Ukulawulwa Kwekhwalithi Ekuqedeni Nge-Waste Heat Ngemuva KOKWAKHA

Amazwe emhlabeni wonke ayikhuthaza ngamandla inqubomgomo yokwehlisa ukungcola nokusetshenziswa: izifundiswa eziningi zasekhaya kanye nezinkampani zithathe izinyathelo ezivela ezicini ezahlukahlukene, futhi ukucisha ukushisa kwemfucuza ngemuva kokufaka kungenye yezinyathelo ezibalulekile.

Ukuqedwa kokushisa okuqediwe ngemuva kokufaka ukwelashwa kokushisa okuphezulu kwe-thermomechanical ekwelashweni kokushisa kwe-thermomechanical. Idatha [1, 2, 3] inezincazelo ezithile. Kuze kube manje, abakhiqizi abaningi basekhaya basebenzise ukucisha imfucumfucu okwenziwe ngemuva, futhi abakhiqizi abambalwa sebethule → behlisile → sebephunguliwe noma bakhuphuka → behlisiwe → bayaqhubeka ukwehla ngenxa yezinyathelo ezingezinhle zokulawula ikhwalithi.

Uma kuqhathaniswa nokwelashwa okuvamile kokushisa, ngenxa yokushisa okuphezulu nokushisa okusakazwayo, umngcele we-martensite-angle engela okusanhlamvu wensimbi uyanda, ukushuba kwesibalo kuyanda, i-hydrogen yokuqala iyaphunyuka kancane, imifantu yoqobo iyaphiliswa futhi yehliswe, kanye ne-carbides zihlakazekile futhi zanwela. Ubulukhuni obucimayo bezingxenye zensimbi buthuthuke kakhulu (ngokujwayelekile buthuthukiswa cishe ngo-10%). Ngesikhathi se-tempering, izingxenye zensimbi zinokumelana nokushisa okuphezulu (izinga lokushisa lokushisa liyathuthukiswa uma kuqhathaniswa nokujwayelekile, imvamisa i-20 ℃ -30 ℃).

- 1. Lapho saya endaweni yokuhlanza ukushisa ngenxa yezizathu ezahlukahlukene, abasebenzi abaningi bezobunjiniyela nabezobuchwepheshe baphakamisa ukuthi izinto zokusetshenziswa nezinye izinto zilungile, ukuthi ungasibikezela kanjani isenzeko sokucima ukuqeda ngemuva kokubukana? Lesi yisifingqo semiphumela emithathu emikhulu (le miphumela emithathu emikhulu futhi inenani lesethenjwa le-hydrogen embrittlement kanye nengcindezi yokuqhekeka kwemfucumfucu kwinqubo yokwelashwa komhlaba).

- 1.1 Umphumela wokwenziwa kwamakhemikhali: Isibonelo: insimbi yekhabhoni: usayizi ofanayo ф6, amanzi afanayo okucima usawoti: insimbi engu-35, insimbi engama-40, insimbi engama-45, insimbi engama-50, insimbi engama-55, insimbi engama-60, insimbi engama-65, insimbi engama-45, umphumela ukuthi insimbi engu-60 ~ insimbi engu-0.6 iphuka kalula. Ngoba ukuphakama kokuqukethwe kwekhabhoni ye-martensite, kukhula ukucindezeleka, futhi okuqukethwe kwekhabhoni okuphezulu kungu-0.6%. Lapho okuqukethwe kwekhabhoni kwensimbi kuphakeme kakhulu, kuzoba ngaphezulu kuka-42%, kuthi kwenziwe insalela engu-A, ebambezela ukukhishwa okukhethiwe kwengcindezi yemartensite futhi okungelula ukwaphuka. Ngokuvamile: Ingxubevange yensimbi iyona esengozini enkulu ekucimeni nasekuqhekekeni. Isibonelo: 100CrM. Lapho usayizi umkhulu фXNUMX, amanzi acimayo ngeke aqhekeke. Lo ngumphumela wosayizi ochazwe ngezansi.

- Umphumela weSayizi we-1.2: Isibonelo: insimbi engu-45: ф1, ф2, ф3 ...... ф10 imiphumela yokuqeda ukuthola ukuthi i-ф6 iyona engacishwa kakhulu. Ngoba ngaphansi kwe-ф6, ingaqedwa ibe yi-martensite. Kodwa-ke, ushintsho oluphelele lwe-ф6 lube yi-martensite lunengcindezi enkulu kunazo zonke, ngakho-ke kulula ukulugqashula.Isizathu esifanayo: ukucindezela okuphelele okuphelele kwensimbi ye-alloy yinkomba yokuqina (ukuqina okuyi-half martensite), okucishe kube ngu-2/3 . Ngakho-ke, okokuqala hlola inkomba yokuqina yensimbi ethile ye-alloy, bese ubheka indawo yokusebenza. Yini ubukhulu obuyingozi kakhulu?

