Ukuhlukaniswa kweMishini Yokuphonsa i-Die kanye nenqubo yokusebenza

Umshini wokuphonsa umshini uyisisekelo esibalulekile semishini yokukhiqiza ekukhiqizeni okufa, okunomthelela oqondile kwikhwalithi, ukusebenza kahle kokukhiqiza, izindleko zokusebenza, umfutho wabasebenzi, imvelo, kanye nenhlanzeko yezingxenye zokufa. Ngakho-ke, kufanele kube nokuqonda okucacile komshini wokulingisa, ukuze umshini wokufa ungasetshenziswa ngendlela ebekiwe futhi enengqondo ukuqinisekisa inqubekela phambili ebushelelezi yokukhiqizwa kokufa futhi kwandise umkhiqizo wezisebenzi.

Ukuhlukaniswa Komshini Wokuphonsa Okufa

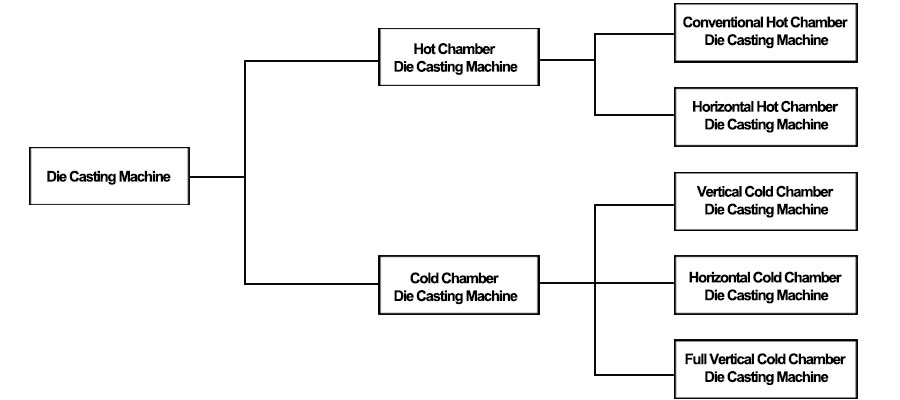

Kunezindlela eziningi zokuhlukanisa zemishini yokufa. Ngokuya ngobubanzi bokusetshenziswa, zihlukaniswe zaba yimishini ejwayelekile yokufa futhi imishini ekhethekile yokufeza; ngokusho kwamandla okubamba, ahlukaniswe ngemishini emincane (≤4 000 kN), imishini emaphakathi (4 000 ~ 10 000 kN) nemishini emikhulu. Umshini (≥10 000 kN); Ngokuvamile, ihlukaniswa kakhulu ngokuya ngesakhiwo somshini nendawo yegumbi lokujova (ngemuva kwalokhu elibizwa ngokuthi ikamelo lokucindezela) nezimo zokusebenza kwalo. Amagama ezinhlobo ezahlukahlukene ze ukufa-okusakaza imishini iboniswa ku-Figure 1.

Fig. 1 Ukwahlukaniswa die ekubunjweni umshini

Umshini ovundlile wegumbi lokushisa osakazayo kuMfanekiso 1 ubekwe ngokuvundlile. Yaqala ukwenziwa yiHarvill Company e-United States ngo-1981, futhi yakhangiswa ngo-1982. Ngo-1983, yabukiswa engqungqutheleni ye-12th International Die-casting Conference and Exhibition e-United States. Ovundlile hot egumbini umjovo mshini. Ngenxa yezizathu ezahlukahlukene, lolu hlobo lomshini alukaziwa, ngakho-ke ngeke ngilwethule okwamanje.

