Ubuchwepheshe Bokuphonsa Ingcindezi Ephansi ye-Aluminium Alloy Cylinder Head ye-Passenger Car Engine

Ngokucatshangelwa okuphelele kwezindleko nezakhiwo zemishini, ukwandisa ukusetshenziswa kwe-aluminium alloy njengamanje kuyindlela eyinhloko yokunciphisa isisindo sezimoto zabagibeli nokunciphisa ukusetshenziswa kukaphethiloli. Isibonelo, ikhanda lesilinda lenjini manje selenziwe ngokuphelele nge-aluminium alloy. Yize kunezindlela eziningi zokukhiqiza zamakhanda e-aluminium alloy cylinder, izinqubo ezijwayelekile zokukhiqiza ziyisikhunta sensimbi sokuphonsa nokucindezela okuphansi. Phakathi kwabo, iYurophu neChina ikakhulukazi basebenzisa isikhunta sensimbi, kuyilapho iJapane ne-United States basebenzisa ingcindezi ephansi bephonsa okuningi.

Uma kuqhathaniswa namandla adonsela phansi wensimbi, ukukhishwa kwengcindezi ephansi kunezinzuzo zekhwalithi enhle yokwakha kanye nenqubo ephezulu yesivuno ngenxa yokugcwaliswa kanye nokuqina kwekristalu ngaphansi kwengcindezi, kepha nge-cylinder head castings enezimo eziyinkimbinkimbi nezidingo zokusebenza okuphezulu, kunezinqubo eziyinkimbinkimbi, Ukulawulwa kudinga izinkinga zobuchwepheshe ezithuthukile. Ngakho-ke, le ndatshana igxile kubuchwepheshe bokuphonsa obunengcindezi ephansi yamakhanda e-aluminium alloy silinda namaphuzu asemqoka wokulawulwa kwepharamitha, ukuze kudlalwe ngokugcwele kuzinzuzo zobuchwepheshe zenqubo yokukhipha ingcindezi ephansi futhi ikhiqize ukukhishwa kwekhwalithi ephezulu yamasilinda .

Amaphoyinti abalulekile wenqubo yokuphonsa ingcindezi ephansi yekhanda lesilinda

2.1 Isibonelo sohlelo lwesango

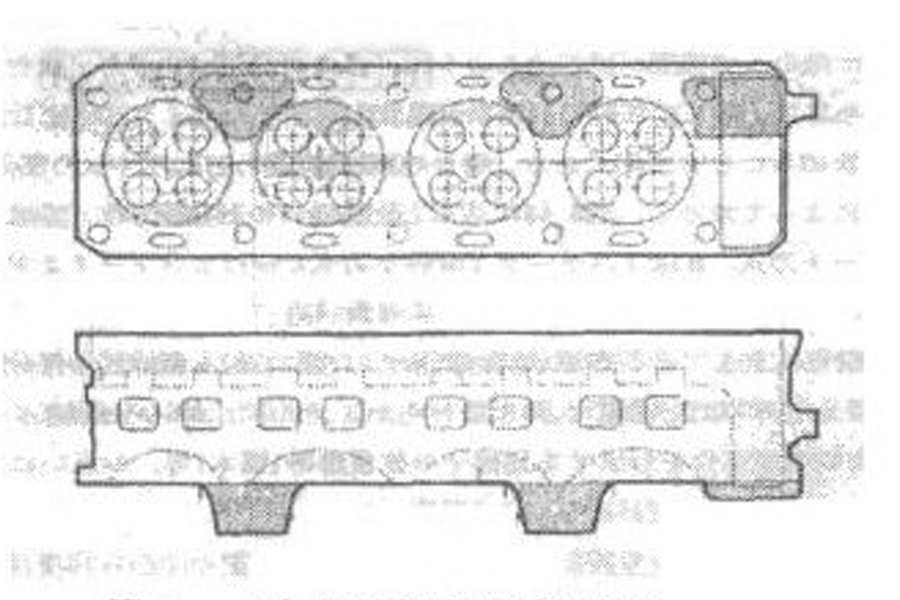

Uhlelo lwenqubo yokukhipha ingcindezi ephansi yekhanda lesilinda ngokuvamile lisesimeni sepayipi elikhuphuka namasango amaningi, okuluhlobo lokuqhekeka kwesisindo esiningi. Isibonelo, ikhanda lesilinda lamasilinda amane linezinhlelo ezimbili zokumela, okungukuthi, amasango amabili noma amane abekwe eceleni kwegumbi lokushisa. Umdwebo 2 umdwebo wesakhiwo senqubo yamasango amabili. Lolu hlelo lufanele isikhunta esisodwa noma isikhunta ezimbili.

