Kulahlekile Ukwehlulwa Kwamagwebu Okulahliwe Kwezingxenye Ezinkulu Ze-Shell Ezizacile

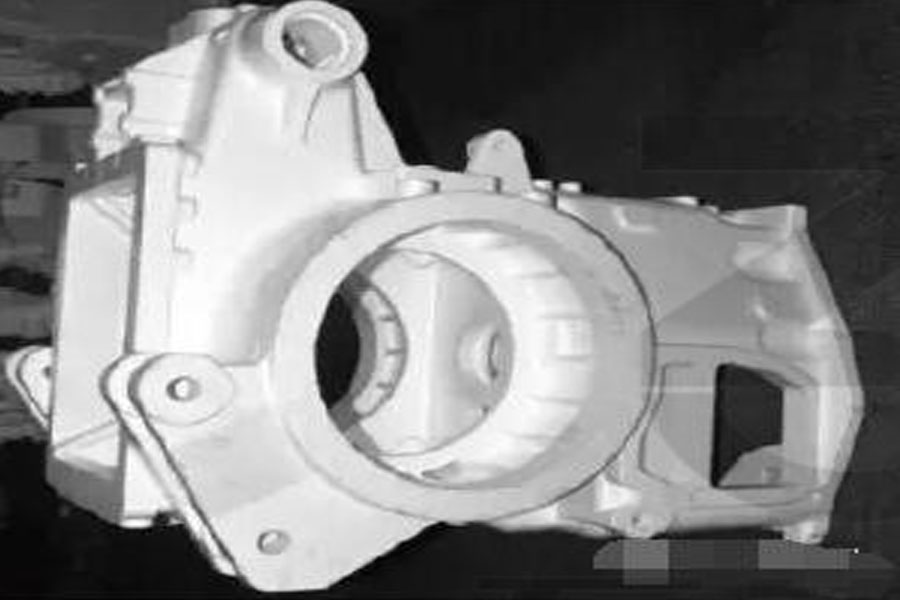

Ugandaganda onamasondo aphehla ugesi ngokuzimela owenziwe yiChina YTO Group Co., Ltd. unecala elikhulu lokudlulisa langemuva nesakhiwo esiyinkimbinkimbi kakhulu (bheka Umfanekiso 1), enobukhulu bangaphandle obungu-1050mm × 925mm × 750mm, kanye nevolumu yangempela ukusakazwa kungu-0.085m3. Isisindo sethiyori silinganiselwa ku-615kg.

Ekukhiqizweni kwesivivinyo kwale ngxenye yegobolondo, kusetshenziswe ubuchwepheshe bokulahla amagwebu obulahlekile. Ingxenye yegobolondo elincanyana elinomthamo omkhulu nesisindo nesakhiwo esiyinkimbinkimbi yakhiqizwa yilobu buchwepheshe, futhi kunemibiko embalwa emaphephabhukwini nakomagazini abakhona. Ngemikhiqizo eminingi yesilingo, kutholakale ukuthi ukusakazwa ngemuva kokuthelwa kunezinkinga ezintathu ezilandelayo: eyodwa ukususwa kokuphonsa, okwenza kube nzima ukuqinisekisa ukunemba kobukhulu bokusakaza; okwesibili ukuthi isihlabathi esimbozwe ngensimbi sakhiwa kalula emgodini wangaphakathi wokuphonsa, okwandisa ubunzima bokuhlanza; okwesithathu kungubuso bokusakaza. Kukhiqizwa ukukhubazeka okumnyama kweCarbon, okwenza ukuthi ukusakazwa kusulwe ngesikhathi kusetshenzwa.

Kunezici eziningi ezibangela ukukhubazeka okungenhla kokuphonsa, kepha ukumboza kudlala indima ebalulekile kuyo yonke inqubo yokulahla amagwebu elahlekile. Uma ukumbozwa kukodwa kungalungiswanga kahle futhi ukusebenza kokumboza kungalungile, ngeke nje kuphela kuxazululeke kahle inkinga, kepha kuzodala ukukhubazeka.

