Amaphuzu Ayisihluthulelo Wohlobo Olusha Olunemisebenzi Ehlukahlukene ye-Aluminium Alloy Oil Housing Die Casting

Ukuhlose ukuthambekela kokuthuthuka kwezinjini zezimoto kubhekane nesisindo esilula nokuhlanganiswa, amaphuzu aphambili ohlobo olusha lwepani lika-oyela lokuphonsa ifa achazwa ngokugcizelela. Amaphoyinti obuchwepheshe bokuklanywa kwe-Die-casting ahlukaniswe izingxenye ezintathu, kusetshenziswa izindlela ezahlukahlukene zokuthela nobuchwepheshe obusha bokuklama imikhiqizo; kusukela kumaphoyinti wokulawulwa kwenqubo yokufa, into ngayinye ethinta ikhwalithi yomkhiqizo kunqubo yokukhiqiza ihlolwe ukunciphisa amazinga wokukhubazeka komkhiqizo. Ngalezi zici ezimbili zokulawula, izinga lokufaneleka komkhiqizo lingaphezu kwama-97%, futhi ukukhiqizwa kwesisindo kuzinzile.

Ngokuthuthuka okusheshayo kwemboni yezimoto, izidingo eziphakemeyo zibekwa phambili ezintweni zokwakha, ukuklama nokukhiqizwa kwezingxenye, nokuhlanganiswa okuphezulu, ukusebenza okuphezulu, nezindleko eziphansi sekuyinkambiso yentuthuko. Kokubili ipani likawoyela nebhulokhi elingaphansi kuyizingxenye ezibalulekile zenjini yemoto. Ngokuhlanganisa i-cylinder block shaft shaft ephansi kanye neqoqo lamafutha wepani nomsebenzi wokuhlunga engxenyeni efanayo, isisindo nevolumu yenjini kuncishiswa ngempumelelo. Kodwa-ke, ngenxa yesakhiwo esiyinkimbinkimbi nezinguquko ezinkulu zodonga, kudingeka ihlukaniswe ibe yimikhiqizo ehlukene futhi icutshungulwe ngokwehlukana bese ihlanganiswa futhi icutshungulwe, okuholela ebunzimeni ekukhiqizeni umkhiqizo.

Ipani likawoyela elididiyelwe lenjini elifundwe kulesi sihloko liqukethe ukusakaza okuthathu: umzimba wepani kawoyela, ikhava ethwala ibhalansi kanye nekhava ethwala ibhalansi eyodwa. Usebenzisa i-A380 modified alloy material, ubukhulu basodongeni bokuphonsa yi-3 mm, ubuncane bodonga obungu-2.5 mm, futhi ubukhulu bento engenalutho buyi-10.74 kg. Umgodi wangaphakathi uyadingeka ukuthi ungavuzi ngaphansi kwe-300 kPa, futhi indawo kawoyela ayivuzwanga ku-600 kPa futhi izinga lokushisa lidlula ama-60 ℃. Ukuvuza, okusetshenziswa ezinjinini ze-1.5T, ngokukhipha minyaka yonke izingcezu ezingama-400,000, okuyindawo ejwayelekile yokuphonsa uwoyela oyinkimbinkimbi.