Ukwakheka Komshini We-Die Casting

- Umshini wokubamba isikhunta ushayela isikhunta sokufa ukuvala nokuvula. Lapho isikhunta sivaliwe, sinamandla okwanele ukukhiya isikhunta ukuqinisekisa ukuthi indawo yokuvalelisa isikhunta ngeke ikhule ngesikhathi senqubo yokugcwalisa umjovo. Amandla okubamba isikhunta abizwa ngokuthi yi-clamping force (eyaziwa nangokuthi amandla okuvala), futhi iyunithi yi-kilonewton (kN), okuyipharamitha eyinhloko ehlukanisa ubukhulu bomshini wokuphonsa kufa.

- Indlela yomjovo iphusha insimbi encibilikisiwe egumbini lengcindezi ngejubane elicacisiwe, futhi inamandla anele okuyenza igeleze ngomgijimi nangesango langaphakathi kusikhunta, bese igcwalisa emgodini wesikhunta, bese igcina ingcindezi ethile dlulisela ku-Insimbi encibilikisiwe iyaqina kuze kube yilapho kwenziwa ukubunjelwa kokufa. Ngemuva kokuthi isenzo somjovo sesiqediwe, isibhakela somjovo sibuyela ukusetha kabusha.

- Uhlelo lwe-hydraulic lunikeza amandla anele namandla okusebenza komshini wokuphonsa odongeni.

- Uhlelo lokulawula ugesi lulawula ukwenziwa kwendlela ngayinye yomshini wokuphonsa ukuze usebenze ngokuya ngohlelo olunqunywe kusengaphambili.

- Zonke izingxenye nezingxenye zesisekelo somshini zihlanganisiwe futhi zihlanganisiwe ukwakha wonke umshini wokuphonsa die futhi uhleli esisekelweni somshini.

- Amanye amadivayisi Umshini wokuphonsa odonsa phambili nawo unemibono yokuthola ipharamitha, i-alarm alarm, inqubo yokuqopha inqubo yokufa, ukugcinwa kwemininingwane yokusiza ekhompyutheni, ukushaya, ukuphrinta nokuphatha izinhlelo.

- Idivayisi esizayo ifakwe amadivayisi njengokuthela, ukufafaza, nokukha ngokuya ngezinga lokuzenzakalela.

