Izinto Ezinhlanu Ze-Aluminium Die Castings Ukukhiqiza iStoma

Izici Zabantu

- Ngabe umenzeli wokukhishwa ufuthwe kakhulu? Ngoba i-ejenti ekhishwayo inenani elikhulu legesi, lapho inani likhulu kakhulu, ayishiswa ngaphambi kokuthululwa, ukuze igesi eguquguqukayo isongwe ebusweni bokusakaza. Ngakho-ke, ngaphansi kwezimo ezifanayo, abanye abasebenzi bazokhiqiza ama-pores amaningi ngesikhathi sokusebenza. Khetha umenzeli okhipha onomoya omncane, umthamo uzacile futhi ulingene, futhi isikhunta sizovalwa ngemuva kokusha.

- Isiteshi sokuchichima nomsele wokukhipha awucocwanga kaningi?

- Ngabe isikhunta sivuleka kusenesikhathi? Ingabe isikhunta sishiselelwe? Ngabe ukushisa kwengxenye ngayinye kufudunyezwa kancane nangokulinganayo? Yenza ukushisa kwangaphakathi komgodi kanye nomgogodla kube ngu-150C ~ 200C

- Ingabe imikhiqizo ikhiqizwa lapho izinga lokushisa lesikhunta liphansi ekuqaleni?

- Uma ingekho into yokufudumeza, ingabe i-aluminium alloy material isetshenziselwa ukuphusha embotsheni ukushisa noma ukusebenzisa ezinye izindlela ukuyifudumeza?

- Ngabe uthathe uketshezi oluhlanzekile lwe-aluminium, futhi ngabe ungqimba lwe-oxide selufakiwe egumbini lokucindezela?

- Lapho uthela, noma ngabe isipuni sesobho siseduze nechweba lomjovo wegumbi lokucindezela ukugwema amagagasi ezindizayo, i-oxidation, noma ukubandakanyeka ekupholiseni komoya, njll.

- Lapho nje insimbi encibilikisiwe ithelwa egumbini lokucindezela, ingabe umjovo uqala? Ingabe izinga lokushisa selinciphile?

- Ekupholiseni nasekuvuleni kwesikhunta, ukhetha isikhathi sokuvula isikhunta ngokuya ngemikhiqizo ehlukile?

- Ngabe sikhona isizathu sokwesaba ukuthi i-aluminium encibilikisiwe izophuma (amanzi andizayo) futhi ungalinge usebenzise ingcindezi ejwayelekile yokuphonsa ukufa? Ungalokothi uzame ukwandisa ingcindezi ethile ngokufanele.

- Ingabe i-opharetha igcina ngokuqinile inqubo yokusakaza?

- Ngabe kukhona ukuthululwa okulinganiselwe? Ungalinquma kanjani inani lokuthela?

Izici zemishini, isikhunta kanye namathuluzi

Izici zemishini, isikhunta kanye nokusetshenziswa kwamathuluzi ikakhulu kubandakanya izinga lesikhunta nokusebenza kwemishini.

