Ucwaningo Kuhlelo Lokufa Lokulingisa Isikhunta

Ukulingiswa kwe-die kungenye yezindlela ezibalulekile zokwenza insimbi engasebenzi. Ngesikhathi senqubo yokufa, ngenxa yezimo ezahlukahlukene zokugeleza kwensimbi encibilikisiwe emgodini, kungenzeka izinto ezingathandeki njengezithiyo ezibandayo, amaphethini, izimbotshana kanye nokuhlukaniswa. Ukuze uvimbele lezi zenzakalo ezingathandeki, kudingekile ukulawula ukuhamba kwensimbi encibilikisiwe emgodini. Ukhiye wokulawula ukugeleza kwensimbi encibilikisiwe emgodini ulele ocwaningweni nasekuklanyweni kohlelo lokufa lokuphonsa okufa.

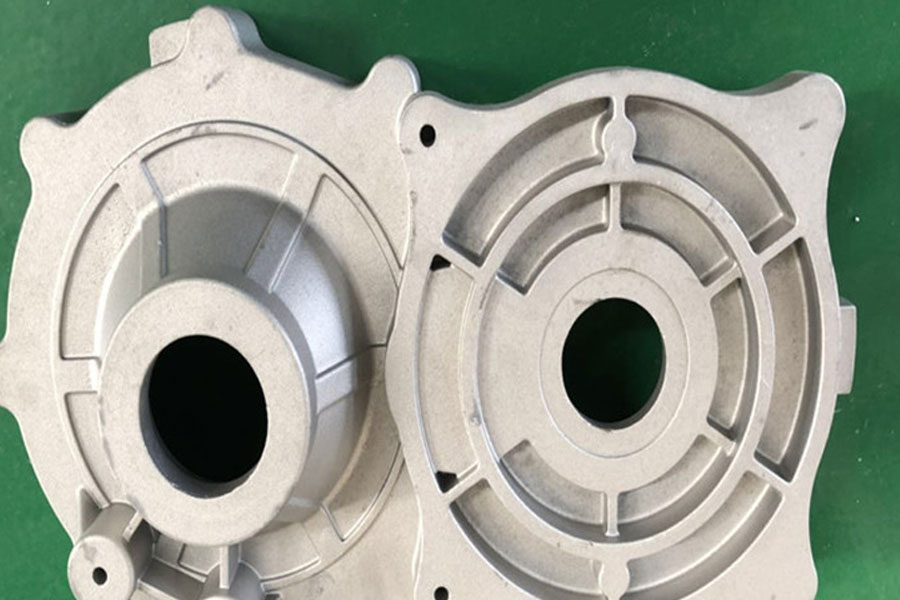

Inqubo Production Of Die-Ekubunjweni Isikhunta

Inqubo ye-CAD / CAE / CAM / CAT ye- die ekubunjweni isikhunta ukwenziwa.

Idizayini Yesistimu Yokuthela Isikhunta Sokuphonsa

Ocwaningweni lohlelo lokufa lokuphonsa kufa, ukuma kwesango nokuma kwazo yizinto ezibalulekile zokulawula isimo sokugeleza nokugcwaliswa kwesixazululo. Okokuqala, gxila endaweni yesango nokuma komgijimi, yakha isango, umgijimi, isikhwama se-slag, umkhombe wokugcwala, nomsele wokukhipha; bese usebenzisa isoftware yeCAE ukuhlaziya ukuhamba kwesisombululo ngaphakathi komgodi. Ukuma nosayizi womgijimi wangaphakathi kanye nesango langaphakathi kunethonya eliwujuqu endleleni yokugcwalisa.

Umklamo Wesango Langaphakathi

Lapho ubeka isango kumkhiqizo ophelile, kuvame ukwenziwa ngokwenqubo elandelayo:

- Ifomula yokubala yendawo yesigaba esinqamulelayo: A = U / (vt): ivolumu yomkhiqizo (cIn.): A: Indawo enqamulelayo yesango (cm2) / v: Isivinini sesisombululo se-aluminium yesango (cm / s) / T: Ukugcwalisa isikhathi (isikhathi)

- Bala indawo enqamulelayo yesango elingaphakathi.

- Ngokwendawo enqamulelayo yesango elingaphakathi, setha ukwakheka kwesango, bese usetha indawo yesango, bese uqala ukuklama indawo yomkhombe wokugeleza kanye nesikhwama se-slag.

- Yenza izikimu ezahlukahlukene zamasango (imvamisa yenza indawo enqamulelayo yomgijimi wangaphakathi incane kuqala, bese uyanweba uma kunesidingo ngemuva kovivinyo), bese wenza idatha ye-3D.

- Yenza ukuhlaziywa kwe-CAE (okungukuthi, ukuhlaziywa kokugeleza) ngokusekelwe kudatha ekhiqizwayo ye-3D.

- Linganisa imiphumela yokuhlaziya.

