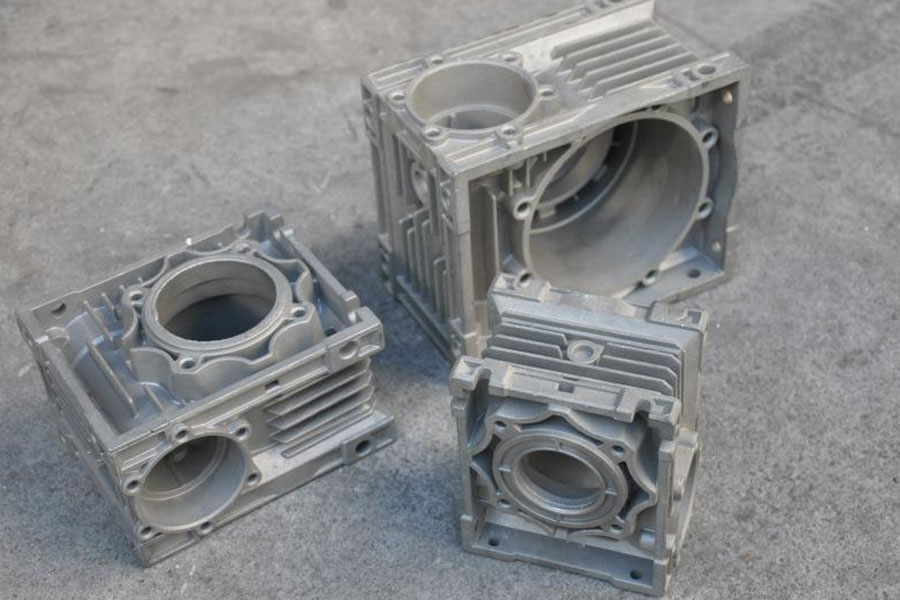

Kuyini Isikhunta Trial Ukuze Die Ekubunjweni

Ukulingwa kwe-die-casting kuyinqubo yokuqinisekisa yokukhiqizwa kwangempela nokwakhiwa kwesikhunta, futhi kuyindlela ebalulekile yokuphonsa isikhunta, imishini, inqubo yokwenza kahle nokulungiswa kokukhiqizwa ngobuningi. Lo mbhalo wethula ikakhulukazi inqubo yokwakhiwa kwesikhunta ukuqinisekisa ukulingwa kwesilingo nokwenza ngcono okulandelayo nokulungiswa.

Esigabeni sokukhiqiza umkhiqizo omusha kanye nokulingwa okusha kwesikhunta, kuzoba nezinkinga eziningi noma eziholela ekuhlulekeni kwesivivinyo. Futhi kunezici eziningi ezithinta ukwehluleka kokuhlolwa kwemodeli. Yiziphi izici ezifanele?

Okokuqala, ukubuyekezwa nokuhlaziywa kwesakhiwo sokulingisa nokwakhiwa kwesistimu yesango esigabeni sokuthuthuka. Okwesibili, imingcele yenqubo yokukhiqizwa kokufa okufana nokushisa kwensimbi encibilikisiwe, ingcindezi yokufa, isivinini kanye nephuzu lokushintsha ngokushesha kunengqondo. Futhi njalo njalo, ezinye izinto ziyisihluthulelo sokuthinta ngqo ikhwalithi yangaphakathi nangaphandle yokuphonswa kwabantu abafayo.

Kepha ezimweni eziningi, ukwakheka kwesikhunta nokukhiqizwa kuhlobene kakhulu. Izici ezithinta isikhunta, kufaka phakathi inani lezimbobo, ukwakheka kohlelo lwesango, uhlobo lwesango (isikhundla, indawo, isiqondiso), njll. kupholisa nakho kuyasetshenziswa. Ukufeza injongo yokulinganisa izinga lokushisa lesikhunta. Kungokwakhiwa okuhle kwesikhunta kuphela lapho kutholakala uhla olubanzi lwamapharamitha wenqubo, avumela kakhulu ikhwalithi yangaphakathi neyangaphandle yokusakaza. Ukubuyekezwa nokuhlaziywa okuthile, kufanele sisebenzise isoftware ethile esizayo. Isibonelo: isoftware yokuhlaziya isikhunta, inqubo yesoftware yokuhlaziya ipharamitha umdwebo we-PQ 2 njalonjalo.