2.2 Izinto ze-alloy nokuncibilika

Okokusebenza kwekhanda le-aluminium alloy cylinder ngokuvamile kukhetha ama-alloys ochungechunge we-AI-Si-Cu afana ne-ZL105 kanye ne-107. Ukuze uthole insimbi esezingeni eliphezulu encibilikisiwe, ukusebenza okujwayelekile kufanele kusebenzise i-Ar igesi ejikelezayo yokugaya ukucwenga nokwengeza i-Sr ukushintsha ne-AJ-Ti-B ukucwenga izinhlamvu.

2.3 Inqubo yokuthela

2.3.1 Ukugcinwa kwesikhunta

Ukuhlanzwa njalo nokunakekelwa kwesikhunta kubaluleke kakhulu ekukhiqizeni okuzinzile kwekhwalithi ephezulu yamasilinda ekhanda nokwelula impilo yenkonzo yesikhunta. Ngokuvamile, ukugcinwa kwesikhunta kufanele kwenziwe ngemuva kokuthi kukhiqizwe izingcezu ezingama-500-700. Okuqukethwe okuyinhloko ukuqaqa isikhunta, ukuhlanza indawo yokumboza yomgodi ngebhulashi elithambile, bese ususa ama-aluminium chips nezinhlayiya zokumboza ezingena esikhaleni esiphakathi kwenduku ye-ejector nomgodi wokukhipha. , Ukuqinisekisa ikhwalithi yesimo sokusakaza, ukukhishwa okushelelayo nokukhipha okushelelayo.

2.3.2 Ukugqoka

Ngaphambi kokuthela, isikhunta sifudunyezwa sibe cishe ngama-200 ℃ bese sifuthwa ngopende. Ukuma kwekhanda lesilinda kuyinkimbinkimbi, ngakho-ke ukunakwa okukhethekile kufanele kukhokhwe kusayizi ohlukile wepende ezingxenyeni ezihlukile. Ubukhulu bokumbozwa kwezingxenye ezijwayelekile bulawulwa ngaphakathi kwe-0.1 --- 0.2mm: izidingo zokunemba ziphakeme. Isibonelo, indawo yegumbi lokushisa kufanele ifakwe izinhlayiya ezinhle ngobukhulu be-O.OSmn. Okwamasango, ukukhuphuka, abagijimi bangaphakathi nezinye izindawo ezidinga ukuqiniswa kancane, kungaba mkhulu, ngokuvamile cishe ngo-0.5-1 mm.

2.3.3 Hlunga

Inhloso yokubeka okokuhlunga ukuvikela ukungcola kwe-oxide kushubhu ekhuphuka ekungeneni emgodini nokwakha ukugcwaliswa kwe-laminar. Ingasetshenziswa imishini yensimbi eshibhile futhi esebenzayo, ubukhulu bocingo bungu -4-0.6mm, 1214 mesh.

Ukushisa okungu-2.3.4

Izinga lokushisa le-aluminium encibilikisiwe linomthelela omkhulu emaphutheni angaphakathi ekhanda lesilinda nekhwalithi yokubukeka. Izinga lokuthela kufanele libe phakathi kobubanzi obungu-680-730, futhi ukuphambuka kokushisa ekusebenzeni kwangempela kufanele kulawulwe kungakapheli ama-20 ° C.

