Inqubo Yokulawulwa Kokukhiqizwa Kwe-Vermicular Iron

Uma kuqhathaniswa nensimbi empunga, amandla aqine wensimbi engu-vermicular andiswa okungenani ngama-70%, i-modulus ye-elasticity inyuswa ngama-35%, futhi amandla okukhathala acishe aphindeka kabili. Uma kuqhathaniswa ne-aluminium alloy, amandla nokuqina kwensimbi eyi-vermicular kuphakeme kabili, futhi amandla okukhathala aphindwe kabili. Lezi zici zensimbi engu-vermicular zinikeza ithuba lokuthi injini ithuthukise isilinganiso samandla / isisindo futhi inyuse umfutho wesilinda. Ukukhuphula ingcindezi yesilinda kuyisihluthulelo sokusebenza kahle kwenjini elandelayo ye-diesel ejova isizukulwane esilandelayo. Ukuze kuhlangatshezwane nokusetshenziswa okubanzi kwensimbi eyi-vermicular, imboni yezisekelo njengamanje ilungiselela ngenkuthalo, itshala imali eningi futhi yakha kabusha izinqubo ezintsha zokwenza ukukhiqizwa kwensimbi eyi-vermicular kuzinze futhi kuthembeke.

Ezinjini zensimbi ezenziwe ngophethiloli kusuka kohlobo oluthile kuya ekukhiqizweni, into enqumayo ubungozi bekhwalithi. Ngensimbi esezingeni eliphakeme yensimbi, indawo ezinzile incane kakhulu, kuphela ebangeni lokuqukethwe kwe-magnesium engu-0.008%. Inani elilandelwayo, njengokulahleka kuka-0.001% we-magnesium, lizokhiqiza i-flake graphite, okuzokwenza ukuthi izakhiwo zemishini zehle ngo-25% kuye ku-40%. Lo mbhalo uchaza uhlelo lokulawula inqubo olususelwa kuzindlela zokuhlaziya ezishisayo. Uhlelo lulinganisa ukulahleka kwe-magnesium futhi lulungisa isimo sensimbi encibilikile online ukuvimbela ukwenziwa kwe-flake graphite. Le ndlela yokulawula nokulinganisa eku-inthanethi inciphisa ukuntengantenga enqubeni yokukhiqiza i-vermicular iron iye ezingeni eliphansi kakhulu, futhi isusa ngokuphelele ubungozi bekhwalithi obubangelwa ukukhiqizwa kwensimbi eyi-vermicular.

Isidingo samandla aphakeme amahhashi, i-torque ephezulu, ukukhishwa kwe-exhaust ephansi kanye nokwehla kokusetshenziswa kukaphethiloli kuyaqhubeka nokukhula. Lokhu kuphoqa abaqambi bezinjini ezinamandla amakhulu zikadizili ukuthi bakhuphule umfutho ophakeme wokuthungela, okwandisa kakhulu umthwalo oshisayo kanye nomthwalo womshini wenjini. Umthwalo oshisayo kanye nomthwalo womshini uyanda ngasikhathi sinye, ukuze izinjini ezijwayelekile zensimbi ne-alloy cast iron (CrMo) ezisetshenzisiwe manje zifinyelele noma zeqe umkhawulo ongaphezulu wokusetshenziswa kwazo. Abakhiqizi benjini badinga izinto ezinamandla aphakeme nokumelana kangcono nokushisa.

Insimbi yomlomo isheshe yaba yinto ekhethwa ngabantu. Ithuthukisa kakhulu ukuthembakala kwebhokisi lesilinda, ikhanda lesilinda kanye ne-cylinder liner yesizukulwane esisha sezinjini zamaloli. Ukuze kuzuzwe inhlanganisela enhle kakhulu yezakhiwo ezahlukahlukene (ezinjengezindawo zokulingisa, izakhiwo zemishini, ukuqhutshwa okushisayo nezakhiwo zemishini), lezi zingxenye kufanele zenziwe ngesilinganiso se-spheroidization esingu-0% kuye ku-20% (isilinganiso sokuqaqa esingu-80% kuye ku-100% Yenziwe nge-vermicular iron. Uma isilinganiso se-spheroidization sidlula ama-20%, sizodala uchungechunge lwezinto ezingezinhle. Isibonelo, inani lokuncipha likhulu kakhulu, futhi izingxenye ezinokuma okuyinkimbinkimbi njengamakhanda amasilinda zithambekele ikakhulukazi ekunciphiseni. Esinye isibonelo ukwehliswa kwempilo yamathuluzi ngenxa yokugqoka ngokweqile ngesikhathi semishini. Kukhona nokwehla okuphawulekayo kokuhamba kokushisa, okubangela ukucindezeleka okushisayo njalonjalo. Ngakolunye uhlangothi lwensimbi engu-vermicular, ukuvela kwe-flake graphite kuzodala ukwehla okuqondile kwezakhiwo zomshini, okwenza injini ingakwazi ukuhlangabezana nezidingo ezintsha. Ngokufingqa, ukuze kuhlangatshezwane nezidingo zesizukulwane esisha sezinjini zamaloli, isilinganiso se-spheroidization yensimbi enamandla amakhulu i-vermicular iron kufanele ibe phakathi kuka-0% no-20% (okungukuthi, isilinganiso sezinambuzane singaphezu kuka-80%, ngaphandle kwama-flakes).