Usebenza Kanjani Umshini Wokulingisa

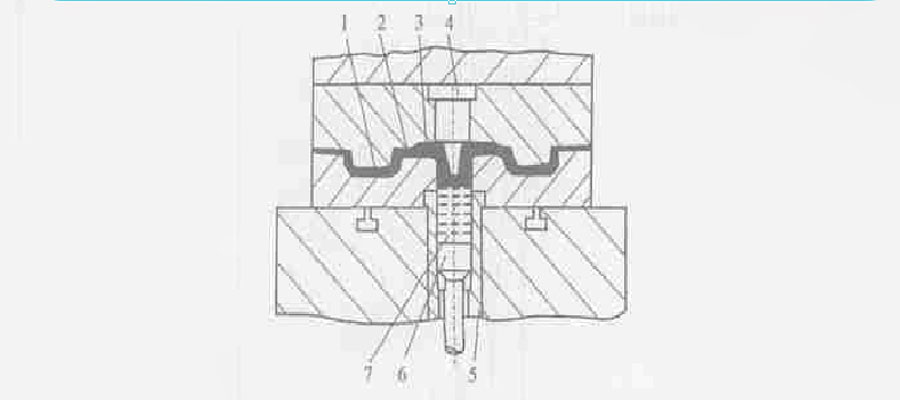

Hot ekamelweni die umshini ekubunjweni

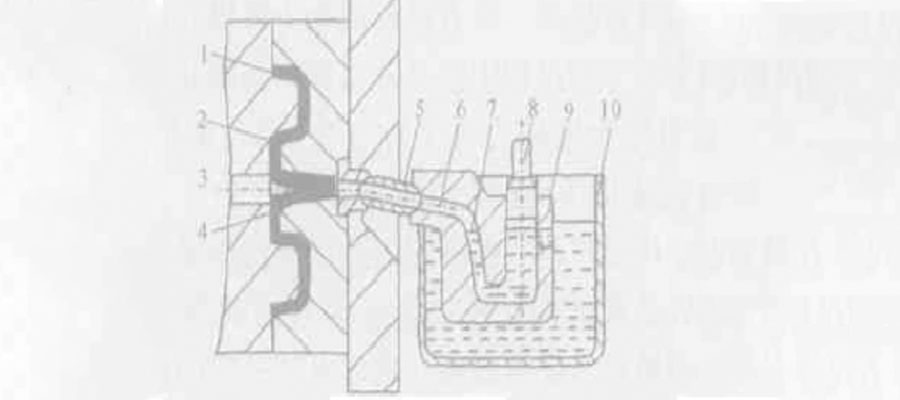

Imodi yokusebenza ejwayelekile yomshini oshisayo wokukhipha umshini uboniswa kuMdwebo 2. Isithando somlilo somshini oshisayo wekhamera eshisayo sibekwe emshinini.

Kuthelwa esithandweni somlilo, ibhodwe elithululelwayo elinekamelo lengcindezi kanye nesiteshi se-gooseneck kanye ne-injection punch 9 konke kugxiliswe ensimbi encibilikisiwe 8. Izenzo zokuvula nokuvala zesikhunta zihamba ziye phezulu. Emva isikhunta ivuliwe, ekubunjweni die uhlala isikhunta ezithathekayo. Izinyathelo zokusebenza zimi kanje:

- Ipuleti lekhanda lomshini nomkhono we-mold sprue useduze nombhobho (eminye imishini ayinalo lolu hlelo);

- Vala isikhunta;

- Lapho isibhakela somjovo sisesimweni esiboniswe emfanekisweni, insimbi encibilikisiwe ingena ezikhaleni ezahlukahlukene ebhodweni elithelayo kusuka kuma-orifices ohlangothini. Ngemuva kokugeleza, isiteshi se-gooseneck

- Izinga loketshezi ngaphakathi liyashayisana nezinga loketshezi esithandweni somlilo;

- I-punch yomjovo yehlela phansi ngejubane lomjovo ohamba kancane kuze kuvalwe imbobo eseceleni;

- I-punch yomjovo iphusha insimbi encibilikisiwe ngejubane elikhulu, futhi idlula esiteshini se-gooseneck 6, umbhobho ongu-5, u-sprue 4 wesikhunta, i-splitter 3, kanye nesango langaphakathi

- 2 Gcwalisa emgodini wesikhunta, bese uqinisa ube yi-die casting 1;

- Isibhakela somjovo siyaphakanyiswa, futhi insimbi encibilikisiwe eshibhini nasemgudwini we-gooseneck igelezela emuva ebhodweni elithelayo;

- Vula isikhunta, shiya ingxenye yokufa futhi isango kusikhunta esihambayo, bese ukhipha bese ukhipha ingxenye yokufa;

- Ipuleti lekhanda lomshini nomkhono wesikhunta se-mold shiya umbhobho (eminye imishini ayinalo lolu hlelo); kuze kube manje, umjikelezo wokuphonsa odongeni usuphelile.

Umdwebo 2 Imodi Yokusebenza yomshini oshisayo wokushisa

1. die castingparts

2. Isango langaphakathi

3. I-splitter

4. Isihlahla

I-5. Umbukiso

6. Isiteshi seGooseneck

7. Uketshezi lwensimbi

8. Umjovo wesibhakela

9. Ukubhodla imbiza

10. Isithando Somlilo

Umshini Wokuphonsa weCold Chamber Die

Injini enkulu yekamelo elibandayo ifa umshini wokuphonsa uhlukaniswe nesithando somlilo, isithando somlilo sibekwa eceleni, futhi insimbi encibilikisiwe idluliswa isuka esithandweni iye egumbini lokucindezela lenjini enkulu. Isithando somlilo sivame ukuqinisekiswa kuphela.Ngenxa yokuthi sisetshenziselwa ukufudumala, kuvame ukubizwa ngokuthi isithando somlilo; kuphela lapho inani lemishini lincane noma lincane lokukhiqizwa kweqoqo, isithando somlilo sisebenza njengendawo yokuncibilika. Igumbi elibandayo lokufa umshini wokulingisa uhlukaniswe igumbi elibandayo elibheke phezulu, igumbi elibandayo elibandayo negumbi eligcwele eliqondile eliqondile.

