Izici Nezinyathelo Zokuqapha ze-CNC Lathe Machining

Ubuchwepheshe machining of lathes CNC iyafana naleyo lathes ezejwayelekile, kodwa ngoba CNC lathes kukhona okukodwa ngesikhathi clamping futhi okuqhubekayo machining okuzenzakalelayo ukuqedela zonke izinqubo turning, izici ezilandelayo kufanele zinakwe.

1. Ukukhetha Okufanelekile Kokusika Inani

Ngemishini yokusika insimbi esebenza kahle kakhulu, okokusebenza okuzocutshungulwa, ukusika amathuluzi, nezimo zokusika yizinto ezintathu ezinkulu. Lokhu kunquma isikhathi semishini, impilo yethuluzi nekhwalithi yemishini. Indlela yokonga nephumelelayo yokwenza imishini kumele kube ukukhetha okunengqondo kwezimo zokusika.

Izakhi ezintathu zezimo zokusika: isivinini sokusika, isilinganiso sokuphakelayo kanye nokujula kokusika kubangele ukulimala kwethuluzi ngqo. Ngokwanda kwejubane lokusika, kuzonyuka izinga lokushisa kwethiphu yethuluzi, okuzodala ukugqokwa kwemishini, kwamakhemikhali nokushisa. Ijubane lokusika lenyuke ngo-20%, impilo yamathuluzi izokwehliswa ngo-1/2.

Ubudlelwano phakathi kwesimo sokuphakelayo nokugqokwa ngemuva kwethuluzi kwenzeka ebangeni elincane kakhulu. Noma kunjalo, izinga lokuphakelayo likhulu, izinga lokushisa lokusika liyakhuphuka, futhi ukugqoka emuva kukhulu. Inethonya elincane kuthuluzi kunokusika isivinini. Yize ithonya lokusika ukujula kuthuluzi lingalingani nejubane lokusika nesilinganiso sokuphakelayo, lapho usika ekujuleni okuncane okusikiwe, into ezosikwa izokhiqiza ungqimba, oluzothinta nempilo yethuluzi.

Umsebenzisi kufanele akhethe isivinini sokusika esizosetshenziswa ngokuya ngezinto ezicutshunguliwe, ubulukhuni, isimo sokusika, uhlobo lwezinto ezibonakalayo, isilinganiso sokuphakelayo, ukusika kokusika, njll.

Ukukhethwa kwezimo zemishini ezifanele kukhethwa ngokuya ngalezi zinto. Ukuhlala njalo, ukugqoka okuzinzile nokuphila isikhathi eside kuyizimo ezifanele.

Kodwa-ke, ekusebenzeni kwangempela, ukukhethwa kwempilo yamathuluzi kuhlobene nokugqokwa kwamathuluzi, izinguquko ezilinganiselwe ezizocutshungulwa, ikhwalithi ephezulu, umsindo wokusika, nokushisa kwemishini. Lapho kunqunywa izimo zemishini, kuyadingeka ukwenza ucwaningo ngokuya ngesimo sangempela. Okwezinto okunzima ukuzicubungula ezinjengensimbi engagqwali nama-alloys amelana nokushisa, ama-coolants noma ama-blades anokuqina okuhle angasetshenziswa.

2. Ukukhetha okunengqondo kwamathuluzi

- Lapho u-roughing, khetha ithuluzi elinamandla aphezulu nokuqina okuhle ukuhlangabezana nezidingo zokuphinda ubambe emuva okukhulu nokuphakelayo okukhulu lapho kukalwa.

- Lapho uqeda ukujika, khetha amathuluzi wokunemba okuphezulu futhi aqinile ukuqinisekisa izidingo zokunemba kwemishini.

- Ukuze kuncishiswe isikhathi sokuguqulwa kwamathuluzi futhi kube lula ukusethwa kwamathuluzi, imimese eboshwe ngemishini namakhreyithi aboshwe ngomshini kufanele asetshenziswe ngangokunokwenzeka.

3. Ukukhethwa Okufanelekile Kokulungiswa

- Zama ukusebenzisa izinto zalapho ezijwayelekile ukubopha umsebenzi, gwema ukusebenzisa izinto ezikhethekile;

- Ingxenye yokubeka datum ihlangana ukunciphisa iphutha lokuma.

