I-Development Trend Of Automobile Castings Nobuchwepheshe Bayo Bokukhiqiza

Ukulingisa kungenye yezindlela ezindala zokwenza insimbi. Cishe i-15% kuye ku-20% yezingxenye ezizenzakalelayo kungukusakaza okukhiqizwa izindlela ezahlukahlukene zokulingisa. Lokhu kusakazwa ikakhulukazi izingxenye ezisemqoka zohlelo lwamandla nezakhi ezibalulekile zesakhiwo. Njengamanje, ubuchwepheshe bokukhiqiza bokuphonswa kwezimoto emazweni athuthukile ezimbonini zezimoto zase-Europe naseMelika sekuthuthukile, nekhwalithi yomkhiqizo omuhle, ukusebenza kahle kokukhiqiza nokungcoliswa kwemvelo okuphansi. Ukulingisa izinto zokusetshenziswa eziluhlaza nezisizayo zenziwe zafakwa i-serial futhi zenziwa zangqinwa, futhi yonke inqubo yokukhiqiza iye yanomshini, yasebenza ngokuzenzakalela, futhi ihlakaniphile. Lawa mazwe ngokuvamile asebenzisa ubuchwepheshe bedijithali ukuthuthukisa izinga lokuklanywa kwenqubo yokusakaza. Izinga lokwenqatshwa kokuphonsa cishe liyi-2% kuya ku-5%, futhi uhlelo lwamazwe omhlaba selusunguliwe futhi ukwesekwa kobuchwepheshe benethiwekhi sekuqalisiwe. Ngokuphambene nalokho, yize ukukhishwa kwezimoto ezweni lami kukhulu ngokuqhathaniswa, iningi lazo kungabantu abamnyama abanenani elingeziwe eliphansi kanye nokuqukethwe kwezobuchwepheshe, nesakhiwo esilula, esikude nezinga langaphandle. Le ndatshana ikhuluma kakhulu ngokuqondiswa kokuthuthukiswa kokuphonswa kwezimoto nobuchwepheshe bezimoto kusuka ezidingweni zokuthuthuka zokonga amandla ezimoto nokuvikelwa kwemvelo.

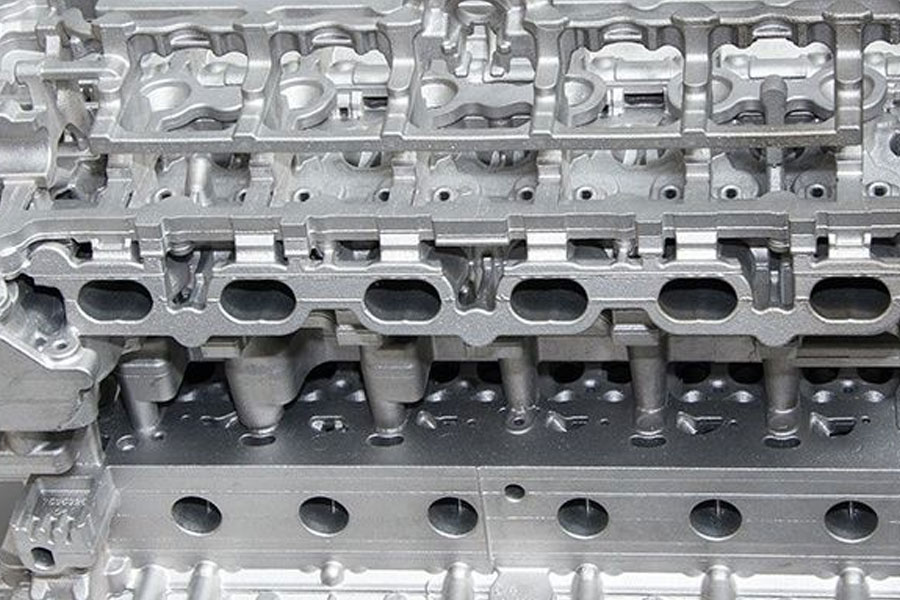

Idizayini edidiyelwe yokuphonswa kwezimoto

Ngezidingo ezandayo zokongiwa kwamandla nokuvikelwa kwemvelo kwezimoto nokuncishiswa kwezindleko zokukhiqiza, sizosebenzisa ngokugcwele izinzuzo zokuphonsa ukuze siqaphele ukusakazwa kwezingxenye ezihlanganisiwe ngokuklanywa okunengqondo nokwenziwa okuhlelekile kwezingxenye eziningana ezakhiwe ngonyathela, ukushisela, UKWAKHA futhi ekubunjweni. Ukwakha kunganciphisa ngempumelelo isisindo sezingxenye futhi kunciphise izinqubo zokucubungula ezingadingekile, ngaleyo ndlela kufinyelelwe izingxenye ezingasindi nezisebenza kahle.

