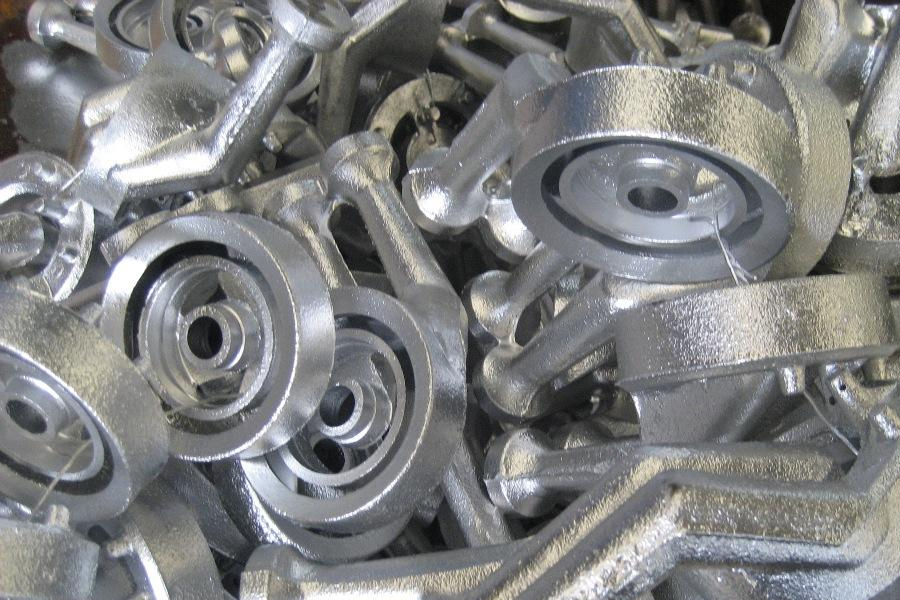

Surface nezindlela zangaphakathi zokuhlola ikhwalithi yokusakazwa

Ukuhlolwa kokuphonswa ikakhulukazi kubandakanya ukuhlolwa kosayizi, ukuhlolwa okubukwayo kokubukeka nobuso, ukuhlaziywa kwamakhemikhali kanye nokuhlolwa kokusebenza komshini. Okokuphonsa okudinga izidingo ezibaluleke kakhulu noma okujwayele ukuba nezinkinga kunqubo yokusakaza, ukuhlolwa okungonakalisi nakho kuyadingeka, okungasetshenziselwa ukusakaza i-ductile iron castings. Amasu wokuhlola angonakalisi wokuhlolwa kwekhwalithi afaka ukuhlolwa kokungena kuketshezi, ukuhlolwa kwezinhlayiyana kazibuthe, ukuhlolwa kwamanje kwe-eddy, ukuhlolwa kwe-radiographic, ukuhlolwa kwe-ultrasonic, nokuhlolwa kokudlidliza.

Ukutholwa kwamaphutha angaphezulu nokuseduze kobuso bokusakazwa

1. Ukutholwa kokungena kuketshezi

Ukuhlolwa kokungena kuketshezi kusetshenziselwa ukubheka ukukhubazeka okuhlukahlukene kokuvula ebusweni bokusakazwa, njengokuqhekeka kwendawo, izimbobo zomhlaba nokunye ukukhubazeka okunzima ukukuthola ngamehlo. Ukuhlolwa kokungena okusetshenziswa kakhulu ukuhlolwa kombala, okumanzi noma ukufafaza uketshezi olunemibala (ngokuvamile olubomvu) (olungena ngaphakathi) olunekhono lokungena eliphezulu ebusweni bokusakaza. Lowo ongena ngaphakathi ungena kusici sokuvula bese esula masinyane umuntu ongena ngaphakathi. Ngemuva kwalokho fafaza i-ejenti yokubonisa eyoma kalula (ebizwa nangokuthi unjiniyela) ebusweni bokusakaza. Ngemuva kokuthi umuntu ongenayo oshiye isici sokuvula ekhishwe, i-ejenti yokubonisa idayiwe, engakhombisa ukwakheka nokuma kwephutha. Usayizi nokusatshalaliswa. Kudinga ukukhonjiswa ukuthi ukunemba kokuhlolwa kokungena kuyancipha ngokwanda kobukhulu bendawo yempahla ehloliwe, okungukuthi, lapho ukukhanya kukhanya khona, ngcono umphumela wokuhlola. Ukunemba kokuhlolwa komhlaba komshini wokugaya kuphakeme kakhulu, futhi kutholakala nemifantu ye-intercrystalline. Ngaphezu kokutholwa kombala, ukutholwa kokungena kwe-fluorescent futhi kuyindlela esetshenziswa kakhulu yokuthola uketshezi lokungena kuketshezi. Kudingeka ifakwe ukukhanya kwe-ultraviolet ukuze kubhekwe imisebe, futhi ukuzwela kokutholwa kuphakeme kunalokho kokuthola umbala.