Ukuthi kufanele kusetshenziswe inqubo yenqubo yokukhiqiza noma cha kuncike ekuphumeni konyaka komkhiqizo, ubunzima bomkhiqizo nobubanzi obuvumelekile bezinguquko kusakhiwo se-metallographic. Njengoba kukhonjisiwe kuMdwebo 1, izingxenye ezilula, ezinevolumu ephansi, njengezikhunta ze-ingot, ngokuvamile zingakhiqizwa ngezindlela ezivamile zokusakaza. Ukulawulwa kwenqubo ngokuvamile akudingeki, futhi akubizi ngokwezomnotho. Lapho umkhiqizo waminyaka yonke wezinto ukwanda, njengamapayipi wokukhipha, imikhono emincane kanye nabakaki, kufanele kube nengqondo ukwethula ukulawulwa kwenqubo. Yize lolu hlobo lomkhiqizo lunokukhishwa okukhulu konyaka, ithani lonyaka lokusakaza alikho phezulu. Izidingo zesakhiwo se-metallographic azinzima kangako, zivumela izinga le-spheroidization ukuthi lifike kuma-50%. Ngaphezu kwalokho, ngenxa yemishini encane yokwenza lezo zingxenye, ukwanda kwe-titanium okungangezwa ekukhiqizeni kungavunyelwa ukwandisa ibanga elilawulekayo. Kulolu hlobo lomkhiqizo, izindlela ezijwayelekile zokusakaza nokuqeqeshwa okuqinile ngokuvamile kufanelekile ekukhiqizeni i-vermicular iron. Kepha ngokombono wokulawulwa kwekhwalithi, inqubo yokulawula kufanele iphephe kakhulu. Ngokufanayo, ukulawulwa kwenqubo futhi kunikeza isiqinisekiso sokukhiqizwa kwamabhulokhi amakhulu ezinjini zasolwandle namakhanda amasilinda. Yize ubukhulu obukhulu kanye nobungako bokukhiqiza obuphansi bufanelekile ekwenziweni kwemikhiqizo, ukulahleka kwezomnotho okubangelwe yimikhiqizo edlula izinga kujwayelekile ukwengeza isethi yohlelo lokulawula inqubo.

Imikhiqizo edinga kakhulu ukulawulwa kwenqubo ngamabhulokhi wezinjini zemoto, amakhanda amasilinda kanye nama-disc brake anokukhipha okukhulu konyaka, ubunzima obuphakeme nezidingo zobuchwepheshe eziqinile. Umthamo wonyaka wokukhiqiza kanye nethoni yonyaka yale mikhiqizo iphezulu kakhulu. Ziyinkimbinkimbi ngosayizi, zifuna ukwakheka kwe-metallographic, futhi zivame ukukhiqiza izimbotshana zokuncipha. Le mikhiqizo akufanele ibe nezingozi zekhwalithi, ngaphandle kwalokho ukulahleka kuzoba kubi kakhulu.

