Umphumela we-Drill ne-Nickel ekuphikisweni komonakalo we-Thermal we-4Cr5Mo2V Die Casting Die Steel

I-4Cr5 Mo2V iyinsimbi yensimbi esetshenziswa kakhulu yokufa. Enkambisweni yokufa kwe-aluminium alloy, ngenxa yokuguguleka nokunamathela kwe-aluminium encibilikisiwe, isikhunta sizohlukumezeka ngokushisa, njengokukhathala okushisayo nokulahleka kwe-thermal melt, okuholele ekwehleni kobulukhuni babo nokwehluleka kwangaphambi kwesikhathi.

Ukuze ufunde ukuthi ngabe i-nickel noma ukoma kungathuthukisa ukumelana nokulimala okushisayo kwe-aluminium alloy die-casting molds, i-4Cr5 Mo2V steel kanye ne-4Cr5Mo2V steel block block equkethe i-1% Ni ne-1% Co (ingxenyenamba) yalungiswa, futhi yafakwa ukucima nokushisa. Ekufeni okungaguquki kwesikhunta sokufa, i-ADC12 aluminium alloy enezinga lokushisa elingu-800 ℃ yabe isiphonswa izikhathi ezingama-200 kuye kwayi-1,000 XNUMX, futhi kwahlolwa i-morphology enkulu nobulukhuni be-block block.

Imiphumela ikhombisa ukuthi ngemuva kokuphonswa kwe-aluminium alloy izikhathi eziyinkulungwane, ibhulokhi yokuhlola yensimbi engu-1,000Cr4Mo5V ithobele i-aluminium kakhulu futhi yakhiqiza imifantu emincane kakhulu efana net; i-Ni-containing steel block block yayilandelwa i-aluminium, ne-Co-containing steel block block yayinamathela ku-aluminium okuncane, okukhombisa ukuthi okuqukethwe yinsimbi engu-2% Co 1Cr4Mo5V kunakho konke ukulimala okushisayo kokuphikisana nama-alloys e-die-cast aluminium. Ngaphezu kwalokho, uma kuqhathaniswa nobulukhuni ngaphambi kwe-die-casting aluminium alloy, ngemuva kokuphonswa izikhathi ezingama-2, ubunzima bensimbi yensimbi engu-1,000Cr4Mo5V, izibonelo zensimbi ezine-nickel futhi omile ezine-2Cr4Mo5V zehle ngo-2, 2.8 no-1.8 HRC, okungukuthi, ama-alloys amaningi e-die-casting aluminium. Umphumela omubi ebulukhuni bensimbi ene-nickel equkethe futhi eyomile ye-1.4Cr4Mo5V incane kunaleyo yensimbi ye-2Cr4Mo5V, ehlobene nomphumela wokuqinisa isixazululo esiqinile se-Co ne-Ni, esizuzisa ukuthuthukisa ukumelana nokuguguleka kwe-aluminium liquid isikhunta futhi senze isikhunta singabi sengozini yokulimala okushisayo.

I-Aluminium alloy die-casting iyinqubo eyinkimbinkimbi yokushisa okuphezulu nokucindezela okukhulu. Kunezici eziningi ezithinta umonakalo oshisayo (kufaka phakathi ukukhathala nokushisa okushisayo) ukusebenza kwe-aluminium alloy die-casting molds. Phakathi kwabo, ukwakheka kwensimbi eshisayo kusebenza kakhulu kubaluleke kakhulu.