Amaphuzu obuchwepheshe wedizayini yokufa

1.1 Idizayini yomgijimi

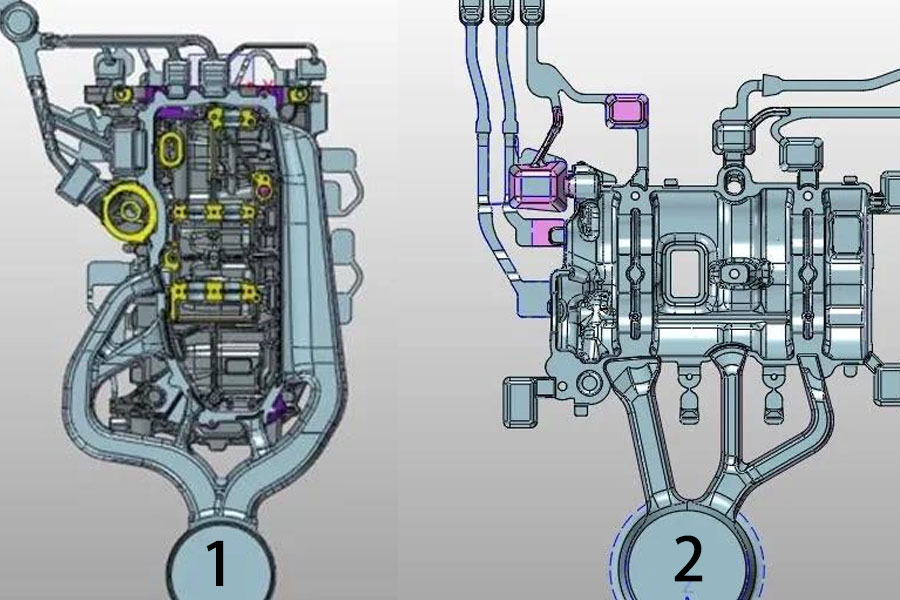

Ukusakaza okungu-1 kwamukela ukwakheka kokuchela okuzinhlangothi ezintathu, kepha kugxila ekuthelweni okuphelele ohlangothini olulodwa, njengoba kukhonjisiwe ku-Figure 1. inkinga yenqubo ende, ukuze ugcwalise umkhiqizo ezindaweni ezahlukahlukene. Kodwa-ke, uma kubhekwa ukuthi ubukhulu bodonga bomkhiqizo bukhulu futhi kuningi okufakiwe okuphakanyisiwe endaweni ethululelwayo, ukuze kugwenywe ukuswakama kwe-aluminium encibilikisiwe kuvinjelwe, ukugcwaliswa kolunye uhlangothi kuyaqiniswa, ne-cross-sectional indawo incishiswa kancane kancane sisonke ukusheshisa ukugeleza kwe-aluminium encibilikisiwe. Idizayini yesakhiwo.

Ukulingisa i-2 ikhava ethwala ibhalansi, enesimo esilula, kuphela imijikelezo kawoyela yebhaft emibili emaphakathi ishubile. Ngokuya ngephethini elula yokugeleza kwe-aluminium encibilikisiwe, ukonga izindleko nokwandisa inani eliphumayo lokukhipha i-aluminium encibilikisiwe, kwamukelwa uhlelo lokuthela uhlangothi olulodwa, futhi isango libekwe endaweni yobukhulu bodonga ukuze kufakwe, njengoba kuboniswe ku-Figure 2.

