Amathrendi Wocwaningo Ekwelashweni Kokushisa Kwama-Alloys Amelana Nokushisa Nama-Superalloys

Enye yezingqinamba ezibaluleke kakhulu ekwakhiweni kwamasethi kagesi ka-700 ℃ omphunga we-A-USC ukuthuthukiswa kwama-alloys amelana nokushisa kwabaphehla ugesi. Abanye abacwaningi bakhiqize i-Ni-0.05C-18Cr-13Co-9Mo-1.3Al-1.4Ti-0.1Ta-0.3Nb alloy esekwe ku-Inconel 617 njengezinto eziyisisekelo futhi yathuthukisa ukwakheka kwe-alloy, futhi kwenziwa inhlolovo impeller isampuli elingisa impeller yomshini wangempela. Kunemibiko yocwaningo ngezinto ezibonakalayo zezingxenye ezahlukahlukene zesampula yempepho.

Kuhlolisiswe ezinye izinto zokusakaza ezingasetshenziswa kuma-generator e-A-USC anezinga lokushisa lomusi elingu-700 ℃. Mayelana ne-Ni-0.04C-26Cr-21Co-1Al-1.9Ti-1.8Nb alloy, ama-castings akhiqizwe ngesivivinyo anosayizi odongeni obunamasentimitha ama-3 enziwe kwenziwa nezinto zokuhlola. Umbiko wocwaningo wethule umthelela wobandlululo emandleni okungena.

I-superalloy esekwe e-Ni-Fe kulindeleke ukuthi ibe yizinto zokuphehla ugesi ophehlwa u-A-USC. Kodwa-ke, ukuze kuqinisekiswe izici nokwenziwa kokufakwa kwe-turbine, kubalulekile ukulawula izinto zokulandela umkhondo. Kusenamaphuzu amaningi angacacile mayelana nomthelela wezinto ezilandelwayo kuma-superalloys asuselwa eNi-Fe kulabo abasebenzisa i-turbine. Ngakho-ke, abanye abacwaningi baphenye umthelela wezinto ezilandelwayo ngokuya ngezici ezinwabuzelayo.

Enqubeni yokuthuthukisa i-generator engu-700 ℃ -class A-USC, ukuze kusetshenziswe izinto zokufaka izinto ezihlanganisiwe ezifakwe ku-Ni-based kanye ne-Fe-based impellers, ukuzinza kwesakhiwo nezakhiwo zomshini we-impeller okushisayo okushisayo zahlongozwa. Faka isicelo. Abanye abacwaningi bakhiqize okokushisela okungaphansi kwe-alloy steel / Inconel 617 njengesitayela esibonakalayo sezinto ezahlukahlukene ze-Fe / Ni, futhi bahlola umphumela wokuguga okushisayo ekushintsheni kwe-microstructure kwesixhumi esibonakalayo se-welding.

Ukuze kwehliswe ukukhishwa kwe-CO2, kwenziwe ucwaningo olunzulu ngemishini ye-A-USC. I-23Cr-45Ni-7W alloy (ASTM UNS N06674) yinto ethuthukisa amandla okuhamba ngokuqinisa imvula yezigaba ze-M23C6 neLave. Ingasetshenziswa njengenye into ehlukile yamashubhu e-A-USC aphezulu ashubisa umusi namashubhu wokubilisa. Abanye abacwaningi bahlole umthelela wezimpawu zokungena kwe-alloy ekuziphatheni kwesimo sokuzinza kwesigaba seLave.