Ngaphansi kwezimo ezijwayelekile, ukwehluleka kokufa ekubunjweni kuyafa ngenxa yokuqhekeka nokwenziwa kwepulasitiki kungagwenywa. Ukuqhekeka kwesikhunta kuvame ukubangelwa ukulayishwa ngengozi kwemishini noma ukulayishwa okushisayo, okuholela ekugxilisweni okukhulu kwengcindezi. Ukukhathala kokuqala okushisayo nokuqhekeka kokushisela (ukulimala komhlaba okushisayo) kwesikhunta sokuphonsa kufa yizindlela eziyinhloko zokuhluleka, futhi lezi ezimbili zivame ukuthintana. Insimbi ye-4Cr5Mo2V iyinsimbi esetshenziswa kakhulu eshisayo yensimbi, enokumelana okuhle kokugqoka kanye nokumelana ne-plastic deformation. I-Drill ne-nickel yizinto ezivame ukusetshenziswa ekuhlanganiseni izinto, ezingakhuphula ngempumelelo amandla nobulukhuni bensimbi, futhi zibe nomthelela othile ekumelaneni nomonakalo oshisayo. Ngakho-ke, i-4Cr5Mo2V steel, i-4Cr5Mo2V equkethe i-1% Ni ne-1% Co (ingxenyenamba enkulu, efanayo ngezansi) iyafundwa. Ukumelana kwensimbi ekulimaleni kwe-aluminium encibilikisiwe kubaluleke kakhulu ukuqondisa umkhiqizo wangempela.

Kodwa-ke, izindlela eziningi zokutadisha umonakalo oshisayo we-die-casting die steel ngaphambi komlomo ukulingisa ukushisa nokupholisa. Isampula yensimbi efayo ayixhumani ngqo ne-aluminium encibilikisiwe, futhi ayibandakanyi umphumela wokushaywa kwe-aluminium encibilikisiwe, njengokushiswa okuqondile kokufakwa kwesampula yensimbi. -A. Kuleli phepha, amabhulokhi wokuhlola ensimbi enziwe ngezinto ezintathu alungiswa futhi afakwa kusikhunta sokufa ukuze kwenziwe isivivinyo sokufa se-ADC12 aluminium alloy. Ukulimala kokusebenza kwe-aluminium encibilikisiwe.

Izinto ze-1.Test Nezindlela

1.1 Izinto Zokuhlola

Ukwakheka kwamakhemikhali kwensimbi ye-4Cr5Mo2V, i-4Cr5Mo2V yensimbi equkethe i-1% Ni (ngemuva kwalokhu ebizwa nge-4Cr5Mo2V + Ni steel) kanye ne-4Cr5 Mo2V steel equkethe i-1% Co (ngemuva kwalokhu ebizwa nge-4Cr5Mo2V + Co steel) kuboniswa kuThebula 1. Isivivinyo senziwa i-cast ne-ADC12 Ukwakheka kwamakhemikhali kwe-aluminium alloy kuboniswa kuThebula 2.

| Itafula 1 | |||||||

| Material | C | Cr | Mo | V | Co | Ni | Si |

| Insimbi ye-4Cr5Mo2V | 0.39 | 4.65 | 2. 21 | 0.46 | - | - | 0. 23 |

| 4Cr5Mo2V + Ni insimbi | 0.38 | 4.72 | 2.34 | 0. 51 | - | 1.02 | 0. 21 |

| Insimbi ye-4Cr5Mo2V + Co | 0.41 | 4.67 | 2.40 | 0.48 | 1.03 | - | 0. 24 |

| Ithebula 2 Ukwakhiwa Kwamakhemikhali Kwe-ADC12 Aluminium Alloy% | |||||||||

| I-Element | Cu | Mg | Mn | Fe | Si | Zn | Ti | Pb | Sn |

| Amaphuzu wekhwalithi | 1.74 | 0.22 | 0.16 | 0.76 | 10.70 | 0.87 | 0.064 | 0.035 | 0. 010 |

1.2 Indlela Yokuhlola

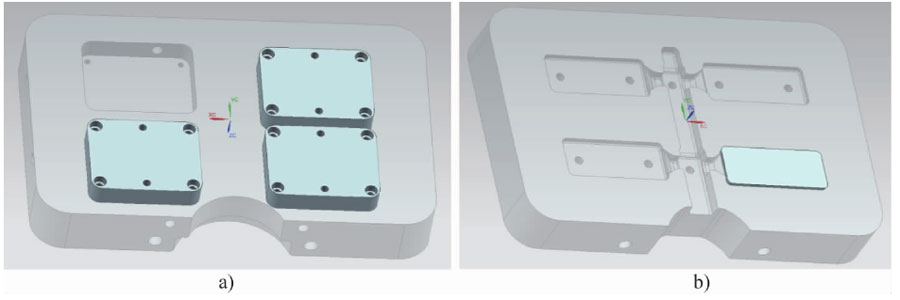

Insimbi emenyezelwe ye-4Cr5Mo2V, i-4Cr5Mo2V + Ni insimbi ne-4Cr5Mo2V + Co insimbi icutshungulwe yaba amabhulokhi wokuhlola njengoba kukhonjisiwe ku-Figure 1. Ngemuva kokucinywa kwe-vacuum, bavuthwa kabili, ngobulukhuni obucishe bube ngu-47 HRC, nomhlabathi ocijile wokususa isikali se-oxide.

