Inqubo Yokulawula Ukulingiswa Kwe-Die

Ngenxa yokwehlukahluka kwezinto ezithinta ikhwalithi yokusakaza nobunzima benqubo yokukhiqiza, njengamanje inhlangano enengqondo, inqubo yokulawula inendima ebalulekile ekukhuthazeni ukwenziwa kwenqubo, ukuqeqeshwa kwezobuchwepheshe kanye nokulawulwa kokukhiqizwa, ngenhloso enkulu ngukuqaphela ukuvimbela okusebenzayo nekhambi lokukhubazeka okusakazwayo. Ukuhlaziywa kafushane ngokulawulwa kwe-alloy melt, isikhunta nokulawulwa kwenqubo yokufa, ukuhlolwa kwangaphakathi nangaphandle kwemikhiqizo kuyenziwa.

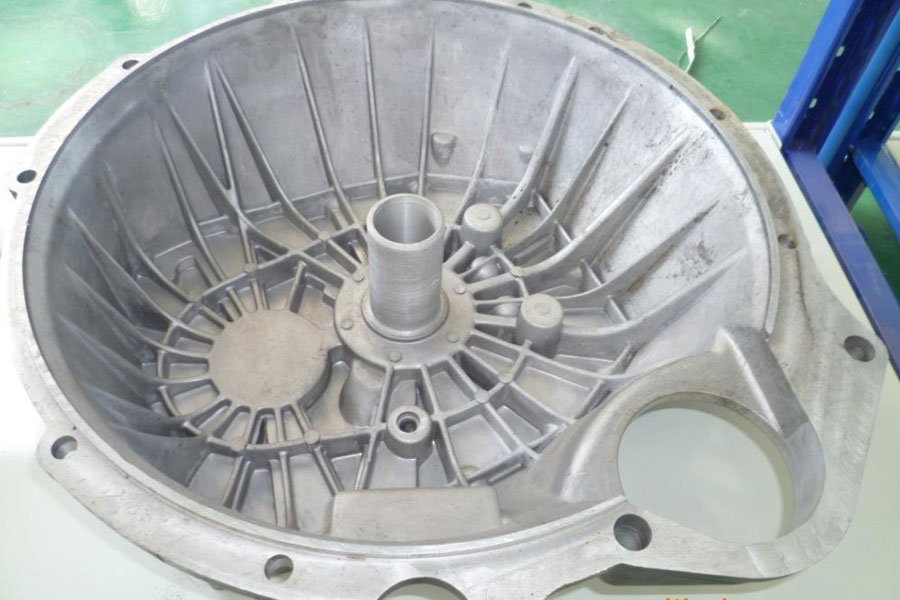

Idizayini yebhlokhi yenjini iyathuthuka maqondana nesisindo esilula nobunzima. Ngenxa yobuningi bayo obuphansi nokusebenza kahle kokuphonsa, i-aluminium alloy ivame ukusetshenziselwa ukukhiqiza i-aerospace nezingxenye zezimoto ezinobunzima obunzima, izindonga ezincanyana, kanye nemithwalo emaphakathi. Uchungechunge lwamabhulokhi enjini akhiqizwa yiChangan Automobile Jiangbei Engine Factory akhiwa ngokufaka ingcindezi ephezulu kusikhunta esine-aluminium alloy esezingeni eliphakeme (efana nomkhiqizo wasekhaya i-YL113). I-cylinder block yalolu chungechunge lwezinjini is a high-strength, thin-wall wall casting. Iningi lezimbobo ku-cylinder block zifakwa ngaphambili ngama-cores cores, angenazo izidingo eziphakeme kuphela zemishini yehadiwe efana nesikhunta nemishini yokufa, kepha ukulawula yonke inqubo yokukhiqiza kuqinisekisa ukulethwa Ukusakazwa kubushelelezi, futhi ukwenziwa ngcono kwekhwalithi yomkhiqizo nakho kubaluleke kakhulu.