- Umphumela Wokwakheka: ushintsho olungazelelwe esigabeni esiphambanweni, i-R engeli encane kakhulu, iphuma emaceleni abukhali acijile, imisele ejulile emaphethelweni, isibhakela nokumaka imiphetho ebukhali, izimbobo eziyimpumputhe, ukuvuleka okuphansi, ukuvuleka kwamasango, izikhala zemigodi engafanele, nosayizi wokuvula ongafani Njll, indawo enqamulelayo ye-asymmetry, njll.

- 2. Ukukhethwa kwezinga lokushisa langaphambi kokupholisa: Wonke umuntu uyazi ukuthi izinhlamvu zesakhiwo se-martensite ezicinyiwe ngqo ngaphandle kokupholisa ngaphambi kokufaka zincane. Ingakwazi ukuhlangabezana nezidingo zamanje ezijwayelekile zasekhaya ze-metallographic, futhi ukusebenza nakho kuhle, kepha ezingxenyeni ezinkulu nezinkimbinkimbi, ukucima uwoyela akukwazi ukuhlangabezana nezidingo, ukucisha ngamanzi noma okucisha uketshezi olunamanzi kalula kungadala ukuqhekeka. Icima uwoyela, ukuvimbela ukungcoliswa komhlaba kanye nokonga izindleko, kufanele iguqulwe ibe yindawo yokuqeda amanzi esuselwa emanzini ngangokunokwenzeka; I-42CrM emhlanganweni wamaloli asindayo weSteyr okhiqizwe yinkampani eChongqing. Insimbi; Ukukhohlwa komgudu wangaphambili we-axle kanye ne-shaft shaft, abasebenzi abathile bezobuchwepheshe benkampani bashintshe i-unilaterally ukushisa kwangaphambi kokupholisa ≈800 ℃ kuya ku -850 ℃ ukucima okuqondile, okwenze cishe imifantu emikhulu engama-80%. Vele, kwahlaziywa imbangela yokwephuka, futhi okuqukethwe kwe-B kwempahla eluhlaza kufinyelele ku-0.0022% wombiko wokuhlola weChongqing Construction Group, kanye neChangan Group yeSouthwestern Physical and Chemical Inspection Center yoMnyango Wezikhali babika 0.0042%. Qaphela: (1). Izinga lamasosha kazwelonke i-GJB2720-1996, izinga lokuqukethwe kwe-boron nge-boron steel lingu-0.0005 ~ 0.0035%; (2). Izimo zobuchwepheshe zensimbi ezakhiwe ngegolide engu-GB3077-88 boron ejwayelekile yokuqukethwe yensimbi ye-boron ingu-0.0005 ~ 0.0035%. Ukuhlukaniswa kwebhendi ezingeni I ... kungenye yezizathu.Inkinga yokwehlukaniswa okunzima kwe-zonal kwezinto zokusetshenziswa ezifinyelela ezingeni I kuyisici esibalulekile semifantu (ukuhlukaniswa okusindayo kubangela ukwakheka kwamakhemikhali okungalingani nokwelashwa kokushisa okuqeda ukusatshalaliswa kwengcindezi, okulula ukudala ukuqhekeka okucimayo);