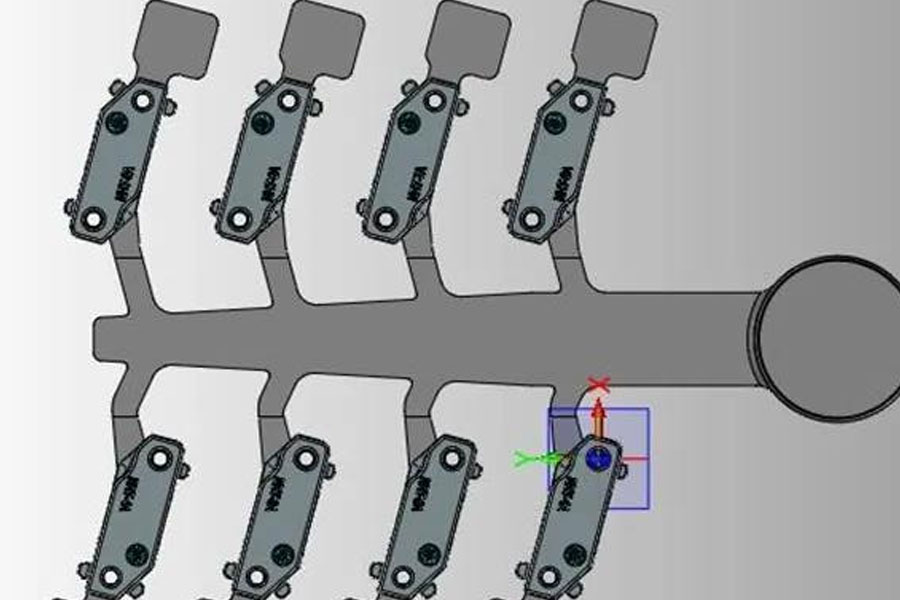

Ukulingisa i-3 ikhava yethayela elilodwa le-shaft shaft enengxenye encane (usayizi 63 mm) × 15 mm × Ukwakhiwa kwesikhala esisodwa kanye nesikhunta eziyisishiyagalombili kwamukelwa ukugcwalisa nokuthela, njengoba kukhonjisiwe kumdwebo 3.

1.2 Indlela yokukhipha

Ekusakazeni okuyinkimbinkimbi 1, kusetshenziselwa i-vacuum ephezulu. Ukusakaza 2, kusetshenziswa uhlobo olujwayelekile lwe- "washboard". Ekulingiseni 3 ngqo usebenzisa isikhwama slag kanye isikhunta core qeda isiteshi at umsila wesikhwama slag. Amaphuzu ayinhloko obuchwepheshe be-exhaust bokuphonsa i-1 agcizelelwe lapha.

Njengoba izindinyana zikawoyela ezinengcindezi enkulu kanye nezihlungi zikawoyela zokuphonsa kugxilwe emsileni wamanzi, umphumela wokukhipha umsila wamanzi yinto ebalulekile enquma ikhwalithi yangaphakathi yalezi zindawo. Ukusakaza 1 kusebenzisa ukukhipha okuphezulu okuphezulu ukunciphisa ingcindezi yomoya endaweni engaphansi kwengcindezi yomsila wamanzi wokusakaza. Okokuqala, ivolumu yethangi elingenalutho kufanele ikhethwe ≥ 800 L (800 L lapha kuphindwe izikhathi ezingaphezu kwezingu-10 ivolumu yesikhunta equkethe umgodi nomkhombe) ukwenza ngokushesha isiteshi sengcindezi esibi. Okwesibili, ipayipi elixhuma isikhunta nomshini we-vacuum kufanele livalwe futhi lingangeni emoyeni, futhi ne-vacuum degree yepayipi kufanele igcinwe ngaphakathi kuka-2 000 Pa. ziboshwe nge-sealant. Ngemuva kokuthi isikhunta sivaliwe, i-vacuum cavity kufanele igcinwe ngaphakathi kwe-Pa 4. Okokugcina, khetha ukukhiqizwa okuhle kakhulu kwesibhakela esivaliwe, noma sebenzisa inguqulo enwetshiwe ye-punch ukwandisa indawo yokufaka uphawu lwe-punch, futhi unciphise ngempumelelo ukuvuza komoya emgodini.

1.3 Ukushisa kwesikhunta

Ngenxa yezici zomshini ophakeme, i-aluminium encibilikisiwe ayigcwaliswanga ngokuphelele ngokuya ngesimo se-theoretical fluid (bheka Umdwebo 4), futhi i-aluminium encibilikisiwe kulula ukuqinisa ngokushesha ezindaweni ezithile lapho imunca kuyo, ibangele ukukhubazeka kokufa okunjalo njengokufa kokuphonsa izimbotshana, izimbobo zokuncipha, nemifantu. Umkhiqizo walokhu kusakazwa okungu-1 uqala ukuphuma lapho i-punch idlulela endaweni engu-410 mm (ukugcwala ketshezi kwe-aluminium kufinyelela imfuneko engama-70%), bese kuvala isikhala endaweni engama-540 mm. Isikhathi), i-vacuum stroke ingu-130 mm, kanti isikhathi ngu-0.874 s. Esikhathini esifushane kangaka, kufanele kuqinisekiswe ukuthi uketshezi lwe-aluminium oludonselwe ngeke luqine endaweni ebalulekile emsileni wamanzi ngaphambi kwesikhathi. Ngakho-ke, ukushisa kwesikhunta kulezi zikhundla kulawulwa ku-220 ℃ naku-180 ℃ ngokulandelana ngokusebenzisa umshini wokushisa kawoyela. Ukukhuphuka kwamazinga okushisa kwesikhunta kanye nokwezezimali okwenziwe ngcono kwe-aluminium encibilikile kuyisihluthulelo sokuqinisekisa ikhwalithi yangaphakathi yalezi zindawo ezimbili ezibalulekile.

