Icubungula Ubuchwepheshe Be-Aluminium Alloy Alloy Shell

Ngokuthuthuka okunamandla kwemikhiqizo yezinkontileka zezindiza zomhlaba wonke, ukubambisana phakathi kwamakhasimende nakho sekusondele. Ubunzima bezingxenye zokucutshungulwa nakho kushintshile kusuka ezingxenyeni zokuqala ezingashadile nezenziwe lula kuya ezingxenyeni ezinokushisa okuphezulu okukhethekile nezingxenye zomhlangano eziqondile zenqubo eyinhlanganisela. Izingxenye zegobolondo zebhokisi lensimbi elinzima kakhulu. Ngenxa yomkhawulo wesisindo sendiza, izinto zezingxenye eziningi zegobolondo zithambekele kakhulu ezintweni ze-aluminium alloy. Isibonelo, amamaki wezinto ezibonakalayo angama-L168, 6061, 2024 namanye ama-alloys e-aluminium asetshenziswa emhlabeni jikelele. Lezi zinhlobo zezinto zokwakha nazo zingafinyelela ukumelana nokugqwala okuhle futhi zigqoke ukumelana ngokusebenzisa ukwelashwa okubandayo kwasekuqaleni nokwelashwa komhlaba sekwephuzile. Zisetshenziswa ezingxenyeni zezindiza ezahlukahlukene zomphakathi ezinjenge-Airbus, iBoeing ngisho ne-C919 yezwe lami. Namuhla sifunda inqubo yokucubungula ye-aluminium alloy shell ene-porous, ukulingisa okulingene okunendonga okuncane isakhiwo asymmetric.

1. Incazelo Yezinkinga Zokucubungula

- Kunezimbobo ezingama-49 ezingxenyeni, kanti ingxenye encane yodonga ingu-3mm kuphela.

- Izimbobo eziyi-14 sezinokubekezelelana ngaphakathi kuka-0.01mm, lapho izimbobo zangaphakathi eziyi-7 zinokubekezelelana okungama- ± 0.004mm.

- Ukubekezelelana kwesikhundla kwezimbobo ezincane ezi-4 akumele kweqe u-0.025mm.

2. Uhlelo Lokucubungula

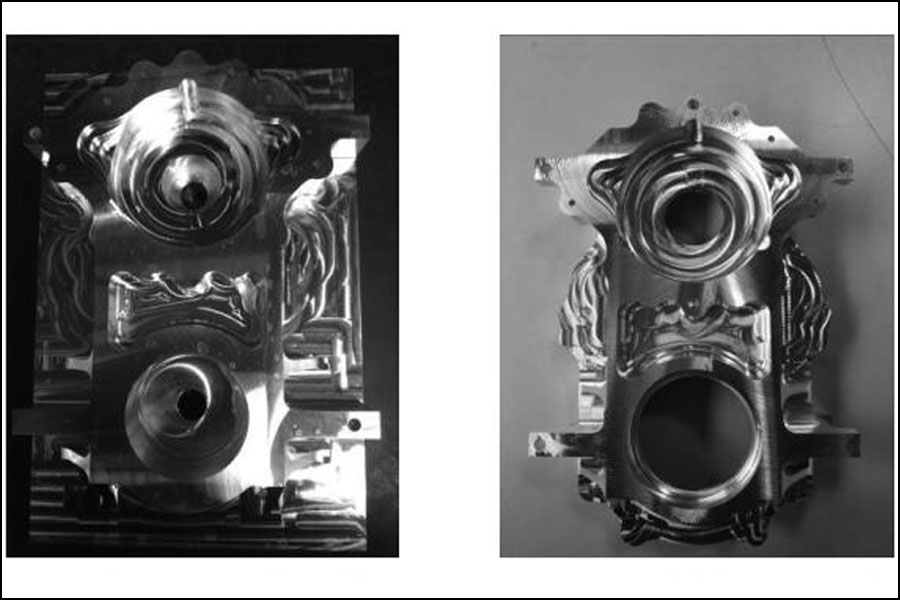

Ukucutshungulwa kwezingxenye ezinamapulangwe ezinomzimba omncane kungalandela imithetho ejwayelekile yokucubungula yezingxenye zegobolondo, njengoba kukhonjisiwe kuMdwebo 2. Lokho kungukuthi, imishini emibi, ukuqeda semi, nokuqeda; phakathi kwabo, izidingo zokugcina zingatholakala ngezinqubo ezithile zokuqedela okufana nokuqothula, ukugaya, ukugaya, nokubhora okuhle ngokuya ngokubukeka okuthile, ukuma kanye nezidingo zokubekezelela usayizi wengxenye ngesikhathi sokuqeda. . Ingacutshungulwa ngqo ngosayizi wokugcina uma izinga lokunemba kwemishini livumela. Kusukela ezintweni zokusetshenziswa, izikhala zokusakaza noma amabhulokhi e-aluminium wangempela angasetshenziswa ukuqala ukucubungula ngokuya ngezidingo zamakhasimende. Ukusetshenziswa kwe-castings kungonga isikhathi esiningi sokucubungula kumshini wokuqala onzima.

- Enqubeni yemishini emibi, ubukhulu bodonga nobukhulu bokujula kufanele bube yi-3mm ebekelwe ukusetjenziswa kokuqeda, kanye no-0.5mm obekelwe ubukhulu bokucaca komgodi. Ngokuya ngezingxenye ezikumfanekiso 1, izinqubo zokubeka izimbobo zokucutshungulwa ngemuva kufanele zenziwe ngasikhathi sinye. Sebenzisa inqubo yokubeka izimbobo ngezikhonkwane zokucutshungulwa ngemuva kwezingxenye. Umgodi wenqubo unconywa ukuthi wenziwe nge-engela engu-60 ° phakathi kwezindonga ezimbili zengxenye ukuqinisekisa amandla afanayo nokuzinza kobukhulu ngesikhathi sokucubungula kamuva. Usayizi wembobo u-5mm, futhi ukubekezelelana kungu -0.005. Uma izimo zemishini zingakuvumeli ukuthi icubungule izinhlangothi zombili ngasikhathi sinye, okungenani kungezwe izimbobo ezimbili zenqubo nezimbobo ezimbili zokuma ohlangothini ngalunye ukukhulisa ukuzinza kwezingxenye esigabeni sokuqeda kamuva.