Izidingo eziqinile ekusebenzeni kwebhulokhi yenjini, ikhanda lesilinda nesihlalo sesilinda zibeke isisekelo sokwenza imininingwane yemikhiqizo. Ukuze uthole ukusebenza okuhle kakhulu okuphelele kwe-castability, machinability kanye nezakhiwo zemishini, isilinganiso se-spheroidization kufanele sibe ku-0% kuya ku-20% kuzo zonke izingxenye eziyinhloko zento. Okubaluleke kakhulu, i-flake graphite kufanele igwenywe ngokuphelele ukuvikela ukulimala kwezingxenye ezibangelwa ubuthakathaka bendawo. Ukuze kuzuzwe ukutholakala okuhle kwemishini, ama-carbide wamahhala kufanele ancishiswe okungenani. Ngakho-ke, i-titanium akufanele yengezwe. Ekugcineni, ngokombono wokukhiqiza, isisekelo sidinga inqubo ezinzile nethembekile yokuqinisekisa isilinganiso esilahlekile kunazo zonke esidalwa isakhiwo se-metallographic. Abakhiqizi embonini yezimoto badinga ukuqinisekiswa kwekhwalithi, futhi ama-100% wokuphosa kumele ahlangabezane nezidingo ze-metallographic. Ukukhiqizwa okukhulu, okuthembekile kwamabhulokhi esilinda, amakhanda amasilinda nezihlalo zesilinda kudinga ukuhlaziywa okunembile nokulungiswa kwe-inthanethi kwensimbi encibilikisiwe ukuqeda ukuguquguquka kwenqubo ngaphambi kokuthela.

Ukuqina Kwensimbi Okunamandla

Isizathu esenza ukuthi insimbi ehlangene ingasetshenziswa ngobuningi ukukhiqiza izingxenye eziyinkimbinkimbi (njengezinjini zenjini) yingoba indawo ezinzile yensimbi ehlanganisiwe incane kakhulu ukuqinisekisa ukuthi ayikho ingozi ekukhiqizeni. Ngokuvamile, le ndawo ezinzile ihlanganisa kuphela indawo engu-0.008% magnesium, njengoba kukhonjisiwe kuMdwebo 2. Usayizi nokuma kwepulatifomu endaweni ezinzile kuyahluka ngomkhiqizo. Eqinisweni, uhla olutholakalayo lwe-magnesium lincane kunalokhu. Ngoba yonke imizuzu engu-5, i-magnesium esebenzayo izoshisa i-0.001%. Iphoyinti lokuqala lokuthululela insimbi encibilikisiwe kufanele libe kude ngokwanele nendawo yokujika ebukhali yensimbi ehlanganisiwe iye kwinsimbi empunga ukuqinisekisa ukuthi ayikho i-flake graphite evelayo engxenyeni yokugcina yabalingisi. Lapho i-magnesium ifakwa ensimbi encibilikisiwe, i-flake graphite izovela cishe emizuzwini engu-15.

Indawo yokuqala akufanele isondele kakhulu ohlangothini lwesokunene lweplatifomu elizinzile (okuqukethwe okuphezulu kwe-magnesium), ngaphandle kwalokho kuzodala inani elikhulu le-spheroidal graphite ukwakheka engxenyeni encane kanye nengxenye yokupholisa esheshayo.

Ngaphezu kwendawo encane yesikhulumi etholakalayo, indawo yesikhulumi ihlala ihamba. Uma okuqukethwe oksijini nesulfure okusebenzayo kuphezulu, bazosebenzisa i-magnesium esebenzayo futhi ipulatifomu yonke izohamba iye kwesokudla (okuqukethwe kwe-magnesium ephezulu). Ngakolunye uhlangothi, uma okuqukethwe okusebenzayo kwe-oxygen nesulfure kuphansi, ipulatifomu izothuthela ngakwesobunxele (okuqukethwe okuphansi kwe-magnesium). Izinguquko ekwakhiweni kwezinto zokusetshenziswa, ubumsulwa, izinga le-oxidation nomswakama, njll., Kwenza kube nzima ngabantu ukulawula i-vermicular iron ngebanga elihleliwe lokwakheka kwamakhemikhali.