Ukujula okungu-2 no-3 kulula ngokwakhiwa, kufushane ebangeni lokugcwalisa, futhi kulula ukwakheka. Azidingi ukushisa okuphezulu kwesikhunta, inqobo nje uma izinga lokushisa lesikhunta liphezulu futhi umkhiqizo ungaguquki ube mnyama.

1.4 Izinketho zokupholisa isikhunta

Lokhu kusakaza oku-1 kusebenzisa ubuchwepheshe bokupholisa obuphezulu kakhulu nobuchwepheshe bokuphakelwa kwamanzi ngezikhathi ezithile. Njengoba umkhiqizo wokulingisa udinga ukugcina izinga lokushisa eliphakeme, futhi kukhona abaphathi abaningi bokufaka ohlangothini lwesikhunta esinyakazayo, kubalulekile ukuqinisekisa ukuthi izinga lokushisa eliphakeme aliqinisekiswanga nje kuphela, kodwa nokuthi ukufakwa okuphakanyisiwe ngeke kwakheke amalunga ashisayo futhi kubangele ukuncipha kokuncipha nokunye ukukhubazeka. Inqubo yokusika yenziwa ngokufakwa ngakunye, futhi ukupholisa kwendawo kuqhutshwa ngaphakathi kokufakwa. Imishini yokusebenza ehambisanayo isebenzisa indlela yokuhambisa amanzi ngezikhathi ezithile. Ngesikhathi sesigaba sokuqinisa umkhiqizo, kuvulwa i-valve ye-solenoid ukupholisa umkhiqizo endaweni. Lokhu akutholi kuphela ukushisa okuphezulu, kepha futhi kuthola nomphumela omuhle wokupholisa. Inqubo yokupholisa iphoyinti eliphezulu yakhelwe izinaliti eziyisisekelo zokufa, njengoba kukhonjisiwe kumcibisholo ku-Figure 1. Inaliti engu-4 mm maphakathi nendawo yobukhulu bodonga izodala ngqo ukuncipha. Idizayini ephakeme kakhulu yokupholisa isetshenziselwa inaliti engu-4 mm, engaxazulula inkinga ye-pore yomgodi ocishiwe. Ngokufanayo, kwezinye izindawo ezishisayo, ukwakheka kwenaliti ebanda kakhulu kusetshenziswa lapho kungakhishwa khona inaliti, okunciphisa kakhulu izinkinga zokusha, i-stomata, nezinaliti eziphukile. Isikhathi esibekiwe sokupholisa nendawo yokuphakelwa kwamanzi ngezikhathi ezithile kudinga ukucubungula ukushuba kodonga lwembobo eboshiwe kanye nendawo okuyo. Ngakho-ke, izinaliti ezibandayo kulezi zindawo ezihlukene zidinga ukwabiwa ngokulawulwa.

Ukulingisa 2 kunembobo ka-4 mm kagesi we-groove phakathi nendawo ye-shaft yebhalansi kanye nomgodi we-mm8 mm umshudo endaweni yokungenisa okuphakelayo, esebenzisa ukulawula okubandayo okuphezulu kakhulu. Ngoba ngemuva kokuthi uketshezi lwe-aluminium selukhuhliwe, kuzokwakhiwa isiteshi esixekethile phakathi kwezindawo zobukhulu bodonga oluphakathi, inaliti ebanda ngaphezulu kufanele isetshenziselwe ukukhulisa ngenkani ungqimba oluminyene oluzungeze umgodi, ngokulibaziseka ngo-1 s nokupholisa okungu-10 s. Izinaliti ezincane eziyi-16 ze- Φ8 mm ekubunjweni kwe-3 zonke zisebenzisa ukulawula okubandayo okuphezulu kakhulu ukugcina ubukhulu besendlalelo esinyene eduze komgodi.

