I-Titanium Casting

Izinsizakalo Zokulingisa iTitanium - Izingxenye Zokuphonsa Ngokwezifiso ze-Titanium Alloy China Inkampani

IATF 16949 EQINISEKISWE UKWAKHIWA KWE-CAST KWE-TITANIUM CASTINGS

Kuyini Ukulingisa kweTitanium? Ekubunjweni Titanium Ingxubevange kubhekisa kunqubo yokuncibilikisa nokuthela okokusebenza kwe-titanium kokuphonswayo ngaphansi komshini noma izimo zokuvikela igesi. Ama-alloys amaningi we-titanium akhubazekile anezindawo ezinhle zokulingisa. Enye yezinto ezisetshenziswa kakhulu yi-Ti-6A1-4V alloy. Inokusebenza okuhle kakhulu kwenqubo yokusakaza nesakhiwo esizinzile, futhi inamandla amahle (5σb≥890MPa) nobulukhuni bokuqina ngaphansi kuka-350 ° C.

Ama-titanium castings asetshenziswa kakhulu embonini ye-aerospace. Izingxenye ezibalulekile ezisetshenzisiwe yilezi: i-engine compressor casing, isikebhe esiphakathi, izindwani, umhlahlandlela ongenalutho, iringi yangaphakathi, i-turbocharger impeller, ethwele izindlu nokusekelwa, ubakaki wendiza, igumbi lesambulela, izikhwama, ugongolo olufushane, i-flap Wing slides, amagobolondo amabhuleki; amakhabethe wokulawula imicibisholo, izimpiko zomsila, amakhanda angemuva erokhethi, izikhala zomphakathi, njll .; iziphuphutheki zokufakelwa, amafreyimu wesithwebuli, imiphongolo yamalensi, njll. Isetshenziswa kakhulu embonini yezombangazwe ukwakha imizimba yamaphampu amelana nokugqwala, ama-valve, izinto zokufaka izinto; isikulufa sophephela emikhunjini; amagobolondo, abakaki namasilinda emishini yokwenza kahle; amalunga wokufakelwa nezakhi zokufakelwa zokusetshenziswa kwezokwelapha; amakhanda egalofu okokusebenza kwezemidlalo, amathuluzi amahhashi, izingxenye zebhayisikili, njll.

IMinghe yinkampani yokusakaza i-titanium China ekhethekile ezingxenyeni ezenziwe ngokwezifiso ze-titanium iminyaka engaphezu kwengu-35, ngemishini esezingeni eliphakeme endlini kanye nethuluzi lamathuluzi, abasebenza ngemishini abanekhono, nobuchwepheshe obucebile, singanikeza ngezinsizakalo zokuphonsa ngobuningi be-titanium futhi senze ngezifiso izingxenye zekhwalithi ze-titanium ukucaciswa okuqondile, amanani wesabelomali kanye nokulethwa ngesikhathi okuya ngezidingo zakho. Esitolo sethu se-titanium casting, i-Die Casting, i-Sand Casting, i-Investment Casting, i-Lost Foam Casting nezinye izinqubo ziyatholakala, kanye nokuqedela okuhle kakhulu komhlaba. Ukuhlelwa kwethu kwezingxenye ze-titanium ne-titanium alloy kungasetshenziswa ezinhlotsheni eziningi zezimboni kanye nokusetshenziswa, okubandakanya izingxenye zezindiza kanye nezibophelelo, izinjini zegesi, ama-compressor blades, ama-casings, ama-enginelings kanye nezihlangu zokushisa. Sihlose ukusungula ukubambisana okusondele nobungani namakhasimende emhlabeni jikelele.

Xhumana nonjiniyela wethu wokulingisa we-titanium namuhla ukuze uxoxe ngokuningiliziwe kwamaphrojekthi akho anzima.

Umlando Wokuphonsa kwe-Titanium Alloy.

I-Titanium isebenza kakhulu esimweni esincibilikisiwe. Isikhathi eside, bekulokhu kungatholakali ukuthola indlela efanelekile yokulingisa nezinto zokumodela. Ngenxa yalokhu, phonsa i-titanium lags ngemuva kwe-alpitanium alloy ekhubazeke iminyaka engaphezu kwengu-20. Ukusuka ngo-1956 kuya ku-1962, i-American Bell (Beal) nabanye bakha ubuchwepheshe bokuncibilikisa igobolondo lobucwebecwebe be-arc, okwenze ukukhishwa kwe-titanium kwangena ngokusemthethweni ekukhiqizeni izimboni. Ngama-1970s, yaqala ukusetshenziswa emkhakheni we-aerospace. Kusukela ngawo-1970, ubuchwepheshe be-titanium alloy enkulu-thin-wall precision casting ubuchwepheshe buthuthukisiwe futhi busetshenziswa. Ngaphansi kwesisekelo sokuthi ukusebenza kwayo kwempahla kusondele noma kulingana nokundiza kwe-aviation titanium, izindleko zehliswe cishe ngo-50%, ngakho-ke ubuchwepheshe be-titanium casting buthuthuke ngokushesha. Kulindeleke ukuthi esikhathini esizayo esiseduze, izuze isikhundla esifanayo esibalulekile njenge-alloy titanium alloy.