- (1) Upende unokulengiswa okuncane. Upende osetshenzisiwe esivivinyweni sokukhiqiza upende osuselwa emanzini, kanti isikhunta esimhlophe secala lokudlulisa langemuva senziwe ngogwebu lwe-polystyrene, okungelula ukuthi lunanziswe noma lungenwe ngopende osuselwa emanzini. Ukungabi manzi kahle, ukumboza okungalungile, nopende ngeke kuxhomeke ebusweni besikhunta esimhlophe noma akunamathele kahle. Ngakolunye uhlangothi, kuzobangela iphethini ukuthi ifakwe izikhathi eziningi, futhi ukuthambekela kwesikhunta esimhlophe kukhubazeke phakathi kwezinqubo eziningi zokumboza nokumisa kuzokwanda. ; Ngakolunye uhlangothi, kuzodala ukungalingani kokumboza okungalingani, noma ukumboza okuyekiswayo, nokuvezwa kwendawo kwesikhunta esimhlophe kuzodala ukukhubazeka kwesihlabathi. Ngenxa yobukhulu obukhulu besikhunta esimhlophe secala lokudlulisa langemuva (bona Umfanekiso 2), ukubhoboka okwenziwe ngesikhathi sokuntywila kuzobangela ukuthi ukubukeka kwephulwe. Ngakho-ke, ukusetshenziswa kwesikhunta esimhlophe kusebenzisa inhlanganisela yokufafaza namakhethini enamathela. Izakhiwo zokumboza zibeka phambili izidingo eziphakeme.

- (2) Amandla enamathela aphansi. Isikhunta esimhlophe secala lokudlulisa elingemuva sinevolumu enkulu, udonga oluncane nobukhulu obuphansi. Isikhunta sonke esimhlophe asinakho ukuqina okungokwemvelo. Amandla wokunamathisela wokumboza ekamelweni lokushisa awaphakeme, futhi kulula ukwenza ukuthi ukumboza kuqhume futhi kulimaze ngesikhathi sokomiswa nokuphathwa kwephethini. Akunakuqinisekiswa ukuthi iphethini inokumelana okwanele ekuguqulweni ngesikhathi senqubo yokugcwaliswa kwesihlabathi nokuhlangana, okuholele ekuguqulweni; amandla okushisa aphezulu wokumboza awekho phezulu, ngaphansi kwezimo zokushisa okuphezulu, akunakwenzeka ukuvimbela ukulimala kwengubo ngenkathi kusakazwa futhi kwakhiwa inqubo yensimbi encibilikisiwe, edala ukuwa, ukunamathela kwesihlabathi nokunye ukukhubazeka, ukuze ukunemba kobukhulu nekhwalithi yesimo sokusakaza akunakuqinisekiswa; amandla ayizinsalela asele enamathela azodalaAkulula ukuhlanza ukumboza ebusweni bokusakaza ngemuva kokuthela.

- (3) Ukungena komoya kokumboza kubi. Ngoba okokusebenza komkhiqizo wesivivinyo yi-HT250, esivivinyweni sokukhiqiza, izinga lokushisa elithelwayo lilawulwa ngo-1380 ~ 1430 ℃, kanti okokusebenza kwesikhunta esimhlophe yigwebu le-polystyrene, elisebangeni lokushisa elingu-1350 ~ 1550 ℃. , Iqala ukuqhekeka ngokushesha, ishe futhi ivuthe, kuthi ama-polymers anesisindo esiphansi aqhephuke ngokushesha, futhi inani elikhulu le-hydrogen nekhabhoni yamahhala kuyacwaswa. Uma ukungena komoya kokumboza kukuncane, inani elikhulu lemikhiqizo ye-pyrolysis ayikwazi ukuthunyelwa ngokushelela ngokumbozwa, okuzodala izimbotshana ekusakazweni; uma ukumboza kungakwazi ukumunca izinsalela ezikhiqizwe ngesikhathi kusha igwebu le-polystyrene, ukusakazwa kuvame ukuba nezici eziyinsalela zokufakwa kwekhabhoni.