1.5 Ukukhethwa kobuchwepheshe bendawo be-extrusion

Iphini yendawo ye-extrusion ingasombulula ngokushesha ukuncipha endaweni yokujiya kodonga futhi isetshenziswa kakhulu emkhakheni wokulingisa. Ukuhlaziywa kwamalunga ashisayo okugeleza kwesikhunta kuboniswa kuMdwebo 5. Kunezinhlanganisela eziningi ezishisayo ekubunjweni kwe-1, futhi isikhundla sezikhonkwane ze-extrusion sidinga ukuhlelwa kahle. Okokuqala, susa ama-node ashisayo angaqedwa ngokusebenzisa inaliti ebandayo, futhi okwesibili ususe ama-node ashisayo angekho ezindaweni ezibalulekile. Ekugcineni, udinga ukucubungula ukuhlelwa kwesilinda sokucinana kwephini esikhaleni sangaphakathi sesikhunta. Imvamisa ihlelwe lapho isakhiwo sinzima futhi kuvinjelwa ukuvuza komoya ..

Amaphuzu abalulekile wokulawulwa kwenqubo yokufa

2.1 Ukulawulwa kokugeleza kwesifutho ngesikhathi sokukhishwa kokufa

Ngesikhathi senqubo yokufa, isilinganiso sokugeleza kwesifutho silinganiswa ngokwehlukana yisikhunta esihambayo nesilungisiwe, isikhunta esihambayo silawulwa ku-3 200 ml, kanti isikhunta esinqunyiwe silawulwa ku-2 200 ml. Ngaphezu kwalokho, amanani wokuphambuka aphezulu naphansi asethwe ngokuhlukile kumazinga wokugeleza wokuguquguquka onamandla nolungisiwe. Njengoba i-flowmeter kagesi ekhethiwe inokunemba kwama-50 mL, ukuphambuka kokusetha kungama- ± 200 mL, kanti ama-200 ml yinani langempela elilinganisiwe ngemuva kokuncishiswa kwesibhamu esisodwa. Ngesikhathi senqubo yokukhiqiza, uma inani lokuphambuka lidluliwe, isignali ye-alamu izokhishwa ngqo ukumisa umjikelezo wokukhiqiza wokufa. Ngakho-ke, kungavimbela ngempumelelo ukuthi ukufafaza kungavinjelwa ngenxa yesibhamu sokufafaza, okungadala ukunamathela kwesikhunta nokusha.

Inqubo yokulawula ukushisa kwe-aluminium encibilikisiwe

Njengoba umphumela wokulondolozwa kokushisa kwesithando somlilo muhle, kepha isilinganiso sokushisa sihamba kancane kunesithando somlilo, izinga lokushisa elingenayo le-aluminium encibilikisiwe idinga ukulawulwa. Izinga lokushisa lokusakazwa kwe-aluminium encibilikisiwe liyi-675 ± 10 ° C, ngakho-ke izinga lokushisa elingenayo le-aluminium encibilikisiwe elanini lezokuthutha kufanele ligcinwe ngaphezu kuka-700 ° C. Ukondla ngezansi kwaleli zinga lokushisa kuzothinta isimo sokugeleza kwe-aluminium encibilikisiwe ngesikhathi sokugcwaliswa, okuholela ekukhuleni kwesilinganiso sezimbotshana ezindaweni zasendaweni. Ukungeza izinto ezingaphezulu kuka-730 ℃ kuzobangela ukusha okukhulu nokunamathela kwe-aluminium ebusweni besikhunta, okuzothinta ukubonakala kwekhwalithi yokusakaza. Setha i-alamu yokushisa ye-aluminium encibilikisiwe yesithando somlilo. Uma izinga lokushisa elithululayo lingekho ebangeni, isithando somlilo sizokwazisa futhi simise umjikelezo wokukhiqiza wokufa, ongavimbela ngempumelelo ukukhubazeka okubangelwa ukuphambuka kokushisa kwe-aluminium encibilikisiwe.