Indlela Yokulingisa Ye-Titanium

Ukufakwa kwe-Titanium kusetshenziswa kakhulu esithandweni esivuthayo esivuthayo nasekuphonsweni kwe-graphite. Uma kuqhathaniswa nama-alloys akhubazekile enhlanganisela efanayo, amandla awo alingana ngokuyisisekelo, kepha izakhiwo zepulasitiki nokukhathala cishe zingama-40% -50% aphansi, futhi ukuqina kokuqhekeka kungcono kakhulu. Iningi lokuphonswa kwe-titanium liphathwa ngokuncishiswa okuzinzile. Ukwelashwa kwesixazululo nokwelashwa kwe-hydrogenation ocwaningwayo kungacwenga isakhiwo sokuphonsa ingxubevange futhi kwandise amandla ayo okukhathala aye ezingeni lokuthethelelwa.

1.I-Graphite Ukulingisa Kwe-Titanium

I-graphite yiyona nqubo eyinhloko yokubumba yokukhiqizwa komphakathi we-titanium castings. Ihlukaniswe ngokucubungula uhlobo lwe-graphite nohlobo lwe-graphite tamping. Isetshenzwe isikhunta se-graphite senziwa ngokucubungula okwenziwe ngesandla noma ngomshini wekhwalithi ephezulu yokufakelwa kwe-graphite. Ngokuya ngobulukhuni besikhunta, inhlanganisela yama-block ehambayo ingasetshenziswa. Lesi sikhunta singasetshenziswa izikhathi eziningi. Uhlobo lwe-graphite tamping lwakhiwa ngokugaya nokuxuba isihlabathi se-graphite sokufakelwa kanye ne-carbonaceous organic binder ibe yingxube, ebunjwa ngesandla noma ngemishini yokumodela kusikhunta sokhuni noma ebhokisini leshlabathi lesikhunta sensimbi. Isikhunta sesihlabathi esiphelile se-graphite siyabhakwa, somiswe futhi siqiniswe ezingeni lokushisa eliphansi, bese sikhishwa ekushiseni okuphezulu ngaphansi kwesembozo somswakama we-graphite owomile noma ngaphansi kokuvikelwa komoya ongeyona i-oxidizing. Ngemuva kokuthi inhlanganisela yesikhunta yenziwe, ingafakwa esithandweni sokuphonsa. Ekhiqizweni kokuphonswa kwe-aerospace ngezidingo eziqinile zekhwalithi, izinhlobo zokucubungula nezokuthinta zidinga ukukhishwa ngomswakama ngaphambi kokusakaza

2.Ukutshalwa Kwezimali KweTitanium

Ukulingiswa kotshalo-mali kuyinqubo eyinhloko yokukhiqiza ukukhishwa kwe-titanium ingxubevange yezindiza ngokunemba okuphezulu, ukwakheka okuyinkimbinkimbi, indawo ebushelelezi nengaphakathi eliminyene. Indlela yokukhipha utshalomali ye-titanium ngokuyisisekelo iyefana nenqubo yokusakaza yensimbi, ngaphandle kwezinto zokwenziwa kwegobolondo nezinqubo ezithile.Kunezinqubo ezintathu ezisetshenziselwa ukukhiqiza ukusakazwa kokunemba kwe-titanium namuhla:

- - Inqubo yegobolondo le-Graphite.

- - Ceramic igobolondo ubuchwepheshe ngensimbi ebusweni ungqimba.

- - Inqubo yegobolondo ye-oxide ceramic. Uhlobo lokuqala lushibhile futhi lungasetshenziselwa ukukhiqizwa kokuphonswa okuncane naphakathi, kanti lezi ezimbili zokugcina zingasetshenziselwa ukukhiqizwa kokuphonsa okukhulu kodonga oluncane.