- Uma kunezimo ezingezinhle ngemuva kokuhlolwa, uhlelo kufanele luthuthukiswe, bese kwenziwa ukuhlaziywa kweCAE kuze kutholakale uhlelo olwenelisa kakhulu.

Design Of Sprue Futhi Exhaust System

Isango langaphakathi kufanele libekwe endaweni lapho insimbi encibilikisiwe igeleza kahle kakhulu emgodini, i-exhaust igcwele, futhi wonke amakhona omgodi angagcwaliswa ngensimbi encibilikisiwe. Sebenzisa isango langaphakathi lapho kungenzeka khona. Uma kudingeka amasango amaningi angaphakathi, kufanele kunakekelwe ukuqinisekisa ukuthi ukuhamba kwensimbi encibilikisiwe akuphazamisani noma kuhlangane emgodini ngaphandle kokuhlakazeka (okusho ukuhola ukugeleza kwensimbi kuye ohlangothini olulodwa) ukugwema ukuhlangana insimbi encibilikisiwe emgodini we-vortex.

Lapho usayizi we ukufa-okusakaza likhulu, kwesinye isikhathi akunakwenzeka ukuthola indawo edingekayo enqamula umgijimi kumgijimi oyedwa kuphela, ngakho-ke abagijimi abaningi kufanele basetshenziswe. Kodwa-ke, kufanele kuqashelwe ukuthi ukubekwa komgijimi wangaphakathi kufanele kuqinisekise ukuthi insimbi encibilikisiwe iqondiswa ukugeleza kuphela ohlangothini olulodwa, ukuze kugwenywe imisinga eddy lapho insimbi encibilikile esemgodini ihlangana.

Umfudlana wensimbi oncibilikisiwe kufanele ujike kancane ngangokunokwenzeka emgodini ukuze insimbi encibilikile ifinyelele engxenyeni ebiyelwe ngodonga yokuphonsa okufa.

Ukugeleza kwensimbi encibilikisiwe kufanele kube kufushane futhi kufane ngangokunokwenzeka.

Indawo enqamulelayo yomgijimi wangaphakathi incipha kancane kancane ibheke kumgijimi wangaphakathi ukunciphisa ukungena kwegesi, okuzuzisa ukuthuthukisa ukuhlangana kokuphonsa okufa. Umgijimi wangaphakathi kufanele aguqulwe ngokushelelayo ngesikhathi senqubo yokugeleza ukugwema ukujika okucijile nomthelela wokugeleza ngangokunokwenzeka.

Lapho kunezimbotshana eziningi, indawo enqamulelayo yomgijimi kufanele yehliswe ngezigaba ngokuya ngenani levolumu yomgodi ngamunye.

Umoya osemgodini kanye negesi eligcwele amandla okugcoba kufanele liphushelwe endaweni yokukhipha insimbi encibilikisiwe, bese libalekela umgodi emgodini wokukhipha. Ngokuyinhloko, ukugeleza kwensimbi encibilikisiwe akufanele kushiye igesi emgodini oyimpumputhe futhi kuvimbele inkatho yokukhipha ngaphambi kwesikhathi.

Ukusakazwa kwensimbi akufanele kube nokwethuka okushisayo ekusakazekeni kokushisa okuncane. Okokufa okunezimbambo, insimbi kufanele igeleze iye ezimbanjeni ngangokunokwenzeka.

Kufanele kugwenywe ukuthi insimbi encibilikisiwe igeza ngqo izingxenye zesikhunta nezinsimbi ezilimale kalula. Uma kungenakugwenywa, indawo yokuhlukaniswa kufanele isethwe ku-sprue ukugwema ukushaqeka okushisayo.

Ngokuvamile, lapho umgijimi wangaphakathi ebanzi futhi eba mkhulu, iba nkulu ingozi yokugeleza okungafani. Ngasikhathi sinye, zama ukungasebenzisi amasango aminyene ngokweqile; gwema ukusonteka lapho usika amasango.

I-Exhaust Of Cavity

Umkhombe wokuchichima usetshenziselwa ukususa insimbi encibilikisiwe efafazwe ekuqaleni ngesikhathi sokuphonsa nokwenza ukushisa kwesikhunta kungaguquguquki. I-flow flow groove isethwe lapho i-isikhunta kulula khona ukuqukatha igesi, futhi isetshenziselwa ukukhipha igesi ukwenza ngcono ukugeleza kwensimbi encibilikisiwe futhi iqondise insimbi encibilikile kuwo wonke amagumbi omgodi ukuthola indawo enhle yokusakaza . I-groove yokukhipha ixhunywe ngaphambili kwe-groove echichimayo nesikhwama se-slag, noma ixhunywe ngqo emgodini.

Indawo enqamulelayo enezingxenye zesikhala sokukhipha kufanele icishe ilingane nendawo enqamulelayo yomgijimi wangaphakathi.