Ukulawulwa kwenqubo

Enkambisweni yokuphathwa kokukhiqizwa kokufa, kubaluleke kakhulu ukuzinzisa nokwenza ngcono ikhwalithi yomkhiqizo kusuka kuzici zokulawulwa kuketshezi kwe-aluminium, ukulawula isikhunta, ukulawula inqubo yokufa nokuhlolwa komkhiqizo.

Ukulawulwa Kwamanzi we-Aluminium

Ukukhubazeka kokuqina kwe-cast aluminium alloy kuthinta kakhulu ukusebenza kokuphonswa, futhi ukulawula noma ukuqeda ukukhubazeka kokuqina kubaluleke kakhulu ekuthuthukiseni isivuno sabaphangi. Njengoba izidingo zezakhiwo eziphelele zama-alloys zikhuphuka ngokwanda,

Ucwaningo lokwengeza izinhlobo eziningi zezinto zokuhlanganisa izinto ukuze kuthuthukiswe izakhiwo eziphelele zama-alloys seluqhubeke ngokujula, futhi indlela yokulawula ukwakheka kwe-alloy ibaluleke kakhulu. Ukukhubazeka okuvamile kuma-alloys we-cast aluminium kubunjiniyela, njengokuhlukaniswa, ukuqhekeka okushisayo, i-microporosity, shrinkage, njll., Kudinga ukulawulwa kusuka emthonjeni. Ngokuphendula ukukhiqizwa okuluhlaza, isisekelo sokukhiqiza sale modeli eChangan Automobile's Jiangbei Engine Plant sisebenzisa ukunikezwa okuqondile kwe-aluminium encibilikisiwe, ngakho-ke ikhwalithi yokunikezwa okuqondile kwe-aluminium encibilikisiwe isetshenziswa njengesisekelo sokuthi i-aluminium encibilikisiwe iyahlangabezana yini nezidingo. Kusetshenziswa umshini wokulungiselela isampula ukuthola ubukhulu obulinganayo be-ingxube ye-aluminium ingots, i-spectrum analyzer isetshenziselwa ukuhlaziywa komzimba namakhemikhali, futhi ukutholwa kwe-K-mode kwenziwa kumanzi ohlangothini lomlilo we-aluminium amanzi njalo ukubheka ubukhulu okulingana, ukwakheka kwamakhemikhali, nokuhlanzeka kwe-aluminium alloy.

Isikhunta Control

Ukuphathwa, ukuhlolwa kwendawo, kanye nokugcinwa kwesikhunta kuyingxenye yokufa, futhi isimo sesikhunta sibaluleke kakhulu kwikhwalithi yomkhiqizo. Isisekelo sesikhunta senziwe ngensimbi yensimbi. Ngesikhathi somjovo, amanzi e-aluminium ageleza egumbini lokucindezela, i-sprue, umgijimi wesiphambano, kanye nomgijimi wangaphakathi womjovo womjovo kusuka phansi kuye phezulu. Lonke uhlelo lwesango luyidizayini evaliwe yokunciphisa ukungena kwamanzi e-aluminium. Ingaphakathi lomgodi wesikhunta livulwa ngamanzi ukulinganisa inkambu yokushisa kwesikhunta, futhi zonke izingxenye zomzimba wesilinda ziqiniswa ngasikhathi sinye, futhi igesi eliyinsalela emanzini e-aluminium liyasakazeka futhi lisatshalaliswe. Ngokusemandleni, izimbobo zokuphonsa kufanele zifakwe ngaphambili ngamanzi apholile. Indawo yokupholisa ingcindezi ephezulu noma yokubuyisa indlela yokupholisa amanzi ingakhethwa ngokuya ngezidingo zangempela. Amanzi okupholisa angafinyelela ngqo phezulu kwephini lokuphonsa, ukuze ingxenye ephezulu nayo ingaphola.