2. Eddy ukuhlolwa kwamanje

Ukuhlolwa kwamanje kwe-Eddy kufanelekile ukuhlola ukukhubazeka ngokuvamile okungekho ngaphezu kuka-6 ~ 7mm ekujuleni ngaphansi kobuso. Ukuhlolwa kwamanje kwe-Eddy kwehlukaniswe izinhlobo ezimbili: indlela yokubekwa kwamakhoyili kanye nendlela yekhoyili. : Lapho ucezu lokuhlola lubekwe eduze kwekhoyili enezikhathi ezishintshayo, inkambu kazibuthe eshintshanayo engena kucezu lokuhlola ingenza i-current (eddy current) egeleza ku-eddy current direction perpendicular to the excitation magnetic field in the test piece. Kuzokwenziwa amandla kazibuthe aphambene nesiqondiso sendawo kazibuthe ethokozisayo, okuzonciphisa kancane amandla kazibuthe wokuqala kwikhoyili, okuzodala ushintsho lwe-impedance yekhoyili. Uma kukhona ukukhubazeka ebusweni bokuphonsa, izici zikagesi zamanje ze-eddy zizophazamiseka, ngaleyo ndlela kutholakale ubukhona besici. Okubi kakhulu ekuhlolweni kwamanje kwe-eddy ukuthi ubukhulu nokuma kwephutha elitholakele akukwazi ukuboniswa ngokubonakalayo, futhi ngokuvamile kuphela indawo engaphezulu nokujula kwesici okunganqunywa. Ngaphezu kwalokho, akuyona ebucayi njengokutholwa kokungena kokuthola amaphutha okuvula amancane ebusweni bento yokusebenza.

3. Magnetic kuyizinhlayiyana ukuhlolwa

Ukuhlolwa kwezinhlayiyana zeMagnetic kufanelekile ukuthola ukuthambekela kwendawo kanye nokukhubazeka ngamamilimitha ambalwa ukujula ngaphansi komhlaba. Kudinga i-DC (noma i-AC) imishini yokwenza uzibuthe kanye ne-powder kazibuthe (noma ukumiswa kukazibuthe) ukwenza imisebenzi yokuthola. Imishini ye-Magnetization isetshenziselwa ukukhiqiza amandla kazibuthe ezindaweni ezingaphakathi nezangaphandle zokuphonsa, futhi i-powder kazibuthe noma ukumiswa kukazibuthe kusetshenziselwa ukubonisa ukukhubazeka. Lapho kukhiqizwa inkambu kazibuthe ngaphakathi kohlobo oluthile lokusakaza, ukukhubazeka endaweni enozibuthe kuzokhiqiza amandla kazibuthe avuzayo. Lapho impuphu kazibuthe noma ukumiswa kufafazwa, i-powder kazibuthe iyakhangwa, ukuze iphutha liboniswe. Amaphutha akhonjiswa ngale ndlela ngokuyisisekelo amaphutha awela imigqa yamandla kazibuthe, futhi amaphutha amise okwesikhathi eside ahambisana nemigqa yamandla kazibuthe awakwazi ukuboniswa. Ngalesi sizathu, isiqondisi sikazibuthe sidinga ukuguqulwa njalo ngenkathi sisebenza ukuqinisekisa ukuthi kutholakala ukukhubazeka okuhlukahlukene ezindaweni ezingaziwa. .

Ukutholwa kwamaphutha angaphakathi ekubunjweni

Okokukhubazeka kwangaphakathi, izindlela zokuhlola ezingezona ezonakalisayo ezisetshenziswayo ukuhlolwa kwe-radiographic nokuhlolwa kwe-ultrasonic. Phakathi kwabo, ukuhlolwa kwe-radiographic kunomphumela omuhle kakhulu. Ingathola izithombe ezinembile ezibonisa uhlobo, ukwakheka, usayizi nokusatshalaliswa kwamaphutha angaphakathi. Kodwa-ke, ngokusakazwa okukhulu ngobukhulu obukhulu, ukuhlolwa kwe-ultrasonic kuyasebenza kakhulu, futhi indawo yokukhubazeka kwangaphakathi kungalinganiswa ngokunembe kakhudlwana. , Usayizi ofanayo nokusatshalaliswa.