Ihlose ukukhipha ukukhubazeka okubangelwa ukumbozwa ngemuva kwezobuchwepheshe, igxila ekuthuthukiseni ukwakheka kokumboza futhi ngasikhathi sinye ihlola inqubo yokuhlangana kwezingubo.

Ukuthuthukiswa kokwakhiwa kokumboza

1. Ukwakheka nokukhethwa kwezinto ezibonakalayo

- (1) I-powder ekhiphayo elahlekile i-foam coating inezidingo ezintathu ezibalulekile ekukhetheni i-powder ekhanyelayo: Okokuqala, usayizi wezinhlayiyana we-powder refractory kufanele uqweqwe, kepha uma umkhulu kakhulu, ukumelana nesihlabathi kwengubo kuzothinteka, futhi kuzobhekwa nesihlabathi sokulwa nenduku. Futhi ukungena komoya okuphezulu, khetha usayizi wezinhlayiyana ongu-0.08 ~ 0.071mm (180/200 mesh); okwesibili, ukuzungeza ukuma kwempuphu ekhonjiwe, kungcono, impuphu eyindilinga inamandla okungena emoyeni; okwesithathu ukuthi i-powder ekhombayo inokungena okuhle komoya; Imikhiqizo ye-pyrolysis yamapulasitiki e-foam kufanele ibe namandla we-adsorption. Ukuze uthuthukise ukusebenza kukonke kokumbozwa, i-alumina bauxite clinker powder ephezulu (usayizi wezinhlayiyana 0.08mm) kanye ne-mica powder (usayizi wezinhlayiyana 0.071mm) kukhethwa njenge-powder refractory. I-alumina powder ephezulu ye-bauxite inesakhiwo esinamapulangwe esinezinhlamvu eziyindilinga, ezingathuthukisa ukungena komoya kokumboza kanye namandla we-adsorption wemikhiqizo ye-foam pyrolysis; i-mica powder iyi-silicate egqinsiwe evela esakhiweni, engamelana nokushisa futhi engamelana nokugqoka, ukusebenza kwe-Insulation, ukuqina okuhle nokuzivumelanisa nezimo, ukungeza ingxenye ethile ye-mica powder ekugqokeni kungathuthukisa ukumbozwa, ukushisa okuphezulu komoya nokungeneka lokwembathiswa.

- (2) Isibopho se-Binder EPC enamathela yingxenye ebalulekile yokumboza. Akugcini nje ngokunikeza amandla nokusabalala kwengubo, kepha futhi kuthinta nokungena komoya nokumiswa kwengubo. Imvamisa, ukuhlanganiswa kwe-binder engaphili kanye ne-organic binder akuqinisekisi kuphela amandla wokumboza ekamelweni lokushisa nasezingeni eliphakeme lokushisa, kepha futhi kuthuthukisa ngempumelelo ukungena komoya kokumboza. Ngenxa yevolumu enkulu nodonga oluncane lwecala lokudlulisa kanye necala lokuhambisa, ukuze kuqinisekiswe ukuqina, amandla nomoya ukutholakala kwembatho, izinhlobo ezintathu zokunamathela, i-latex emhlophe, isitashi se-α ne-RSF powder enomphumela wokumanzi, kukhethiwe. Umenzeli obophayo uhlanganisiwe futhi usetshenziswe ngokulingana okuthile. Ikakhulukazi ukukhethwa kwe-RSF powder kuthuthukisa ngempumelelo ukuqina, amandla nomoya ukutholakala kwengubo.