Ukuhlaziywa Kwemininingwane Yethiyori

1) Hlaziya ukwakheka kokuqala kwendawo yesango, indawo nokuqondisa, indawo yokukhipha isikhwama se-slag, njll ngesoftware yokugeleza kwesikhunta. Qonda ukungena, ukusatshalaliswa kwamazinga okushisa, ukugeleza kwendlela nejubane lensimbi encibilikisiwe egeleza emgodini, kanye neqoqo le-slag nokukhishwa kwesikhwama se-slag, bese uthola izinkinga zokunikeza isisekelo sokubuyekezwa okulandelayo nokuguqulwa, ngakho-ke ukuthola uhlelo olungcono lwe-gating.

2) Usebenzisa umdwebo we-PQ 2 ukufaka isikhunta, imishini nokunye ukuhlaziywa kwemingcele, ekuqaleni singasetha imingcele yenqubo nokuhleleka kokukhethwa kwamathani we-press tonnage, thola izinkinga kuzilungiselelo zepharamitha yenqubo bese uzilungisa ngesikhathi; futhi singathola futhi inkolelo yokuthi Amapharamitha enqubo engenhla anokuqonda okuqondisayo kokulungiswa kwamapharamitha enqubo yomshini wokulingisa wokufa.

Ukulingwa Kokulingwa Kwesikhunta Nenqubo Yokukhulisa Ipharamitha

Inhloso eyinhloko yesivivinyo sesikhunta ukuthola izinqubo ezenzelwe inqubo nohlelo lokuguqulwa kwesikhunta. Kuyadingeka ukuthi noma ngabe izinto, izilungiselelo zomshini noma izinto zemvelo zishintshile, isengakwazi ukuqinisekisa ukuthi isikhunta singakhiqiza ngaphandle kokuphazanyiswa imikhiqizo efanelekile ngamaqoqo. Thuthukisa "ukuzivumelanisa nezimo" kwesikhunta kuze kube semkhawulweni, hhayi nje ukuthola amasampula wokuhlola okuhle ambalwa.

Umsebenzi wokulungiselela ngaphambi kokuhlolwa kwesikhunta. Ngokuya ngemidwebo yokuklama kwesikhunta, yenza ukuhlolwa okuningiliziwe kobukhulu obufanele (ikakhulukazi ubukhulu be-interface ye-sprue bushing); thola ukulandelana kwesenzo sengxenye ngayinye ehambayo yesikhunta (ukudonsa okuyisisekelo nesilayida); qinisekisa ukuthi yini ezokwamukelwa Imodeli yomshini wokulingisa wokufa, isikhundla somjovo, isikhombimsebenzisi se-tubing, ubukhulu begumbi lengcindezi nosayizi we-interface kuyahambisana nezidingo zangempela zesikhunta. Ukunakekelwa okukhethekile kufanele kukhokhelwe umshini wokuphonsa osetshenziswe kusikhunta sesilingo kufanele uhambisane nemodeli yomshini wokulingisa osetshenziswa ekukhiqizeni ngobuningi isikhunta, ngaphandle kwalokho isikhunta singasebenziseka.

Ngokwamapharamitha enqubo yezemfundiso etholwe eshadini le-PQ2, ukukhiqizwa kwesilingo kwenziwa ukuthola umehluko phakathi kwemingcele yangempela neyethiyori. Futhi qhubeka nokulungisa futhi uguqule, kuze kutholakale ukusakaza okwenziwe kahle okunekhwalithi enhle yangaphakathi. Phakathi kwabo, ukusebenza kwabezindaba kungahle kungazinzi, okwenza kube nzima ngathi ukwahlulela le nkinga. Ngalesi sikhathi, "umjovo wokuqapha" ungasetshenziswa ukuqapha ijubane, ingcindezi, ukufuduka kanye neminye imingcele yenqubo yokujova, futhi wahlulele ngokushintshashintsha kwejika. Sisize ukuthola inkinga ngokunembile, uqondise kahle ukulungiswa kwamapharamitha wenqubo futhi uqonde ukusebenza kwemishini. Ekugcineni, kuzotholakala isethi yamapharamitha wenqubo efanelekile alungele le mishini.