Enqubeni yokukhiqiza, izinga lokushisa lesikhunta linethonya elikhulu kumkhiqizo nasempilweni yesikhunta, futhi izinga lokushisa eliphakeme livame ukunamathela kusikhunta, ubuso bokuphonsa bunamandla, futhi izimbobo zokuncipha nemifantu kungenzeka futhi. Ngenxa yokunamathela kwesikhunta, ukungqubuzana.

Amandla okwenyuka okwenyukayo awuphinda kabili amandla endawo aqine, okwenza ukuhamba kwendawo kwesikhunta kunganembi futhi kulimaze isikhunta. Isilawuli sokushisa kwesikhunta ngokuvamile sisethwe ngokushuba kodonga lokusakazwa nokusatshalaliswa kokugeleza kwe-aluminium encibilikisiwe. Umthamo wamanzi wokupholisa nesikhathi sokupholisa sezingxenye ezahlukahlukene zesikhunta kungalungiswa. Ukupholisa ngaphandle kwesikhunta nakho kubalulekile, futhi kuhlobene kakhulu nokuma, ukuqondiswa kanye nenqubo (isikhathi) sokufafazwa kwe-ejenti yokukhipha. Ukukhethwa, isilinganiso nenani le-ejenti ekhishwayo kuzothinta ukusetshenziswa kwesikhunta kanye nekhwalithi yomkhiqizo. Ukugcinwa kwesikhunta kuhlukaniswe kwaba ukugcinwa kokuvikela, ukugcinwa kwesibikezelo nokuhlolwa kwendawo. Nquma umjikelezo wesondlo wokuvikela wokuvikela isikhunta ngokuya ngesipiliyoni esinqwabelene, thola isikhathi sokulungiselela esibikezelayo ngokusho kombuso nokusetshenziswa kwesikhunta, futhi wenze ukuhlolwa kwansuku zonke ngesikhathi senqubo yokukhiqiza. Okuqukethwe kwesondlo kuhlanganisa uhlelo lokupholisa (amanzi, uwoyela, igesi), uhlelo lwe-vacuum, ukubekwa uphawu, ukuhlanzwa kwendawo engaphezulu, njll.

Inqubo Yokulawula Ipharamitha

Ukulawulwa nokwenza kahle inqubo yokufa-kufa kuyingxenye ebalulekile yokukhiqizwa kokufa, okuthinta ngqo indawo nekhwalithi yangaphakathi yezingxenye zokufa. Imingcele yenqubo yokufa ifaka ikakhulukazi ingcindezi, isivinini nesikhathi.

Imingcele yokulawulwa kwezobuchwepheshe ilawulwa ngobuningi ukuqinisekisa ukuthi ukugeleza, ukuqiniswa, kanye nokushintshana kokushisa kwensimbi ketshezi kwenziwa ngendlela ebekiwe, ukuze kuqinisekiswe ikhwalithi yezingxenye ezifayo. Ikhwalithi yangaphakathi yokusakaza izwela kakhulu ekushintsheni kwemingcele yomjovo. Uma ingcindezi iphansi kakhulu, ukusakaza kuzoba nezimbotshana eziningi, ukuncipha nokunye ukukhubazeka. Uma ingcindezi iphezulu kakhulu, yize isakhiwo sokulingisa siminyene, sizokhiqiza ukukhanya okukhulu nama-burrs, okuzolimaza isikhunta. . Ngesikhathi sokukhiqiza, kubalulekile futhi ukukhombisa ukuthi iphuzu lokushintsha kusuka kumjovo ohamba kancane uye ngokushesha nalo libaluleke kakhulu. Ukushintsha ngaphambi kwesikhathi, i-aluminium encibilikisiwe idlula kumgijimi wangaphakathi futhi ingena emgodini ngejubane elikhulu. Umzila mude, ubangela ukugeleza okunesiyaluyalu kwe-aluminium encibilikisiwe, okubandakanya inani elikhulu legesi, futhi kulula ukwenza ezinye iziphosiso zokuphonsa ngokungajwayelekile; sekwephuze kakhulu ukushintsha, uketshezi lwe-aluminium luhlala egumbini lengcindezi isikhathi eside, izinga lokushisa liphansi, kulula ukukhiqiza izithiyo ezibandayo, ukuthululwa okunganele nezinye izinkinga. Eqinisweni, kusukela ekubukeni kwe-anatomical, ukuba khona kwama-pores nezimbobo zokuncipha ekusakazeni akunakugwenywa. Okusemqoka ukulungisa imingcele yomjovo ukuze igesi eketshezi le-aluminium ikwazi ukukhishwa ngempumelelo ngangokunokwenzeka, kuthi inani elincane elisele lama-pores lihlakazeke lisatshalaliswe ngaphakathi. Ukungena kwesigaba kubangela ukuvuza kokusakazwa. Ijubane lomjovo lifaka ijubane le-punch (okungukuthi, ijubane lokunyakaza le-piston kulilinda lomjovo) kanye nejubane lokugcwalisa (okungukuthi, isivinini se-sprue).