Ifomu eliyinhloko lezindlu ezijwayelekile ze-ekseli le-monolithic axle ukuthi amapayipi wensimbi angenamthungo acindezelwa emaphethelweni womabili wezindlu ze-axle njengemikhono ye-axle axle futhi alungiswa ngezikhonkwane ukwakha umhlangano wezindlu ze-axle. Ukuze kuqhutshekwe kwenziwe ngcono amandla nokuqina kwendlu ye-ekseli futhi yenze inqubo ibe lula, iQembu le-FAW lenze izindlu ezihlangene ze-ekseli lapho imikhono ye-ekseli (izingxenye ezinhlangothini zombili zezindlu ze-asi ku-Figure 1) ziphonswa ngqo izindlu ze-axle. Ukucubungula kunzima, ukwehliswa kwezindleko kungaphezulu, ukwakheka kwezindlu ze-asi kuvame ukuba lula, futhi ukuqina kwe-axle izindlu kungcono, kungenziwa kube isimo esiyinkimbinkimbi nesikahle, ukujiya kodonga kungashintshwa, ukusatshalaliswa kokucindezeleka okuhle kungatholakala, namandla ayo futhi ukuqina kokubili kukhulu, Kusebenza ngokuthembekile. Ngenxa yokuhlanganiswa komkhono we-axle, ubukhulu bokusakaza bukhuphuke kakhulu. Ubude bokuphonsa bungu-2 258 mm, kanti isisindo saso esisodwa singaphezu kwama-200 kg. Ngenxa yezici zalokhu kuqoshwa okuhlanganisiwe, inkampani isungule ulayini wokukhiqiza ozinikele ukuqinisekisa ukukhiqizwa.

Umkhuba wokuthuthuka wokuhlanganiswa kokuphonswa kwezimoto ubonakala kakhulu ekwakhiweni kokuphonswa kwe-non-ferrous alloy. Ukuze usebenzise ngokugcwele izici zenqubo yokusakaza engafinyelela ekukhiqizeni ukwakheka kwesakhiwo esiyinkimbinkimbi, ukwakheka okuhlanganisiwe kokuphonswa okuphezulu kwengcindezi njengamaphaneli angaphakathi omnyango, amafreyimu ezihlalo, amafreyimu wezinsimbi zensimbi, amafreyimu angaphambili kanye nama-firewall anakho kwavela. Ubukhulu bukhulu kakhulu kunalokho okwenziwa manje. Okokuphonsa, umshini wokulingisa wokufa onethani lamathani ayi-4 000 kuye ku-5 000 noma nangaphezulu uyadingeka ekukhiqizeni.

Ukungasindi kokuphonswa kwezimoto

Esimeni sokuqinisekisa ukuqina nokuphepha kwemoto, nciphisa isisindo semoto ngangokunokwenzeka ukuze uzuze isisindo esincane, ngaleyo ndlela kuthuthukiswe amandla emoto, kunciphise ukusetshenziswa kwephethiloli, futhi kunciphise nokungcola kokukhipha. Ekunciphisweni kwesisindo samakhilomitha ayi-100 esisindo semoto, ukusetshenziswa kukaphethiloli ngamakhilomitha ayi-100 kungancishiswa ngo-0.3 kuye ku-0.6 L. Uma isisindo semoto sehliswa ngo-10%, ukusebenza kahle kukaphethiloli kungakhuphuka ngo-6% kuye ku-8%. Njengoba kunesidingo sokuvikelwa kwemvelo nokonga amandla, ukungasindi kwezimoto sekuyindlela yokuthuthuka kwezimoto emhlabeni, kanti ukusindwa kwezimoto okusetshenzisiwe nakho kube ngenye yezinkomba ezibalulekile zokuthuthukiswa kwezimoto ezisakazwayo.