Ukusebenza imodi mpo egumbini abandayo die ekubunjweni umshini

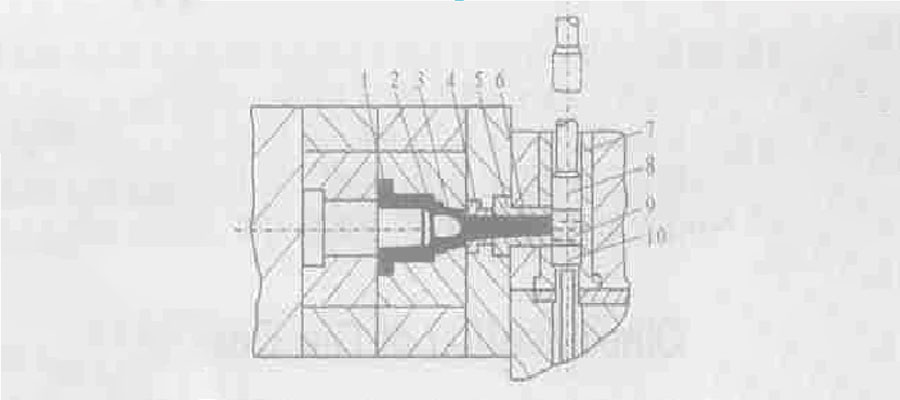

Imodi yokusebenza yegumbi elibandayo elibandayo lokukhipha umshini ikhonjiswa kuMdwebo 3. Igumbi lokucindezela 7 libekwe mpo, kanti isibhakela esingenhla esingu-8 singaphezulu kwegumbi lengcindezi (indawo engaphezulu kwesibalo), kanti isibhakela esiphansi esingu-10 sitholakala endaweni lapho kuvinjelwe khona umlomo wombhobho 5, ukuze uvimbele insimbi encibilikile ekutheleleni egumbini lengcindezi futhi igeleze imbobo yombhobho iyodwa. Ukuvulwa nokuvalwa kwesikhunta kuvundlile Emva kokuhambisa nokuvula isikhunta, ukusakazwa kokufa kuhlala kusikhunta esihambayo. Izinyathelo zokusebenza zimi kanje:

Figure 3 Ukusebenza imodi mpo egumbini abandayo die ekubunjweni umshini

1. die izingxenye ekubunjweni

2.Shunt

3. Isango langaphakathi

4. Umkhono we-Sprue

I-5. Umbukiso

6. Isihlahla

7. Igumbi lokucindezela

8. Isibhakela esingenhla

9. Ikhekhe lokusala

10. Isibhakela esiphansi

- Vala isikhunta;

- Thela insimbi encibilikisiwe egumbini lokushicilela ngesandla noma ngezinye izindlela;

- I-punch engenhla yehlela phansi ngejubane lomjovo ophansi, ingena egumbini lengcindezi bese ivele ithinte indawo encibilikisiwe yensimbi;

- I-punch ephezulu iphendulwa ijubane lomjovo eliphakeme ukucindezela phansi, kuyilapho i-punch engezansi ne-punch ephezulu igcina ibanga elihambisanayo phakathi kwesigaba esiphakathi nensimbi encibilikile bese yehla ngokushesha;

- Lapho isibhakela esingezansi sihlehlela phansi ukukhipha umbhobho wombhobho wombhobho, simane siye ezansi bese siyasekelwa; ngakho-ke, izibhakela ezingenhla nezingezansi zikhama insimbi encibilikisiwe ngejubane elikhulu kuya emgodini wombhobho (ingxenye yesiprue 6) iJet;