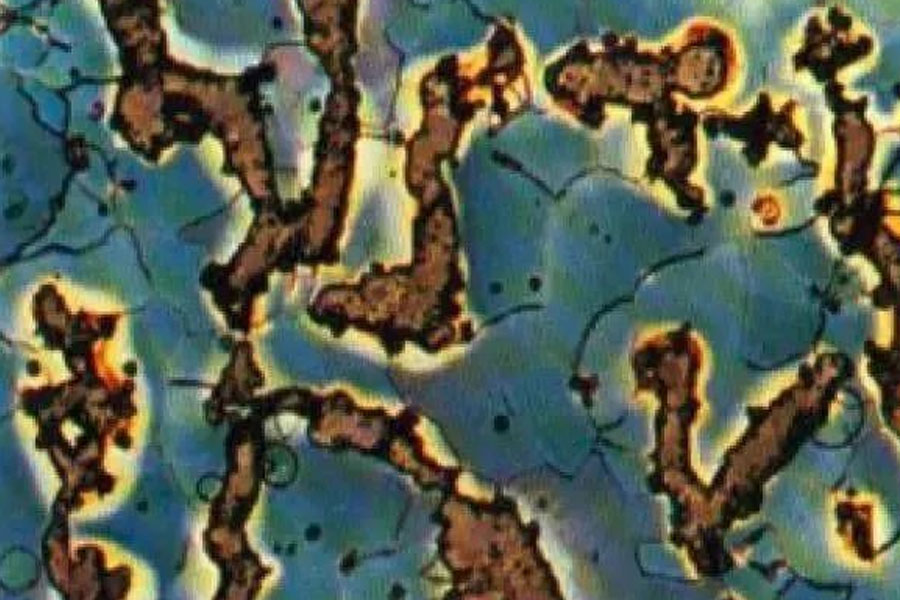

Yize ukuguqulwa kusuka ku-vermicular iron kuya ku-grey iron kudinga kuphela ukunciphisa i-magnesium esebenzayo ngo-0.001%, ukushiswa kwe-magnesium akubangeli ukuthi yonke ingxenye ibe yi-flake graphite. Lapho i-magnesium esebenzayo inganele, i-graphite iqala yakha ama-flakes, bese inwebela ngaphandle njengoba iqina, futhi i-magnesium sags bese igxila ekugcineni kwengaphambili kwe-solid-liquid interface. Uma inani lokuqala le-magnesium elisebenzayo lifanele, i-vermicular graphite izokwakhiwa emngceleni we-eutectic, njengoba kukhonjisiwe kuMdwebo 3. I-Flake graphite iqala ukuvela njengamabala e-flake graphite. Ngokungafani nayo yonke i-flake graphite ejwayelekile, lezi zindawo ezikude ze-flake graphite kunzima ukuzibona nge-ultrasound. Amathuba okuthi ziskenwe yi-ultrasound awaphakeme.

Ukuzwela kwe-magnesium kuya ku-vermicular iron kungakhonjiswa kuMdwebo 4: Ngethani lensimbi eshisayo eshisayo, vele ungeze amagremu ayi-10 we-magnesium, amabala we-flake graphite ahlakazeke kusampula yokuhlola engu-Φ25 ingaguqulwa ngokuphelele ibe i-vermicular graphite. Amandla wokuqina webha yokuhlola enezindawo ze-flake graphite angama-MPA angama-300 kuphela, kanti amandla okuqina ebha yokuhlola efanayo anokreleksa ophelele afinyelela kuma-450 MPa.

I-inoculant ibuye izwele kakhulu kwipulatifomu ezinzile yensimbi engu-vermicular, njengoba kukhonjisiwe kuMdwebo 5: ukufaka ama-gram angama-80 we-inoculant kuthani elilodwa lensimbi encibilikisiwe kuzokhulisa isilinganiso se-spheroidization kubha yokuhlola engu-Φ25 kusuka ku-3% kuye ku-21%. Inani le-inoculation liphezulu, futhi i-crystal nucleus iningi, evumayo ekwakhiweni kwe-graphite eyindilinga. Lokhu kuphakamisa ipulatifomu yensimbi eyi-vermicular ekuqondeni kwezinga eliphezulu le-spheroidization. Izinga eliphansi le-inoculation libangela ukuthi ipulatifomu ihambele phansi. Izici eziningi, njengokushisa okushisayo kwensimbi encibilikisiwe, isikhathi sokubamba, ukwakheka kwamakhemikhali kwezinto zokusetshenziswa, uhlobo lwe-inoculant nenani le-inoculation, kuzothinta ukuma kwepulatifomu yensimbi eyi-vermicular.

Isidingo esiyisisekelo kunazo zonke ubuchwepheshe bokulawula inqubo ukukala ngokunembile nokuhlaziya isimo sensimbi encibilikisiwe. Nge-vermicular iron, ukulawulwa kokukhiqiza okuthembekile kudinga ukulinganisa ngasikhathi sinye kwephuzu elibucayi le-magnesium esebenzayo kusuka ekuguqulweni kwe-creep-ash, izinga lokutubeka okulandelayo kwe-magnesium, nezinga le-inoculation.