Isici sokuphonsa okuphansi kwengcindezi ukuthola ukuqiniswa okuhle okulandelanayo. Ngemuva kwalokhu, kubalulekile ukulawula ukushisa kombiko ukuthi kube ngokulingene ekusakazweni kwengcindezi ephansi. Ukusatshalaliswa kokushisa okuhle kwesikhunta kuncishiswa kancane kancane kusuka esangweni kuya kwisikhunta esiphezulu, futhi uhla oluthile lokulawula ubuso lwengxenye ngayinye luyashintshwa ukuze luthole. Inkambu yezinga lokushisa eshiwo ngenhla kanye nokwenza ngcono ukusebenza kwe-cylinder head castings nokunciphisa umjikelezo wokukhiqiza kufanele kuphoqelelwe kusikhunta esingenhla nasembumbeni oseceleni. yehlisa umoya. Ngokuvamile ihlukaniswe ngamanzi apholile napholile, kusetshenziswa izilungiselelo zeziteshi eziningi, isiteshi ngasinye silawulwa ngokuzimela (ukugeleza nengcindezi). Ukupholisa kwamanzi kusebenzisa ipompo lamanzi elinika ingcindezi ukuxazulula inkinga yokungahambi kahle kwamanzi okubangelwa ukuphefumula okushisa okuphezulu ngaphakathi kwesikhunta, futhi umoya ocindezelweyo usetshenziselwa ukupholisa umoya.

Ngoba ikhanda lesilinda linamasango amaningi, ibanga elifushane phakathi kwamasango womabili lizodala ukuthi izinga lokushisa kwengxenye yokukhipha phakathi kwamasango ikhuphuke, kanye nokulandelana kokuqina kwesango nale ngxenye kuzobuyiselwa emuva. Ngakho-ke, ukupholisa okuphoqelelwe kwasendaweni kufanele kusethwe kule ngxenye ukuthola i-gradient yokushisa edingekayo.

Uma ucabanga ngempilo yesikhunta nokuphepha, ukupholisa okungaqondile kufanele kube yindlela eyinhloko yokupholisa, futhi ukupholisa okuqondile kungasetshenziswa lapho ubukhulu bokusakazwa kwasendaweni kukhulu khona. Kunezindlela ezimbili zokuqina kokupholisa: ukulawula isikhathi nokulawula izinga lokushisa. Ukulawulwa kwesikhathi ukulawula isikhathi sokudlula kwamanzi noma umoya. Le ndlela ilula futhi kulula ukuyisebenzisa, kepha ukunemba akuphezulu. Ukulawulwa kwethempelesha ukusetha i-thermocouple endaweni yokupholisa, futhi i-PC izovula noma icishe amanzi okupholisa noma umoya ngokuya ngamazinga okushisa alinganiswa yi-thermocouple. Ukunemba kokulawula kuphezulu kakhulu.

Eminyakeni yamuva nje, ukuthuthukiswa kobungqingili bezinombolo zokulingisa ubuchwepheshe kunikeze ireferensi enhle yokwenza kahle inqubo yokuphonsa ingcindezi yamakhanda wesilinda. Ingayiqonda ngokugcwele imiphumela yokuqina yokuqina ngaphansi kwezimo ezahlukahlukene, iqinise ukulawulwa kwenqubo yokusakaza, futhi iqinisekise ikhwalithi yokulingiswa.

2.3.5 Isikhathi sengcindezi

Isikhathi esisuka ekugcwaliseni nasekuqiniseni isango sibizwa ngokuthi yisikhathi sokushicilela, esithinteka kakhulu ukushisa. Ngaphansi kwezimo zokukhiqiza ezizinzile, yize isikhathi sokucindezela sihluka ngesisindo sekhanda lesilinda, ngokuvamile silawulwa ku-2-8min. Ngokombono wokwenza ngcono ukusebenza kahle kokukhiqiza, izindlela ezifana nesikhunta esisodwa, izingxenye ezimbili, ukucindezela kwesigaba ezimbili, njll kungasetshenziswa ukunciphisa isikhathi.

2.3.6 Isikhathi sokukhishwa kwesikhunta

Njengesikhathi sokucindezela, siyashintsha ngenxa yezinguquko ekushiseni. Lapho isikhathi sifushane, ukusakaza kulula ukukhubazeka; lapho isikhathi siside kakhulu, ukusakaza kulula ukunamathela kusikhunta futhi akukwazi ukukhishwa. Ngakho-ke, ngokuvamile ilawulwa cishe ku-1/3 wesikhathi sokucindezela. Ukuze kwandiswe izinga lokupholisa lokusakaza, isikhunta eseceleni esinokumelana okuphansi kwesikhunta singavulwa kuqala lapho isikhunta sidonswa, futhi isikhunta esingenhla singavulwa ngemuva kokupholisa isikhathi esithile.

