Ungasithola Kanjani Isikhundla Esihle Kakhulu Sokuvungula Umshini Ku-Die Cast Tooling?

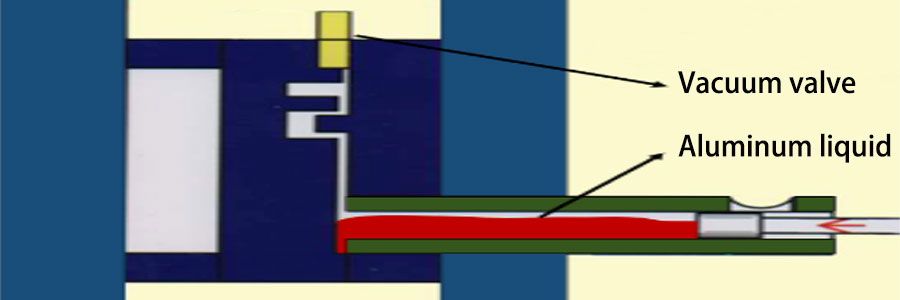

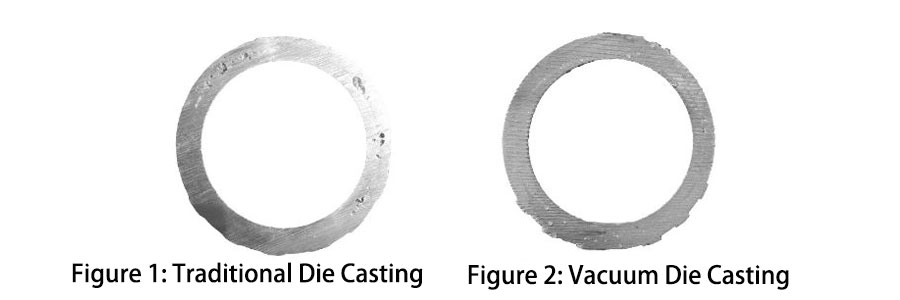

Uma kuqhathaniswa nesihlabathi isikhunta futhi adonsela phansi ekubunjweni, microstructure yendabuko die castings aligculisi. Isizathu esiyinhloko ukuthi umjovo wokugeleza kwensimbi enejubane esangweni kulula ukuxhumana nomgodi kunalapho insimbi ifakwa kancane kancane esihlabathini noma emoyeni wesikhunta sensimbi. Ukugxila kwenqubo yokuphonsa i-vacuum ukunciphisa lokhu kuthintana negesi-ketshezi. Ngakho-ke, ukukhipha igesi ngempumelelo emgodini kuyisihluthulelo somklamo wesikhunta sokufa.

Okwenziwe isikhunta sokufa, awukho umehluko obalulekile phakathi kokuklanywa kwendabuko yendabuko nokuklanywa kwe-vacuum qeda. Okuwukuphela kwendlela yokukhipha ukuthi eyokuqala ukukhipha nje, okusebenzisa ukugeleza kwensimbi ukukhipha igesi, okubizwa ngokuthi yi-positive pressure injection; eyokugcina i-Exhaust esebenzayo, okusho ukuthi, ngokusebenzisa umshini wokukhipha igesi ukukhipha igesi emgodini, ubizwa nangokuthi umjovo omubi wokucindezela. Ngokuphathelene nomphumela wokukhipha, kunomehluko omkhulu phakathi kwalokhu okubili. Isicelo esifanele sokukhipha umshini sizonciphisa kakhulu okuqukethwe kwegesi emgodini, ngaleyo ndlela kuthuthukiswe ngempumelelo ikhwalithi yomkhiqizo.

