Ukuhlaziywa kwe-Aluminium Alloy Die Casting Key Technology

Ukubuka konke kwe-Aluminium Alloy Shell Castings

I-Aluminium alloy shell castings isetshenziswa kakhulu embonini yesimanje yezimoto. Ngenxa yezimo zazo ezingajwayelekile, kunzima kwezinye izakhiwo ukuthi zihlangabezane namazinga ekhwalithi ngokucutshungulwa kwemishini. Ngakho-ke, okunye ukusakazwa kwe-aluminium kusetshenziselwa kuphela ukwakheka okungaphezulu komhlaba kwamagobolondo ezimoto. Ngokombono wokuphepha kokusetshenziswa kwezimoto, imboni inezidingo eziqinile zekhwalithi ye-aluminium castings. Konke ukusakaza kunamazinga aqinile wokuqina kwempahla. Ezidingweni zokusakazwa kwegobolondo, ubuso, izindinganiso eziphindwe kabili zekhwalithi yangaphakathi. Ukuqinisekisa ikhwalithi yomkhiqizo, abanye abakhiqizi basebenzise ubuchwepheshe bokubona iphutha lokulawula ukulawula yonke inqubo yokukhiqiza.

| Ukuziphatha Kwemishini | Grade |

| Amandla eqine Mpa (iminithi) | 240 |

| Isivuno amandla Mpa (iminithi) | 140 |

| Ukunwebeka% (iminithi) | <1 |

| Brinell ubulukhuni HB (iminithi) | 80 |

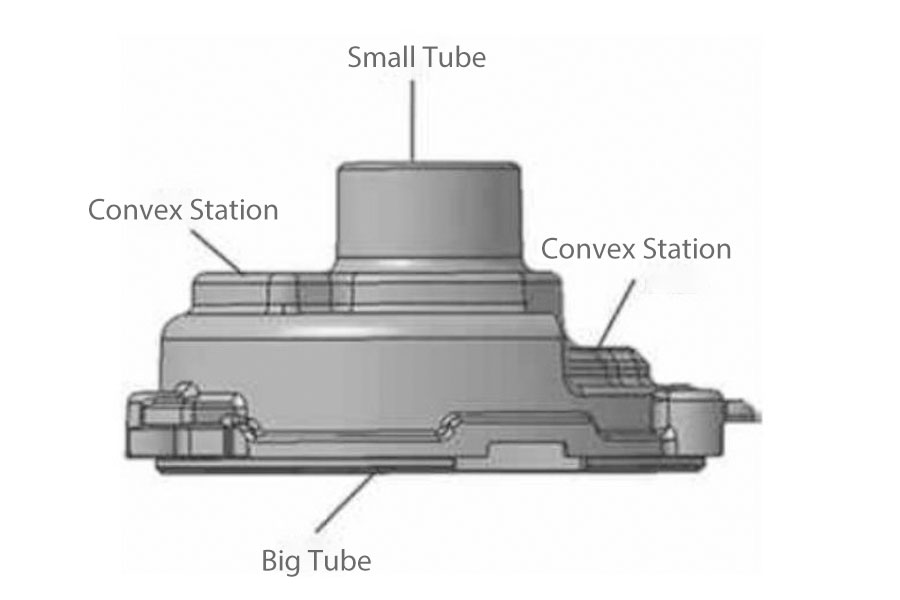

Isembozo segobolondo se-aluminium alloy esethulwe kule ndatshana sinesakhiwo esilula futhi izingxenye ezimbili kuphela okudingeka zenziwe ngomshini. Kodwa-ke, ngenxa yesimo segobolondo esingajwayelekile, ukuphakama kwabaphathi ababili kwehlukile. Phakathi kwazo, ubukhulu obukhulu bangaphandle, ukuphakama, Izingxenye ezishubile zodonga zingu-105mm, 40mm no-3.5mm ngokulandelana. Izingxenye ezidinga ukwenziwa ngomshini ububanzi bezingxenyana zangaphandle zamagobolondo amakhulu nezincane. Ukubekezelelana kwemishini kumele kulawulwe ngaphakathi +/- 0.1mm. Njengoba le ngxenye ayidingi ukucubungula umgodi wangaphakathi, ubunzima bokuphonsa kufa bukhulu kakhulu.

Ukuze kuqinisekiswe ukuthi ukusebenza kokuphonsa kungahlangabezana nezidingo zokumelana namandla we-static okuchoboza ngaphezulu kwe-20kN, inqubo yokukhiqiza idinga ukulawulwa ngokuya nge-GB6414-86 CT6 ukuqinisekisa ukuthi ukusakaza akunakho ukungcola nokuqhekeka ngesikhathi inqubo yokufa, futhi i-welding ayivunyelwe. Lungisa umkhiqizo ngokulungisa noma ngokuntywila.