Isampula yokuhlaziywa okushisayo kwamagremu angama-200 itholakala ngokufaka iphenyo le-Xinte ensimbi ebunjiwe ngemuva kwe-spheroidization kanye ne-inoculation. Ngesikhathi senqubo yokufakwa kwemizuzwana emithathu, udonga lwesayensi nensimbi encibilikile kufinyelela esimweni sokulingana esishisayo. Ihlukile kunenkambiso ejwayelekile yokuhlaziya isampula yenkomishi, lesi sampuli esinezindonga ezincanyana asiqinisekisi kuphela ivolumu yesampula efanayo isikhathi ngasinye, kodwa futhi sigwema namachibi ensimbi encibilikisiwe ethululela enkomishini yesampula. Isilinganiso se-superheat sinembe kakhudlwana ngoba akukho mkhuba onje ngesimo sokuncipha okunodlame ekuhlaziyweni okuvamile kokushisa.

Njengoba kukhonjisiwe kuMdwebo 6a, iphenyo yeXinte yenziwa ngensimbi yensimbi ecindezelweyo. Ngokuyisisekelo isitsha esiyindilinga. Udonga lwensimbi oluncane oluqukethe insimbi encibilikisiwe lunolwelwesi lwe-vacuum-like insulation. Ubukhulu besendlalelo sokuqinisa buminyaniswe ngokulingana ngokuya ngesikhombisi sokuphakama ukuze kuqinisekiswe ukushabalalisa kokushisa okufanayo nokupholisa okuzungezile, futhi amanzi e-iron zz kuwo asondele ekuqiniseni komzimba oyindilinga. Kunezinhlobo ezimbili ze-N zohlobo lwe-thermocouples kuthumbu lokuvikela kuphenyo. I-thermocouple ingakhishwa ngemuva kwesilinganiso ngasinye futhi isetshenziswe kaningi izikhathi ezingaphezu kwezingu-100. Enye yama-thermocouples amabili itholakala ezansi kwesitsha, kanti enye itholakala enkabeni yokushisa kwesitsha. Njengoba isitsha siyindilinga futhi simiswe ngokukhululekile (lokhu kwehlukile kunenkomishi ejwayelekile yokuhlaziya isampula ehlala kubakaki odonsa ukushisa), insimbi encibilikisiwe idala ukugeleza kokushisa okufanayo esitsheni, njengoba kukhonjisiwe kuMfanekiso 6b. Lokhu kugeleza kokushisa kubangela ukuthi insimbi encibilikisiwe iguqulwe ngokuqhubekayo esitsheni, yenze ukwahlukaniswa kokugeleza ezansi kwephenyo.

Ukuze ulingise ukulahleka kwemvelo kwensimbi encibilikisiwe ngesikhathi sokuthululelwa, kukhona ukumbozwa odongeni lwe-probe oluphendula nge-magnesium esebenzayo. Insimbi encibilikisiwe igeleza ngasodongeni oluboshwe oluqhutshwa ukugeleza kokushisa. Ngemuva kokuphendula, okuqukethwe kwe-magnesium yensimbi encibilikisiwe kuyehla futhi kuqoqane egumbini elingezansi kwesiqukathi. Ukukhuluma ngokuqondile: I-thermocouple enkabeni yesheke ilinganisa insimbi encibilikisiwe engaphenduliwe, okuyisimo sokuqala sokuthelwa; i-thermocouple ezansi ilinganisa izwe ngemuva kokuphela kokuthululwa. Ukwakheka kokumbozwa okusebenzayo kubaluleke kakhulu. Kumele kuqinisekiswe ngokunembile ukuthi insimbi encibilikile eqongelelwe egumbini ingaphansi kokusebenza okungu-0.003% kunensimbi encibilikiswe enkabeni. Ngakho-ke, uma okuqukethwe kokuqala kwe-magnesium kusondele kakhulu lapho kuguquka khona umlotha, insimbi encibilikile egumbini izokhiqiza insimbi empunga, ezolinganiswa ne-thermocouple kule ndawo. Ngale ndlela, ekuqaleni kokuphonsa, i-workshop ingangeza i-magnesium eyengeziwe ukuze isuse ukulahlekelwa okungenakugwemeka kokushisa kwe-magnesium.

