Aluminium Ingxubevange Futhi Auxiliary Materials Management In Die Casting Production

Ukuphathwa Kwezinto Eziyinhloko

1. Ukulawulwa kokungena kwama-aluminium ingots ingots

Ngenxa yokuqukethwe kwegesi nezidingo zephoyinti eliqinile le-aluminium alloy, izitshalo zokukhiqiza ze-aluminium ingot kumele zenze umsebenzi omuhle wokucwenga, ukususa i-degassing, nokususa i-slag ukuvimbela ukukhubazeka okufana nokuqukethwe kwegesi ephezulu nokungcola okuningi kuma-aluminium ingots ekutholeni ifa- ekubunjweni aluminium ketshezi. Ngemuva kokungena kwe-aluminium ingot efektri, isinyathelo sokuqala ukuhlola ukubukeka. Ingaphezulu le-ingot ye-aluminium liyadingeka ukuba libushelelezi, lingabi nobukhulu, lingenawo amabala kawoyela, isikhutha, nesikali se-oxide, futhi ukwakheka kwe-aluminium ingxube ingot kulungile futhi kuminyene. Akufanele kube nokuhlukaniswa okukhulu, ukuncipha, noma ukuncipha. I-slag nokufakwa. Ukwenza isampula ukwakheka kwenqwaba ngayinye nenombolo yokushisa ukuqinisekisa ukuthi ukwakheka kwengxubevange esetshenzisiwe kufanelekile. Ekhiqizweni kwemikhiqizo enezidingo ezikhethekile, ezinye izinto zokuhlola zidinga ukungezwa. Isibonelo, lapho kukhiqizwa imikhiqizo enezidingo zokusebenza ngomshini, lapho i-ingxube ye-aluminium ingot ihanjiswa ukukhiqizwa, kuyadingeka ukuhambisa ibha yokuhlola eqine esithandweni ngasinye; lapho kukhiqizwa imikhiqizo enezidingo zokuvala umoya, kufanele kukhuphuke izinga le-pinhole ye-aluminium alloy ingot. Thola