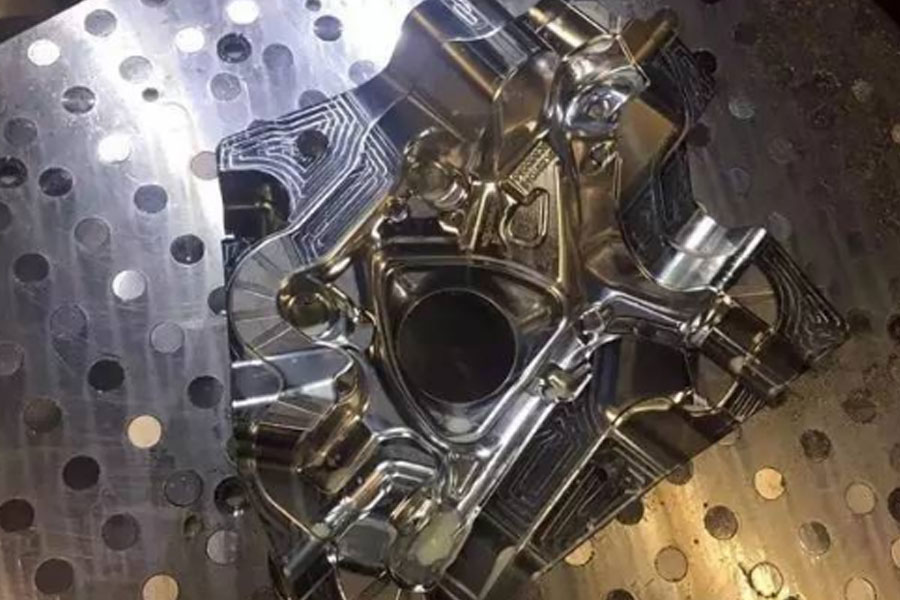

Ingabe idizayini yokufa-isikhunta inengqondo? Ngabe izodala izimbotshana?

Izizathu zokufa ekubunjweni kwesikhunta:

- Ukuthi ukukhethwa kwesikhundla se-orifice nokuma kokuphambukisa akulungile, okwenza insimbi encibilikisiwe ingene emgodini ikhiqize umthelela wangaphambili kanye ne-vortex. (Yehlisa isivinini somjovo ukugwema ukubambeka kwe-vortex)

- Ingabe kukhona noma yimuphi umklamo omubi wesimo se-sprue?

- Ngabe ijubane lesango langaphakathi liphakeme kakhulu, lidala ukusakazeka kokugeleza?

- Ingabe ukukhipha akushelelezi?

- Ngabe indawo yomgodi wesikhunta ijule kakhulu?

- Ingabe isabelo semishini sikhulu kakhulu? Ingena kungqimba oluminyene lobuso, iveze izimbotshana ezingaphansi? Isabelo semishini sokuphonswa kokufa kufanele sibe sincane, ngokuvamile sizungeze u-0.5mm, esinganciphisa isisindo se-castings futhi sinciphise inani lokusika ukucubungula. Nciphisa izindleko futhi ugweme ukuvezwa kwama-pores angaphansi. Imajini akufanele ibe nkulu kuno-0.5mm, ukuze indawo elungisiwe ingakwazi ukubona ama-pores, ngoba ivikelwe ungqimba oluqinile.

2.2 Ingabe imbobo yokukhipha ivinjiwe futhi nomoya awukwazi ukukhishwa?

2.3 Ngabe kukhona igrisi eningi kakhulu esibhakeleni, noma emakhoneni ashile? Lokhu futhi kungenye yemithombo yegesi.

2.4 Ngabe ukuma kwesango nokumiswa kokuphambukisa kuqala kuqinisa kanjani uhlelo lokuchichima endaweni yokuvalelisa?

2.5 Ngabe ukuma kwesango langaphakathi akunangqondo? Ngemuva kokudlula esangweni elingaphakathi, insimbi ngokushesha ishaya udonga olubunjiwe bese idala imisinga eddy, bese kuthi igesi idonswe ekugelezeni kwensimbi?

2.6 Ukuma komsele we-exhaust akulungile, okudala izimo zokukhishwa ezimbi?

2.7 Ngabe indawo yomjelo wokuchitheka inkulu ngokwanele? Ingabe ivinjiwe futhi ingabe itholakala endaweni yokugcina yokugcwalisa? Ingabe ingxenye yokubhoboza isikhunta ihlanzwa kaningi? Ukugwema ukulahlekelwa umphumela wokuvuleka ngenxa yokuvaleka komenzeli wokukhishwa

2.8 Ingabe izinga lokushisa lesikhunta liphansi kakhulu?

2.9 Ngabe umgijimi ujika ngokwanele? Khulisa isango langaphakathi ngokufanele?

2.10 Ngabe kukhona ama-plug plugs emgodini ojulile, noma ukusebenzisa okufakwayo ukwandisa ukuphuma?

2.11 Ngabe kukhona noma iyiphi ingxenye okunzima ukuyikhipha ngenxa yomklamo ongenasisekelo wokuphonsa izidumbu?

2.12 Ingabe indawo ephelele yokuhlukaniswa okuchichimayo ingaphansi kwama-60% wendawo ephelele yokuhlukaniswa kwesango elingaphakathi, futhi umphumela wokususa i-slag mubi?

2.13 Ingabe ikhona indlela yokwandisa ukushuba kwesango langaphakathi ukunciphisa ijubane lokugcwalisa ngaphansi kwezimo ezinhle zokubumba?