Inombolo yeqembu lebhulokhi yokuhlola ishunyekwe emgodini wesikhunta esinqunyiwe, futhi umgodi we-die-cast aluminium alloy usethwe kusikhunta esihambayo, njengoba kukhonjisiwe kuMdwebo 2. Umshini wokuphonsa u-500 t ovundlile futhi isikhunta esenzelwe wena sisetshenziselwe ukuhlolwa kokufa kwe-ADC12 aluminium alloy sheet, kwathi i-aluminium alloy yasetshenziswa futhi. Izinga lokushisa le-aluminium encibilikisiwe liphakeme, 800 ° C, ukuze kusheshiswe isivivinyo (imvamisa, izinga lokushisa lokufa le-ADC12 aluminium alloy (650 120) ° C). Njengoba izinga lokushisa le-aluminium encibilikisiwe ingu-800 ℃, engafiki lapho kuncibilika khona i-Fe-A1 intermetallic compound, ingxube evelayo izobakhona ku-aluminium encibilikisiwe njengokungcola ngemuva kokuwa. Ukusetshenziswa okuphindaphindiwe kwe-aluminium encibilikisiwe nakho kuzodala ukwanda kokungcola futhi kuqinise i-aluminium. Umphumela wokukhuhla ketshezi, ngaleyo ndlela usheshise isivivinyo.

Ngemuva kokuhlolwa kokufa, kwasetshenziswa imicroscope yesitiriyo ukubona isimo sokunamathela kwe-aluminium ebusweni bebhulokhi yokuhlola; kwasetshenziswa imicroscope ye-ultra-depth-of-field ukuqhubekisela phambili ukugcina izinga lokunamathela kwe-aluminium nokuthi ngabe kukhona ukuqhekeka yini ebusweni be-block block.

Imiphumela Yesivivinyo Nokuhlaziywa

2. 1 I-Surface Morphology Ye-Test Block

2.1.1 I-Aluminium Yokunamathela Okuphezulu

Umdwebo 3 ukhombisa ukwakheka komhlaba kwe-morphology yamabhulokhi amathathu okuhlolwa kwensimbi ngaphandle kokuphonswa kokufa nangemuva kwezikhathi ezingama-600,1000 zokulingisa. Kungabonakala kusuka ku-Figure 3 (b, e, h) ukuthi ngemuva kwezikhathi ezingama-600 zokuphonsa, i-4Cr5Mo2V block block block ine-aluminium enamathela kakhulu.

I-4Cr5Mo2V + Co steel block block inamathela ku-aluminium encane. Umdwebo 3 (c, f, i) ukhombisa ukuthi ukunamathela kwe-aluminium ebusweni bamabhulokhi amathathu wokuhlola kukhuphuke ngemuva kwezikhathi eziyi-1,000 4 zokuphonsa ukufa. Ubuso be-5Cr2Mo4V steel block block bunokunamathela okusobala kwe-aluminium, kuyilapho amanye amabhulokhi amabili wokuhlola enokunamathela okuncane kwe-aluminium. Ukuhlolwa kwensimbi kwe-5Cr2Mo4V + Co Isigaxa se-aluminium sincane kakhulu futhi sifana, okukhombisa ukuthi insimbi ene-5Cr2Mo4V equkethe idayimane inokumelana okuhle nomonakalo we-aluminium oketshezi, kuyilapho insimbi ye-5Cr2Mo9V iyimbi kakhulu. Ukwengezwa kwezakhi ze-drill ne-nickel kuyasiza ukuzinzisa ukushisa okuphezulu kwensimbi ye-die 10-XNUMX, futhi indawo akulula ukuthi "ithambe" lapho uthintana kaningi ne-aluminium encibilikisiwe, ngakho-ke ukumelana nokuguguleka kwe-aluminium okungamanzi kungcono, nokunamathela kwe-aluminium incane. Ngesikhathi sokuhlolwa kokufa, i-aluminium encibilikisiwe ingena emgodini ukuze ixhumane nebhulokhi yokuhlola, futhi isakhiwo esingalingani sebhulokhi yokuhlola, indawo enesici semishini nezinye izindawo zendawo zizonamathela ku-aluminium. I-aluminium esendaweni eboshwe nge-aluminium izosabela ngensimbi ukuze yakhe i-Fe.} I-brittle intermediate compound, ezophucwa futhi ihlutshulwe ngaphansi kokushaywa kuketshezi lwe-aluminium ephezulu, okuholela emigodini ebusweni besikhunta, nokuningi ukubopha okukhulu kwe-aluminium ngaphansi kokushaywa ketshezi lwe-aluminium.

