Izinzuzo ze-AlSi10MgMn Alloy Die Casting

Eminyakeni yakamuva, imboni yezimoto yezwe lami ithole ukuthuthuka okusheshayo. Ngokukhathazeka okwandayo kwezinkinga zokuvikelwa kwemvelo, ubuchwepheshe bokonga ugesi kanye nokwehlisa ukungcola okugxile ekusindiseni isisindo kube ngenye yezinkinga ezijwayelekile embonini yezimoto. Njengokwakhethwa kobuchwepheshe obulula, i-aluminium alloy isetshenziswe kabanzi embonini yezimoto.

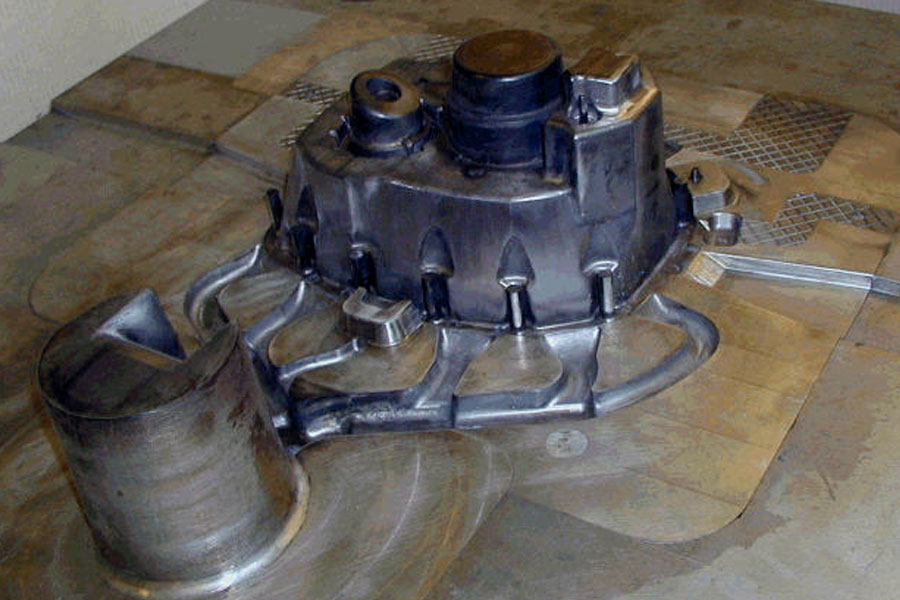

Ukulingiswa kwe-die kungenye yezindlela eziyinhloko zokwakha i-cast aluminium alloy. Inezici zokusetshenziswa okuphezulu kwempahla, ikhwalithi enhle yokwakha indawo nezakhiwo ezinhle kakhulu zemishini. Iphethe isikhundla esibalulekile ekukhiqizeni izingxenye ze-aluminium alloy auto. Ingxubevange ye-Die-casting AlSi10MgMn yi-Al-Si-Mg-Mn chungechunge lwamandla amakhulu nobulukhuni be-aluminium alloy esebenza kahle ekubunjweni. Ukuphonsa ngokufa izingxenye, ikakhulukazi izingxenye eziphezulu zokuphonsa izidumbu, zinezici ezinhle kakhulu zemishini, futhi zingaqiniswa ngokwengeziwe ngokushisa kokushisa. Ngakho-ke, lolu hlobo lwengxubevange lunodonga oluncane nesakhiwo Lunamathemba abanzi wokusebenza ekukhiqizeni izingxenye eziyinkimbinkimbi nezithwala umthwalo zemoto noma izingxenye zokuphepha.

Ngokuya ngobuchwepheshe bokuziphonsa obufakwa ngokuziphilisa obuphezulu, leli phepha lifunda ithonya lesikhunta somshini wokugcoba esakhiweni nasekusebenzeni kokuphonsa lapho insimbi encibilikisiwe igcwele; ubuchwepheshe be-die-casting high-vacuum busetshenziselwa ukutadisha imiphumela yokuguga okufakelwayo i-T1, ukwelashwa kwesisombululo sokushisa okuphezulu i-T5, ne-T6 ngokulandelana.

