Inqubo Yokulingisa Engagqwali Yensimbi Engagqwali

- Inqubo ye-silica sol ingeyalokho okuthiwa ukusakaza utshalomali. Kuyinto ukusika ongaphakeme noma cha-ahlabayo inqubo ekubunjweni. It is a omuhle kakhulu inqubo ubuchwepheshe embonini Foundry futhi has anhlobonhlobo izicelo. Akulungele kuphela ukusakazwa kwezinhlobo ezahlukahlukene nama-alloys, kepha futhi kukhiqiza ukusakazwa ngokunemba okuphezulu nobukhulu bekhwalithi kunezinye izindlela zokulingisa, futhi ngisho nokuphonsa okunzima, okumelana nokushisa okuphezulu, futhi okunzima ukucubungula okunzima ukusakaza ngezinye izindlela zokusakaza. Ingaphonswa ngokusakazwa kokutshalwa kwezimali.

- Investment thusi ithuthukiswa ngesisekelo wasendulo wax thusi. Njengempucuko yasendulo, iChina ingelinye lamazwe okuqala ukusebenzisa lobu buchwepheshe. Emuva emakhulwini e-BC, abantu bakudala abasebenzayo bezwe lethu bakha lobu buchwepheshe obulahlekile be-wax casting, obasetshenziselwa ukwenza amaphethini nezinhlamvu ezahlukahlukene ezinhle. IZhong Ding, izitsha kanye neminye imikhiqizo, efana nethuna likaZeng Hou Yi ngePrince and Autumn Period. Isisekelo sethuna lethuna likaZenghou Yi sakhiwe ngamadragoni amaningi ahlanganisiwe, axhunywe ekugcineni naphezulu futhi axegezela phezulu naphansi akha iphethini eligcwele umgodi we-multilayer moiré. La maphethini kunzima ukukhiqizwa ngamasu ajwayelekile okusakaza, kepha afakwa ngendlela elahlekile ye-wax. Ubungcweti bungasizakala ngokungabi namandla kwephalafini wax nokukhululeka kokuqoshwa. Amathuluzi ajwayelekile angasetshenziselwa ukuqopha imisebenzi yezandla eyenziwe ngophalafini wax afana nethuna lethuna likaZenghou Yi, bese ufaka uhlelo lokuthela, ukumboza, ukudambisa amanzi, nokuthulula. Ungathola ipuleti lethuna elihle likaZeng Hou Yi.

- Ukusetshenziswa okusebenzayo kwezindlela zesimanje zokufaka imali ekukhiqizeni izimboni kwakungu-1940. Ukwakhiwa kwezinjini zezindiza zezindiza ngaleso sikhathi kwakudinga ukwenziwa kwezingxenye ze-alloy ezingamelana nokushisa ezifana nezinsimbi, izinto zokufaka, imibhobho, njll., Enezimo eziyinkimbinkimbi, ubukhulu obunembile nezindawo ezibushelelezi. Ngoba izinto zokuxhuma ezingamelana nokushisa kunzima ukuzisebenzisa futhi izingxenye ziyinkimbinkimbi ngokuma, akunakwenzeka noma kube nzima ukwenziwa ngezinye izindlela. Ngakho-ke, kuyadingeka ukuthola inqubo entsha yokubumba ngokunemba. Ukuthuthukiswa kwezindlela zesimanje zokuphonsa imali kuthole ukuthuthukiswa okubalulekile ngesisekelo sobuciko bakudala. Ngakho-ke, ukuthuthukiswa kwemboni yezindiza kukhuthaze ukusetshenziswa kokuphonsa utshalomali, futhi ukuthuthuka okuqhubekayo nokuphelela kokuphonswa kotshalo-mali nakho kudale izimo ezincomekayo embonini yezindiza ukuze iqhubeke nokwenza ngcono ukusebenza kwayo.

- izwe lami laqala ukufaka isicelo sokutshala imali ekukhiqizeni izimboni ngawo-1950s naku-1960. Kusukela lapho, le nqubo yokusakaza esezingeni eliphakeme yathuthukiswa kakhulu, futhi isetshenziswe kabanzi ezindizeni, ezimotweni, kumathuluzi wemishini, emikhunjini, ezinjini zangaphakathi zomlilo, ophephela begesi, imishini yokuxhumana ngocingo, izikhali, imishini yezokwelapha, nemimese, nezinye izimboni zokukhiqiza. Ukukhiqizwa kobuciko obuhle.