Isikhunta esikhiqizwa yifektri yesikhunta imvamisa ngenxa yokucatshangelwa okungalungile noma ukucubungula okungalungile kunqubo yokukhiqiza. Kaningi kunezinkinga ezithile, njengokubekezelelana ngokweqile, ushintsho lwendawo olungagudluki, ukwakheka okungafanelekile, nokuhlelwa kwamanzi okungenangqondo okungenangqondo. Umehluko omkhulu wokushisa, njll., Okuholela ekusakazeni okungafanelekile noma ukwehluleka kokukhiqizwa kwesivivinyo sesikhunta. Ngenxa yomehluko phakathi kwemiphumela yangempela kanye nombono, isivivinyo sesikhunta siyindlela elula, eqondile nephumelelayo yokuthola izinkinga zesikhunta. Ungazi futhi ukusatshalaliswa kwezinga lokushisa kwesikhunta nokuthi indawo yokupholisa amanzi iyafaneleka yini ngomdwebo we-imaging oshisayo, osiza kakhulu ukunweba impilo yesikhunta. Ibuye ibaluleke kakhulu ekuqondiseni ukulungiswa kwesifutho.

Enqubeni yesikhunta sesivivinyo, izingxenye zesikhunta sesivivinyo ezikhiqizwe ngemuva kokuthi izinqubo zenqubo zizinzile zidinga ukubuyekezwa kwesayithi ngonjiniyela bomkhiqizo, ochwepheshe bezinqubo nonjiniyela bekhwalithi ngokuya ngezidingo zamakhasimende. Okuqukethwe kokubuyekezwa okuyinhloko yilokhu:

- Ukulinganiswa kobukhulu obukhethekile nokukalwa komugqa wobuso bemishini;

- Ukuthi ukubunjwa kwentambo yokubukeka kusakazekile yini, noma ngabe ulayini wokuvalelisa awulungile, noma ngabe kukhona uhlobo, ukudabuka, ukuncipha, njll .;

- Ukuhlolwa kwe-Anatomy ne-X-ray ukuhlola i-porosity nokuncipha ngaphakathi kokusakazwa. Qonda isimo sekhwalithi sokuphonsa kanye nezinkinga zesikhunta ngokubuyekezwa kokuqala, futhi unikeze isisekelo nesiqondiso sokulungiswa kamuva.

Ukulingwa kwe-Die-casting isivivinyo akuyona nje inqubo yokutholwa kokufundwayo nokusebenzayo, kepha futhi kuyinqubo yokulungiswa kwephutha okuqhubekayo nokwenza ngcono. Ngaphezu kwalokho, ukulingisa okwenzeka esikhathini samanje kune-software ethe xaxa yokusiza nemishini yokusisiza ukuthi sihlole isikhunta ngokwesayensi. Yenza ukuhlaziywa okuhlelekile kwesakhiwo sokulingisa, isakhiwo sesikhunta, inqubo yokufa nokusebenza kwemishini yokufa ukuze uthole umehluko nezinkinga. Ngemuva kokuthi inkinga ixazululwe, ukwakheka kwesikhunta nezinqubo zenqubo zilungiswa. Yenza isikhunta sethu silungele ukukhiqizwa okuzinzile nokugcinwa kwekhwalithi. Lokhu kubonisa ngokugcwele ukubaluleka kokulingwa kwesikhunta sokufa.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Kuyini Isikhunta Trial Ukuze Die Ekubunjweni

Inkampani kaMinghe Casting inikezelwe ukukhiqiza nokuhlinzeka ngekhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zifeza ububanzi zifaka ikakhulu I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off