2.3.7 Ijika lengcindezi

Ingcindezi yokucindezela ithinta ngqo ukusebenza kokugcwalisa uketshezi nomphumela wokudla wensimbi encibilikisiwe, futhi ijika lokucindezela liyingxenye ebalulekile yokulawulwa kwenqubo yokuphonsa ingcindezi ephansi. Ingcindezi yokucindezela ingabalwa ngale ndlela elandelayo:

P = γx (1 + S / A) x ΔH x 10-2

Kule fomula engenhla, i-P-pressure (MPa), i-γ-aluminium gravity ethile (2.4-2.5), ΔH-aluminium liquid rising rising (m), S-lift pipe cross-sectional area (m2), A-cavity cross indawo enesigatshana (m2) o

Ingcindezi yokuphakelayo kukhuphuka ngokuvamile imayelana ne-0.005-0.01MPa. Yize umphumela wengcindezi ephezulu muhle, uma ingcindezi yeqa u-0.01 Mpa, izodala ukuthi upende ucwebe, uketshezi lwe-aluminium luzovimba umoya wesikhunta bese lungena emgodini wesihlabathi. Kuyadingeka kakhulu ukukhipha igesi eyenziwe ngomlilo womgogodla wesihlabathi ngesikhathi ngenqubo yokuthela, kepha ngenxa yokuthi ingqimba yesihlabathi esetshenziswe ekhanda lesilinda inesakhiwo esiyinkimbinkimbi nenombolo enkulu kunazo zonke, kunzima ukusetha inombolo enkulu izimbobo zokukhipha isikhunta. Ngalesi sikhathi, ukukhuphula ingcindezi ye-feeder ye-feeder kuye eduze komkhawulo ongaphezulu kungavimba ngempumelelo ukuthi igesi lingabandakanyeki ekusakazweni.

Ukushintshwa kwezinga loketshezi emhumeni wezithelo ezisawolintshi kuthinta ukuphindaphindeka kwejika lengcindezi, ngakho-ke ingcindezi yenhlekelele ye-citrus kufanele inxeshezelwe ngokuzenzekelayo. Ngokuphonswa kwekhanda lesilinda, izinzwa zingasethwa ukulawula ngokunembile iphuzu likaziro I81 wejika lengcindezi.

Ngaphezu kwalokho, uma isikhawu esiphakathi kwengxenye engezansi yepayipi elikhuphuka kanye nangaphansi kwe-crutch orange sincane kakhulu, ikhambi lizoveza kalula ukugeleza okunesiyaluyalu. Ngakho-ke, ngaphandle kokuthinta ukusetshenziswa kwesixazululo, ibanga eliphakathi kwengxenye ephansi yepayipi elikhuphuka kanye nangaphansi kwembiza ye-orange cishe liyi-200mm.

Ukusakaza ukukhubazeka nezinyathelo zokulwa

Ithebula 1 libala ukukhubazeka okuvamile kokuphonsa ingcindezi ephansi kanye nezinyathelo ezizothathwa. Engxenyeni eyinkimbinkimbi efana nekhanda lesilinda, ukushintshashintsha kwemingcele ehlukahlukene kungathinta ikhwalithi yokusakaza. Ngakho-ke, kuyadingeka ukwenza ukuhlaziywa okuningiliziwe nokuphenywa ngezici ezahlukahlukene ezinjengecebo lenqubo, ukwakheka kwe-stencil, inqubo yokusakaza, njll ukucacisa izimbangela ezahlukahlukene zokukhubazeka, nokuthatha izinyathelo ezihambisanayo ngalesi sizathu.

Isiphetho

Kuze kube manje, amakhanda e-aluminium alloy cylinder angenye yezingxenye ezimbalwa zomkhawulo ezilinganiselwe ezifanele ukusakaza okuphansi kwengcindezi. Ngakho-ke, badlala ngokugcwele ezinzuzweni zokukhiqizwa okuphezulu nekhwalithi yangaphakathi enhle yokwandisa ukukhiqizwa nokusetshenziswa kobuchwepheshe bokuphonsa obuphansi basekhaya emakhanda e-aluminium alloy cylinder. Ukuzivumelanisa nentuthuko esheshayo yobuchwepheshe bezimoto ezweni lami.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Ubuchwepheshe Bokuphonsa Ingcindezi Ephansi ye-Aluminium Alloy Cylinder Head ye-Passenger Car Engine

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off