Uma i-thermocouple ezansi ibonisa ijika le-vermicular iron, kukhombisa ukuthi okuqukethwe kokuqala kwe-magnesium kuphakeme ngokwanele ukuthi ngeke kube khona i-flake graphite ngemuva kokuphela kokusakaza.

Umdwebo 7 ngumdwebo wokuguguleka kwesigaba esiphambanweni sephenyo yeXinte ngemuva kwesilinganiso sesampula. Kulesi sibalo, ungayibona ngokucacile indawo yokwahlukanisa, indawo eyisampula enkulu nethubhu yokuvikela i-thermocouple. Njengoba i-magnesium esebenzayo incishiswa ngo-0.003%, kwakhiwa i-graphite emise okwe-D ne-ferrite matrix endaweni yokwehlukanisa. Ubukhulu bendawo ye-flake graphite ezansi buveza ngqo okuqukethwe kokuqala kwe-magnesium endaweni eyisampula enkulu. Ubukhulu bale ndawo bungabalwa kusukela ekushiseni okukhishwe ezansi. I-coefficient of variance regression phakathi kokukhishwa kokushisa nosayizi wokwahlukanisa idlula i-0.9, okufakazela ukuthi ubudlelwano phakathi kwalokhu kusondele kakhulu. Ukushisa okukhishiwe kutholakala ngokuhlanganiswa kwesikhathi kwejika lokupholisa. Le ndlela yokulinganisa isimo sensimbi encibilikisiwe okwamanje futhi ekugcineni kokuthelwa ngasikhathi sinye iqinisekisa ukunemba kokuqukethwe kwe-magnesium ngaphambi kokuthela.

Njengoba i-vermicular iron izwela kakhulu kuma-spheroidizing agents kanye nama-inoculants, akunakwenzeka ukuthi abakwa-foundries basebenzise izindlela zokwelashwa ezeqile ezisetshenziswa ekukhiqizeni i-grey iron ne-ductile iron. Njengoba kukhonjisiwe kuMdwebo 8, ngenxa yokuzwela kwayo, i-vermicular iron izinzile kuphela ngaphakathi kwewindi lesikwele, hhayi nje indawo yesikhulumi se-magnesium. Inqubo yokukhiqiza insimbi ethembekile kufanele ilawule i-spheroidization kanye ne-inoculation kusukela ekuqaleni kuze kube sekugcineni ukuqinisekisa ukuthi isakhiwo se-metallographic siyahlangabezana nalokho okubhekiswe kuye.

Kungakhathaleki ukuthi kwenziwa umzamo ongakanani, noma ngabe ukuphathwa kuqine kangakanani, ukuguquguquka kwensimbi encibilikile kuhlala kungagwemeki. Ingasaphathwa eyokuthi abantu banembe kangakanani ngokunemba ngensimbi encibilikisiwe, izindlela zokwelashwa okuyisinyathelo esisodwa, njenge-sandwich method, azikwazi ukuqinisekisa ukuthi ukwelashwa ngakunye kuzowela ngaphansi kwewindi elincane le-vermicular iron. Ukuhlukahluka okuningi kokukhiqiza, okufana nokuxuba isilinganiso, izinga lokushisa kwesithando somlilo, isikhathi sokubamba, ukushisa kwensimbi yensimbi encibilikisiwe, isivinini sokushaya, ukuthepha indawo yokuthinta insimbi encibilikisiwe (ngaphakathi noma ngaphandle kwesilinganiso), ngokuthepha isisindo sensimbi esincibilikile, isimo sesikhwama se-alloy, i-ejenti ye-spheroidizing okuqukethwe okwenziwe nge-magnesium kwe- (PeSiMg), ukuhlelwa kwe-alloy koqweqwe ngalunye lwendlela ye-sandwich, nokufakwa kwezinsimbi ezilahliwe, njll., konke kuzothinta ukumuncwa kwe-magnesium. Ngaphezu kwalezi zinto, okuqukethwe kwe-oxygen esebenzayo nesulfure esebenzayo nakho kuzoshintsha usayizi nokuma kwewindi le-vermicular iron. Izinguquko esikhathini sokuhlala sensimbi encibilikisiwe ku-ladle, isikhathi sokuhamba nesikhathi sokuthela konke kuzoshintsha isikhathi esivuthayo sokushisa.

Kodwa-ke, ukuguquguquka okungalindelekile kakhulu amaphutha we-opharetha, noma umehluko phakathi kwama-opharetha ahlukene ngenxa yemikhuba yokusebenza ehlukile.