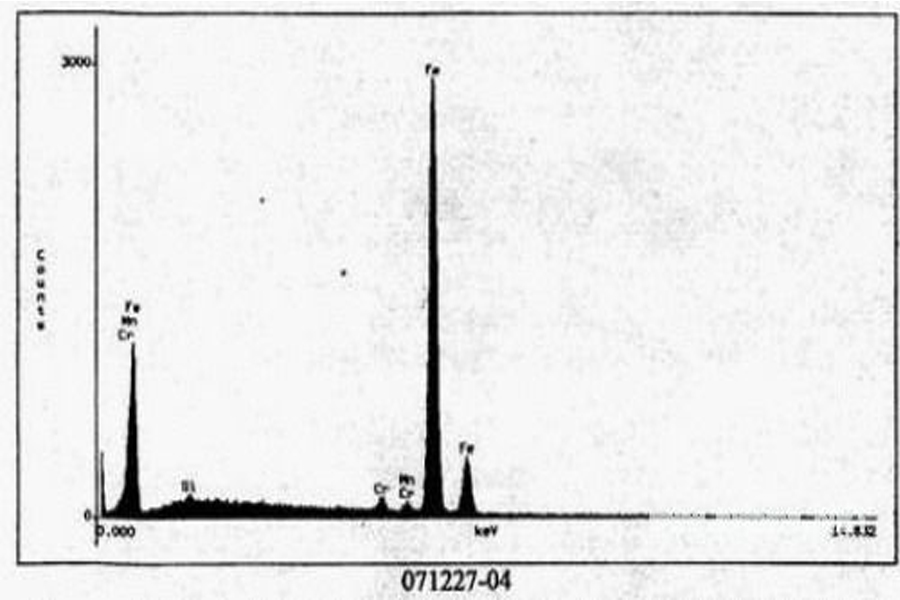

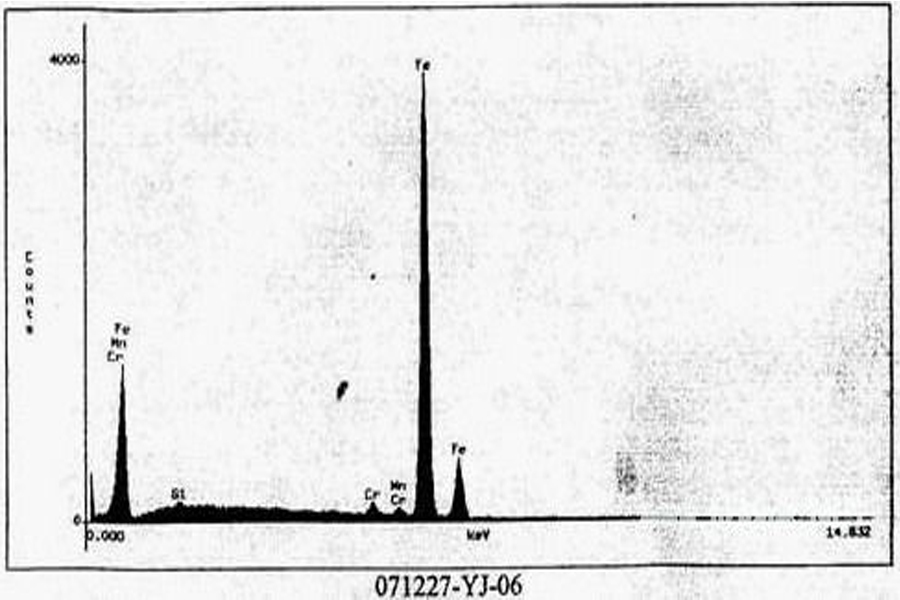

Kusetshenziswa ukuhlaziywa kwe-spectrum yamandla e-X-ray: Imingcele yokusanhlamvu kanye ne-matrix esakhiweni sesampula se-metallographic esilungisiwe kwahlaziywa ngokulingana nangokubala okulinganiselwe nge-Vantage X-ray energy spectrum analyzer. Imiphumela yokuhlaziywa ikhonjisiwe kuMdwebo 1, Umdwebo 2 kanye neThebula 1.

Noma kunjalo, enye insimbi yesithando inokuqukethwe okuphezulu kwe-boron nokuhlukaniswa okukhulu. Ukuhlungwa kwe-PAG kulungiswa ngokwehlisa izinga lokushisa langaphambi kokupholisa, ngakho-ke akukho mifantu eyenzekile.

Ukukhethwa kokushisa okuphambi kokupholisa: Okokuqala, ngokwemiphumela emithathu eshiwo ngenhla, thola ingxenye esengozini kakhulu. Amapharamitha enqubo kufanele alungiswe ngokufanele. Isib:

- (1) "Ngenhla kogongolo oluvala amasondo angaphambili" 42CrM. Sipholisa ngaphambilini ≈800 ℃ ukucima i-PAG, futhi kulula ukulawula i-HRC ku-48-52.

- (2) Ifektri enkulu yesithuthuthu esisebenza eChongqing: yamukela indlela yokoma nolayini ngaphambi kokupholisa ngemuva kokufaka ukuze kuzuzwe ukupholisa kwangaphambili ≈770 ℃ kokucima i-PAG, futhi isebenzisa indlela yokuphakamisa ibhande lemeshi ukushiya indawo engamanzi ngaphandle kokubanda futhi ukuzincisha umoya kancane. Ngemuva kokuvala, ukushisa kwangaphambi kokupholisa kwensimbi engama-45 ne-40Cr kuyafana, kepha ukuhlushwa kwe-PAG kuhlukile.