2.3 Ukulawulwa komshini

Njengoba isikhunta esingu-1 sivalwe ngeteyiphu yokufaka uphawu yokuhambisa futhi engaguquki, zonke izikhonkwane ze-thimble kanye ne-core zivalwa ngokusebenzisa i-sealant, futhi i-chute nayo iyi-chute ebalulekile, kepha isibhakela asisebenzisi isibhakela esikhethekile sokufaka uphawu, kepha sisebenzisa isibhakela se-Plate eseluliwe (enwetshiwe saba ngu-150 mm). Esimweni esinjalo esivaliwe, i-alamu izobangelwa lapho i-vacuum degree isethwe ukuthi yeqe i-4 kPa (i-4 kPa iyinani le-alamu elinamandla elisethwe ngokwezinga eliphakeme lokuphasa ngesikhathi senqubo yokukhiqiza), kanti ne-vacuum degree ngokuvamile icishe ibe yi-2.3. k Pa. Amanani wokuhlanzeka nokuvaleka ngokuvamile asondele ku-101 kPa, futhi inani le-alamu elibekiwe lingu-90 kPa (90 kPa isethwe ngokomjikelezo wokuhlanza wethangi lokuhlunga efektri). Ekupheleni komjikelezo wokuhlanza, i-vacuum valve filter tank kufanele ihlanzwe ngesikhathi. Ukwehluleka ukuyihlanza kuzothinta umphumela wokuhlanza. Inani lesethangi le-vacuum tank liyi-1 kPa, ngokuvamile ephakathi kuka-2.2 no-400 Pa. Uma nje inani elidingekayo lidluliwe, i-alamu izokhishwa bese umshini wokukhipha u-die uzovalwa.

2.4 Ukuqapha imingcele yangempela yomjovo

Umshini die-ekubunjweni usebenzisa imodeli Ube ezifuywayo 1650T. Ngaphezu kohlelo lwayo lokulawula umshini wokuphonsa umshini wokufa, ibuye isebenzise uhlelo lokulandelela lwezinhlangothi ezimbili (olubizwa nge-MES system efektri) ukuxhuma umshini wokuphonsa okokufa kanye nemishini yokulekelela eseceleni ukuze uhlelo lwe-MES lukwazi ukufunda amapharamitha wokukhiqiza wesikhunta ngasinye ngesikhathi sangempela bese ubaphakela efwini ukuze uqhathanise efwini (inani lokuqhathanisa ifu lifakwe efwini kusengaphambili njengoba kudingeka, futhi amanani amabanga ahlukile akhishwa ngokusho kwangempela kokuhlukile Isibonelo, isivinini esihamba kancane ngu- ± 0.05 m / s, isivinini esikhulu siyi- ± 3 m / s, njll., bheka iThebula 2), imikhiqizo eyeqa ibanga ngemuva kokuqhathanisa izokhiywa yisistimu bese yahlulelwa njengengafanelekile . I-Cloud Big Data futhi ibala njalo ubudlelwano besikhathi sangempela phakathi kokuphelelwa yisikhathi komkhiqizo nezinguquko zepharamitha ngokuya ngevolumu yedatha ebuyekeziwe. Thola izizathu zokushintshashintsha kwezinga lezinto ezilahliwe esikhathini esithile, bese uthuthukise izinga elifanelekile lokugcina imikhiqizo. Kukhona ukushintshashintsha kwenqubo yokukhiqiza okufa, okungathola ngokushesha amaphuzu ezinkinga futhi kukhuthaze ngempumelelo umjikelezo omuhle khona lapho.