Isivinini sokugcwalisa sisho ijubane eliqondile le-alloy encibilikile edlula umgijimi wangaphakathi, okuyipharamitha ebalulekile yokuqinisekisa ikhwalithi yokuphonswa kwabafa. Isikhathi somjovo sakhiwa isikhathi sokujova kancane, isikhathi somjovo osheshayo, isikhathi sokucindezela, isikhathi sokubamba ingcindezi, nesikhathi sokugcinwa kwesikhunta. Ekukhiqizweni, isikhathi sokubamba nesikhathi sokugcina isikhunta kuvame ukulawulwa futhi kuthuthukiswe ndawonye, okubizwa ngokuthi yisikhathi sokubamba ingcindezi nesikhathi sokugcina isikhunta. Ingcindezi eyanele yokubamba kanye nesikhathi sokugcina isikhunta kusho ukuthi ukusakazwa kokufa akukhubazi noma kunwebe ngesikhathi sokuvula isikhunta nokukhishwa. Isimo esidingekayo sokuqhekeka. Lezi zinhlaka ezibalulekile zidinga ukubhekwa nsuku zonke futhi ziqhubeke zithuthukiswa ngokuya ngesimo sokusakaza.

Ukuhlolwa Komkhiqizo

Ukuhlolwa kokulingisa kufaka phakathi ukubukeka nosayizi wokuhlola, ukuhlolwa kwekhwalithi yangaphakathi, ukuhlolwa kwembobo yangaphambi kokulingiswa, ukuhlolwa kobukhulu besilinda, ukuhlolwa kwesilinda kwendonga, ukulingisa ukwelashwa kokushisa okungaxhunyiwe ku-inthanethi ukuhlolwa kokugcina, ngokuya ngamalungiselelo abasebenzi kanye nezidingo zangempela zokukhiqiza ngokuya ngemvamisa engaguquki okujwayelekile Ukusakaza kuyafaneleka.

Ukuhlolwa kwamasampula enqubeni yokukhiqiza kungathola izinkinga ngesikhathi futhi kusabele ngokushesha, futhi ngeke kubangele izinkinga ze-batch ngenxa yesikhathi esibi sokutholakala kwezinkinga.

sutras

Ukukhiqizwa kwe-die-casting kuyinkqubo eyinkimbinkimbi kakhulu, efaka ikhwalithi ye-aluminium encibilikisiwe, isimo sesikhunta sokufa, amapharamitha womshini wokuphonsa, inqubo yokufa nokuhlolwa komkhiqizo, njll. eduze eduze nekhwalithi yezingxenye zokufa. Ekukhiqizweni kokufa, inqubo inquma umphumela, ukuphathwa okuhle kwenqubo kuzoholela kukhwalithi yomkhiqizo ozinzile, futhi ukukhiqizwa kwenqwaba okulawulwayo kuzoletha izinzuzo ezinkulu kwezomnotho.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Inqubo Yokulawula Ukulingiswa Kwe-Die

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off