Ukusetshenziswa kwesakhiwo nezakhiwo ze-high-vacuum die-casting AlSi10MgMn; ngokwezidingo zangempela zokukhiqiza, kwafundwa ithonya lokuqukethwe kweMg esakhiweni nasezakhiweni zokuphonsa i-low-vacuum (ezejwayelekile) zokuphonsa i-AlSi10MgMn. Ucwaningo lukhombisa:

- Ukuphuma okuphezulu okuphezulu kunganciphisa kakhulu okuqukethwe kwegesi kokuphonswa futhi kukhulise ubukhulu be-castings. Uma kuqhathaniswa nokujikijela okujwayelekile, inkomba yobunzima bokuphonsa okokuphakama okuphezulu ikhuphuke ngo-55.1%, futhi amandla aqine, amandla okuvuna, ukunwebeka nobulukhuni bento ikhule ngo-12.7%, 38.4%, 130.4%, kanye no-4.9%, ngokulandelana.

- Ukuguga okwenziwe kungathuthukisa ngokuphawulekayo ukusebenza kokuphonsa okuphezulu kwe-AlSi10MgMn castings, ikakhulukazi amandla. Izinga lokushisa eligugile lingu-170 ℃, isikhathi sokuguga ngu-8h, amandla aqine ento afinyelela ku-351.3MPa, namandla okuvuna afinyelela ku-248.9MPa, ngokulandelana akhuphuke ngo-13% no-30.5% ngokuqhathaniswa nokusakazwa ku-as-cast isimo.

- Ukwelashwa kokushisa okuphezulu kwe-T5 kungathuthukisa ukwakheka kokuphonsa, futhi amandla nokunwebeka kokuphonsa kuthuthukiswe kakhulu, ikakhulukazi ukunwebeka. Lapho ukushisa kwesixazululo kungu-510 ℃, isikhathi sesisombululo ngu-3h, izinga lokuguga lingu-155 ℃, kanti isikhathi sokuguga ngu-2h, ukunwebeka kokuphonsa ngemuva kokwelashwa kokushisa kungafinyelela ku-9.2%, futhi inkomba yokuqina ingafinyelela ku-1163.9. Ngemuva kokwelashwa kwesixazululo, ukwakheka okuncane kwezinguquko ekusakazweni, kanye ne-silicon eutectic iyancibilika, i-granulation ne-spheroidization, futhi isatshalaliswa ngokulinganayo kusixazululo esiqinile se-α-Al.

- Ngokuhlolwa kwe-orthogonal, ithonya lezinto ezahlukahlukene zenqubo ze-T6 kuzindawo zokulingiswa ziyafundwa. Lapho ukushisa kwesixazululo kungu-500 ℃, isikhathi sesixazululo ngu-2h, izinga lokushisa eligugile lingu-170 ℃, kanti isikhathi sokuguga ngu-4h, amandla okuqina kwento leyo Amandla angafika ku-358.4MPa, amandla okuvuna afinyelela ku-286.6 MPa, izinga lokunweba lifinyelela ku-6.1%, ubunzima be-Brinell bungu-110.4, futhi inkomba yokuqina ifinyelela ku-1103.8.

- Okuphansi cleaner die ekubunjweni kunganciphisa okuqukethwe igesi ngaphakathi thusi. Ngesikhathi sokushisa okuphezulu nokwelashwa kwesixazululo esifushane, akukho ukubhoboza okwenzekayo ebusweni bokuphonsa, futhi usayizi uhlala uzinzile. Izinga lokushisa eliphakeme kanye nokwelashwa okushisa isikhathi esifushane kungathuthukisa ukwakheka kwangaphakathi kokuphonsa, kwandise ukunwebeka kokuphonsa futhi kuthuthukise amandla nobulukhuni bokuphonsa. Ngokuphonsa okungadingi ukwelashwa kokushisa, lawula okuqukethwe kwe-Mg kube ngu-0.4% kuye ku-0.65%; okokuphonsa okudinga ukuguga okufakelwayo, lapho okuqukethwe kweMg kungu-0.2% kuya ku-0.4%, amandla aphezulu nobulukhuni kungatholakala. Okokujwayela ukufa okujwayelekile, lapho okuqukethwe kweMg kungu-0.06%, ukusakazwa kungathola amandla nokuqina okungcono kusimo se-as-cast noma ngemuva kokuguga okufakelwayo.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Izinzuzo ze-AlSi10MgMn Alloy Die Casting

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off