2.5 Ukulawulwa kwezinto zokuhambisa amanzi ezifa

Ekuqaleni kokuthuthwa kwamanzi, umugqa ngamunye usebenzisa i-valve ye-solenoid ukulawula isikhathi sokupholisa ngqo noma iphuzu elijwayelekile lokuhamba kwamanzi abandayo. Ingcindezi yamanzi ingu-0.4 MPa kanti izinga lokushisa lamanzi lingama-30 water amanzi amsulwa. Ngaphandle komkhombe, umkhono wempahla, isibhakela, isigaxa esihlukanisiwe nomkhono wezinto ophoqiwe opholile obandayo ovame ukupholisa uvule futhi uqonde ngqo, konke okunye ukupholisa okuqondile (izithiyo zamanzi) nokupholisa iphuzu elikhulu kulawulwa yi-solenoid valve, ukubambezeleka kwama-3, ukupholisa ama-15 s ukuqinisekisa ukushisa kwesikhunta. Zonke izinaliti, kusuka ku- Φ4 mm kuye ku- Φ14 mm (ithubhu emaphakathi ukusuka ku- .1.5 mm kuye ku- .5.5 mm) ilawulwa amakhaza amakhulu, ingcindezi yokuhambisa amanzi abandayo eyi-super-point ingu-10 MPa, kanye namazinga okushisa okuhamba ngamanzi ngu-10 ℃ (lapha Izinga lokushisa alinakubekwa phansi kakhulu, ukuphansi kakhulu kuzothatha ukushisa okukhulu, kepha kuzodala izinaliti eziphukile kalula), iqembu ngalinye lezinaliti ezibandayo ezilinganayo alidluli ku-8 (ngaphezu kwezinaliti eziyi-8 zeqile ububanzi bobubanzi bepayipi elixhuma u-G1 / 2), zonke izinaliti zihlanganisiwe zaba ngamaqembu ayi-6, ngaphandle kwenalithi ebandayo engu- mm4 mm, isikhathi sokubambezeleka singama-5 s bese ukupholisa kungu-13 s, kanti Φ4 mm iphuzu inaliti ebandayo isethwe ukuthi ibambezele ama-4 futhi isikhathi sokupholisa ngama-13 s ukukhomba inkambu yokushisa kwesikhunta. Endaweni edinga ukupholisa ngokushesha, nciphisa ukwenzeka kwezindawo ezishisayo. Akugcini nje ngokuqinisekisa ibhalansi nokugcinwa kokushisa kokushisa kwesikhunta, kodwa futhi kuqeda izindawo ezishisayo zasendaweni futhi kuqinisekisa ikhwalithi yomkhiqizo.

3. Ikhwalithi yepani entsha kawoyela emisebenzi eminingi. Le mikhiqizo emithathu ikhiqizwa emishinini emibili ehlukene, futhi okukhishwa nsuku zonke kufinyelela ezingxenyeni ezingama-980 / ngosuku, izingcezu eziyi-1,500 / ngosuku, nezicucu eziyi-12,000 / ngosuku kusuka ekusakazweni okungu-1 kuya ekuphoseni 3. Izinga lokuphumelela lemikhiqizo emithathu kuze kube umhlangano wokugcina uphakeme njengama-97%. Umdwebo 8 isithombe sokubonakala kwabalingisi 1, 2 kanye nekhwalithi yangaphakathi yabalingisi 1, 2, no-3.

Isiphetho se-4

- Idizayini namaphoyinti ezobuchwepheshe alolu hlobo olusha lwepani likawoyela ukusetshenziswa okuguquguqukayo komshini, ukupholisa indawo, ukukhipha okungaphezulu, ibhalansi lokushisa kwesikhunta nezinye izinqubo ezingaphansi kwezindlela ezi-3 zokuthululela nokukhipha, futhi ukucubungula kokugcina kuhlanganiswe kube Izingxenye eyodwa.

- Iphuzu elisemqoka lokulawula ukusakaza ukufa ukumba ngokuqhubekayo futhi ubheke izinto ezithinta ukungazinzi kwekhwalithi yomkhiqizo, ukuze kuzuzwe inqubo ezinzile yokukhiqiza.

- Ngemuva kokudlulisa ukwakheka kwepulani lokuqala kanye nokuhlonza nokuhlaziywa kwamaphoyinti ezobuchwepheshe, inqubo yokulawula ejwayele ukuqapha okuzenzakalelayo iyamukelwa, ukuze

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Amaphuzu Ayisihluthulelo Wohlobo Olusha Olunemisebenzi Ehlukahlukene ye-Aluminium Alloy Oil Housing Die Casting

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off