- Insimbi encibilikisiwe idlula ku-sprue 6, eyakhiwe ngombhobho, umkhono we-sprue 4, imbobo e-tapered yesikhunta esinqunyiwe, ne-diverter 2, futhi igcwaliswa embotsheni yesikhunta kusuka esangweni langaphakathi 3;

- Ukugcwaliswa kuqediwe, kepha isibhakela esingenhla sisalokhu sigcina ingcindezi ethile kuze kube yilapho insimbi encibilikisiwe esemgodini iqiniswe ngokuphelele yaba yisigaxa sokufa 1; insimbi encibilikisiwe kumgijimi negumbi lokucindezela liqina lingene esangweni eliqondile nekhekhe elisele 9;

- I-punch engenhla iphakanyisiwe futhi isethwe kabusha; ngasikhathi sinye, isibhakela esingezansi sihambela phezulu ukusika ikhekhe elisele elisaxhunywe esangweni eliqondile;

- I-punch engezansi iyaqhubeka nokukhuphuka, iphakamise ikhekhe lezinto ezisele ngaphandle ebusweni bekamelo lokucindezela, bese ngesandla noma ezinye izindlela zisusa;

- Hambisa isibhakela esingezansi phansi bese usetha kabusha ukuvimba indawo yombhobho;

- Vula isikhunta, ingxenye yokufa futhi isango eliqondile lihlala esikhunjeni ndawonye, bese ukhipha futhi ukhiphe ingxenye yokufa; lapho ikhekhe lezinto ezisele selinqunyiwe, isenzo sokuvula isikhunta singenziwa ngokushesha, noma singancishiswa kancane siye esikhathini esifanele Ukubulawa akuhlangene nokuphakamisa nokusetha kabusha isibhakela esingezansi; Kuleli qophelo, umjikelezo wokuphonsa odongeni usuphelile.

Ukusebenza imodi enezingqimba egumbini abandayo die asakazwe umshini

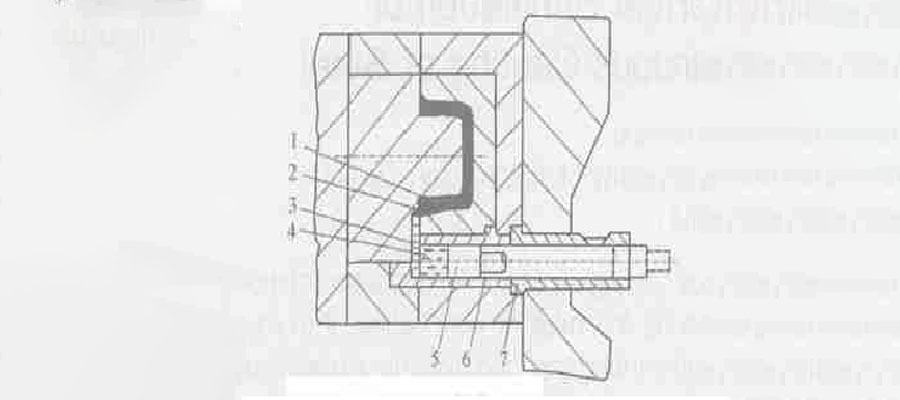

Imodi yokusebenza yekamelo elibandayo elibandayo lokukhipha umshini ikhonjiswa kuMdwebo 4. Igumbi lokucindezela 7 libekwe ngokuvundlile, kanti isibhakela somjovo 5 sisemgqeni onamachashazi ekugcineni kwesokudla kwegumbi lokucindezela. Ukunyakaza kokuvula nokuvala kwesikhunta kuhamba ngokuvundlile. Ngemuva kokuvulwa kwesikhunta, ingxenye yokulingisa ihlala kusikhunta esihambayo. Izinyathelo zokusebenza zimi kanje:

- Vala isikhunta;

- Thela insimbi encibilikisiwe egumbini lokushicilela ngesandla noma ngezinye izindlela;