Idizayini engasindi yokuphonswa kwezimoto

Ngenxa yesidingo sokuphepha okuphelele kokuphonswa, ukwakheka kobukhulu obulinganayo kungenye yezindlela eziyinhloko zokwakhiwa kokuphonswa kwezimoto. Kodwa-ke, okubi okuyinhloko kokuklanywa kobukhulu obulinganayo ukuthi ukusebenza kwesakhiwo akunakusetshenziswa ngokuphelele, futhi isisindo sokuphonsa siyakhuphuka. Sebenzisa ukuhlaziywa kwe-CAE, ukwenziwa kwe-topology nezinye izindlela zokwengeza ukwakheka kwezingxenye, ukuze amanani wokucindezela wezingxenye zezingxenye asondele, okungukuthi, ukushuba kodonga lwengxenye ngayinye akuhambelani, nezingxenye ezinokuncane amabutho ancishisiwe noma akudingekile ukunciphisa izingxenye. isisindo se. Uma ucabanga ukuthi ukusakaza ukwakha kungaqaphela ukwakheka kwesakhiwo esiyinkimbinkimbi, izingxenye ezahlukahlukene ezingafani ezimile zingafinyelelwa. Lapho udizayina, sebenzisa i-CAE noma i-topology optimization ukwenza ukuhlaziywa kwengcindezi kuzinto. Ngokusatshalaliswa kwamandla, nquma ukwakheka kwengxenye nobukhulu bezinto zengxenye ethile. Ngokuqinisa, ukumba izimbobo nokuqinisa ukusakazwa, isisindo sezingxenye singancishiswa kakhulu.

Ingxubevange ekhanyayo yokusakazwa kwezimoto

Ukusetshenziswa kwezinto zokukhanya ze-alloy ezifana ne-aluminium ne-magnesium njengamanje okuyisilinganiso esikhulu sokunciphisa isisindo esamukelwa abakhiqizi bezimoto emazweni ahlukahlukene. Ubuningi be-aluminium bungu-1/3 kuphela waleyo yensimbi, futhi inokumelana okuhle nokugqwala nokuthamba. I-Magnesium inesisindo esiphansi, i-2/3 kuphela ye-aluminium, futhi ine-fluidity enhle kakhulu ngaphansi kwezimo zokuphonsa ezinengcindezi ephezulu. Amandla athile (amandla esilinganiso sobukhulu) we-aluminium ne-magnesium aphezulu kakhulu, adlala indima ebalulekile ekunciphiseni isisindo sakho nasekuthuthukiseni ukusebenza kahle kukaphethiloli. Ukuncintisana okwandayo kwemboni yezimoto yaseMelika eminyakeni emibili edlule kuhlobene kakhulu nokwamukelwa kwayo okukhulu kwe-aluminium-magnesium castings castings kanye nokuhlanganiswa okuhlanganisiwe.

Uchungechunge olusha olungu-5 olwethulwe yinkampani yaseJalimane iBMW lufakelwe isizukulwane sakamuva se-magnesium-aluminium composite ku-line eziyisithupha-cylinder block block, isisindo sincishiswe ngo-10 kg uma kuqhathaniswa nesizukulwane esedlule, esithuthukisa kakhulu ukusebenza nophethiloli umnotho. Kodwa-ke, kufanele kuqashelwe ukuthi intengo yezinto zokusetshenziswa zama-alloys alula njenge-aluminium ne-magnesium iphakeme kakhulu kunaleyo yensimbi, ekhawulela ukusetshenziswa kwayo okubanzi embonini yezimoto. Kodwa-ke, ngaphandle kwentengo ephezulu kakhulu yezinto zokusetshenziswa, ukusetshenziswa kwamanje kwe-magnesium ne-aluminium castings yamabhayisikili bekukhuphuka unyaka nonyaka. Ngakolunye uhlangothi, inqubekela phambili yezobuchwepheshe yenzele ukwanda kwezindleko. Ngakolunye uhlangothi, ukuncintisana kwezimakethe kuphoqe abenzi bezimoto ukuthi banciphise inzuzo futhi basebenzise ama-alloys alula kakhulu. Kodwa-ke, ukukhulisa kakhulu inani lama-alloys akhanyayo nokunciphisa intengo yokuthenga yama-magnesium nama-aluminium ingots, ukuthuthukiswa kobuchwepheshe obuthuthukile kungenye yezihluthulelo.