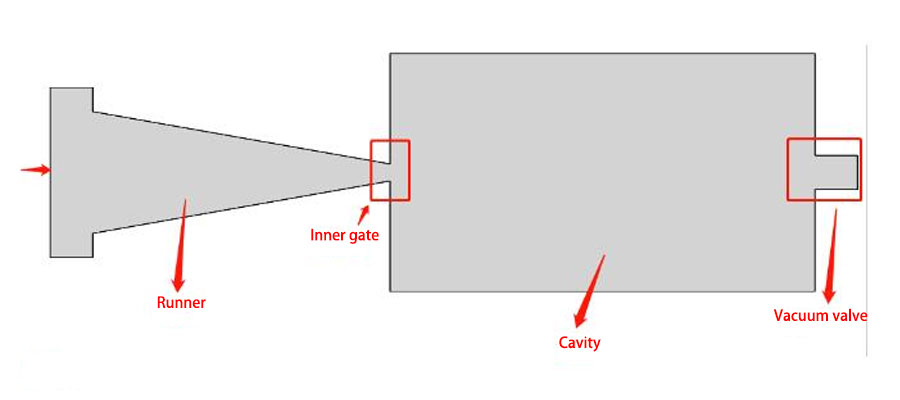

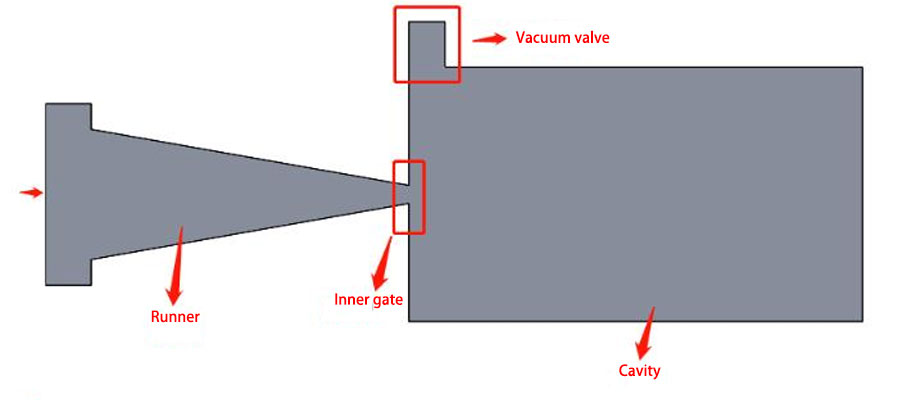

Le ndatshana ihlanganisa i-China Die Casting Cloud Computing Platform ukuxoxa ngendawo ye-vacuum valve ebandakanyeka ekwakhiweni kohlelo lwesikhunta se-vacuum, igxile ekutheni ngabe i-valve yomshini kufanele ibe kude nesango elingaphakathi noma eduze?

Enkambeni yokuklanywa kwesikhunta sokufa, indawo ye-valve yokuhlanza kufanele ikwazi ukugcina i-valve yokuvula ivulekile isikhathi eside, ukuze kukhishwe igesi eningi ngangokunokwenzeka.

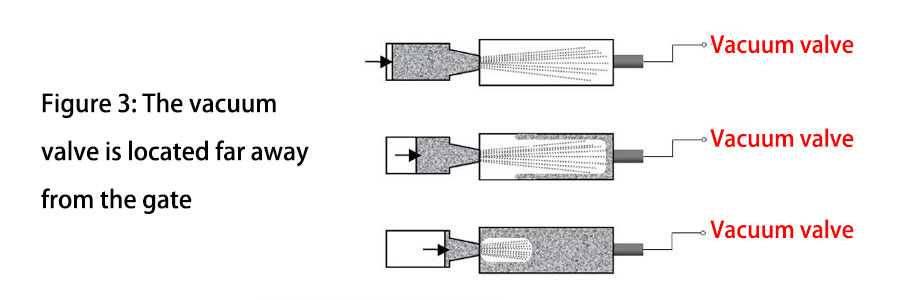

Ivelufa le-vacuum kufanele libekwe lapho kugcwala khona ingxubevange yokugcina, kepha lesi sikhundla singaphikisana, njengoba kukhonjisiwe kuMdwebo 3: Njengokuphonsa okuvamile, i-vacuum die-casting iveza ukugeleza kwe-athomu. Uma i-valve yokuhlanza isethwe kude kakhulu ne-Position yesango, i-valve yomshini ingavalwa ekuqaleni kwenqubo yokugcwalisa umgodi.