- I-punch yomjovo iphusha uketshezi lwensimbi ngesivinini esinqunyelwe kusengaphambili nengcindezi ethile, ukuze idlule kumgijimi 3 wesikhunta, futhi igcwaliswe emgodini wesikhunta kusuka esangweni langaphakathi 2;

- Ngemuva kokugcwaliswa, i-punch igcina ingcindezi ethile kuze kube yilapho insimbi encibilikisiwe iqinile ngokuphelele ukuze ibe ngumlingisi wokufa 1; Ngalesi sikhathi, umgijimi nomkhono we-sprue 6 (isikhunta ngaphandle komkhono we-sprue iyigumbi lokucindezela elihlanganisiwe lapha)) Insimbi encibilikisiwe ngaphakathi nayo iyaqina ngasikhathi sinye, iba yisango nekhekhe lezinto ezisele 4;

- Vula isikhunta, isibhakela sihamba ngokuvumelanayo nesenzo sokuvula isikhunta, ukuze ikhekhe lezinto ezisele liqhutshwe kanye nengxenye yokufa kanye nesango lokuhlala kusikhunta esinyakaziswayo bese ushiya isikhundla esimisiwe.

- Lapho ufinyelela ibanga elithile, isibhakela sizobuyela ukusetha kabusha;

- Ngemuva kokuvulwa kwesikhunta, ingxenye yokufa, isango kanye nekhekhe lezinto ezisele lihlala kusikhunta esinyakaziswayo, khipha bese ukhipha ingxenye yokufa; Kuleli qophelo, umjikelezo wokulingisa usuphelile

Figure 4 Ukusebenza imodi enezingqimba egumbini abandayo die die ekubunjweni umshini

1. die izingxenye ekubunjweni

2. Isango langaphakathi

3. Umgijimi

4. Ikhekhe lokusala

5. Umjovo wesibhakela

6. Umkhono we-Sprue

7. Igumbi lokucindezela

Ukusebenza imodi egcwele mpo egumbini abandayo die ekubunjweni umshini

Imodi yokusebenza yekamelo eligcwele elibandayo elibandayo lokukhipha umshini likhonjiswa kuMdwebo 5. Igumbi lokucindezela 5 libekwa ngokuma engxenyeni engezansi yomshini, futhi ukuvulwa nokuvalwa kwesikhunta kuye phezulu naphansi, ngakho-ke kubizwa umshini wokuphonsa oqondile oqonde mpo. Imvamisa isikhunta esisuswayo sesikhunta sigxiliswa kuso

Ngemuva kokuvulwa kwesikhunta, ingxenye yokulingisa ihlala kusikhunta esihambayo. Izinyathelo zokusebenza zimi kanje:

- Thela insimbi encibilikisiwe egumbini lokushicilela ngesandla noma ngezinye izindlela;

- Vala isikhunta;

- I-punch 6 ihamba futhi icindezele insimbi encibilikisiwe ukuthi idlule kumgijimi 3 diverter 4, bese iyigcwalisa isuka esangweni elingaphakathi 2 iye embotsheni yesikhunta;

- Ngemuva kokugcwaliswa, i-punch igcina ingcindezi ethile kuze kube yilapho insimbi encibilikisiwe iqinile ngokuphelele ukuze ibe ngumlingisi wokufa 1; ngalesi sikhathi, insimbi encibilikisiwe kumgijimi negumbi lokucindezela nayo iyaqina ngasikhathi sinye, futhi ingcindezi egumbini lengcindezi iba ikhekhe eliyinsalela 7;

- Vula isikhunta, bese isibhakela sihambela phezulu ngokuvumelanayo nesenzo sokuvula isikhunta, ukuze ikhekhe lezinto ezisele lilandele ukusakazwa kokufa nesango kanye nesikhunta esihambayo kushiye isikhunta esinqunyiwe. Lapho ufinyelela ibanga elithile, isibhakela siyehla. Setha kabusha;

- Ngemuva kokuvula isikhunta, khipha ngokushesha bese ukhipha ingxenye yokufa; Kuleli qophelo, umjikelezo wokulingisa usuphelile.