1. Ukuhlolwa kwe-Radiographic

Ukuhlolwa kwe-Radiographic ngokuvamile kusebenzisa ama-X-ray noma ama-γ-ray njengomthombo we-ray. Ngakho-ke, imishini nezinye izinsiza ezisizayo ziyadingeka ukukhiqiza imisebe. Lapho umsebenzi usebenza obala kunkambu ye-ray, amandla emisebe yemisebe azothinteka ukukhubazeka kwangaphakathi kokuphonsa. Amandla emisebe ekhishwa ngokusakaza ayahluka endaweni ngosayizi nobunjalo besici, kwakheka isithombe se-radiographic saleli phutha, elibukwayo futhi liqoshwe yifilimu ebonisa imidwebo, noma ukuhlolwa kwesikhathi sangempela nokubukwa yisikrini se-fluorescent, noma yikhawunta yemisebe. Phakathi kwabo, indlela yokuthuthukisa nokuqopha ngefilimu ye-radiographic iyindlela esetshenziswa kakhulu, eyaziwa kakhulu njengokuhlolwa kwe-radiographic. Isithombe esinesici esivezwa yi-radiography sinembile, futhi ukuma, ubukhulu, inombolo, ukuma kwendiza kanye nohlu lokusatshalaliswa kwephutha konke kungakhonjiswa, kepha ukujula kwesici akunakuboniswa ngokujwayelekile, futhi kudingeka izindlela ezikhethekile nokubala ukuthola it. Kulezi zinsuku, ukusetshenziswa kwezindlela ze-radiographic computer tomography kuyavela. Ngoba imishini ibiza kakhulu futhi izindleko zokusebenzisa ziphakeme, ngeke zenziwe zande njengamanje, kepha lobu buchwepheshe obusha bumele inkomba yentuthuko yesikhathi esizayo yobuchwepheshe bokutholwa kwe-radiographic resolution ephezulu. Ngaphezu kwalokho, ukusetshenziswa kwe-micro-focus X-ray system esondela emthonjeni wephoyinti empeleni kungaqeda imiphetho engaconsi phansi eyenziwe ngamadivayisi amakhulu wokugxila futhi yenze umugqa wesithombe ucace. Ukusetshenziswa kwesistimu yesithombe sedijithali kungathuthukisa isilinganiso sesignali nomsindo wesithombe futhi kuthuthukise nokucaca kwesithombe.

2. Ukuhlolwa kwe-Ultrasonic

Ukuhlolwa kwe-Ultrasonic kungasetshenziswa ukubheka ukukhubazeka kwangaphakathi. Isebenzisa imishayo yemisindo enamandla amisindo ephezulu yokusabalalisa ngaphakathi ekusakazweni. Lapho ihlangabezana nokuvela kwangaphakathi noma ukukhubazeka, kuyakhombisa futhi kuthola amaphutha. Ubukhulu bamandla omsindo obonakalisiwe kungumsebenzi wokuqondisa nobunjalo bendawo yangaphakathi noma ukukhubazeka kanye ne-acoustic impedance yalesi siginali. Ngakho-ke, ukukhubazeka okuhlukahlukene noma amandla omsindo akhonjiswa indawo yangaphakathi kungasetshenziswa ukuthola indawo, ukushuba kodonga noma indawo yesici. Ukujula kwesici esilandelayo. Ukuhlolwa kwe-Ultrasonic kuyindlela esetshenziswa kabanzi engeyona eyonakalisayo. Izinzuzo zayo eziyinhloko yilezi: ukuzwela okuphezulu kokuthola, okungathola imifantu emincane; inekhono elikhulu lokungena futhi ingabona ukusikeka kwesigaba esinyene. Imikhawulo yayo eyinhloko yilena: kunzima ukuchaza ukwakheka kwamagagasi okubonakalisiwe kwesici esinqanyuliwe ngosayizi wohlaka oluyinkimbinkimbi nokuqondisa okungalungile; ukwakheka okungathandeki kwangaphakathi, njengosayizi wokusanhlamvu, ukwakheka, i-porosity, okuqukethwe kokufakwa noma ukusabalalisa okuhle Izimbangela, njll. ngaphezu kwalokho, ibhulokhi yokuhlola ejwayelekile kufanele ikhonjwe lapho ihlolwa.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Surface nezindlela zangaphakathi zokuhlola ikhwalithi yokusakazwa

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off