Indlela Yokuthuthukisa Ukusebenza Kwesikhunta

Ngaphezu kokusebenzisana okunengqondo kwe-matrix ngamandla anele nobulukhuni, izakhiwo ezingaphezulu zesikhunta zibaluleke kakhulu ekusebenzeni nasekusebenzeni kwempilo yesikhunta. Lezi zakhiwo ezingaphezulu zibhekise kokumelana nokugqoka, ukumelana nokugqwala, ukungalingani kokungqubuzana, ukusebenza kokukhathala, njll. Ubuchwepheshe bokwelashwa komhlaba buvame ukuthola umphumela ophindwe kabili ngomzamo oyingxenye. Lesi yisizathu sokuthi ubuchwepheshe bokwelashwa kwendawo buthuthuke ngokushesha.

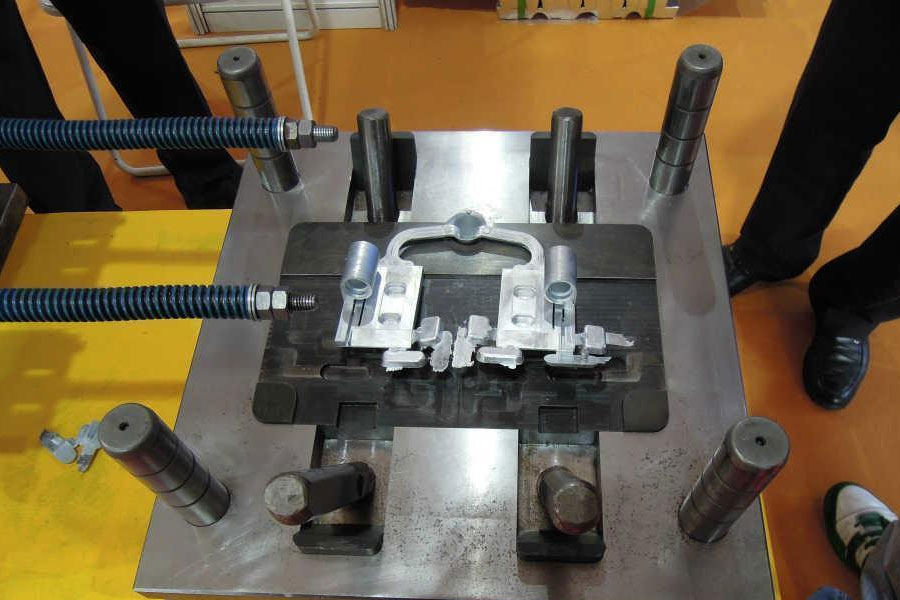

Ubuchwepheshe bokwelashwa ebusweni besikhunta ubunjiniyela obuhlelekile bokushintsha i-morphology, ukwakheka kwamakhemikhali, ukwakheka kanye nesimo sokuxineka kobuso besikhunta ngokumbozwa kwendawo, ukuguqulwa kobuso noma ubuchwepheshe bezokwelapha obuhlanganisiwe ukuthola izakhiwo zomhlaba ezidingekayo. Kusuka endleleni yokwelashwa ebusweni, ingahlukaniswa: indlela yamakhemikhali, indlela yomzimba, indlela yamakhemikhali womzimba kanye nendlela yokwenza. Yize ubuchwepheshe bokucubungula obusha obuhlose ukwenza ngcono ukusebenza kwesikhunta buyavela, izinhlelo ezivame kakhulu ekukhiqizeni isikhunta yi-nitriding, carburizing, kanye nokufakwa kwefilimu okuqinile.

Inqubo ye-nitriding ifaka i-nitriding yegesi, i-nitriding ye-ion, i-nitriding ewuketshezi, njll. Kwindlela ngayinye ye-nitriding, kukhona ubuchwepheshe obuningi be-nitriding, obungahlangabezana nezidingo zezinhlobo zensimbi ezahlukahlukene nezinto zokusebenza ezahlukene. Ngoba ubuchwepheshe be-nitriding bungakha indawo ngokusebenza okuhle kakhulu, futhi inqubo ye-nitriding nenqubo yokuqeda insimbi yokufa inokuxhumana okuhle, ngasikhathi sinye, izinga lokushisa le-nitriding liphansi, akukho ukupholisa okukhulu okudingekayo ngemuva kwe-nitriding, kanye ne-deformation isikhunta sincane ngokwedlulele. Ukuqiniswa kobuso ubuchwepheshe bokuqala be-nitriding, futhi futhi busetshenziswa kakhulu.

Inhloso yokubumba i-carburizing ikakhulukazi ukuthuthukisa amandla jikelele nokuqina kwesikhunta, okungukuthi, indawo yokusebenza yesikhunta inamandla amakhulu nokugqoka ukumelana. Umqondo wezobuchwepheshe owethulwe kusuka kulokhu ukusebenzisa izinto ezisezingeni eliphansi, okungukuthi, ngokusebenzisa i-carburizing kanye nokucisha. Ukufaka izinto ezisezingeni eliphakeme, ngaleyo ndlela kuncishiswe izindleko zokukhiqiza.

Ubuchwepheshe bokufaka amafilimu obunzima njengamanje yi-CVD evuthiwe ngokwengeziwe, i-PVD. Ukuze kwandiswe amandla okubopha ebusweni boqwembe lokwakhiwa koqwembe lwamafilimu, sekuthuthukiswe izinhlobo ezahlukahlukene zobuchwepheshe be-CVD ne-PVD. Ubuchwepheshe bokufaka amafilimu obukhuni buqale busetshenziswa kumathuluzi (imimese, amathuluzi okusika, amathuluzi wokulinganisa, njll.) Kwaba nemiphumela emihle kakhulu. Izinhlobo eziningi zamathuluzi zamukele ukuqinisa ifilimu okuqinile njengenqubo ejwayelekile. Isikhunta siboshwe ngobuchwepheshe befilimu obukhuni kusukela ngawo-1980. Ngaphansi kwezimo zobuchwepheshe ezikhona manje, izindleko zobuchwepheshe bokubekisa amafilimu obunzima (ikakhulukazi imishini) ziphakeme ngokwedlulele, futhi zisasetshenziswa kuphela ekubunjweni okunemba nakokuphila okude. Uma kusungulwa isikhungo sokwelapha ukushisa, izindleko zokumboza ifilimu eqinisiwe zizoncishiswa kakhulu. , Uma isikhunta esiningi sisebenzisa lobu buchwepheshe, izinga lokukhiqiza lesikhunta lonke lingathuthukiswa.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Indlela Yokuthuthukisa Ukusebenza Kwesikhunta

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off