4. Thola Umzila Wokusebenzisa Imishini

Umzila wokumaketha uyindlela yokuhamba nokuqondiswa kwethuluzi elihlobene nengxenye ngenkathi kusetshenzwa i-lathe elawulwa yinkomba.

- Kufanele ikwazi ukuqinisekisa ukunemba kwemishini kanye nezidingo zokuqina kwendawo;

- Umzila wemishini kufanele ufushaniswe ngangokunokwenzeka ukunciphisa ithuluzi isikhathi sokuhamba esingenzi lutho.

5. Ukuxhumeka Phakathi Kwemigwaqo Yemishini Nemvume Yokusebenzisa Imishini

Njengamanje, ngaphansi kwesimo sokuthi i-lathe ye-CNC ayikafiki ekusetshenzisweni okuthandwayo, umkhawulo owedlulele kokungenalutho, ikakhulukazi umkhawulo oqukethe ukwakheka nokukhipha ungqimba wesikhumba esiqinile, kufanele uhlelwe engxenyeni ejwayelekile yokwenza imishini. Lapho abakhiqizi bemishini kumele basebenzise izihlakala ze-CNC, badinga ukunaka ukuhleleka okuguqukayo kohlelo.

6. Amaphuzu Main Of sesimbembembe Ukufakwa

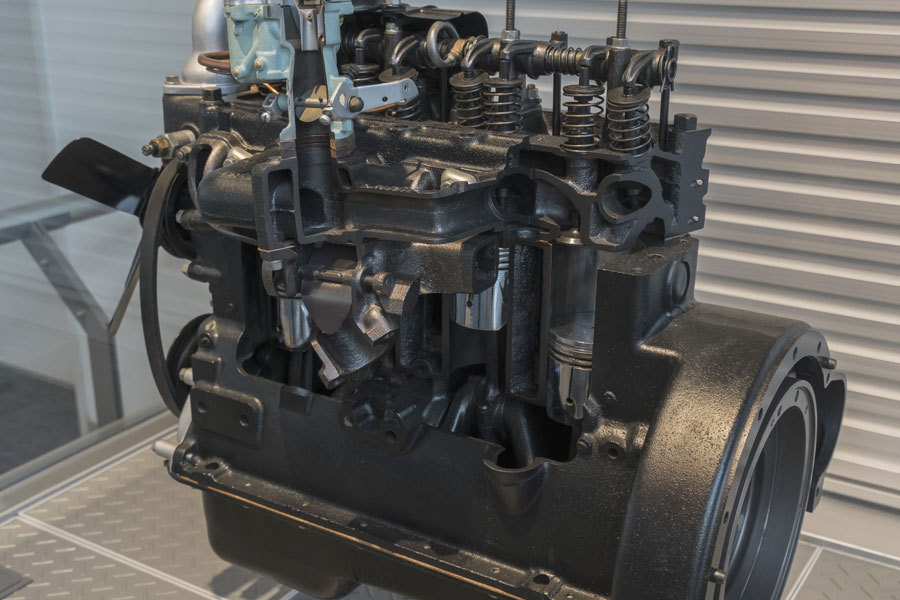

Njengamanje, ukuxhumana phakathi kwe-hydraulic chuck kanye ne-hydraulic clamping cylinder kutholakala ngenduku yethayi, njengoba kukhonjisiwe ku-Figure 1. isilinda, susa ishubhu lokudonsa, bese ulikhipha ngemuva kothini lokuphotha, bese usebenzisa isandla esinyakazayo ukususa isikulufa se-chuck fixing ukususa i-chuck.

I-wiper edge yethuluzi ibhekisa engxenyeni encane yensimbi ehambisana nethiphu yethuluzi eligayiwe lapho kubhekiswa khona i-engeli yesibili yokuphambuka ngemuva kwensimbi yethuluzi. Kusetshenziswa ikakhulukazi ukusika okwesibili ngemuva kokusikwa kwensimbi. Ukwenza ngcono ukuqina kobuso bento yokusebenza kusetshenziswa kakhulu kummese wokuqeda.

Ubuchwepheshe machining of lathes CNC iyafana naleyo lathes ezejwayelekile, kodwa ngoba CNC lathes kukhona okukodwa ngesikhathi clamping futhi okuqhubekayo machining okuzenzakalelayo ukuqedela zonke izinqubo turning, izici ezilandelayo kufanele zinakwe.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Izici Nezinyathelo Zokuqapha ze-CNC Lathe Machining

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off