- (3) Umsebenzi oyinhloko woketshezi lwenkampani ukusabalalisa impuphu ekhiphayo ekuwo. Ekuphonsweni kwe-foam elahlekile, kucatshangelwa izidingo zokuvikelwa kwemvelo, ukufaka isicelo, ukomiswa, ukukhiqizwa kwegesi, nezindleko, kulula ukusebenzisa amanzi njengoketshezi oluthwala. Yenza ukumbozwa kutholwe ukumiswa okuhle, ukuxubha kanye nezakhiwo ezingagobhozi.

- (4) Ukumiswa kokumiswa kwe-ejenti okumisiwe kuthinta ngqo ikhono lokumboza nekhwalithi yokumboza, futhi kuthinta nokusebenza kokusebenza kwengubo. Ngenxa yobukhulu bezinhlayiya eziyimpuphu ye-powder ekhanyelayo kanye ne-viscosity enkulu yokumboza, lapho kulungiswa ukugqoka, i-Lithium bentonite ne-attapulgite zisetshenziswa njengezinto zokumisa. I-lithium bentonite ne-attapulgite zingakha isakhiwo senethiwekhi esinamacala amathathu emanzini. Ukuhlanganiswa kwalaba ababili kungathuthukisa ukumiswa kwengubo futhi kuthuthukise i-rheology nokusebenza kwenqubo yokumboza.

Kunezinhlobo ezintathu ezilandelayo zezithasiselo ezisizayo.

- ①Defoamer. Isetshenziselwa ukuqeda amabhamuza akhiwe ngokunyakazisa ngesikhathi senqubo yokukhiqiza yokumboza.

- UrUkusebenziseka okuhle. Inhloso enkulu yokwengeza inani elincane le-surfactant kokumboza ukuthuthukisa ukunamathela kwengubo kuphethini nokwenza lula ukusetshenziswa.

- ③ Isinqandakuvunda. Ukuze kwenziwe lula ukugcinwa nokusetshenziswa kwesikhathi eside kukapende, kufakwa inani elithile lokulondolozwa kupende, elingavimbela ngempumelelo upende ekungcoleni, ekonakaleni nasekulahlekelweni yi-viscosity ngenkathi enamazinga okushisa aphezulu.

Ucwaningo ngokusebenza kokumboza

1. Indlela yokuhlola yokusebenza kokumboza

- (1) Ubuningi bepende bukalwa ngendlela enesisindo engu-100mL enesisindo sokunquma ubukhulu bepende.

- (2) Isivivinyo sokuqina sokumiswa kwengubo sisebenzisa isilinda esingu-100mL esiqedile ukuthola indlela yesilinganiso sokufakwa kwe-6h.

- (3) Imitha ye-Baume (esetshenziswa endaweni yokukhiqiza) isetshenziselwa ukuvivinya ukugxila kopende.

- (4) Ukuvivinywa kokujiya: Gcoba isampula lepulasitiki elilungisiwe le-foam 100mm × 100mm × 12mm (okungcono kusuka kukhunta omhlophe osikiwe), ulicwilise kupende oxubekile wama-10, ulikhiphe, ulifake ku-50 ° C kagesi Ngemuva kokomisa amahora ama-3 ebhokisini lokomisa, khipha ibhulokhi lokuhlola bese ulinganisa ukushuba kwengubo.

- (5) Ukungena komoya okushisa okuphezulu kanye nokuhlolwa kwamandla okushisa okuphezulu kokumboza kuthola umhloli wokusebenza okuningana kusebenza okwenziwe yiHuazhong University of Science and Technology.

2. Ukusebenza kwengubo elahlekile yegwebu kusekelwe kufomula yokumboza engenhla

Inqubo yokulungiselela yengubo

Ukuhlolwa okuningi kutholile ukuthi ukusebenza kokumboza akuhlobene kuphela nokwakheka kokumboza, kepha futhi kuhlobene nenqubo yokwakhiwa kwengubo. Izinqubo ezifanayo zokwakheka nezinqubo zokwakheka ezahlukahlukene zinomthelela omkhulu ekusebenzeni kwengubo. Ukuthola ukumbozwa ngenqubo enhle yokusebenza, inqubo yokulungiselela kufanele iqinisekise ukuthi i-ejenti ye-thixotropic, isibopho kanye ne-solvent ihlakazeke ngokuphelele, futhi ine-adsorption eqinile ne-powder refractory, ukuze izingxenye zokumbozwa zihlanganiswe ngokuphelele, ukuze ukumboza kune-thixotropy enhle nokuqina.