Ukuma kwe-groove yokukhipha endaweni yokuhlukanisa kunqunywa ngokuya kokugeleza kwensimbi encibilikisiwe emgodini. Indawo yokukhipha amanzi kungcono ukuthi "ingaqondile" kepha "igobe" ukuvimbela insimbi encibilikisiwe ukuthi ifafaze futhi ilimaze abantu. Ukujula kwe-groove yokukhipha endaweni yokuhlukanisa imvamisa kungu-0.05mm-0.15mm; ukujula kwe-groove yokukhipha emgodini kuvamise ukuba ngu-0.3mm ~ 0.5mm; ukujula komsele wokukhipha onqenqemeni lwesikhunta imvamisa kungu-0.1mm ~ 0.15mm; Ububanzi slot qeda ngokuvamile 5mm ~ 20mm.

Igebe lokukhipha phakathi kwephini le-ejector nenduku ye-push libaluleke kakhulu ekuqothulweni komgodi, okuvame ukulawulwa ku-0.01mm-0.02mm, noma kukhuliswe kuze kube yilapho kungakhiqizwa ama-burrs.

Ukukhishwa okuyisisekelo okumisiwe kuyindlela esebenzayo yokukhipha. Imvamisa, igebe lika-0.05mm-0.08mm lilawulwa emaphethelweni omgogodla, ukuze kuvulwe intamo yokuma okuyisisekelo ngobubanzi be-qeda nobubanzi be-1mm-2mm, kuthi igesi esemgodini ivulwe ngaphandle qeda isikhala entanyeni. Ikhishwa phansi komgodi. Ubukhali besikhala sokukhipha akumele budebeselelwe. Kufanele kugcine izinga elibushelelezi lokugwema ukuvinjelwa ngopende onamathela kuthuli ngesikhathi sokusetshenziswa, okuzothinta ukuqeda.

Ukuhlolwa Kokuhlaziywa Kokugeleza Nezinyathelo Zokuphikisa

Enqubeni yokwakhiwa kwesikhunta, ukugeleza kwensimbi kufanele kuvunyelwe ukugeleza kohlangothi olulodwa ngangokunokwenzeka. Ngemuva kokuthi ukugeleza kuhlaziyiwe, lapho kutholakala imisinga ye-eddy emgodini, isango langaphakathi lokuhola noma usayizi kufanele liguqulwe ukuqeda isimo samanje esihlelekile.

Lapho insimbi encibilikile ihlangana, vumela insimbi encibilikile iqhubeke nokugeleza ibanga elithile ngaphambi kokumisa ukugeleza; ngakho-ke, umkhombe wokuchichima kanye nesikhwama se-slag kufanele kungezwe ngaphandle komgodi lapho kuhlangana khona ukuvumela insimbi encibilikiswe kakhulu yomoya kanye namakhemikhali omoya agelezele emkhombeni wokuchichima Kanye nesikhwama se-slag; vumela insimbi encibilikisiwe elandelayo ihlanzeke futhi kushise ekamelweni.

Lapho isivinini sokugcwaliswa kwezingxenye ezahlukahlukene sehlukile, ubukhulu noma ububanzi besango langaphakathi kufanele lilungiswe (khuphuka kancane uma kunesidingo) ukufeza inhloso yokugcwalisa isivinini esifanayo sokugcwalisa, kepha kufanele kufinyelelwe ngokwandisa umgijimi wangaphakathi kakhulu ngangokunokwenzeka.

Ngemuva kokuhlaziywa kokugeleza, ingxenye yokugcwalisa esalele itholakala, futhi umgijimi wangaphakathi naye angangezwa. Ezingxenyeni zokuphonsa ezincanyana ezinomzimba omncane, kufanele kukhethwe isikhathi esifushane sokugcwalisa; ngakho-ke, isikhathi sokugcwalisa kufanele sincishiswe ngokwandisa indawo enqamulelayo yomgijimi wangaphakathi ukuze kuzuzwe ikhwalithi engcono yendawo.

Okokuphonsa okujiyelwe ngodonga okudinga ukubumbana okuphezulu, kuyadingeka ukuqinisekisa ukuvuleka okuphumelelayo. Isikhathi sokugcwalisa esimaphakathi kufanele sisetshenziselwe ukusakaza okufa. Ngakho-ke, isigaba esiphambanweni somgijimi wangaphakathi kufanele silungiswe ukuze sithole isikhathi sokugcwalisa esihambisanayo futhi sithole ikhwalithi engaphezulu nekhwalithi yangaphakathi.

Ngamafuphi, enqubeni yokufa-ekubunjweni kwesikhunta, kufanele kunakwe ukugwema izenzakalo eziningi ezingathandeki. Ngisho nasenkathini yanamuhla lapho izindlela zokuhlaziya ze-CAE zitholakala, esigabeni sokuqala sokwakhiwa kwe-sprue, isipiliyoni esifingqiwe siqale sicatshangelwe ohlelweni lwe-gating, luhlanganiswe ngokomzimba, luhlaziywe, lwenziwe ngcono, futhi lwenziwe ngcono, okumele luzuze umphumela wokuphindaphinda isigamu somzamo.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ucwaningo Kuhlelo Lokufa Lokulingisa Isikhunta

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off