Ukusebenza High yezimoto ekubunjweni izinto

Ukwenza ngcono ukusebenza kwento, ukuze isisindo seyunithi sikwazi ukumelana nemithwalo ephakeme, kungenye yezindlela zokwehlisa ngempumelelo isisindo sokusakaza. Uhlobo lwabakaki lokulingiswa kwesakhiwo lubanga ingxenye enkulu yokuphonswa kwezimoto, ngakho-ke ukuthuthukiswa kokuphonswa kwayo kube ngesinye sezinto okugxilwe kuzo. Ngokusebenzisa ukwelashwa kokushisa nezinye izindlela, ukwakheka kwezinto ezincane kuyashintshwa, ngaleyo ndlela kuthuthukiswe amandla, ukuqina noma ukuqina kwezingxenye, ezinganciphisa ngempumelelo isisindo sezingxenye.

I-Austempered iron ductile ayinamandla amakhulu kuphela kunezinto ezijwayelekile zensimbi, kepha futhi inamandla amancane kunensimbi. Ubuningi bayo bungu-7.1 g / cm3, kanti ubukhulu bensimbi engu-7.8 g / cm3, okuyizinto ezinconywe kabanzi eminyakeni yamuva. . Yamukela i-austempered ductile iron, eyi-10% elula ngaphezu kokuphonswa kwensimbi ngaphansi kosayizi ofanayo wokuphonsa. IDongfeng Motor Corporation yenze umsebenzi wokuqinisekisa ongasindi ohlotsheni oluthile lwemoto yezentengiselwano isebenzisa i-austempered ductile iron esikhundleni sokuphonsa insimbi. Ngokubheka kwezimpawu zamandla aphakeme ezingxenyeni zensimbi ezenziwe nge-ductile, izingxenye zokumiswa eziyi-14 zakhiwe kabusha esithangamini sabachwepheshe. Ngokuvamile, ukushintshwa kwezinto ezibonakalayo zokuphonswa kwezimoto kuvame ukuhambisana nokwakhiwa okungasindi kwezingxenye.

Ku-aluminium alloy ne-magnesium alloy castings, kusetshenziswa izinto ezinamandla amakhulu nokuqina okukhulu. Ngesisekelo sokwehliswa kwesisindo sokuqala se-alloy light, izinto zokusebenza eziphezulu zisetshenziselwa ukuqhubeka nokunciphisa isisindo. IGeneral Motors yase-United States isebenzisa ukusebenza kwe-AE44 ingxubevange esikhundleni salokho I-aluminium alloy yasekuqaleni isebenzisa ukusakaza okuphezulu ukuze ikhiqize ifreyimu engaphansi, iphinde yehlise isisindo se-aluminium alloy ngo-6 kg.

Ukufakwa kwedijithali kokuthuthuka kwezimoto

Inhlanganisela ebanzi yentuthuko yezimoto zokukhipha kanye nobuchwepheshe bedijithali bungathuthukisa kakhulu izinga lobuchwepheshe bokusakaza futhi bunciphise ukwakhiwa komkhiqizo nomjikelezo wokukhiqiza isivivinyo. Njengamanje, ubuchwepheshe bokukhiqiza bedijithali busetshenziswe kabanzi ekwakhiweni kokuphonswa kwezimoto. Esigabeni sokuklanywa kwesakhiwo nokwakhiwa kwenqubo, i-3D design software efana ne-Pro / E, i-CATIA, ne-UG isetshenziswe kabanzi, kanti ezinye izinkampani zokulingisa ezithuthukile ziye zaqaphela ukwakheka okungenamaphepha. Isoftware efana neMAGMA, i-ProCAST ne-Huazhu CAE isetshenziswe kabanzi ukulingisa inqubo yokuqinisa, ukwakheka kwemiklamo emincane, ukuhlukaniswa kokwakheka kanye nezinto ezibonakalayo zokuphonswa kwezimoto. Ingabuye ihlaziye inkambu ye-velocity, inkambu yokuhlushwa, inkambu yezinga lokushisa nesigaba kunqubo yokusakaza. Ukulingiswa kwezinkambu, izinkambu zokuxineka, njll., Kungaqinisekisa ukuthi uhlelo lwenqubo lwenziwa ngaphambi kokukhiqizwa ngobuningi.