- Esigabeni sokuqeda, konke ubukhulu obunokubekezelela okungaphezulu kuka-0.01mm kungacutshungulwa endaweni, kufaka phakathi ukushuba kodonga lwezingxenye, umgodi nobunye ubukhulu obunokubekezelela okungaphezu kuka- ± 0.1mm. Ukuze wonge isikhathi sokucubungula, i-0.5mm ingabekelwa bonke osayizi bemigodi yokuqedela. Kwenziwa ngesikhathi sokuqeda. Kumele kuqashelwe lapha ukuthi izingxenye zidinga ukwelashwa ukwelashwa kokuguga kungakapheli amahora ama-4 ngemuva kokuphothulwa kokuphothulwa kokuphothulwa, ngaphandle kwalokho ngemuva kokunqunywa okukhulu, inani elikhulu lengcindezi lizokhishwa futhi ingxenye izokhubazeka.

- Ngokuya ngezinto ezehlukene zezingxenye nobungako bezingxenye, khetha ukushisa okunengqondo okuqeda ukucindezeleka nesikhathi sokususa ngempumelelo ukucindezelwa kwemishini yezingxenye nokunikeza isiqinisekiso esisebenzayo sokuqeda kamuva.

- Ukuze kuqinisekiswe ukusebenza kahle okuphezulu nokuqina kokuqedela, ngemuva kokuphothulwa kokuphothulwa, inqubo eyodwa yokugaya ingenziwa ebusweni obubili bengxenye ukuze kuqinisekiswe ukuthi ukuthamba kobuso bobabili kungaphakathi kwe-0.01mm.

- Esigabeni sokuqeda, indlela yokucubungula ingakhethwa ngokuya ngezimo zemishini yayo. Lapho kunesikhungo semishini esinama-eksisi amathathu kuphela, kuyadingeka ukwenza umshini usayizi wokuqeda wendawo eyodwa kuqala. Uma kungenzeka, khetha ukusebenzisa ithuluzi elibhodlayo elishisayo le-shank clamping; ngokwezidingo zomdwebo, ukuma kwezimbobo ezine kufanele kuqinisekiswe ukuthi kube ngu-0.025mm Ngakho-ke, ngemuva kokucubungula indawo, udinga ukusebenzisa izimbobo ezimbili kule ndawo njengezimbobo zokubeka esikhundleni sezimbobo zenqubo esizigcinile ngesikhathi machining anolaka. Kungale ndlela kuphela lapho umgodi ka-0.025 ungaqinisekiswa ngempumelelo. Izinga lesikhundla

- Uma kunokwenzeka, isikhungo semishini esine-axis ezine singasetshenziselwa ukucubungula ngqo lezi zindawo ezimbili. Vele, iqoqo lezinto eziyizicaba liyadingeka ukusekela. Ngokuvivinywa okuningi, ukuze kuncishiswe ukushiyeka kwezingxenye ngesikhathi sokubamba nokucubungula, uqinisa oluyisicaba ludinga ukuphathwa ngokushisa nje, i-HRC ≥ 35, futhi ubucayi bendawo yokuqinisa ngaphakathi kwe-0.01mm. Ngemuva kokuthi ukufakwa kwepuleti kufakiwe, yilinganise bese uyilungisa ibe ngaphakathi kuka-0.01.

3. Izindaba Ezidinga Ukunakwa

- Njengoba izingxenye ngokwazo kunzima ukuzicubungula, futhi ukubekezelelana kuqinile, ngakho-ke izidingo zemvelo yokucubungula nazo zibeka phambili izidingo eziphakeme. Ngenxa yezinto zokwakha ngokwazo ziyizingxenye ze-aluminium, futhi umjikelezo wokucubungula wezingxenye ubude, i-coolant ebusweni bezingxenye kufanele ihlanzwe ngemuva kokuthi izingxenye zicutshungulwe; ngasikhathi sinye, ngesikhathi senzuzo nokulinda ukucubungulwa, kunconywa ukuthi kusetshenziswe izikhwama eziqinisekisa ukugqwala kwesimo sezulu ukucubungula. ukuvikelwa.

- Esigabeni sokuqeda izingxenye, ezithinteka ukubekezelelana kobukhulu bezingxenye, ukucubungula kufanele kwenziwe endaweni enezinga lokushisa lama-20 ° C ± 1 ° C.

- Ukuze kukalwe izimbobo ezinemba kahle, kunconywa ukuthi kusetshenziswe isibonisi sedijithali esine-jaw yangaphakathi ububanzi be-micrometer ukuqhathanisa ne-gauge yendandatho, bese usebenzisa i-gauge yama-alloy plug gauge yokulinganisa okusizayo ukuqinisekisa ukuthi ubukhulu bezingxenye ziyafaneleka.

Isiphetho 4

Cishe unyaka owodwa wokukhiqiza nokulungiswa kwesivivinyo, kuhloliwe isethi ephelele yemizila yobuchwepheshe bokucubungula, enikeza okuhlangenwe nakho okubalulekile kokucutshungulwa kwalolu hlobo lwezingxenye.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Icubungula Ubuchwepheshe Be-Aluminium Alloy Alloy Shell

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off