Ukuze uthuthukise ama-generator e-A-USC anezinga lokushisa lomusi elingu-700 ℃, kungenzeka ukuthi kusetshenziswe ama-alloys amelana nokushisa kwe-Ni njengoba izingxenye zebhayela zafundwa, futhi kwavezwa ukuthi ingxubevange 617, eyi-alloy eqinisa imvula , ine-relaxation ngenkathi kusetshenziswa izinga lokushisa okuphezulu. Ukuqhekeka (ukuqhekeka kwe-SR) nezinye izindaba ezihlobene. Ngakolunye uhlangothi, ingxubevange ye-23Cr-45Ni-7W (ASME-CC2684), engasisebenzisi lesi sigaba njengesigaba sokuqinisa imvula, inamandla okuqhekeka okuphansi kancane ku-700 ° C kunaleyo ye-alloy 617, ngenkathi Ingxubevange ye-30Cr-50Ni-W ayinqamulwanga. Iyaqiniswa, kepha amandla okuqhekeka enyuka ephakeme kunalawo we-23Cr-45Ni-7W alloy. Ukuthamba kwayo kanye nokumelana nokuqhekeka kwe-SR kuhle. Ingasetshenziselwa i-A-USC main steam pipe. Umbiko wocwaningo wethule izinhlobo ezine zezakhiwo, izakhiwo zemishini kanye nezimpawu zokuhamba kwamapuleti namapayipi akhiqizwa ngobukhulu.

Njengamanje, inkinga yamandla seyiyinkinga ebaluleke kakhulu. Ukuze kuthuthukiswe ukusebenza kahle kokukhiqizwa kwamandla kagesi ashisayo njengoba izindlela eziphambili zokuhambisa ugesi, kwenziwe ucwaningo olunzulu nentuthuko kuzinsimbi ezakhiwe ze-Ni-based. Ukuze kuzinze isigaba sokuqinisa se-Ni-based superalloy, isakhiwo sesigaba, hhayi kuphela isimilo sokuziphatha kwesigaba esizoba nomthelela obalulekile, kepha futhi noshintsho lwe-morphological olubangelwa ukungafani kwe-lattice phakathi kwalo nesigaba somzali. Yiba nomthelela obalulekile. Kodwa-ke, ucwaningo lwalezi microstructures ikakhulukazi ucwaningo olwenziwe kuma-superalloys asuselwe eNi anezinga eliphakeme levolumu yesigaba, kanti ucwaningo kuma-alloys wabalingisi lumbalwa kakhulu. Ngakho-ke, eminye imibiko yocwaningo iphenye ubudlelwano obuphakathi kokushintshwa kwesakhiwo sesigaba kanye nokungahanjiswa kahle kwe-lattice ku-alloy eyakhiwe nge-Ni.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Amathrendi Wocwaningo Ekwelashweni Kokushisa Kwama-Alloys Amelana Nokushisa Nama-Superalloys

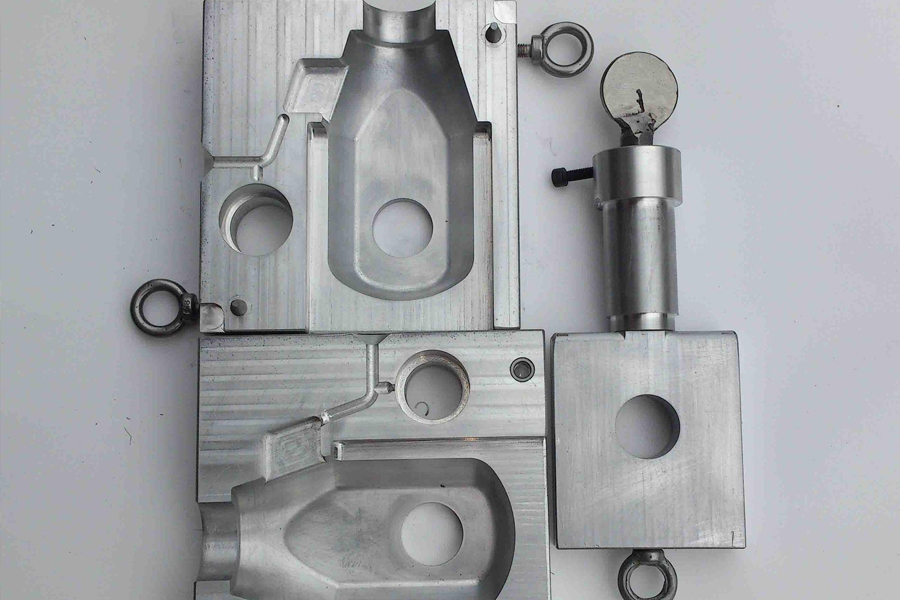

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off