Ukuze kuhlangatshezwane nezidingo zokuthuthuka okusheshayo kokuphonswa kwezimoto, ngokususelwa ekwakhiweni nasekuthuthukisweni kwe-CAD / CAE, i-RP (technology prototyping technology) isetshenziselwe kabanzi ukukhiqizwa kwesivivinyo esisheshayo sokuphonswa kwezimoto. Ngemuva kokuthola idatha yangempela ye-CAD / CAE, indlela yongqimba-nge-ungqimba yamukelwa ukuthola uhlobo lokuphonsa noma uhlobo lwesikhunta oludingekayo ukwakha ukusakaza ngokuhlanganisa, ukugoqa noma ukugcoba. Esokuqala singaba amasampula wokulingisa akhiqizwa ngesivivinyo ngokusakaza utshalomali, ukuphonsa ukhonkolo nezinye izindlela, kuyilapho okwakamuva kungasetshenziswa ngqo njengesikhunta ukwenza ama-cores esihlabathi, futhi ukusakazwa kungathelwa ngokusebenzisa ukumodeliswa komhlangano oyinhloko. Ngaphezu kwalokho, indlela ye-powder laser sintering (SLS) ingasetshenziselwa ukuqedela ngqo ukukhiqizwa kwama-cores esihlabathi kanye nokubunjwa kwesihlabathi, ukuze kutholakale isikhunta sesihlabathi esidingekayo ekukhiqizeni isivivinyo sokuphonswa. Okwenziwe isikhunta sangaphandle ngezakhiwo ezilula, amathuluzi womshini we-CNC angasetshenziswa ukucubungula i-CAM ngopulasitiki abasebenza ngomshini ukuthola ibhokisi eliyinhloko nephethini edingekayo ekukhiqizeni isivivinyo sokuphonswa, noma ukucubungula ngqo ibhulokhi yesihlabathi ukuthola isikhunta sesihlabathi sesikhunta sangaphandle ngqo.

Ngokuvamile, ubuchwepheshe bedijithali bungene kuzo zonke izici zokwenziwa komklamo, ukuthuthukiswa nokukhiqizwa kwesivivinyo, kuthuthukisa ngempumelelo ijubane nokusebenza kahle kokuthuthukiswa kokulingisa. Inkinga enkulu njengamanje ukuthi ubuchwepheshe bedijithali bokuklama, ukuhlaziywa, nokukhiqiza okusheshayo kuzimele komunye nomunye. Lapho inqubo yentuthuko iguqulwa kusuka esigabeni esisodwa kuya kwesinye, umsebenzi wokuguqula idatha oyisidina nawo uyadingeka. Kuyathenjwa ukuthi ngokuzayo, ipulatifomu ebumbene yedatha yokuxhumana ingahle ithuthukiswe kubuchwepheshe bedijithali obusetshenziswa kuzo zonke izici zokuthuthukiswa kokulingiswa, futhi amazinga asezingeni lokuguqulwa kwedatha angasungulwa ukufeza ukuguqulwa kwedatha okungenamthungo phakathi kwesoftware ehlukile, ukuze kuqhubeke ukwanda ijubane lokuthuthuka lokusakaza.

Ukukhiqizwa kobuchwepheshe bezakhiwo eziyinkimbinkimbi ezincanyana

Ngokuthuthukiswa komkhakha wezimoto kanye nesidingo sokonga amandla nokuncishiswa komoya, izingxenye zezimoto ziya ngokuya zikhanya futhi zikhanya kancane. Ngokuqamba okunodonga oluncane, ukunciphisa isisindo kuyindlela ebalulekile yokuthuthuka yamabhulokhi enjini. Thatha i-FAW Casting Co., Ltd. yokukhiqizwa kwe-FAW-Volkswagen yamabhulokhi ensimbi eyisilinda njengesibonelo. Ibhulokhi le-06A elikhiqizwe kusenesikhathi linobukhulu bodonga obungu-4.5mm ± 1.5 mm, kanti i-EA111 cylinder block inodonga olungu-4 mm ± 1 mm. Ibhlinder lamasilinda lamanje elenziwe ngobuningi le-EA888Evo2 linobukhulu bodonga obungu-4 mm ± 1 mm. I-3.5 mm ± 0.8 mm, isakhiwo somkhiqizo wesilinda se-EA888Gen.3 silukhuni ngokwengeziwe, ubukhulu basodongeni baso bungu-3mm ± 0.5 mm kuphela, njengamanje yisigaxa sensimbi sensimbi esincanyana. Yize kunezinkinga ngamakhokho aphukile, ama-cores ezintantayo, nokuguquguquka okukhulu kobonda odongeni ekukhiqizeni ngobuningi, ngokulawula ikhwalithi yezinhlamvu zesihlabathi nesihlabathi sokubumba, inqubo yokuthela evundlile esetshenziswa kakhulu isengakwazi ukuhlangabezana nezidingo zokukhiqizwa kwamasilinda e-EA888Evo2. Kepha ayikwazi ukuhlangabezana nezidingo zokukhiqiza ze-EA888Gen. 3 cylinder block, ngakho-ke inqubo yokuphonsa umhlangano yonke emaphakathi kumele yamukelwe.