Ekukhiqizweni okukhulu kwesisindo, okuwukuphela kwendlela ephephile ukukala izici zokuqina kwensimbi encibilikile ngemuva kokwelashwa. Ngale ndlela, izinto ezahlukahlukene ezithinta usayizi, isikhundla, kanye nokufakwa kwe-alloy kwewindi le-vermicular iron kukalwe, kwahlaziywa futhi kwabhekwa ngokuphelele. Ngemuva kwalokho inani elifanele le-magnesium ne-inoculant lingangezwa. Iladi ngalinye lensimbi encibilikisiwe lithelwa ngemuva kokuthi lithuthukiselwe esimweni esikahle. Le ndlela yezinyathelo ezimbili, yokukala nenqubo yokulungisa inqubo inciphisa ukwehluka kokukhiqiza futhi iqeda ngokuphelele ubungozi be-flake graphite ekusakazweni.

Inqubo Ukulawulwa Of Vermicular Iron Production Nge Zezıhlabane Metal ladle

Njengoba kukhonjisiwe kuMdwebo 9, inqubo yokulawula iqala ngokuhlaziywa okushisayo kwensimbi encibilikisiwe ngemuva kokuqala ukwelashwa kwe-spheroidization nokwelashwa. Ngokuya ngomphumela wokuhlaziywa, umshini wokuphakela ngezintambo ubonisa ngokuzenzakalela ubude bocingo oluzofakwa nge-magnesium ne-inoculant, bese ulinda opharetha ukuthi ayiqale. Lapho ulayini wokuphothula usuphothuliwe, iladi liyathunyelwa kulayini wokusakaza ngokushesha. Yonke inqubo yokulinganisa nokulungisa ithatha cishe imizuzu emithathu. Ngalesi sikhathi, i-workshop ingenza izindlela ezijwayelekile zokwelapha ngaphambi kokulingisa, njengokukhishwa kwe-slag. Lokhu kuqinisekisa ukuqhubeka komugqa wokusakaza.

Ngokombono wokusebenza, i-iron encibilikisiwe eluhlaza ayinayo i-magnesium, futhi amandla ayo okufukamela nawo alinganiselwe kakhulu. Ngemuva kwe-spheroidization kanye ne-inoculation, i-magnesium kanye nama-inoculants kuqala badla i-oxygen esebenzayo nesibabule ensimbi encibilikisiwe, bese "ugxumela" insimbi encibilikisiwe endaweni ethile ebhodini. Esibonelweni kuMdwebo 10, inkomba ye-magnesium kanye ne-inoculation index yensimbi encibilikisiwe ingama-65 no-45, ngokulandelana. Ngoba imingcele eyinhloko yokuguqulwa kokukhiqizwa kwesithunzi iboniswa ensimbi encibilikisiwe ngemuva kokulinganisa nokwelashwa, imiphumela yokuhlaziya okushisayo ikhombisa ngqo isimo samanje sensimbi encibilikisiwe. Konke okusele ukufaka inani elifanele le-magnesium ne-inoculant ukuphakamisa insimbi encibilikisiwe kusuka endaweni yayo yamanje iye lapho kudingeka khona. Esibonelweni esikumdwebo 10, amayunithi ayisikhombisa wezintambo ze-magnesium afakwa kuqala, bese kwengezwa amayunithi angama-23 wezintambo ezigonyelwayo. Ubudlelwano obuhambisanayo phakathi kweyunithi yenkomba nobude bekhebuli bulinganiswa ngokomkhiqizo nomhlangano wokusebenzela, futhi buhlanganiswa ohlelweni. Ngokusekelwe kokuhlangenwe nakho okwedlule kokuphonswa kwensimbi okuyi-vermicular, inani elijwayelekile lekhebula le-magnesium elengeziwe ngamamitha ama-100,000 ngethani. Iqukethe amagremu ayi-5 we-magnesium ngemitha, futhi ibalwa ngesilinganiso sokumunca esingu-12%, inani le-magnesium elengeziwe ngethani lensimbi encibilikisiwe lingama-gramu angama-50 kuphela. Njengoba inani lokungeza lincane kakhulu, futhi izinguquko ezinkulu sezivele zenzekile ekwelashweni kokuqala, ukulungiswa kusebenza kakhulu futhi kunokwethenjelwa. Ngemuva kokulungiswa, asikho isidingo sokwenza ukuhlaziywa okushisayo.