Ekubunjweni titanium ingxubevange nekhwalithi yokulingisa Ama-alloys amaningi akhubazekile we-titanium angasetshenziselwa ukuphonsa, okusetshenziswa kakhulu yi-Ti-6A1-4V alloy. Inezindawo ezinhle zokulingisa nezakhiwo zenhlangano ezinzile. Uma kuqhathaniswa ne-deformation alloy yokwakheka okufanayo, amandla we-cast titanium alloy ngokuyisisekelo ayalingana, kepha izakhiwo zayo zepulasitiki nokukhathala cishe zingama-40% -50% aphansi, futhi ukuqina kokuqhekeka kungcono kakhulu.

Ama-titanium castings ngokuvamile aphathwa ngokuncishiswa okuzinzile. Ukwelashwa kwesisombululo nokwelashwa kwe-hydrogenation okucwaningwayo kungacwenga okusanhlamvu, kuthuthukise ukwakheka, futhi kuthuthukise ukusebenza kokukhathala kwe-alloy kuya ezingeni lokukhohlwa. Ukucindezela okushisayo kwe-isostatic kuyindlela ejwayelekile yokwelashwa yokuphonswa kwekhwalithi ephezulu ye-titanium. Ngemuva kokushisa okuphezulu nokwelashwa kwengcindezi enkulu, ubukhulu bokuphonsa abuguquki, kepha ukwakheka kwangaphakathi kuyaqina, nokuqina kwezakhiwo zemishini kuzothuthukiswa kakhulu. Ikhwalithi yokulingiswa kufanele ihlolwe ngokuya nge-standard ejwayelekile kazwelonke ye-GB6614, indinganiso kazwelonke yezempi i-GJB2896 noma i-aviation standard HB5448. Izici zobuchwepheshe ze-titanium alloy castings zibhalwe kuthebula

Izifundo zeMinghe Case Of Titanium Casting

Izinsiza zokukhiqiza ze-Minghe ziyatholakala kukho konke ukuklama zibe ngokoqobo futhi ziphansi kuya ekukhiqizeni ivolumu ephezulu yezingxenye zakho zokuphonsa i-aluminium, izingxenye zokukhipha i-zinc, i-magnesium casting, izingxenye zokukhipha i-titanium, izingxenye zokuphonsa insimbi engagqwali, izingxenye zokuphonsa ithusi, izingxenye zokukhipha izinsimbi, ukulingisa ithusi izingxenye nokuningi.

Iya Kokubuka Izifundo Eziningi Zezingxenye Zokulingisa >>>

Khetha Umhlinzeki Ohamba Phambili We-Titanium

Njengamanje, izingxenye zethu ze-titanium zokulingisa zithunyelwa eMelika, Canada, Australia, United Kingdom, Germany, France, Sout Africa, nakwamanye amazwe amaningi emhlabeni jikelele. Singabantu i-ISO9001-2015 ebhalisiwe futhi eqinisekiswe yi-SGS.

Insizakalo yethu yokwenza izinto ngokwezifiso ze-titanium ihlinzeka ngemishini ehlala isikhathi eside futhi engabizi kakhulu ehlangabezana nokucaciswa kwakho kwezimoto, ezokwelapha, i-aerospace, i-elekthronikhi, ukudla, ukwakhiwa, ezokuphepha, ezasolwandle nezinye izimboni. Ngokushesha ukuthumela uphenyo lwakho noma uthumele imidwebo yakho ukuze uthole isilinganiso samahhala ngesikhathi esifushane.Xhumana nathi noma nge-imeyili sales@hmminghe.com ukubona ukuthi abantu bethu, imishini kanye nokusetshenziswa kwamathuluzi kungaletha ikhwalithi engcono kakhulu ngentengo engcono kakhulu yephrojekthi yakho yokusakaza i-titanium.

Sinikezela Ngezinsizakalo Zokulingisa Faka:

Izinsiza ze-Minghe Casting ezisebenza ngesihlabathi, i-casting yensimbi, ukusakazwa kwezimali okutshalwayo okulahlekile, futhi okuningi.

Ukulayishwa kweSand

Ukulayishwa kweSand inqubo yokulingisa yendabuko esebenzisa isihlabathi njengezinto eziyinhloko zokumodela ukwenza isikhunta. Ukuvuthwa kwamandla adonsela phansi kuvame ukusetshenziselwa isikhunta sesihlabathi, nokuphonsa ingcindezi ephansi, ukusakaza kwe-centrifugal nezinye izinqubo kungasetshenziswa uma kunezidingo ezikhethekile. Ukusakazwa kwesihlabathi kunezinhlobonhlobo zokuzivumelanisa nezimo, izingcezu ezincane, izingcezu ezinkulu, izingcezu ezilula, izingcezu eziyinkimbinkimbi, izingcezu ezilodwa, nobuningi obukhulu bungasetshenziswa.