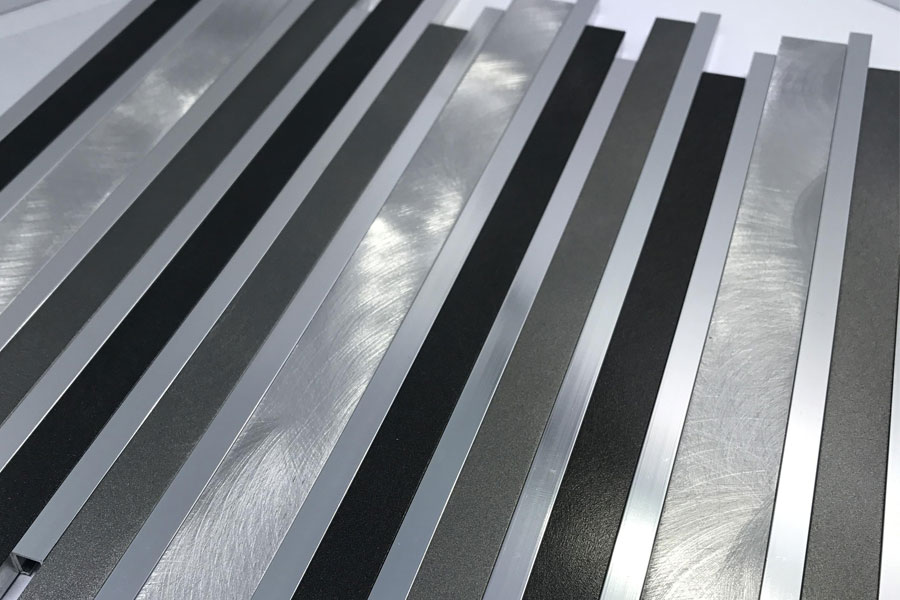

Izinhlobo zama-aluminium alloys asetshenziswa ekukhiqizeni uqobo akuvamisile ukukhawulwa ebangeni elilodwa, futhi izidingo zamakhemikhali ebangeni ngalinye le-aluminium alloy zihluke kakhulu. Izinto eziyinhloko ebangeni elilodwa le-alloy zikwelinye ibanga le-alloy. Kungathathwa njengokungcola. Ngokuhlalisana kwamamaki amaningi, kubalulekile ukuhlukanisa ngokusobala ama-alloys ebanga ngalinye ukuvimbela ukuvela kokuxubana ngesikhathi sokusetshenziswa. Isilinganiso esejwayelekile ukucacisa ngokusobala nangokufananayo umbala wokuvela kwama-alloys ama-aluminium wemikhiqizo ehlukene nabakhiqizi abahlukene, bese kugcinwa izinto ezahlukahlukene ezindaweni ezahlukahlukene ngemuva kokufika efektri.

2. Ukulawulwa kwenqubo yokuncibilika kwe-Aluminium

Umkhuba wokukhiqiza ukhombisa ukuthi ukwenza ngcono ikhwalithi ye-alloy melt kuyisici esibalulekile ekuthuthukiseni ikhwalithi yokuphonswa kwabantu abafayo. Ngakho-ke, ukuphathwa kwempahla eluhlaza kungalawulwa ngokuqinile ukuze izinto zokusetshenziswa ezingafaneleki zingafakwa eworkshop noma ekukhiqizweni. Sebenza ngokuqinile ngokuya ngamazinga adingekayo ngenqubo yokuncibilika kwe-alloy, futhi uqinise ukuphathwa kwezinto zokusetshenziswa ezahlukahlukene (izinto ezintsha, izinto ezenziwe kabusha, nezinto ezisizayo).

Inqubo yokuncibilika kwe-aluminium alloy kumele ibe nemithetho ecacile ngokushisa okuncibilikayo, isikhathi sokuncibilikisa, kanye nenani lezinto ezisetshenziswa kabusha, ikakhulukazi izinto ezifakwe kabusha kufanele zihlukaniswe ngokuqinile futhi ziphathwe, futhi akufanele zixutshwe. Izinto ezenziwe kabusha kufanele zihlanzeke futhi zingabi nawo uwoyela, ukugqwala, udaka, umswakama nokufakwa. Okungcolisayo okunamafutha ezintweni ezenziwe kabusha kungalungiswa ngumenzi we-aluminium ingot futhi akunakufakwa ngqo esithandweni sokuncibilika okusetshenziswayo; ngamabhulokhi e-aluminium ahlakazekile, kufanele ahlolwe futhi uthuli, isihlabathi nokunye ukungcola ngaphakathi kungasuswa. Sebenzisa: Lapho i-aluminium encibilikisiwe isetshenziselwa ukuvuselela, isilinganiso se-ejenti yokucwenga kanye ne-slag remover inkulu kunaleyo lapho kusetshenziselwa kuphela ingilazi ye-aluminium ingot. Ekukhiqizweni kwesimo sezulu esinomswakama ophakeme kakhulu, inani lezinto ezisetshenziswe kabusha akufanele leqe ama-30%, futhi okokuphinda kusetshenziswe kabusha kungakhushulwa ngokufanele esimweni sezulu esomile, kepha akufanele kudlule ama-40%.

Ukuhlatshwa kwe-aluminium encibilikisiwe ngemuva kokuncibilikisa kufanele kwenziwe ngesikhathi, futhi nemingcele efanele kufanele iqoshwe njengoba kudingeka. Enqubeni yokuncibilika ephakathi nendawo, ukwakheka kwamakhemikhali ebhodweni ngalinye le-aluminium liquid kufanele kuhlolwe ukuqinisekisa ukuthi ukwakheka kwamakhemikhali komkhiqizo kuyafaneleka ngesikhathi senqubo yokuncibilika. Ngaphezu kwalokho, ukuncibilikisa isikhathi eside kufanele kugwenywe, ngaphandle kwalokho okuqukethwe kwe-hydrogen kuketshezi lwe-aluminium alloy kuzokhula, okuzothinta ukuqina nomoya womkhiqizo odonsa okokufa. Ngokuvamile, ayidluli i-4h kusuka ekuncibilikeni nasekuphonseni ukufa.