Ukukhiqiza ubuchwepheshe bezingxenye ezinkulu zesakhiwo se-aluminium-magnesium

Ngezidingo ezandayo zokonga ugesi, ukuvikelwa kwemvelo, kanye nokwehliswa kwezindleko zezinto, i-aluminium-magnesium alloy isikali esikhulu isibe umkhuba obalulekile wokuthuthuka, futhi ubuchwepheshe babo bokukhiqiza babuye baba ukugxila kwamanje kwezentuthuko. Njengamanje, ubuchwepheshe obukhulu bokukhiqiza bezingxenye ezinkulu zesakhiwo se-aluminium-magnesium alloy zihlanganisa ukuphonsa okuphezulu, ukukhipha ukukhipha nokuphonsa okuphansi. Ngenxa yokusebenza kahle kokukhiqizwa kokuphonsa ingcindezi ephezulu nekhwalithi yomkhiqizo omuhle, sekuyinqubo yokukhiqiza eyinhloko njengamanje. Ukuthuthukiswa kobuchwepheshe bayo bokukhiqiza kugxile kakhulu ekungenisweni kalula kwegesi ngesikhathi senqubo yokufaka umfutho ophakeme, nokwakhiwa kwama-pores ngaphakathi kwabalingisi, okungakwazi ukuthuthukisa inkinga yokwelashwa kokushisa.

Inkampani yaseJalimane i-Fulai yathuthukisa inqubo yokuphonsa ingcindezi engemihle, yonke inqubo yokufa isenziwa ngaphansi komshini omkhulu (ngaphansi kuka-30 mbar). Insimbi encibilikile idlula phakathi kwesikhunta, ikamelo lokucindezela kanye nepayipi lokudonsa esimweni se-vacuum futhi imuncwa esithandweni ngepayipi lokudonsa ngaphandle kwe-oxidation, futhi umusi we-ejenti wokukhishwa nawo ukhishwa ngohlelo lwe-vacuum. Izici eziyinhloko zenqubo yokuphonsa ingcindezi engezansi esetshenzisiwe engenhla yilezi: lapho ukuthululwa kwamanani kuqalisiwe, lonke uhlelo lusesimweni esiphezulu sokuhlanza; kunqubo yokuthulula ngobuningi, igesi esemgodini nensimbi encibilikisiwe ingakhishwa ngempumelelo; ngesikhathi senqubo yokuthulula Akukho oxidation yokuncibilika kwensimbi; akukho ukulahleka kokushisa ngesikhathi senqubo yokuthela, futhi izinga lokushisa eliphansi lingasetshenziselwa ukuthululwa, futhi ukugcwaliswa kokugeleza kwe-laminar okungaphazamiseki kungenziwa ngaphansi kokuqapha kwesikhathi sangempela. Inqubo engenhla isetshenziswe ngempumelelo ekukhiqizweni kwenqwaba yezimoto ezisikiwe ze-Auto Expert Forum, ukuhlinzeka ngezindlela ezithuthukile zokwenza nezinqubo zokusetshenziswa kokuphonswa kwekhwalithi ephezulu yokukhanya.