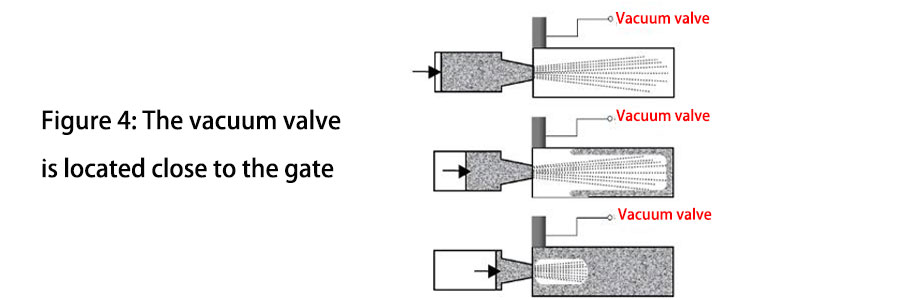

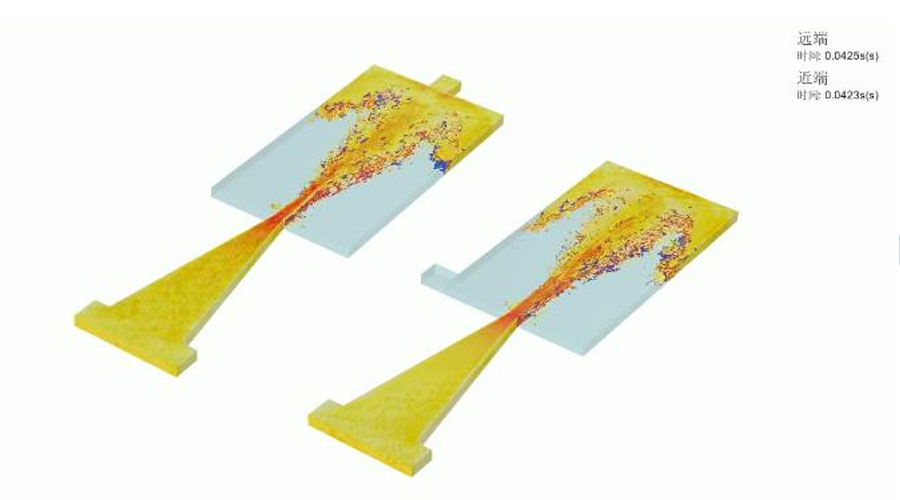

Ukuze kucaciswe kahle umbono ongaphezulu, amamodeli amabili ahlosiwe aklanywa, njengoba kukhonjisiwe kumanani 5 no-6 ngezansi. Ukulingiswa kokugcwalisa isikhunta sokufa kwenziwa ngokusebenzisa ipulatifomu yokuphonsa ifu lokuphonsa ifu lamaShayina ukubona ukugeleza kwe-alloy encibilika emgodini futhi uqonde ngokuqonda umehluko phakathi kwalezi zindawo ezimbili zokuvala i-valve kunqubo yangempela yokuphonsa.