Ukuphathwa Kwezinto Ezisizayo

1. Ukulawulwa komenzeli wokukhishwa

Ukusetshenziswa kwe-ejenti yokukhipha isikhunta kungenza ukugcwaliswa kwensimbi okusamanzi kahle, kube lula ukwakha, kuvimbele ukunamathela kwesikhunta, kwenze ukulingiswa kutholakale ikhwalithi yendawo ekhanyayo, ebushelelezi futhi eyisicaba, futhi ibe nethonya elikhulu kwisigqi sokukhiqiza, ukukhipha ubuso nekhwalithi yangaphakathi. Ngasikhathi sinye, ingavikela isikhunta, igweme ukuguguleka kwensimbi eshisayo yensimbi ebusweni besikhunta, inciphise ukuqhutshwa kokushisa nokushisa kwesikhunta kwesikhunta, futhi kwandise impilo yesikhunta. Lapho isikhunta sivulwa, silungele ukukhishwa okushelelayo kokuphonsa, futhi futhi kudlala indima ebalulekile ekwehliseni ukungqubuzana nokugqoka kwesibhakela, induku ye-ejector, nezingxenye ezihambayo. Ukulawulwa kommeli wokukhishwa akubandakanyi kuphela ukukhethwa kanye nobubanzi be-ejenti yokukhipha uqobo, kepha kufaka phakathi ukuphathwa kokufuthwa nokomiswa kommeli wokukhishwa ngumhlinzeki. Ngokuvamile, ukukhethwa kwe-ejenti yokukhipha kunezidingo ezilandelayo.

- It has Lubricity omuhle at lokushisa eliphezulu futhi ongaphakeme volatilization iphuzu. Amanzi akwi-ejenti ekhishwayo angazungeza ngokushesha ku-100-150 ° C.

- Ayinawo umthelela onakalisayo ku-die-casting isikhunta nezingxenye zokufa, futhi inokusebenza okuzinzile. Umenzeli wokukhishwa akumele aqine ngokushesha okukhulu futhi ashise emoyeni.

- Ayikho igesi eyingozi ezonqamuka emazingeni okushisa aphezulu, futhi akukho ukungcola okuzokwenzeka ebusweni bomgodi wokuphonsa.

Njengamanje, ukufafazwa komenzeli wokukhishwa ikakhulukazi kungukusebenza okwenziwa ngesandla, futhi ukusebenza kokufafaza okunengqondo kuyisici esibalulekile sokuqinisekisa ikhwalithi yokusakaza, impilo yesikhunta sokufa, kanye nokusebenza kahle kokukhiqiza. Isikhathi sokufafaza se-ejenti yokukhipha isikhunta sibuye sishintshe ngokusebenza kokukhishwa kwesikhunta, isilinganiso sokuxubeka, izinhlobo ezahlukahlukene zokufa, kanye namazinga okushisa ahlukahlukene wesikhunta ezinhlobo ezahlukahlukene zama-ejenti wokukhipha isikhunta. Umenzeli wokukhishwa ufuthwa kusuka kusibhamu sokufafaza kuya ebusweni besikhunta ukuze ungene kwifilimu evikelayo. Kuthatha isikhathi eside. Lapho inqubo ingakaqedwa, umsebenzi wokusakaza uyenziwa, okuvame ukuba yimbangela yeziphambeko ezixekethile zokusakaza. Ngokuya ngemithethonqubo yenqubo yokufa, kufanele kutholakale ibanga lesikhathi sokufafaza lohlobo olwehlukile lommeli wokukhishwa kanye nezilinganiso ezihlukile zokuxuba. Abasebenzi be-Die casting kumele baqonde okushiwo yimingcele ephezulu nengezansi yamapharamitha wenqubo kanye nethonya lokulungiswa kwethonya, futhi benze ukulungisa okufanele ngokuya ngezimo zomhlaba zokukhishwa kokufa okukhiqizwayo.

