Izinhlobo Ezintathu ZeMagnesium Alloy Injection Molding Technology

I-Magnesium alloy injection injection molding technology isibe yindawo yokucwaninga embonini ngenxa yezinzuzo zayo eziningi. Kunezinhlobo ezintathu zezinhlobo zobuchwepheshe bokujova ezivele muva nje: indlela yomgijimi eshisayo, indlela yokulingisa kanye ne-ejenti yokukhipha impuphu.

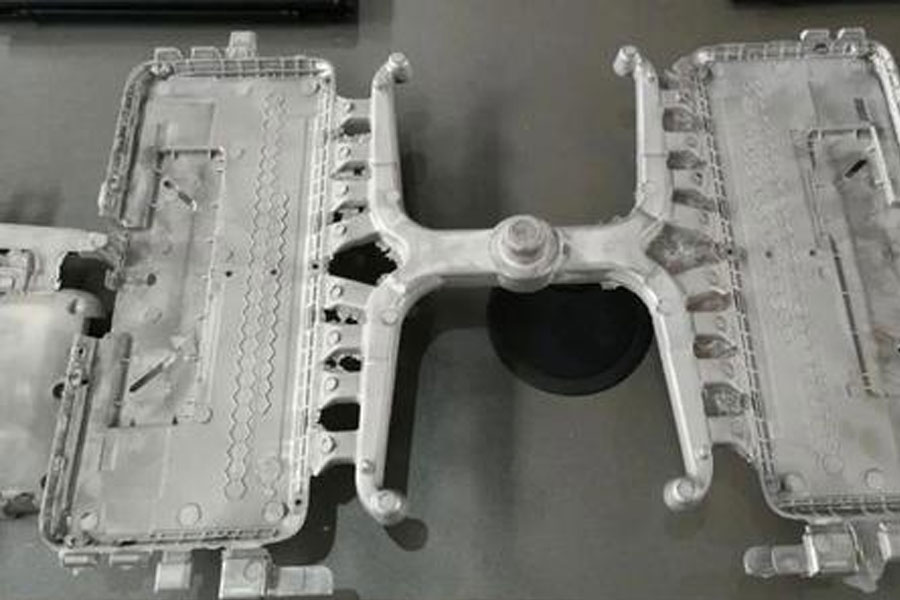

Umgomo oyisisekelo wokujova ngomjovo ukuncibilikisa i-alloy point alloy ephansi, bese uyigcwalisa isikhunta sensimbi ngejubane elikhulu kanye nengcindezi ephezulu. Izinto zokusetshenziswa ezingosayizi wezinhlamvu zelayisi zondliwa zisuka echwebeni lokondla, bese zifakwa kwisilinda zifudunyezwe kuzinga lokushisa elibekiwe bese ziyiswa ngaphambili. Ngalesi sikhathi, amandla okushefa ayanda ngokuzungezisa ucingo, futhi i-alloy melt yenziwa yaba yisimo esincibilikisiwe, yabe isijoyina isikhunta sensimbi ngejubane elikhulu. Ukushisa kwe-alloy melt kugcinwa ku-560 kuya ku-630 ° C, futhi isilinganiso sesigaba esiqinile silawulwa. Okungeniswa yiJapan Steel ubuchwepheshe obunelungelo lobunikazi be-American Thixomat Company, futhi benza futhi buthengise imishini yokwakha.

Uma kuqhathaniswa ne- ifa i-china isakaza indlela, indlela ye-magnesium alloy injection yokubumba inengcindezi ephakeme yokusakaza, ngakho-ke okusanhlamvu kwe-crystal okuseduze nobuso kuyacolisiswa, ukuze kutholakale ukumelana nokugqwala okuphezulu namandla womshini. Ukukhiqizwa kabusha kwesikhunta sensimbi nakho kuhle. Ngoba izinga lokushisa lokuncibilika kwengxubevange liphansi ngama-50 kuya ku-70 ° C kunaleyo yendlela yokuphonsa, ukushintshwa kwesayizi komkhiqizo obunjiwe nge-shrinkage yokushisa kungalawulwa, ngaleyo ndlela kwandise impilo yensizakalo yefilimu yensimbi. Ngaphezu kwalokho, akusetshenziswa isithando somlilo esincibilikayo negesi esetshenziswa ilangabi i-SF6, ukuqhuma nothuli ngeke kwenzeke, futhi kuhlangabezana nezidingo zokuphepha nokuvikelwa kwemvelo.

The yakamuva umjovo udini ubuchwepheshe:

- Indlela yomgijimi oshisayo: Shisisa njalo umgijimi kusikhunta sensimbi ukwandisa isivuno sokwaziswa ngokugcina insimbi encibilikisiwe. Inezinzuzo zokunciphisa isikhathi somjikelezo, ukucubungula ukubunjwa okuningi, nokwenza umshini wokubumba ube mncane.

- Izindlela zokulingisa: Imikhiqizo ebunjiwe yimikhiqizo eqediwe esondelene nokuma komkhiqizo ophelile, futhi kunenqubo eyodwa kuphela yokunemba kokufaka. Inenzuzo yokungakhiqizi imifantu noma ngejubane elikhulu lokufaka.

- Umenzeli wokukhishwa kofulawa: ngokujwayelekile fafaza i-ejenti yokukhipha encibilikiswa ngamanzi, kunesenzakalo sommeli wokukhishwa ondizayo. I-Japan Steel Corporation isungule indlela yokumuncwa komoya we-ejenti yokukhipha impuphu kusikhunta sensimbi esivaliwe. Kunomphumela wokunciphisa isikhathi somjikelezo nokwenza ngcono impilo yesikhunta sensimbi endaweni ehlanzekile.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Izinhlobo Ezintathu ZeMagnesium Alloy Injection Molding Technology

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off