aerospace, i-elekthronikhi, ukudla, ukwakhiwa, ezokuphepha, ezasolwandle nezinye izimboni. Ngokushesha ukuthumela uphenyo lwakho noma uthumele imidwebo yakho ukuze uthole isilinganiso samahhala ngesikhathi esifushane.Xhumana nathi noma nge-imeyili sales@hmminghe.com ukubona ukuthi abantu bethu, imishini kanye namathuluzi kungaletha ikhwalithi engcono kakhulu kunani lentengo engcono kakhulu yephrojekthi yakho yokusakaza insimbi engagqwali.

Sinikezela Ngezinsizakalo Zokulingisa Faka:

Izinsiza ze-Minghe Casting ezisebenza ngesihlabathi, i-casting yensimbi, ukusakazwa kwezimali okutshalwayo okulahlekile, futhi okuningi.

Ukulayishwa kweSand

Ukulayishwa kweSand inqubo yokulingisa yendabuko esebenzisa isihlabathi njengezinto eziyinhloko zokumodela ukwenza isikhunta. Ukuvuthwa kwamandla adonsela phansi kuvame ukusetshenziselwa isikhunta sesihlabathi, nokuphonsa ingcindezi ephansi, ukusakaza kwe-centrifugal nezinye izinqubo kungasetshenziswa uma kunezidingo ezikhethekile. Ukusakazwa kwesihlabathi kunezinhlobonhlobo zokuzivumelanisa nezimo, izingcezu ezincane, izingcezu ezinkulu, izingcezu ezilula, izingcezu eziyinkimbinkimbi, izingcezu ezilodwa, nobuningi obukhulu bungasetshenziswa.

Permanent Isikhunta Ukulingisa

Permanent Isikhunta Ukulingisa unempilo ende nokusebenza kahle kokukhiqiza, hhayi nje ukuthi unokunemba okuhle nobuso obushelelezi, kepha futhi unamandla aphakeme kunokusakazwa kwesihlabathi futhi mancane amathuba okuthi alimale lapho kuthululwa insimbi efanayo encibilikisiwe. Ngakho-ke, ekukhiqizweni ngobuningi bokuphonsa izinsimbi eziphakathi nendawo nezincane, inqobo nje uma iphuzu lokuncibilika kwento yokuphonsa ingekho phezulu kakhulu, ukukhishwa kwensimbi kuvame ukukhethwa.

Ukutshalwa Kwezimali

Inzuzo enkulu ye- ukukhipha utshalomali lokho kungenxa yokuthi ukusatshalaliswa kokutshalwa kwezimali kunokunemba okuphezulu nobuso obuphezulu, banganciphisa umsebenzi wemishini, kepha bashiye isabelo esincane semishini ezingxenyeni ezinezidingo eziphakeme. Kungabonakala ukuthi ukusetshenziswa kwendlela yokutshala imali kungagcina imishini eminingi yamathuluzi womshini nokucubungula amahora omuntu, futhi kugcine kakhulu izinto zokusetshenziswa zensimbi.

Lost Foam Ekubunjweni

Ilahlekile i-foam ekubunjweni ukuhlanganisa i-parafini wax noma amamodeli we-foam afana nosayizi wokuphonsa nomumo ube ngamaqoqo ezimodeli. Ngemuva kokuxubha nokomisa okubhangayo okukhanyayo, bangcwatshwa esihlabathini esomile se-quartz sokumodela kokudlidliza, futhi bathelwe ngaphansi kwengcindezi engemihle yokufaka imodeli amandla. , Insimbi ketshezi ithatha isikhundla semodeli futhi yakha indlela entsha yokusakaza ngemuva kokuqina nokupholisa.

I-Die Casting

Ukufa kwe-die kuyinqubo yokusakaza yensimbi, ebonakala ngokusebenzisa ingcindezi ephezulu kwensimbi encibilikisiwe isebenzisa umgodi wesikhunta. Isikhunta ngokuvamile senziwa ngama-alloys anamandla aphakeme, futhi le nqubo icishe ifane nokubunjwa komjovo. Iningi lokufa kwabantu alinansimbi, njenge-zinc, ithusi, i-aluminium, i-magnesium, i-lead, i-tin, ne-lead-tin alloys kanye nama-alloys awo. UMinghe ubelokhu ehamba phambili eChina die inkonzo ekubunjweni kusukela 1995.

I-Centrifugal Casting

I-Centrifugal Casting kuyindlela nendlela yokujova insimbi ketshezi kwisikhunta esigijimayo esinejubane, ukuze insimbi engamanzi inyakaze nge-centrifugal ukugcwalisa isikhunta futhi yenze ukusakaza. Ngenxa yokunyakaza kwe-centrifugal, insimbi eyiketshezi ingagcwalisa isikhunta kahle esiqondisweni se-radial bese yakha indawo yamahhala yokusakaza; kuthinta inqubo ye-crystallization yensimbi, ngaleyo ndlela ithuthukise izakhiwo zemishini nezomzimba zokusakaza.

Ukuphonsa Ingcindezi Ephansi

Ukuphonsa Ingcindezi Ephansi kusho ukuthi isikhunta ngokuvamile sibekwa ngaphezu kwesibambo esivaliwe, futhi umoya ocindezelweyo wethulwa ku-crucible ukudala ingcindezi ephansi (0.06 ~ 0.15MPa) ebusweni bensimbi encibilikisiwe, ukuze insimbi encibilikisiwe inyuke isuka kumbhobho ophakamayo iye gcwalisa isikhunta nokulawula Indlela yokusakaza eqinile. Le ndlela yokulingisa inokuphakelwa okuhle nesakhiwo esinyene, okulula ukusakaza ukusakazwa okuyinkimbinkimbi okunamapulangwe amancane, akukho risers, kanye nesilinganiso sokutakula kwensimbi esingu-95%. Akukho ukungcola, okulula ukukuqaphela ukuzenzekelayo.

Ukuphoswa Kokuqothula

Ukuphoswa Kokuqothula inqubo yokuphonsa lapho insimbi incibilikiswa khona, ithululelwe futhi ifakwe emgodini we-vacuum. Umshini ekubunjweni kunganciphisa okuqukethwe kwegesi ensimbi futhi kuvimbele i-oxydation yensimbi. Le ndlela ingaveza ukufunwa kwensimbi ekhethekile efunwa kakhulu kanye nokufakwa kwe-titanium alloy castings okulula kakhulu. UMinghe Casting unendawo yokukhipha umshini ongaphansi, okwanele ukuxazulula zonke izinkinga ezihlobene nokulingiswa komshini