Uma usebenzisa ama-ejenti wokukhishwa asuselwa emanzini, isilinganiso sama-ejenti wokukhipha kufanele silawulwe ngokuqinile. Uma isilinganiso somenzeli wokukhishwa emanzini siwugqinsi kakhulu, kuzokwakhiwa ifilimu ejiyile ebusweni besikhunta, futhi ukunqwabelana kwe-ejenti yokukhululwa kuzokwakheka kancane ebusweni besikhunta. Umswakama ku-ejenti ekhishwayo awukwazi ukukhishwa ngokuphelele futhi kuzokhiqizwa negesi, okuzokwenza ingxenye yokulingisa. Ukuxinana kwangaphakathi kuyawohloka. Uma isilinganiso somenzeli okhipha amanzi sincane kakhulu, umphumela ngeke utholakale, futhi izingxenye zokuphonsa zizohlushwa uhlobo lokunamathela nokunamathela.

Ngakho-ke, ekuphathweni kwekhwalithi yomhlangano wokulingisa wokufa, ukuphathwa kwe-ejenti yokukhipha kunomthelela omkhulu kuzinga lezingxenye zokulingisa. Kuyadingeka ukuqinisa abaphathi kule ndawo, njengokuqoka umuntu okhethekile ozobhekana nenani lommeli okhululayo, futhi echaza ngokusobala izinhlobo ezahlukahlukene zokwehluka kwesilinganiso somenzeli wokukhishwa namanzi enqubeni yokukhiqiza yokusakaza imikhiqizo inqunywa futhi ilinganiswe ngokwenqubo yokulungiselela umenzeli wokukhishwa. Lapho ufafaza, opharetha uzokwenza ukuqeqeshwa okuqinile ngesenzo sokufafaza, futhi isenzo kufanele senziwe ngokuya ngezidingo nezincazelo, futhi akuvunyelwe ukufafaza okuningi, okuncane, noma ukuphuthelwa isifutho.

2. Punch uwoyela ukuphathwa

Njengamanje, ukusetshenziswa okuningi kwesibhakela esuselwa ku-oyili okugcoba uwoyela noma ukuthambisa kwezinhlayiyana, akukhathalekile ukuthi uluhlobo luni lwe-punch lubrication, ngemuva kokuthi uketshezi lwe-aluminium lungene emgqonyeni, kufanele lushiswe ngokuphelele ngesikhathi esifushane, futhi okusele kufanele kusatshalaliswe kusendlalelo esiphezulu se-alloy liquid, Ukuze umthelela wamafutha we-punch kumkhiqizo ungabi mkhulu kakhulu. Ngaphandle kwalokho, igesi eyenziwe ngomlilo nezinsalela ngemuva komlilo izongena kumkhiqizo, futhi umphumela ungacatshangwa.

Indlela elula yokuqinisekisa uwoyela we-punch ukubuka umbala wesibambo sezinto ekubunjweni. Ngokuvamile, ukushuba kwesibambo sempahla kungu-1/3 kuya ku-1/4 wobubanzi besibhakela, futhi ubude bokwenza mnyama kukawoyela we-punch akufanele budlule u-3 wobukhulu besibambo sezinto. / 5; Ngasikhathi sinye, akufanele kube khona ukufiphaza okusobala ekugcineni kwesibambo sezinto (okungukuthi, izinsalela eziningi kakhulu ze-graphite powder). Ngaphandle kwalokho, ngemuva kokuthi umkhiqizo usucutshunguliwe, ukukhubazeka okufana nama-pores kuzokwenyuka nakanjani.