- (3) Ifektri ye-crankshaft eChongqing: isebenzisa idivayisi engena esithandweni sokushisa esisheshayo ngemuva kokufaka ukuze isipholise ngaphambi kuka -770 ℃ bese icisha isixazululo esenziwe ngamanzi ...

Ukukhethwa kwendlela yokuqeda: kususelwa ocwaningweni lwakamuva oluvela emhlabeni wonke, umphumela obizwa ngokuthi yi-hard shell. Okudingekayo: Izinga lokuqala lokupholisa lokujikeleza kwe-pearlite kufanele lisheshe ukwakha umphumela wegobolondo onzima ngokuxineka okucindezelayo. I-martensite iphenduka kancane, ukuze imifantu kungabi lula ukwenzeka, futhi nochungechunge lwemiphumela yocwaningo njengokusebenzisa ukupholisa okuphrintwa ngohlelo ukulawula isivinini kufanelekile ukwandiswa nokusetshenziswa.

Uketshezi oluqeda i-PAG-ⅢA ne-PAG-ⅢB olwenziwe yithi lususelwa esidingweni esiphuthumayo sohlobo olusha lwejubane lokuguqulwa kwe-pearlite elifana namanzi anosawoti namanzi ane-alkaline, nejubane lokuguqula i-martensite elifana nelawoyela, othatha isikhundla sokucinywa kwamanzi no-oyela ngempela ukupholisa. Icima uketshezi, namandla okulwa nokugqwala agcinwa izinsuku ezingaphezu kwezingu-5. Ukwenza ushintsho lwe-pearlite lufane nosawoti namanzi ane-alkaline, ifilimu ye-bubble eyakhiwe lapho umsebenzi wokucisha ungena kuketshezi kufanele iqhekeke ngokushesha, ukuze izinga lokupholisa lisheshe. Isibonelo, ekugxileni kwe-3%, isilinganiso sokuqala sokupholisa asifani namanzi we-brine ne-alkaline, okungukuthi, izengezo ezihlanganisiwe noma ezihlanganisiwe kumele zengezwe ukuhlangabezana nezidingo ezingenhla. Eqinisweni, ukuhlushwa kwe-PAG-ⅢA kufinyelela kusivinini sokuqala ngokushesha ukwedlula amanzi ne-polyvinyl alcohol, kanti isivinini sesibili sihamba kancane kunesabanye abakhiqizi abangaphansi kokuhlungwa okufanayo kwe-PAG ....... Ekucobeni nasekucimeni imesh iziko lamabhande: I-PAG-ⅢA yathuthukiswa futhi yasetshenziswa ngezindlela eziningi ... Njengamanje, kunamahhafa ebhande anezikhala angaphezu kwama-20 asetshenziswa ezweni lonke; ikakhulukazi i-mesh belt esithandweni se-carburizing ixazulula inkinga yamabala athambile, ubulukhuni obanele, ukusonteka okukhulu ...…. Ikhono lokulwa nokugqwala lingaphezu kwezinsuku ezi-5, futhi ukusetshenziswa kwe-PAG kuncishiswe ngama-20%.

Kunezicelo eziyi-6 ze-PAG-inA e-Chongqing. Ngoba abanye abakhiqizi basebenzisa le modeli, eminye imikhiqizo ekhethekile ixazulula izinkinga okunzima ukuzixazulula neminye imidiya, futhi umphumela uyanda. Ngenxa yemfihlo, ngeke sibethule ngamunye ngamunye. Isetshenziswa kabanzi kumvamisa ophakeme; shaft yemoto emaphakathi evala shaft shaft.

Ukuhlushwa, izinga lokushisa nokunyakaza ketshezi lokucima

Iyunithi esiyisebenzelayo: ukuminyana kwe-PAG koketshezi oluqeda, ngokusho kwebanga lensimbi, ubukhulu bezingxenye, nobukhulu bangaphandle ngokuya ngombono nesipiliyoni sokulungisa ukugxila kwayo ....

Ukushisa koketshezi kulawulwa ku-30-50 ℃, futhi ichibi elikhulu lokujikeleza ngaphandle kwesitshalo lisetshenziselwa ukujikeleza ukushisa kokushisa. Ukugqugquzela nokusakazwa komzimba kuhlangene ngokuphelele.

Ukulawula ukuqina ngemuva kokucima

Ubulukhuni ngemuva kokucinywa kuyinkomba ebaluleke kakhulu yokuvimbela ukuqhekeka: ikakhulukazi lapho kusetshenziswa uketshezi olususa amanzi, kukhuphuka ubulukhuni, imifantu nokwanda kokukhubazeka kulula ukwenzeka. Thatha i-42CrMo. Isibonelo, ugongolo lwama-asi wangaphambili kufanele ulawulwe ku-HRC48 ~ 52.