Figure 5 Okugcwele mpo egumbini abandayo die asakazwe umshini

1. die izingxenye ekubunjweni

2. Isango langaphakathi

3. Umgijimi

4.Shunt

5. Igumbi lokucindezela

6. Umjovo wesibhakela

7. Ikhekhe lokusala

Izindinganiso ezifanele zaseChina zifa umshini wokulingisa

Ukuze kuqhutshekwe nokukhuthaza ukuthuthukiswa kokukhiqizwa kwemishini yezwe lami, iminyango efanelekile yomkhakha wemishini yezwe lami yakhipha amazinga wokuphonsa umshini wokufa ngo-1980 futhi yabuyekezwa ngo-1990. Ngawo lowo nyaka, amazinga okunemba kanye izimo zobuchwepheshe zomshini wokulingisa nazo zaphinde zamenyezelwa, ezinikeze ireferensi yokwakhiwa, ukwenziwa nokwamukelwa komshini wokulingisa. Kusukela lapho, ibuyekezwe kaningana ukuyenza iphelele futhi isebenze ngokwengeziwe. Izindinganiso zemikhakha yemishini yemishini yokuphonsa kufa kanye nezinombolo zayo ze-serial ezikhishwe ngemuva kokubuyekezwa ngonyaka ka-2000 zimi kanje. Amapharamitha womshini wokuphonsa (JB / T 8083 -2000) Izinga lichaza amapharamitha womshini wokuphonsa. Umshini wokuphonsa uhlukaniswe waba yizinhlobo ezintathu: umshini wokuphonsa umshini wokubanda wokushisa ovundlile, umshini wokuphonsa umshini obandayo obheke phezulu nomshini wokushisela owushisayo. Amapharamitha amakhulu namanani ayisisekelo wepharamitha ezinhlobo ezintathu afakwe kuhlu lwesithasiselo.

- Ukunemba kwekamelo elibandayo lokufa umshini wokuphonsa (JB / T 8084.1 -2000) Leli zinga libala ukunemba nokuhlolwa kwendlela yokubanda komshini obandayo.

- Izimo zobuchwepheshe zekamelo elibandayo lokufa umshini wokuphonsa (JB / T 8084.2 -2000) Leli zinga libala imigomo nezincazelo ezifanele, izidingo zobuchwepheshe, izindlela zokuhlola, imithetho yokuhlola, njll.

- Ukunemba kwekamelo elishisayo lokufa umshini wokuphonsa (JB / T 6309.2 -2000) Leli zinga libala ukunemba nokuhlola kwendlela yokushisa imishini eshisayo.

- Izimo zobuchwepheshe zeshishini lokushisa elishisayo (JB / T 6309.3 -2000) Leli zinga libala imigomo nezincazelo ezifanele, izidingo zobuchwepheshe, izindlela zokuhlola, imithetho yokuhlola, njll.

- Izidingo zokuphepha komshini wokuphonsa (JB 10145-1999) Izinga elijwayelekile libala imigomo efanelekile nezincazelo zayo, izinto ezibalulekile eziyingozi, izidingo zokuphepha kanye / noma izinyathelo, kanye nokuzimisela kwezidingo zokuphepha kanye / noma nezinyathelo.

- Izindinganiso ezifanele zekhamera ebandayo ebheke phezulu ebandayo azikaze zamenyezelwe. Ngokuthuthukiswa kobuchwepheshe bokufa, izidingo ezintsha zihlala zibekwa phambili kumishini yokufa, izindlela zokusebenza zemishini yokufa izothuthukiswa ngokuqhubekayo, futhi izinhlobo zemishini yokufa izophenduka kancane kancane.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Ukuhlukaniswa kweMishini Yokuphonsa i-Die kanye nenqubo yokusebenza

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off