Enqubeni yokukhiqiza, kufanele sinake nesimo sokusebenza sedivayisi yokuthambisa i-punch ngaso sonke isikhathi. Uma i-lubricant ifafazwa kakhulu noma incane kakhulu, izoba nomthelela omubi empilweni yegumbi lokucindezela kanye ne-punch kanye nekhwalithi yokusakaza okufa. Lapho ulungisa inani lesithambisi esisetshenzisiwe, kubalulekile ukucubungula ukuthambisa kwesibhakela nokudonswa kwesikhunta. Ikakhulukazi lapho usebenzisa i-particle lubrication, noma ngabe ama-pellets we-wax asetshenziswa kanjani kusikhunta sokufa, kuzoba nenkinga yokwehliswa kwezinto eziphilayo. Uma inani elikhulu lezinto eziphilayo eziguquguqukayo lingakwazi ukukhishwa kahle, lizoba nomthelela omkhulu ekukhiqizeni ama-pores engxenyeni yokuphonsa okufa.

3. Ukuphathwa kwesibhakela

I-punch negumbi lengcindezi kwakha uhlelo lokuncikelana. Ngaphansi kwezimo ezijwayelekile, impilo yegumbi lengcindezi ingafinyelela eminyakeni emi-2 kuya kwengu-3, futhi impilo yesibhakela imfushane, ishifu eyodwa, futhi impilo ende ingafinyelela izikhathi ezingaphezu kwezingu-10,000 XNUMX. Umehluko esikhathini sokuphila sizodala ukwehla kwekhwalithi yomkhiqizo kanye nezinguquko ezinkulu ezindlekweni zokukhiqiza. Ngakho-ke, ukuphathwa okuhle kwesibhakela akukwazi nje kuphela ukusimamisa ikhwalithi yezingxenye zokufa, kepha futhi kunciphisa kakhulu izindleko zokukhiqiza zokulingisa.

- Idizayini yosayizi wepunch. Ngaphansi kwezimo ezijwayelekile, kudingeka ukuthi kube khona imvume ethile phakathi kwe-punch negumbi lokucindezela. Ukuzijwayeza kukhombisa ukuthi igebe elifanele cishe lingu-0.1 mm. Ngesikhathi somjovo, uma igebe likhulu kakhulu, i-aluminium alloy liquid ingangena esikhaleni, bese kuvela ukuvuza oketshezi lwe-aluminium kanye nentuthu, okuzobhebhethekisa ukugqokwa kwesibhakela futhi kunciphise impilo yesibhakela; uma igebe lincane kakhulu, isibhakela sizohamba ngenqubo Kukhona ukugudluka, isivinini sesibhakela asikwazi ukufinyelela kusivinini esinqunyelwe inqubo, isikhathi sokugcwaliswa kwesikhunta sihlala isikhathi eside, futhi nezinkinga zekhwalithi yokusakazwa izingxenye ziyanda. Ngakho-ke, ukucubungula nokukhiqizwa kwesibhakela kufanele kwenziwe ngokuqinile ngomdwebo, ukuze ekugcineni ulawule igebe elibucayi, wandise impilo yesibhakela, futhi uqinisekise ikhwalithi yomkhiqizo.

- Ukupholisa kwesibhakela Njengoba inqubo yokuphonsa inquma ukuthi izinga lokushisa le-punch liyashintsha njalo, ngokushintsha kwamazinga okushisa, igebe phakathi kwesibhakela negumbi lengcindezi nalo liyashintsha. Lezi zinguquko azithinti kuphela impilo yesevisi ye-punch, kodwa futhi nokuzinza kwenqubo yokujova ngesikhathi senqubo yokufa. Ukugcina igebe elifanele, kuyadingeka ukupholisa isibhakela. Ekuklanyeni, kubhekwa ukuthi i-plunger ipholile ngokuphelele ngumgogodla wamanzi wenduku yomjovo, futhi ukushisa kwesibhakela kuthathwa kuze kufike ezingeni eliphezulu, futhi igebe elifanele phakathi kwe-punch negumbi lokucindezela lingagcinwa esitebeleni. Lezi zinyathelo zisiza ukuqinisekisa ukuzinza kwenqubo yokujova isikhunta ngasinye kanye nokuqina kwekhwalithi yemikhiqizo ekhishwa ngokufa. Ukuzijwayeza kukhombisile ukuthi uhlelo lokujova ngephini elihle lokupholisa lungakhulisa kakhulu impilo yensimbi ngenkathi kuqinisekiswa ukuqina kwenqubo yokujova. Kodwa-ke, kuyadingeka ukwenza umsebenzi omuhle wokufaka uphawu lwamanzi okupholisa we-punch, futhi uqaphele ukuvuza kwamanzi okupholisa okubangelwa ukuvalwa okungalungile phakathi kwe-punch kanye nenduku yomjovo. Uma kunganakwa ngokwanele ukuvuza kwamanzi okupholisa, kuzothinta kakhulu umkhiqizo. Ukuqina komoya.