Ukuhlaziywa Kwenqubo Yomkhiqizo

Inqubo yokukhiqiza 2.1

Inqubo yokukhiqizwa kwezingxenye yilezi: izinto ezingenayo → ukuncibilika / ukufa ekubunjweni → ukusika / ukuhlanza → imishini → ukuhlanza → inhlangano.

2.2 Ukuhlaziywa kwesici

Yize ukusakazwa kwegobolondo le-aluminium alloy kwethulwe kule ndatshana kunesakhiwo esilula, ukukhubazeka okulandelayo kokukhiqiza kuvame ukwenzeka ngesikhathi senqubo yokukhiqiza:

- (1) Ukwehluka: Umehluko wokushisa phakathi kwensimbi nesikhunta, isivinini sokugcwalisa ngesikhathi sokuncibilikisa, nosayizi wesamba sokufafaza ngesikhathi senqubo yokudubula awulawulwa kahle, obangela kalula umbala wokusakaza ukuthi ube mnyama futhi mnyama.

- (2) Amaphutha okulangazelela: Lolu hlobo lwenkinga alunakugwenywa ngokuphelele enqubweni yokukhiqizwa kwe-aluminium alloy castings. Isidingo sokulawulwa kwenkinga ye-porosity yokusakaza ukuqinisekisa amandla amakhulu egobolondo, futhi kuyadingeka ukuqinisekisa ukuthi indawo ebucayi ayikhiqizi i-porosity eyeqa izinga le-ASTME505 level 2. Ububanzi bobubanzi obamukelekayo bama-pores ekusakazweni ngu-.1.6mm, isilinganiso se-pore kufanele silawulwe ngaphakathi kuka-6.2%, futhi ubukhulu bezimbotshana ezisendaweni yomshini akufanele bube bukhulu kune-2.0mm.

Ngokuya ngokulawulwa kwekhwalithi yokukhiqiza, ukuhlolwa okubukwayo kubhekele ikakhulukazi ukuhlolwa kwamaphutha wokubukeka kwabalingisi, futhi ukuhlolwa kwe-X-ray kubhekele ukulawulwa kwekhwalithi yangaphakathi yokuphosa. Kodwa-ke, ekukhiqizweni ngobuningi, ngokombono wokusheshisa isivinini sokukhiqiza nokulawula izindleko zokukhiqiza, lezi zindlela ezimbili zinamaphutha athile. Ngakho-ke, inqubo ye-aluminium alloy die-casting iyahlaziywa futhi ibhekiswe ne-CAE nobunye ubuchwepheshe obusizayo ukuze kuthuthukiswe ikhwalithi yemvelo yabalingisi. Ukulawulwa kwenkinga kusingathwa esigabeni esinzima.

2.3 Amapharamitha enqubo nokukhethwa kwemishini

Ngokuya ngezici zesakhiwo nezidingo zokukhiqiza zokusakaza, ingcindezi yokusakaza isethwe ku-350T. Ngokwesipiliyoni sokukhiqizwa kwemikhiqizo efanayo esikhathini esedlule, njengokuhlanganiswa kwesikhunta okungenangqondo nokukhethwa okungalungile kwemingcele yenqubo, inkinga yejubane lokugcwalisa insimbi ngokweqile izokwenzeka ngesikhathi senqubo yokufa. , Umphumela wokuvinjelwa kokukhishwa kwegesi emgodini, futhi ekugcineni kwakheke ukukhubazeka kwekhwalithi okufana nama-pores noma ukungcola okweqile kwe-oxide kumkhiqizo ophelile, okuthinta izinga lokuphosa lokusakaza.

Ngokuya ngezidingo zokuklanywa kokuphonsa, ubukhulu besendlalelo sobuso obukhulu be-Shell-castled casting yi-0.8mm kuphela. Uma icutshungulwa kahle, isakhiwo sendawo sizoba sikhululekile, okuzoholela ekwehliseni ukusebenza kwegobolondo nokumelana nengcindezi. Ngakho-ke, lapho kuklanywa isikhunta, iphini lokuma lisetshenziselwa ukuxhumanisa ukuma, futhi ivolumu yokucubungula ilawulwa ngaphakathi kwe-0.5mm. Lokhu konga isikhathi semishini futhi kunikela kakhulu ekwenzeni ngcono ikhwalithi yemvelo yokusakaza.

2.3.1 Ukukhethwa kohlelo lwesikhunta

Ngokuya ngezidingo zokuklanywa kwe-aluminium alloy shell casting, ukwakheka okubonakalayo kwenziwa kusetshenziswa isoftware ye-AnyCast, futhi kutholakale izikimu ezintathu zokuklama zokungena. Ngokuqhathanisa, isiteshi sokugeleza ngokugcwaliswa kokugeleza okushelelayo ekugcineni sanqunywa. Umklamo wohlelo C ukukhiqiza isikhunta, futhi kutholakala ekukhiqizweni kwangempela ukuthi lolu hlelo lunomthelela ongcono ekuthuthukiseni ukukhubazeka kwangaphakathi kokuphonswa kwegobolondo nokwandisa isivuno segobolondo.