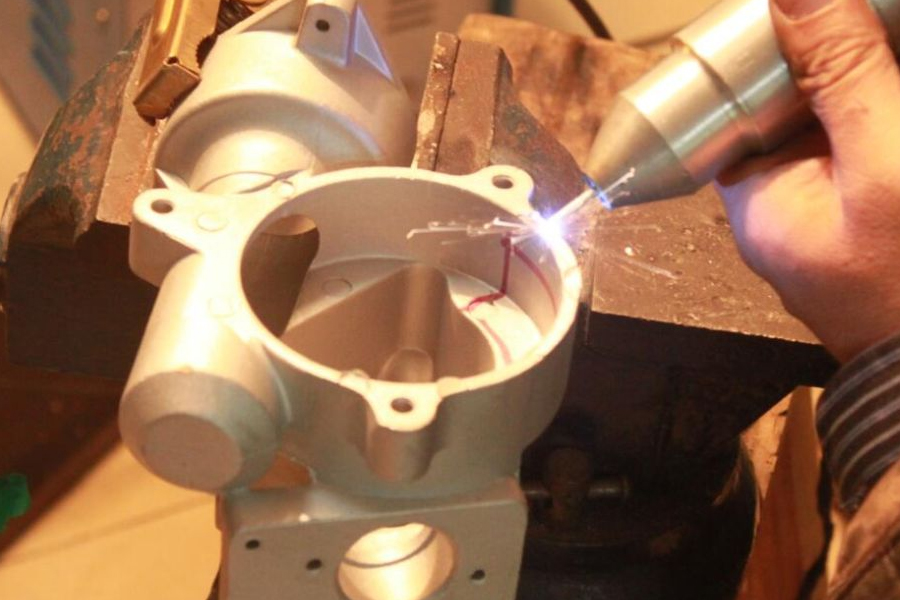

Inqubo okuthiwa yokusakaza utshalomali ukumane usebenzise izinto ezi-fusible (njenge-wax noma ipulasitiki) ukwenza imodeli yefusible (ebizwa ngokuthi utshalomali noma imodeli), faka izingqimba eziningana zokumboza okukhethekile kuyo, bese uyomisa futhi uyiqinise . Ngemuva kokwenza igobolondo elihlanganayo, sebenzisa umusi noma amanzi ashisayo ukuncibilikisa imodeli egobolondweni, bese ufaka igobolondo ebhokisini lesihlabathi, ugcwalise isikhunta ngesihlabathi esomile esizungezile, bese ekugcineni ufake isikhunta esithandweni sokuwosa ngokushisa okuphezulu (uma kusetshenziswa isikhunta esinamandla amakhulu, igobolondo lesikhunta ngemuva kokudilizwa lingasuswa ngqo ngaphandle kokumodela). Ngemuva kokukhishwa kwesikhunta noma isikhunta, insimbi encibilikisiwe ithelwa kuyo ukuthola ukulingiswa.

Ukunemba ntathu of utshalomali castings kuyinto kuqhathaniswa eliphezulu, ngokuvamile kuze kufinyelele CT4-6 (CT10 ~ 13 for sand sand casting and CT5 ~ 7 for die casting). Vele, ngenxa yenqubo eyinkimbinkimbi yokusakazwa kotshalo-mali, kunezinto eziningi ezithinta ukunemba kobukhulu bokuphosa, okufana nesikhunta. Ukuncipha kwento, ukuguqulwa kwesikhunta sokutshala imali, ushintsho oluqondile lwegobolondo kunqubo yokushisa nokupholisa, ukuncipha kwe-alloy kanye nokusonteka kokuphonsa ngesikhathi senqubo yokuqinisa, njll, ngakho-ke ukunemba okuyisisekelo ukusatshalaliswa okujwayelekile kokutshalwa kwezimali kuphezulu, kepha ukuvumelana kwayo kusadinga ukwenziwa ngcono (ubukhulu bokuvumelana kokuphonswa ngama-wax wokushisa okuphakathi naphakathi kufanele kuthuthukiswe kakhulu).

Lapho ucindezela isikhunta sokutshala imali, uhlobo lwengcindezi olunobushelelezi obuphezulu bomgodi luyasetshenziswa, ngakho-ke ubushelelezi bendawo yesikhunta sokutshala imali buphezulu kakhulu. Ngaphezu kwalokho, igobolondo lenziwe ngengubo ekhonjiwe eyenziwe ngento yokunamathela ekhethekile enezinga eliphezulu lokushisa nokumelana nayo, eboshwe kusikhunta sokutshala imali, nengaphezulu langaphakathi lomgodi elixhumana ngqo nensimbi encibilikisiwe bushelelezi high. Ngakho-ke, ukuphela kobuso bokuphonsa utshalomali kuphakeme kunalokho kokuphonsa okujwayelekile, ngokuvamile kufinyelela kuRa. 1.6 ~ 3.2μm.

Inzuzo enkulu yokusakazwa kokutshalwa kwezimali ukuthi ngenxa yokuthi ukusatshalaliswa kwezimali kunokunemba okuphezulu nobuso obuphezulu, umsebenzi wemishini ungancishiswa, kepha kuphela inani elincane lesabelo semishini esingashiywa ezingxenyeni ezinezidingo eziphakeme, futhi abanye abaphosayo baneKhefu kuphela isabelo sokugaya nokupholisha, futhi singasetshenziswa ngaphandle kokulungiswa kwemishini. Kungabonakala ukuthi ukusetshenziswa kwendlela yokutshala imali kungagcina imishini eminingi yamathuluzi womshini nokucubungula amahora omuntu, futhi kugcine kakhulu izinto zokusetshenziswa zensimbi.

Enye inzuzo yendlela yokulingisa utshalomali ukuthi ingaphonsa ukusakazwa okuyinkimbinkimbi kwama-alloys ahlukahlukene, ikakhulukazi ama-castings alloy aphezulu. Isibonelo, i-blade yenjini ye-jet, iphrofayili yayo ehlelekile kanye nomgodi wokupholisa, akunakwakhiwa ngobuchwepheshe bemishini. Ukukhiqizwa ngenqubo yokukhipha utshalomali akukwazi ukufeza ukukhiqizwa okukhulu kuphela, ukuqinisekisa ukungaguquguquki kokuphonswa, kepha futhi kugweme ukugxila kokucindezelwa kwamamaki wommese asalile ngemuva kokuchofoza

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Inqubo Yokulingisa Engagqwali Yensimbi Engagqwali

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off