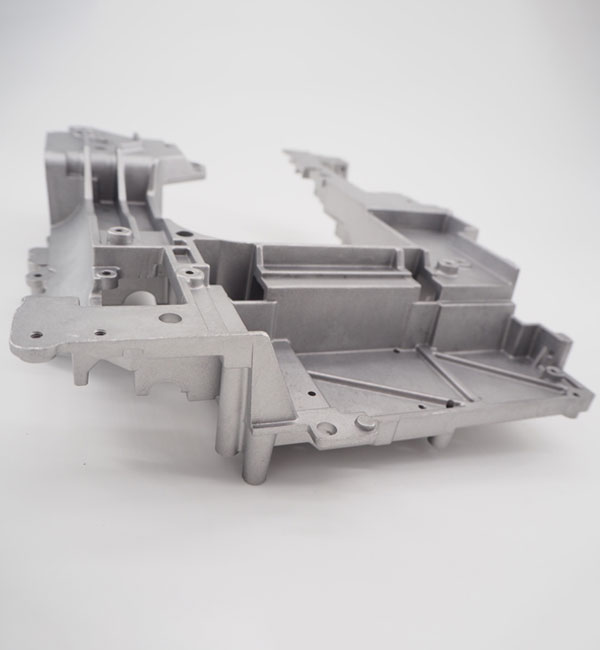

Permanent Isikhunta Ukulingisa

Permanent Isikhunta Ukulingisa unempilo ende nokusebenza kahle kokukhiqiza, hhayi nje ukuthi unokunemba okuhle nobuso obushelelezi, kepha futhi unamandla aphakeme kunokusakazwa kwesihlabathi futhi mancane amathuba okuthi alimale lapho kuthululwa insimbi efanayo encibilikisiwe. Ngakho-ke, ekukhiqizweni ngobuningi bokuphonsa izinsimbi eziphakathi nendawo nezincane, inqobo nje uma iphuzu lokuncibilika kwento yokuphonsa ingekho phezulu kakhulu, ukukhishwa kwensimbi kuvame ukukhethwa.

Ukutshalwa Kwezimali

Inzuzo enkulu ye- ukukhipha utshalomali lokho kungenxa yokuthi ukusatshalaliswa kokutshalwa kwezimali kunokunemba okuphezulu nobuso obuphezulu, banganciphisa umsebenzi wemishini, kepha bashiye isabelo esincane semishini ezingxenyeni ezinezidingo eziphakeme. Kungabonakala ukuthi ukusetshenziswa kwendlela yokutshala imali kungagcina imishini eminingi yamathuluzi womshini nokucubungula amahora omuntu, futhi kugcine kakhulu izinto zokusetshenziswa zensimbi.

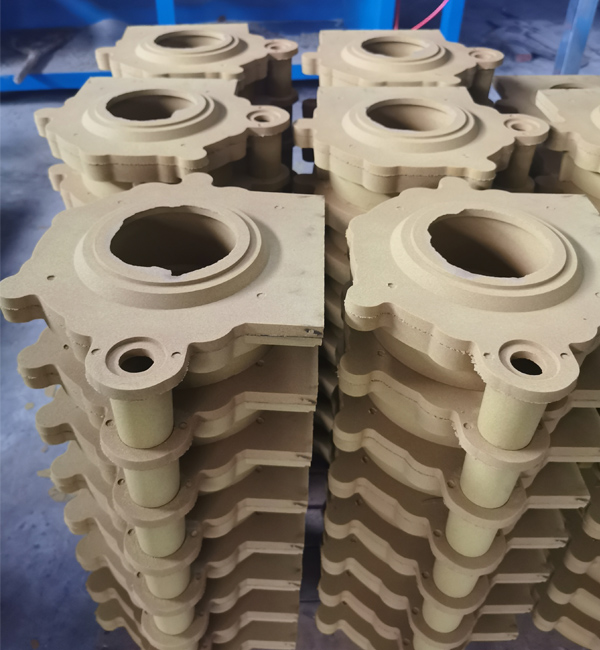

Lost Foam Ekubunjweni

Ilahlekile i-foam ekubunjweni ukuhlanganisa i-parafini wax noma amamodeli we-foam afana nosayizi wokuphonsa nomumo ube ngamaqoqo ezimodeli. Ngemuva kokuxubha nokomisa okubhangayo okukhanyayo, bangcwatshwa esihlabathini esomile se-quartz sokumodela kokudlidliza, futhi bathelwe ngaphansi kwengcindezi engemihle yokufaka imodeli amandla. , Insimbi ketshezi ithatha isikhundla semodeli futhi yakha indlela entsha yokusakaza ngemuva kokuqina nokupholisa.