Inkampani yaseSwitzerland iBuhler isungule uhlelo lokuhlanza olunamakhemikhali amabili lokukhiqiza ukwakhiwa kwesakhiwo. Lobu buchwepheshe bokukhiqiza bubizwa ngokuthi ubuchwepheshe bokukhiqiza obakhiwe. Ukusetshenziswa kobuchwepheshe bokukhiqiza kwesakhiwo kungakhuphula ijubane lokuhlanza, ngaleyo ndlela kutholakale izimo zokukhiqiza ezizinzile futhi kuthuthukise ngokuphawulekayo ukusakazwa kokufa Ikhwalithi yezingcezu. Njengoba kukhonjisiwe ku-Fig. 5, itheku lokukhipha umoya lesekethe elilodwa ohlelweni lwe-vacuum-double circuit luhlelwe ekugcineni kwegumbi lokucindezela, futhi lisetshenziselwa ukukhipha umoya egumbini lokucindezela. Kuqala lapho i-injection plunger iqhubekela phambili ukuvala itheku elithelekayo, bese ivala lapho i-plunger isizovala itheku lokuncela. Okunye ukusethwa kwesekethe kuyefana nenqubo yendabuko yokuhlanza, futhi kusetshenziselwa kakhulu ukukhipha umoya emgodini. Njengamanje, ubuchwepheshe busetshenziswe ngempumelelo ekwenziweni kwemibhoshongo ehlanganisa ukushaqeka e-aluminium ingxubevange, amaphaneli angaphakathi omnyango kanye nojantshi womzimba wezimoto zabagibeli.

Precision ekubunjweni ukwakha ubuchwepheshe be-castings

Okuvame ukubizwa ngokuthi ukusakazwa ngokunemba kokuphonswa kwezimoto ikakhulukazi kubhekisa kubuchwepheshe obulahlekile begwebu kanye nokutshalwa kwezimali. Nge ukuthuthukiswa kwezimoto ekubunjweni ukwakha ubuchwepheshe, ekubunjweni ngokunemba ukwakha kubhekisela uhlobo thusi ukwakha indlela. Ukusakaza okukhiqizwa yilolu hlobo lwendlela yokwakha kungasetshenziswa ngqo ngaphandle kokusika noma ukusika okungaphansi. Ngezidingo ezandayo zokunemba ntathu kokujikijelwa, ubuchwepheshe bokuphonsa ngokunemba buthuthuke ngokushesha eminyakeni yamuva, kanye nochungechunge lwezindlela ezintsha zokuphonsa ezifana nokunemba kwesihlabathi, ukulahlwa kwe-foam, ukulawulwa kwengcindezi okulawulwayo, nokuphonswa kwengcindezi sekuvelile. Indlela yokukhipha iCosworth iyindlela eyenziwe yi-United Kingdom esebenzisa umhlangano we-zirconium sand core kanye nepompo kagesi ukulawula ukuthululwa. Isetshenziswe ngempumelelo ekukhiqizeni ngobuningi kwamabhulokhi e-aluminium alloy cylinder, futhi kuye kwavela izinhlobonhlobo eziningi zenqubo, njengokusebenzisa ukuthela kwengcindezi ephansi esikhundleni seNqubo kagesi efana nokuthela kwepompo. Lolu hlobo lwendlela yokusakaza ingaveza amasilinda e-aluminium alloy ngobukhulu bodonga obungu-3.5 kuye ku-4.0 mm, okuyinqubo yamanje emele ukucutshungulwa kwesihlabathi.

Inqubo yokulahla amagwebu elahlekile isungulwe ngo-1965, futhi ukukhishwa okuyinhloko kwezimoto okukhiqizwayo kungamabhulokhi amasilinda, amakhanda amasilinda, amapayipi okudla nokukhipha neminye imikhiqizo, futhi sekwenze umkhiqizo omkhulu. Kusukela kwethulwa ubuchwepheshe bokulahla amagwebu obulahlekile ngeminyaka yama-1990s ngekhulu lama-20, izwe lami seliqale ukwakheka futhi lithuthukiswa nguhulumeni njengobuchwepheshe obusetshenziswa kakhulu futhi obusha obusetshenziswa kakhulu ukuguqula imboni yesisekelo yendabuko. Njengamanje, kunezinqubo ezintathu zokufaka imali ezitshaliwe ezweni lami: igobolondo le-sodium silicate, igobolondo elihlanganayo negobolondo le-silica sol. Phakathi kwazo, ikhwalithi ephezulu yokusakazwa esetshenzisiwe ekukhiqizeni igobolondo le-silica sol lemikhiqizo yezimoto ingafinyelela kuRa 1.6 μm, futhi ukunemba okuyisilinganiso kungafinyelela ku-CT4. Ibanga, ubukhulu bodonga obuncane bungaba ngu-0.5 ~ 1.5 mm. I-Dongfeng Motor Precision Casting Co., Ltd. isebenzisa inqubo yokwenza igobolondo lamanzi e-silica sol + ukukhiqiza ukwakheka okuyinkimbinkimbi okuhlanganisiwe, okunciphisa kakhulu izindleko zokukhiqiza. Umkhuba wokuthuthukiswa kwenqubo yokubumba ubuchwepheshe bokutshalwa kwezimali ukuthi ukusakazwa kuyasondela futhi kusondele kumkhiqizo wokugcina, futhi ubunzima kanye nekhwalithi yemikhiqizo iya ngokuya iphakama. Ukusetshenziswa kwe-CAD, i-CAM ne-CAE sekuyiyona teknoloji eyinhloko yokuthuthukiswa komkhiqizo, futhi ukubambisana kobuchwepheshe kwaqala ukukhombisa.