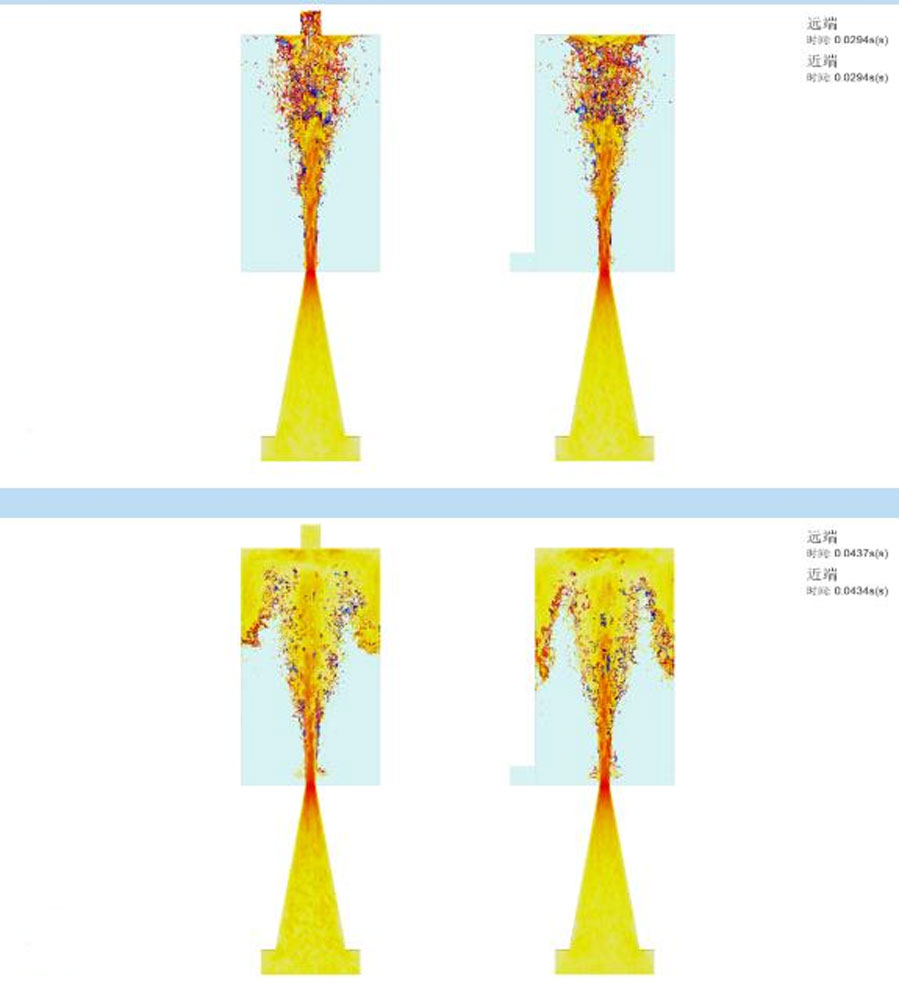

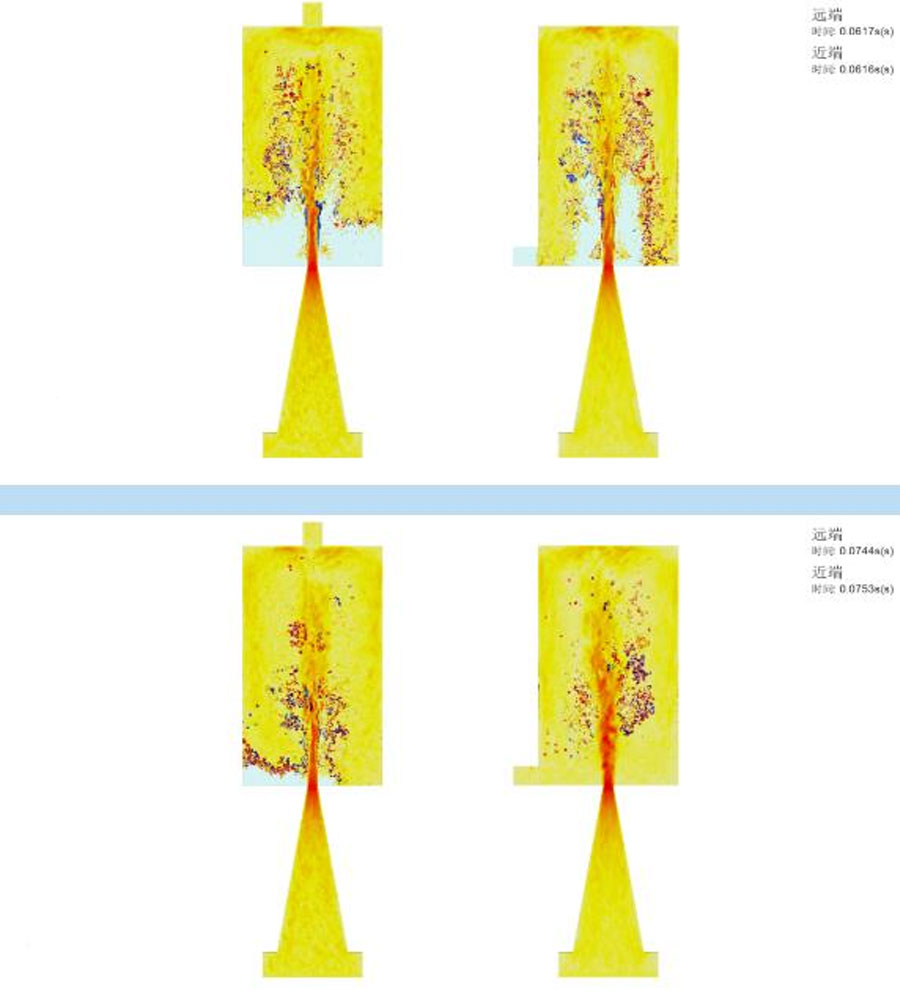

Ukuqhathaniswa Kwemiphumela Yokulingiswa Kwefu LaseChina

Esibonelweni esingakwesobunxele, lapho i-valve yokuhlanza itholakala kude nesango, i-valve yomshini ivinjiwe ekuqaleni kokugcwaliswa;

Esibonelweni esingakwesokudla, lapho i-valve yokuhlanza itholakala eduze kwesango, i-valve yomshini izoqhubeka nokusebenza ngesikhathi senqubo yokugcwalisa

Kuyabonakala ukuthi ukwakheka kweveluvu yokuhlanza kuMfanekiso 5 impela kuyaphikisana. Lapho insimbi encibilikisiwe igcwaliswa, i-vacuum valve isivele ivinjiwe, futhi i-vacuum valve kuMfanekiso 6 ingagcina ukugeleza okuphezulu okungavinjelwe, okubalulekile ekuqedeni i-vacuum. Isikhathi (cishe ama-40ms kulesi sibonelo). Vele, lesi sibonelo semodeli silula. Emsebenzini wangempela wokuklama nokuthuthuka, ukwakheka kwesikhundla se-vacuum valve kungasebenzisa amandla wokulingisa wokufa wokulingisa we-China Die-casting platform computing cloud ukuthola isikhundla sayo esihle.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ungasithola Kanjani Isikhundla Esihle Kakhulu Sokuvungula Umshini Ku-Die Cast Tooling?

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off