2.1.2 Ukuqhekeka kobuso

Umdwebo 4 ukhombisa ukujula okuphezulu kakhulu kwe-morphology yasensimini yensimbi engu-4Cr5Mo2V, 4Cr5Mo2V + Ni steel kanye ne-4Cr5Mo2V + Co izibonelo zensimbi ngemuva kwezikhathi eziyi-1,000 zokuphonsa ukufa. Kungabonakala kusuka ku-Fig. 4 (a) ukuthi kunenani elincane lemifantu emincane esatshalaliswe ngendlela ecishe ibe senetha ebusweni bendawo yokuhlola yensimbi engu-4 Cry Mot V. I-aluminiyamu ebambelele kanye ne-aluminium encibilikisiwe isebenza ngensimbi ukwakha i-Fe.} Ama-Al compounds. Ukulingana kokunwetshwa okushisayo kukaFe.} I-Al yehlukile kunaleyo ye-matrix, okuholela enanini elincane kakhulu lama-microcracks ku-aluminiyamu elandelwayo ne-Fe.} Al kanye nezinhlanganisela. Umphumela wokuklwebheka kwe-aluminium encibilikisiwe wenza ukuthi ama-microcracks asabalale, bese kuthi i-aluminium encibilikisiwe ingene ekuqhekekeni iphinde ihlangane ne-matrix ukwakha izinhlanganisela ze-Fe 2 Al. Enqubweni yokuphonsa ukufa ephindaphindwayo, i-Fe.} Ama-Al compounds ebusweni be-block block ayaxebuka akha imigodi. Ngemuva kokukhethwa kanye nokuhlanzwa kwe-ultrasonic, ingaphezulu lebhulokhi lokuhlola lavela ngokufana nezici zokuklwebha uketshezi lwe-aluminium. Umdwebo 4 (b, c) ukhombisa ukuthi akukho ukuqhekeka ku-4Cr5Mo2V + Co steel naku-4Cr5Mo2V + Ni steel block block, okukhombisa ukuthi ukungezwa kwe-1% drill noma i-molybdenum akukwazi ukunciphisa kuphela ukunamathela kwe-aluminium, kepha futhi kunciphise ukuthambekela kokuqhekeka kwesikhunta futhi kuthuthukise ukumelana ne-aluminium ukusebenza komonakalo wamanzi. Ukwengezwa kwezakhi ze-nickel nedayimane ezingezona i-carbide kungathuthukisa ubunzima bokushisa okuphezulu kwesikhunta, futhi idayimane lingakhuthaza nokusabalalisa kanye nemvula ye-molybdenum carbide ngesikhathi senqubo yokushisa, futhi ithuthukise umphumela wokwenza lukhuni 'z-} 3. Ucwaningo olwenziwe nguLing Qian et al. kukhombisile ukuthi ukwengezwa kwezinto ezizinzile ze-austenite ukuze kufakwe izinsimbi zensimbi kunganciphisa ukugxila kwengcindezi. Kokubili i-drill ne-nickel kuyizinto ezinweba indawo ye-austenite, ngakho-ke i-4Cr5Mo2V + Ni steel ne-4Cr5Mo2V + Co steel die casting surface surfaces azijwayele ukuqhekeka.