2.3.2 Ukusetha kokushisa okuncibilikayo

Kuhlanganiswe nesisindo sokwakheka kwegobolondo lokulingisa, umshini wokuphonsa amakhaza we-350T obandayo usetshenziselwa ukuphonsa abafayo, futhi izinga lokushisa lisethwe ebangeni le-640 ℃ +/- 20 ℃. Ukuze kuqinisekiswe ukuthi ingcindezi yenqubo yokugcwalisa uketshezi yensimbi izinzile, zama ukugwema ukugeleza okuneziyaluyalu, ukusaphaza nezinye izinkinga ezibangelwa ukungena kwe-slag secondaryrain noma ukuguguleka komgogodla, izinga lokunyuka kwengcindezi lisethwe ku-1.3kPa / s.

2.3.3 Ukuhlanzwa kwe-alloy liquid

Ukuze uthuthukise ikhwalithi ye-aluminium alloy shell castings futhi wehlise umthelela wama-pores, ama-pinholes, kanye ne-slag inclusion kuzinga le-qualification yomkhiqizo, isinyathelo sokucwenga sesibili sisetshenziselwa inqubo yokusakaza, okungukuthi, i-alloy iyacolisiswa kanye ngaphambili ngemuva kokukhishwa kwesithando. Ngasikhathi sinye, kusetshenziswa isihlungi sefayibha esikhaleni esikhuphuka esikhuphukeleni, isibuko sesihlungi se-ceramic sisetshenziswa esangweni elingenhla, futhi kufakwa isikrini sokuhlunga esinentambo ephindwe kabili ekugcineni kwesango eliqondile nokuvuleka kwegebe ukwenza ukuhlunga kathathu ukulawula ukwenzeka kokukhubazeka komkhiqizo we-slag. isilinganiso.

Isimo Sangempela Sokukhiqiza Nomphumela

Ngokusho kohlelo nenqubo engenhla, amasampuli ama-shell angu-6 akhethwe ngokungahleliwe ukuze ahlolwe ekukhiqizweni kwangempela, futhi kwatholakala ukuthi uhlelo C lunomthelela ongcono ekuthuthukiseni ukukhubazeka kwangaphakathi kokuphonswa kwegobolondo nokwandisa isivuno segobolondo. Ngokuhlolwa kwe-X-ray, kutholakale ukuthi izinga lokuphasa langaphakathi lifinyelele ku-100%; bese kuthi ukuhlolwa kokunemba ngokunemba kutholakale ukuthi inkomba ye-porosity yendawo eyenziwe ngomshini ifinyelele ezingeni le-ASTM E505 level 2; ngokuhlolwa okuchobozayo okulimazayo, kutholakale ukuthi wonke amasampula angafinyelela Ekumelaneni nengcindezi engaphezulu kwama-25kN. Kungabonakala ukuthi ukwakheka kwe-aluminium alloy shell casting kanye nokukhethwa kwenqubo okwethulwe kule ndatshana kunengqondo, futhi imiphumela ethile itholakele ekulawuleni ikhwalithi yomkhiqizo.

Isiphetho

Ngokuthuthuka okuqhubekayo kwesayensi nobuchwepheshe nezinqubo ezihambisanayo, inqubo yokufa-yokuphonsa izingxenye ze-aluminium ingxube iye yathuthukiswa ngokuqhubekayo. Ukugeleza kwenqubo okuhlobene nendabuko yinde, engakulungeli ukulawulwa kwekhwalithi kunqubo yokusakaza. Ukuze kuqinisekiswe ukuthuthukiswa kwekhwalithi yokukhiqiza, kubalulekile ukuqala ukuphathwa kwekhwalithi kusuka esigabeni sezinto ezibonakalayo. Inqubo yokukhiqiza kanye nobuchwepheshe obuyisisekelo bokuphonswa kwamagobolondo e-aluminium ngenhla kufinyelele emazingeni afanelekile nokwenzeka ngokusebenzisa ukwakheka kwesayensi nokukhethwa kohlelo, okufakazela ukuthi ubuchwepheshe nezinqubo ezifanelekayo zingahlangabezana nezidingo zekhwalithi zokukhiqizwa ngobuningi kwemikhiqizo ehlobene yokusakaza, futhi futhi ziqinisekise ingxubevange ye-aluminium Indima yezingxenye ezibalulekile zobuchwepheshe bokufa ekuthuthukiseni ikhwalithi yonke yemikhiqizo ehlobene.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ukuhlaziywa kwe-Aluminium Alloy Die Casting Key Technology

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off