1. Imishini yokulungiselela upende

Isixhumi esihlakazeka ngesivinini esikhulu, isihlanganisi sesihlabathi esine-roller.

2. Indlela yokulungiselela

- (1) Ukulungiswa kwempuphu emanzi emanzi: Thela impuphu ekhonjiwe esilinganisweni esixubeni sesihlabathi sokugoqa, hlanganisa imizuzu engu-5-10, bese uthela isibopho, ukumisa i-ejenti nezithasiselo ezisizayo engxenyeni ngokulandelana Esigayweni, ngemuva kokuxubana Imizuzu engama-30-40, izogaywa futhi ifakwe esikhwameni ukuze isetshenziswe kamuva.

- (2) Ukulungiswa kopende wesilayidi. Kala inani elithile lopende olumanzi oluyimpuphu, ngokusho kwesilinganiso sempuphu namanzi isilinganiso esingu-1: 0.6 kuye ku-0.7, ulinganisa inani lamanzi athile ebhakedeni lokuxuba upende, bese ufaka ibhakede lokupenda ngaphansi kwesixubanisi sokusabalalisa esinejubane elikhulu. Vula isixubanisi sokusabalalisa esinejubane eliphezulu, bese ufaka upende wempuphu emanzi enesisindo. Hlanganisa ngesivinini esikhulu (800 ~ 900r / min) cishe imizuzu engama-40, bese ugovuza ngesivinini esiphansi (< 600r / min) amahora amabili. Ngemuva kokuxuba upende ofanayo, wushiye amahora angama-2, Ukhule ngokuphelele, futhi umswakama ungalungiswa ngokuya ngezidingo zeBaume degree ngesikhathi sokusetshenziswa.

Isiphetho

- (1) Ukungeza inani elifanele le-mica powder kufulawa elingemuva kungathuthukisa izakhiwo zokumboza nokumiswa kwengubo. Lapho iphethini isetshenziswa, ukumbozwa okujiyile kungatholakala ngasikhathi sinye, ukunciphisa inani lezikhathi zokudweba iphethini nokwenza lula Inqubo yokukhiqiza iyathuthukiswa; engeza inani elifanele le-mica powder ukuthola ukujiya okufanayo, isisindo sonke sephethini ngemuva kokumbozwa sincishisiwe, esingaqinisekisa ngempumelelo ukuqina namandla kwephethini; ukwengeza inani elifanele le-mica powder kunciphisa i-bauxite powder enamathela Sintering lokushisa, ukumboza kulula ukuxebuka ekusakazweni ngemuva kokuthela, futhi indawo yokusakaza ibushelelezi futhi ihlanzekile.

- (2) Kwifomula yokumboza, engeza i-wetting binder RSF powder, ukunamathiselwa kwengubo kuphethini ye-foam ngokusobala kuyathuthukiswa, namandla we-coating ayathuthukiswa, okubaluleke kakhulu ukuqinisekisa ukuqina namandla wephethini .

- (3) I-lithium bentonite ne-attapulgite zisetshenziswa ngokuhlangana. Ngokwenqubo yokuxuba eyenzelwe ukumbozwa kwamagwebu alahlekile, sekuqinisekisiwe ukuthi izakhiwo zokumiswa, i-thixotropy nezokumboza zenziwe ngcono kakhulu. Ubukhulu besendlalelo bufana, kugwema ukukhubazeka kwesihlabathi okubangelwa ukuvezwa kwesikhunta esimhlophe.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Kulahlekile Ukwehlulwa Kwamagwebu Okulahliwe Kwezingxenye Ezinkulu Ze-Shell Ezizacile

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off