Ekwelashweni kokuqala, umbuso ngemuva kokwelashwa kufanele ube ngaphansi kunendawo yokuqala yokuthela, ukuze kuthi noma ngabe zonke izinto ezizuzisayo ukumuncwa kwe-magnesium ne-inoculant zifinyelele inani elifanele, i-iron encibilikisiwe izofinyelela kuphela esimweni sokuqala sokuthulula . Ngaphandle kokuphathwa ngokweqile, insimbi encibilikisiwe ngemuva kokwelashwa ayikho esimweni sensimbi eyimpunga nensimbi emhlophe. Ukuze kwenziwe inqubo yokusakaza isebenze kahle, inkomba ye-magnesium ne-inoculation index yeladi ngayinye yensimbi encibilikisiwe iboniswa kumdwebo wenqubo block. Ngokwesimo esiguqukayo somdwebo webhulokhi, opharetha angalungisa inani lensimbi encibilikisiwe engezwe kwiladi elilandelayo. Inani elilinganayo lekhabhoni nalo liyakhonjiswa esikrinini. Le mininingwane ihlelwe yagcinwa kulog yokukhiqiza, ukuze itholakale futhi ibanzi, futhi ihlangabezana nezidingo zokuqinisekiswa kwekhwalithi.

Yize ukuhlaziywa okushisayo nokulungiswa okulandelayo kungaqinisekisa ukukhiqizwa kwensimbi engu-vermicular, kunconywa ukuthi amasampuli athathwe enkomishini yesipringi yokuphonswa kokugcina kokuhlaziywa. Uma kuqhathaniswa nokuhlolwa kwekhwalithi ejwayelekile, lo mphumela wokuhlaziya oshisayo unganikeza ukuhlaziywa kwe-inthanethi futhi uhlukanise ukusakazwa uma kudingeka. Ukulingiswa kokulahleka kwe-magnesium kuphenyo kwenza le ndlela yokuhlola "engonakalisi" isebenze kakhulu kunezindlela ze-metallographic ne-ultrasonic. Ngoba le ndlela ilinganisa usayizi wesampula omkhulu, ibuye ithole ukuthi insimbi encibilikisiwe izoqina kanjani emizuzwini eyi-10-15 elandelayo.

Ngamafuphi

Ukukhethwa kohlelo lokulawula inqubo kuncike kumkhiqizo nakwinqubo yokusakaza. Lapho kusakazwa imikhiqizo eyinkimbinkimbi efana nekhava yenjini yensimbi ne-cylinder, uhlelo kufanele ngasikhathi sinye lilawule okuqukethwe kwe-magnesium ne-inoculant ukuze kungaphakathi kwewindi elincane kakhulu ukusuka ekuqaleni kuze kube sekupheleni kokuthelwa. Izinga le-spheroidization kumele libe phakathi kuka-0% no-20% (isilinganiso sokuqaqa esingu-80% kuye ku-100%) ukuze kuqinisekiswe ukukhishwa okungcono kakhulu, ukwengeza ngemishini nokunye ukusebenza okuphelele nomsebenzi omuhle kakhulu wokusetshenziswa. Izindawo ze-Flake graphite kumele zisuswe ngokuphelele ukuvikela ukukhubazeka nobuthakathaka bendawo.

Isiqalo sanoma yiluphi uhlelo lokulawula inqubo ukukala ngokunembile nangempumelelo isimo sensimbi encibilikisiwe. Ukukhiqizwa kwensimbi okuthembekile okukhulu okuthembekile kumele kube nezindlela zokulawula ezinokwenzeka ukuqeda izinguquko zenqubo namaphutha wokusebenza kwabantu. Indlela ephumelela kunazo zonke yokuqeda ushintsho lwenqubo ukwenza ukuhlaziywa okushisayo ngensimbi encibilikile ngemuva kwe-spheroidization kanye ne-inoculation. Ngokuya ngemiphumela yokuhlaziywa okushisayo, inani elifanele le-magnesium ne-inoculant libuye lengezwe ngaphambi kokuthela. Le ndlela yokulinganisa nokulungisa oku-inthanethi iqinisekisa ukusimama kolayini wokukhiqiza futhi isuse izingozi ezahlukahlukene ezilethwe ukukhiqizwa kwensimbi okuyi-vermicular enkulu.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Inqubo Yokulawulwa Kokukhiqizwa Kwe-Vermicular Iron

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off