2.14 Ngabe isivinini sesango siphezulu kakhulu, ukugeleza kokugeleza kweqile, futhi ukugeleza kwensimbi kubandakanyeka kakhulu kugesi?

2.15 Ngabe indawo enqamulelayo yesango langaphakathi incane kakhulu futhi ijule ngokungathi sína?

2.16 Ukuthi kufanele ugcwalise ukuze wenze lula ukukhishwa kwegesi yomgodi. Ingabe bukhona ubude obanele be-sprue nomgijimi?

Izici Ezintathu Zezinto

- Ngabe wenze umsebenzi omuhle ekulawuleni ukwakheka kwempahla eluhlaza yomphakeli? Yini okuqukethwe yensimbi? (kuyadingeka ngezansi kuka-0.7)

- Ngabe ubumsulwa be-aluminium buqinisekisiwe?

- Ngabe impahla yesibili (impahla yombhobho) isetshenziswe kakhulu futhi ayenzanga umsebenzi omuhle wokususa i-slag?

- Awuzange ungeze isikhwama semfucuza esiningi kakhulu kuketshezi lwe-aluminium ngesikhathi senqubo yokukhiqiza, bese usithululela ndawonye nesikali se-oxide ngesikhathi sokuthela?

- Ingabe inkampani ilawula inani lokusetshenziswa kwesibili kwemfucuza? Ungayisebenzisa kanjani? Ubani oyihlola?

- Kungenzeka yini ukwengeza imfucumfucu kuketshezi lwe-aluminium lwemikhiqizo yamakhasimende ebalulekile?

- Zama ukushintsha isilinganiso sezinto ezintsha ezintweni ezenziwe kabusha?

- Ingabe inkokhelo ihlanzekile?

Amapharamitha amane e-Die-Casting, ama-Operating Process Factors

- Ngabe kukhona ukukhetha kwamapharamitha wenqubo ngokuya ngemikhiqizo ehlukile? (Ukushisa kwe-die-casting aluminium lokushisa okungu-630-670 * C) Umshini ngamunye ukhetha imingcele yenqubo yokufa, ikakhulukazi isivinini somjovo, futhi ilungisa indawo yokuqalisa esheshayo.

- Ingabe ikhona indlela yokwehlisa okuqukethwe kwamanzi kwe-ejenti ekhishwayo? Ingabe kukhona umenzeli wokukhishwa onomoya omncane?

- Ingabe izinga lokushisa lokutshala i-aluminium liphezulu kakhulu?

- Ungalinganisa kanjani izinga lokushisa le-aluminium encibilikisiwe? Ngabe i-thermometer inembile?

- Ingabe kukhona ukulungiswa okufika ngesikhathi kwejubane lomjovo nephuzu lokuguqulwa kwesivinini somjovo ngokusho komkhiqizo?

- Noma ngabe kukhona imishini emikhulu yokuphonsa izingxenye ezincane. Ingabe igumbi lengcindezi lincane kakhulu?

Izici Ezinhlanu Zemvelo

Ingabe umswakama womoya endaweni yokuphonsa uphezulu?

Ngaphansi kwezimo ezijwayelekile, okuqukethwe yi-hydrogen emoyeni ozungezile akukuningi. Kepha uma umswakama ohlobene emoyeni uphakeme, kuzokhulisa ukuncibilika kwegesi ku-aluminium encibilikisiwe futhi kwakheke izimbotshana zonyaka. Isibonelo, ngenkathi yemvula, ngenxa yomswakama ophezulu womoya, isimo se-pinholes ngesikhathi sokuncibilika kwe-aluminium alloy sibi kakhulu. Yiqiniso, umswakama womoya uphezulu. Ngalesi sikhathi, ama-aluminium ingots ingots, imishini yokuncibilikisa, amathuluzi, njll. Nayo izokwenyusa inani lokukhishwa komswakama ongaphezulu ngenxa yomoya oswakeme, ngakho-ke kufanele kunakwe kakhulu ukwamukela ukushisa nokuqinisa izindlela zokuvikela ukunciphisa ukukhiqizwa kwama-pores.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Izinto Ezinhlanu Ze-Aluminium Die Castings Ukukhiqiza iStoma

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off