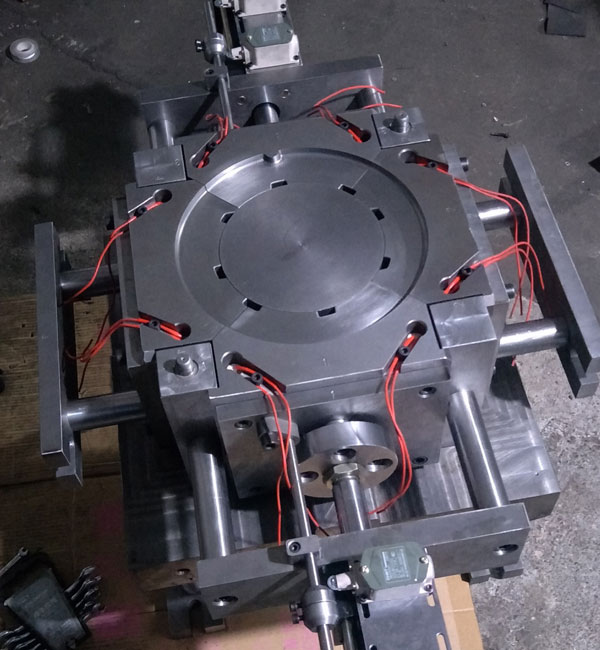

I-Die Casting

Ukufa kwe-die kuyinqubo yokusakaza yensimbi, ebonakala ngokusebenzisa ingcindezi ephezulu kwensimbi encibilikisiwe isebenzisa umgodi wesikhunta. Isikhunta ngokuvamile senziwa ngama-alloys anamandla aphakeme, futhi le nqubo icishe ifane nokubunjwa komjovo. Iningi lokufa kwabantu alinansimbi, njenge-zinc, ithusi, i-aluminium, i-magnesium, i-lead, i-tin, ne-lead-tin alloys kanye nama-alloys awo. UMinghe ubelokhu ehamba phambili eChina die inkonzo ekubunjweni kusukela 1995.

I-Centrifugal Casting

I-Centrifugal Casting kuyindlela nendlela yokujova insimbi ketshezi kwisikhunta esigijimayo esinejubane, ukuze insimbi engamanzi inyakaze nge-centrifugal ukugcwalisa isikhunta futhi yenze ukusakaza. Ngenxa yokunyakaza kwe-centrifugal, insimbi eyiketshezi ingagcwalisa isikhunta kahle esiqondisweni se-radial bese yakha indawo yamahhala yokusakaza; kuthinta inqubo ye-crystallization yensimbi, ngaleyo ndlela ithuthukise izakhiwo zemishini nezomzimba zokusakaza.

Ukuphonsa Ingcindezi Ephansi

Ukuphonsa Ingcindezi Ephansi kusho ukuthi isikhunta ngokuvamile sibekwa ngaphezu kwesibambo esivaliwe, futhi umoya ocindezelweyo wethulwa ku-crucible ukudala ingcindezi ephansi (0.06 ~ 0.15MPa) ebusweni bensimbi encibilikisiwe, ukuze insimbi encibilikisiwe inyuke isuka kumbhobho ophakamayo iye gcwalisa isikhunta nokulawula Indlela yokusakaza eqinile. Le ndlela yokulingisa inokuphakelwa okuhle nesakhiwo esinyene, okulula ukusakaza ukusakazwa okuyinkimbinkimbi okunamapulangwe amancane, akukho risers, kanye nesilinganiso sokutakula kwensimbi esingu-95%. Akukho ukungcola, okulula ukukuqaphela ukuzenzekelayo.

Ukuphoswa Kokuqothula

Ukuphoswa Kokuqothula inqubo yokuphonsa lapho insimbi incibilikiswa khona, ithululelwe futhi ifakwe emgodini we-vacuum. Umshini ekubunjweni kunganciphisa okuqukethwe kwegesi ensimbi futhi kuvimbele i-oxydation yensimbi. Le ndlela ingaveza ukufunwa kwensimbi ekhethekile efunwa kakhulu kanye nokufakwa kwe-titanium alloy castings okulula kakhulu. UMinghe Casting unendawo yokukhipha umshini ongaphansi, okwanele ukuxazulula zonke izinkinga ezihlobene nokulingiswa komshini