Ukushisa kufanele kwenziwe ngokushesha ngemuva kokucima

Isikhathi sokuvala nokushisa: ≤ imizuzu engu-30 (Imikhiqizo yamasosha neyomphakathi yeChongqing Construction Group idinga ukuthi ukuvala uketshezi olususelwa emanzini esikhaleni sokubuyisa amanzi kudlule imizuzu engama-30, khona-ke kuzosuswa) Ukukhiqizwa kwezingxenye ezincane kungasetshenziswa ekuqubeni okuqhubekayo imigqa yokukhiqiza.

Isakhiwo se-Metallographic nezakhiwo ngemuva kokufaka nokuqeda

UKWAKHA ukucisha ukushisa, uma kudingeka ukupholisa kwangaphambili, okusanhlamvu ngokuvamile kukhulu. Idatha [1, 2, 3] ngenxa yokuhlolwa komqondo wokuthweswa iziqu kwabafundi ngalowo nyaka, ama-specimens amancane asetshenziswa ngokuvamile awapholi futhi avele aqedwe ngqo, okunikeza isisekelo esibaluleke kakhulu seTheori.

Ngokuqanjwa kwabantu nentuthuko: ubuchwepheshe bamanje bokukhiqiza manje busebenzisa ukupholisa kwangaphambili nokucima, futhi usayizi wokusanhlamvu imvamisa u-2-3, kepha ukusebenza kuhle kakhulu. Thatha ugongolo lwe-ekseli langaphambili oshiwo ngenhla njengesibonelo: Izinhlamvu zincane, futhi idatha ejwayelekile yokukhathala ukuthi ivunyelwe ukugqashuka ngemuva kwezikhathi ezingama-900,000, futhi umjikelezo wokukhathala wangaphambi kokupholisa nokuqeda ngemuva kokuqanjwa kwamukelwa ukuze ufinyelele ku-1.3 izikhathi eziyizigidi ngaphandle kokuphuka.

Kungani ukwakhiwa, ukupholisa kwangaphambili nokucima okusanhlamvu okumaholoholo nokusebenza okuhle kokuhlolwa? Isizathu esikhulu ukuthi imingcele yezinhlamvu ezincane ezinama-engela iyanda nokwanda kokuphakama kwensimbi, okungabonakali ngaphansi kwemicroscope ejwayelekile yensimbi. Ngakho-ke, amayunithi amaningi okwakha nawokucima kufanele "afundise izinkinga" ngeyunithi yangaphambilini yokuhlola. Ngalesi sizathu, kuyindaba ephuthumayo kubasebenzi bezobunjiniyela nabezobuchwepheshe njengamanje abasebenza emazingeni e-metallographic ukusungula ngokushesha ukwakha nokuqeda izindinganiso zensimbi ...

Isiphetho

- Ukusetshenziswa kwendlela yangaphambi kokupholisa imfucuza yokucima ukushisa ngemuva kokufaka umfutho Ukukhethwa kokushisa okuphambi kokupholisa kusekelwe esakhiweni esidingekayo nokusebenza, inqobo nje uma ihlangabezana nezidingo, kuncipha ngcono.

- Ngemuva kokwenza, indlela yokucima ukucima ukushisa okusalayo ikhethwa ngangokunokwenzeka ukusebenzisa isilinganiso sokuqala sokupholisa (isilinganiso se-pearlite soguquko) ukwakha umphumela wegobolondo onzima. Uketshezi lwesibili lokucima olunezinga elipholisa kancane lokupholisa (isilinganiso se-slow martensite transformation).

- Lapho izinto zokusetshenziswa nezinye izinto zilungile, ngabe ukuhlela kwangaphambili ukukhiqiza imifantu kufanele kuqonde imiphumela emithathu emikhulu.

- Ukwakheka kwamakhemikhali nokwehlukaniswa kwezinto zokusetshenziswa kuthambekele ikakhulu ekuqhekekeni. Kunconywa ukuthi lapho kushintshwa inombolo yesithando somlilo, kufanele kwenziwe iqoqo elincane lokukhiqizwa kwesilingo kanye no-100% wokuhlolwa kukazibuthe. Sebenzisa ngokunenzuzo ukuthola izindlela zokuvimbela inqwaba yezibi ukuthi zingenzeki.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Ukulawulwa Kwekhwalithi Ekuqedeni Nge-Waste Heat Ngemuva KOKWAKHA

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off