4. Ukuphathwa kwe-Crucible

Ukusetshenziswa kokubethelwa kubaluleke kakhulu ekusakazweni kokufa kwama-aluminium alloys, ikakhulukazi ukusetshenziswa kwama-cast iron cast. Uma ama-crucibles engakwazi ukuqhutshwa ngokuqinile ngokuya ngemininingwane ye-crucible, okuqukethwe kwe-Fe ekwakhekeni kwe-aluminium alloy kwinqubo elandelayo yokukhiqiza kungadlula izinga. Ngokwesipiliyoni sethu, uma i-cast iron crucible ingashaywa ngopende we-crucible ngokuhambisana ngokuqinile nezidingo zokusetshenziswa kwembiza entsha, futhi ibhulashe njalo ezinsukwini ezi-3 ngenkathi isetshenziswa, ngokuyisisekelo ukwanda kokuqukethwe kwe-Fe phakathi nalo lonke ufe- Inqubo yokukhiqiza yokusakaza ngeke yeqe u-0.2% (lena idatha yezibalo yenkampani eminyakeni edlule, kungahle kube khona umehluko phakathi kwezinkampani ezahlukahlukene). Ngaphansi kwesisekelo sokulawula ukuhlolwa okungenayo kwama-aluminium ingots ingots, kungaqinisekisa ngokuphelele ukuthi ukwakheka kwengxubevange yama-die castings akhiqizwayo ahlangabezana nezidingo ezijwayelekile. Yize kungekho ukukhathazeka ngokwanda kwensimbi ekusetshenzisweni kwama-graphite crucibles, kufanele futhi kunakwe. Inqubo yokomisa ukusetshenziswa kokuqala kwama-graphite crucibles kumele isetshenziswe ngokuqinile. Le misebenzi izothinta impilo yokusebenza kwama-graphite crucibles ngokuzayo futhi ayikashiswa kahle. Impilo ye-graphite crucible izothinteka kakhulu. Intengo ephezulu ye-graphite crucible ngayinye izothinta izindleko zokukhiqiza zokusakaza oku-die.

Isiphetho

Phakathi kwezinto ezinhlanu eziyinhloko zokuphathwa kwekhwalithi, okungenhla ikakhulu kuxoxwa ngezinkinga "zezinto zokwakha" kanye "nabantu". Ngenkathi ukuphatha izinto zokusetshenziswa nezinto ezisizayo, ukuqeqeshwa kwabasebenzi kanye nokuphathwa kufanele kwenziwe kahle, futhi nezinga lobuchwepheshe labasebenzi bokuphonsa abafayo lifuna ukuthuthukiswa ngokwengeziwe. Ukuze uxazulule ngempumelelo izinkinga zekhwalithi ekukhiqizweni kokufa, sebenzisa umqondo wokuphathwa kwekhwalithi ephelele ekulawulweni kwekhwalithi yomhlangano wokulingisa, bese usebenzisa ulwazi lokuhleleka kokukhiqiza ulwazi lokuqondisa ukuqondisa ukukhiqizwa, nakanjani izothuthukisa ikhono lokulawula ikhwalithi le-workshop yokuphonsa ekuphakameni okusha. .

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Aluminium Ingxubevange Futhi Auxiliary Materials Management In Die Casting Production

Inkampani kaMinghe Casting inikezelwe ukukhiqiza nokuhlinzeka ngekhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zifeza ububanzi zifaka ikakhulu I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off