I-aluminium encibilikisiwe enqubweni yangempela yokufa ifana kakhulu nesikhunta. Ngokusho komdwebo wesigaba se-Fe-A1, izinhlanganisela ze-Fe-Al ezenziwe ngokwenziwa kwensimbi ne-aluminium encibilikile ikakhulukazi i-FeAlz, Fez A15, FeA13, njll. yeqa i-matrix bese ufaka i-aluminium encibilikisiwe ngaphansi kokushaywa kwe-aluminium encibilikisiwe, ishiya imigodi ebusweni besikhunta. Inhlanganisela yengxenye ye-aluminium alloy nemigodi yesikhunta iqine ngokwedlulele futhi ayiwi, bese iqhubeka yakha izinhlanganisela ze-Fe A1. I-aluminium, i-Fe.} I-Al kanye namakhemikhali anamathela lapho athambekele kuma-microcracks ngesikhathi sokupholisa. Ishidi lokuphonsa liqukethe i-aluminium engaphansi ketshezi, ngakho-ke iyaqina ngokushesha, futhi ukusabela phakathi kwesikhunta ne-aluminium ketshezi kuhamba kancane. Ngakho-ke, ubuso be-block block bunemigodi embalwa ngenxa yokusabela kuka-Fe no-Al, futhi i-aluminium enamathelayo eningi ikhiqizwa ukuguguleka kuketshezi lwe-aluminium.

2. 2 Ubulukhuni Baphezulu

Ithebula 3 inani elijwayelekile lobulukhuni bendawo yokufa kwamabhulokhi amathathu okufa kwensimbi ngemuva kwezikhathi ezahlukahlukene zokulingiswa kokufa. Imininingwane ekuThebula 3 ikhombisa ukuthi ubunzima bendawo yezinhlobo ezintathu zamabhulokhi wokuhlola konke kwehla kancane. Njengoba inani lezikhunta ezifayo zikhuphuka, lilingana nokushisa okuphindaphindiwe kwebhulokhi yokuhlola, ngakho-ke ubunzima buyancipha. Ngemuva kwezikhathi eziyi-1,000 4 zokuphonsa ukufa, ubunzima be-5Cr2Mo1.4V + Co steel block block bunokuncipha okuncane kakhulu, okuyi-4 HRC; i-5Cr2MoXNUMXV steel block block inokwehla okusobala kakhulu.

Ngokusobala, yehle ngo-2 HRC; ubunzima bendawo ye-8Cr4Mo5V + Ni yokuhlolwa kwensimbi yehle ngo-2. 1 HRC. Ukuqina kwesikhunta okuzinzile kunenzuzo yokwehlisa ukunamathela kwe-aluminium, okungukuthi, kuyasiza ukumelana nomonakalo oshisayo wokufa.

| Ithebula 3 Surface ubulukhuni bamabhulokhi wokuhlola ngemuva kokulingiswa kokufa ngezikhathi ezihlukile% | ||||||

| Material | Ayikho iDie Cast | I-200 Times | I-400 Times | I-600 Times | I-800 Times | I-1000 Times |

| Insimbi ye-4Cr5Mo2V | 48.6 | 48.4 | 48.1 | 47.2 | 46.9 | 45.8 |

| 4Cr5Mo2V + Ni insimbi | 47.5 | 47.4 | 47.2 | 46.8 | 46.9 | 46.1 |

| Insimbi ye-4Cr5Mo2V + Co | 47.7 | 47.5 | 47.1 | 46.5 | 46.2 | 45.9 |

Ngemuva kokushisa isikhathi eside kwensimbi yokufa, i-martensite iyawohloka bese ama-carbides wesibili aba makhulu, okuholele ekwehleni kobulukhuni bomhlaba. Kokubili i-drill ne-nickel yizinto ezakha i-carbide, ezingathatha indawo yama-athomu e-Fe ukwenza insimbi eqinile yensimbi iqinise u-'5 kuye ku-8, ukuze isikhunta sibe namandla aphezulu okushisa futhi sigcine ubulukhuni obuphakeme ngemuva kokushisa okusheshayo nokupholisa okuphindiwe. I-China Die Casting Association ifunde ukusatshalaliswa kwensimbi kuCr-Mo-V-Ni yensimbi ecinyiwe necashile, futhi yathola ukuthi ngesikhathi sokushisa, izakhi ze-Ni zizothuthukiswa zizungeze ama-carbides, ngaleyo ndlela zivimbele ama-athomu ekhabhoni e-ferrite ezungeze ama-carbides Ukwanda okuqhubekayo kwama-carbide kwandisa amandla wokwenza ukusebenza kwe-carbide coarsening, kuvimbela ukukhula kwama-carbides, ngaleyo ndlela kunciphise ukwehla kobulukhuni bensimbi ene-4Cr5Mo2V ene-nickel, futhi kuthuthukise ukumelana kwayo nomonakalo we-aluminium oncibilikile.