Umshini wokulingisa, ukugcwaliswa kwe-oxygen okugcwele okokufa, insimbi eqinile ye-rheological noma i-thixotropic die casting nezinye izindlela zenqubo ezakhiwe ngesisekelo senqubo yokufaka umfutho ophakeme yenzelwe ukuqeda ukukhubazeka kokuphonsa, ukuthuthukisa ikhwalithi yangaphakathi, nokwandisa ububanzi besicelo sokufa . Ngesikhathi senqubo yokukhipha, cibilika futhi iqiniswe ngaphansi kwengcindezi, enezinzuzo zokubushelelezi, akukho chaphaza lensimbi, ukulahleka kwe-oxidation oketshezi oluncane, ukonga amandla, ukusebenza okuphephile nokunciphisa izimbobo zokuphonsa nezinye izinkinga. Isetshenziswa kuma-aluminium alloy subframes, njll. Ukuthuthukiswa nokusetshenziswa kwe-high-performance aluminium alloy castings kusetshenziswe kabanzi.

Ukukhula okuqhubekayo kokukhishwa kwezimoto ngokuphuthumayo kudinga ukuthuthukiswa kokukhiqizwa kokulingiswa kukhwalithi ephezulu, ukusebenza okuhle kakhulu, eduze kwesimo senetha, izinhlobo eziningi, ukusetshenziswa okuphansi nezindleko eziphansi. Ngoba cishe i-15% kuya ku-20% yezingxenye zemoto ephelele is castings. Lokhu kudinga ukuthi imboni yokulingisa isebenzise ngokuqhubekayo ubuchwepheshe obusha obuhlukahlukene nezinto ezintsha zokuthuthukisa izinga eliphelele lokusakaza. Ukunemba kokulingisa okwakha ubuchwepheshe be-castings kungahlangabezana nezidingo ezishiwo ngenhla zokuphonswa kwezimoto, futhi ukusetshenziswa kwayo kuzophinda kuhlanganise izinqubo ezahlukahlukene zokukhiqiza zokukhishwa kwezimoto.

Isiphetho

Ukuze zivumelane nezidingo eziya ziba lukhuni zemithethonqubo yokuvikelwa kwemvelo, izimoto ziyathuthuka ziqonde kusisindo esilula. Ekunciphiseni konke ngo-10% kwesisindo semoto, ukusetshenziswa kukaphethiloli kungancishiswa ngo-5.5%, umnotho kaphethiloli ungakhuphuka ngo-3% uye ku-5%, futhi ukukhishwa kungancishiswa cishe ngo-10%. Ukusetshenziswa kwe-aluminium-magnesium nokunye okungekho okwenziwe nge-alloy castings, ukuthuthukiswa kwesakhiwo esikhulu esiyinkimbinkimbi sokuhlanganiswa, nokusetshenziswa okubanzi kobuchwepheshe bokwenza ubuchwepheshe kuyizindlela eziyinhloko zokufeza ukukhishwa kwezimoto okungasindi. Ngakho-ke, kuyadingeka ukuthi kwenziwe ucwaningo nentuthuko kanye nokukhiqizwa kokuphonswa kwezimoto ngezinto zokusebenza eziphakeme zokusebenza nokusetshenziswa okubanzi kwemishini yokuzenzekelayo ngesisekelo sokusetshenziswa okubanzi kobuchwepheshe bedijithali ukuhlangabezana nezidingo zemboni yezimoto yanamuhla.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: I-Development Trend Of Automobile Castings Nobuchwepheshe Bayo Bokukhiqiza

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off