I-China Die Casting Association ifunde ukuzinza okushisayo kanye nezinguquko ze-microstructure zensimbi efa nge-1% Ni nangaphandle kwe-Ni, futhi yathola ukuthi esigabeni sakamuva sokuhlolwa kokuqina kokushisa, i-nickel izokwehlisa ijubane lobunzima bensimbi yokufa, ngaleyo ndlela yenza insimbi ezinzile kangcono ngokocansi. Ukubhola kuyisici esandisa indawo yesigaba se-austenite. Ukwengeza i-drill ku-4Cr5Mo2V steel kungakhuthaza ukuqedwa kwama-carbides ngesikhathi senqubo yokwenza amandla, kwandise okuqukethwe kwekhabhoni kwe-austenite, futhi kwandise ukuzinza kwe-austenite, ngaleyo ndlela kwandise i-austenite egcinwe Inani le-tensite nobulukhuni be-martensite, ne-drill nayo ukugqugquzela ukuhlakazeka kanye nemvula ye-molybdenum carbide ngesikhathi senqubo yokushisa, futhi uthuthukise umphumela wokuqina kwemvula u-z'-1.

Umphumela wokuqiniswa kwe-nickel ne-drill kumatrix kwenza ukuthi i-die steel test block isenobulukhuni obuphezulu bendawo ngemuva kokushaywa okuphindaphindiwe kwe-aluminium encibilikisiwe, ukuze ikwazi ukumelana nokuguguleka, okuzuzisa ukwenza ngcono ukumelana kwebhulokhi yokuhlola ekulimaleni kwe-aluminium encibilikisiwe. Ubulukhuni bendawo yokuhlola kanye nezinga lokunamathela kwe-aluminium nakho kuyakhombisa (bona Umfanekiso 3, Ithebula 3): I-block block ye-4Cr5 Mo2V yensimbi inezimbobo ezingaphezulu kanye nokunamathela kwe-aluminium ngemuva kwezikhathi eziyi-1,000 1 zokuphonsa, okungukuthi, ukumelana nomonakalo oketshezi lwe-aluminium kungcono kakhulu. Ngakho-ke, umphumela wokuqinisa wokwengeza i-1% Co ensimbi mkhulu kunokufaka i-XNUMX% Ni, zombili ezilungele ukuthuthukisa ukusebenza kokulimala kwe-anti-aluminium yensimbi efayo.

I-3.Conclusion

- Ngemuva kokuphonsa i-aluminium alloy izikhathi eziyi-1 000, isampula yensimbi engu-4Cr5 Mo2V ene-drill inamathela i-aluminium encane, kanti isampula yensimbi engu-4Cr5Mo2V inamathela ku-aluminium kakhulu, okungukuthi, insimbi engu-4Cr5 Mo2V ene-drill inokumelana okuhle kakhulu kokulimala okushisayo.

- Ngemuva kokuphonsa i-aluminium alloy izikhathi eziyinkulungwane, ubunzima bensimbi ye-1,000Cr4Mo5V steel, 2Cr4Mo5V + Ni steel kanye ne-2Cr4Mo5V + Co izibonelo zensimbi zehle ngo-2, 2.8 no-1.8 HRC, okungukuthi, ukwengezwa kwe-nickel noma i-drill kungathuthukisa kakhulu ukumelana nokulimala komzimba ka-1.4Cr4Mo5V die-thusi die die.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Umphumela we-Drill ne-Nickel ekuphikisweni komonakalo we-Thermal we-4Cr5Mo2V Die Casting Die Steel

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off