Ukuxilongwa Okuphelele Nokulawulwa Kwekhwalithi Yezimoto ze-Aluminium Die Castings

Ukuxilongwa okuphelele nokulawulwa kwekhwalithi yezimoto ze-aluminium alloy die castings kuyahlaziywa futhi kucwaningwe, bese kutholakala izingqinamba namaphutha alandelayo. Ezingxenyeni zokusakaza zemoto i-aluminium alloy, isilinda semoto sinesixhumanisi esikhulu, ikakhulukazi isikhundla sekhava yekhanda lesilinda sithatha isikhala esikhulu futhi isakhiwo siyinkimbinkimbi ngokwengeziwe. Ezinye izingxenye zezixhumanisi ezicutshungulwayo nobuso besilinda akumele zibe nezimbobo nezimbobo, okuthinta kakhulu ikhwalithi yokuphonswa kwabantu abafayo. Okwesibili, ngenxa yezinto ezithengwe ngaphandle nezinto zokwakha, ukungasebenzi kahle, njll., Futhi kuletha nemithelela yekhwalithi ezingxenyeni zokuphonsa izimoto. Ukuze uthuthukise ikhwalithi yezingxenye zokuphonsa ezimotweni zezimoto, kubalulekile ukukhulisa izinga lokunakwa kokuphazamisayo okukhulunywe ngenhla, futhi kuthuthukiswe izixhumanisi zokwakhiwa kwenqubo nezingqinamba zemigodi.

1 Ukuxilongwa okuphelele nokulawulwa kwekhwalithi yezimoto ze-aluminium alloy die castings

1.1 Incazelo yokukhubazeka kwesifo

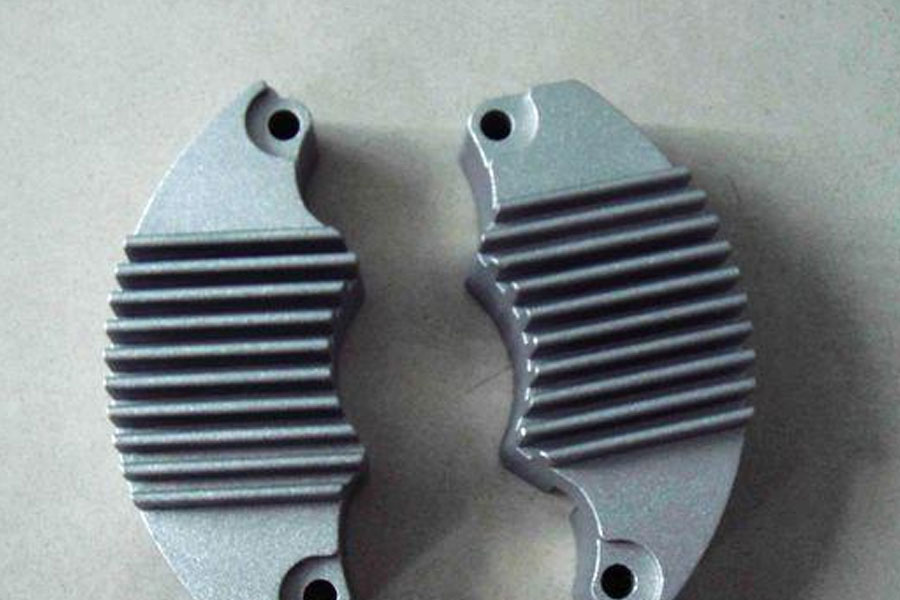

Ezingxenyeni zemoto ze-aluminium alloy die casting zizonke, izixhumanisi zengxenye yemoto eyisilinda zikhulu ngokwengeziwe, ikakhulukazi isikhundla sekhava yekhanda lomzimba wesilinda sithatha isikhala esikhulu futhi isakhiwo siyinkimbinkimbi. Ezinye izingxenye zezixhumanisi ezicutshungulwayo nobuso besilinda abunakubangelwa ukuba khona kwezimbobo nezimbobo. Kulezo zindawo zesilinda ezivumela izimbobo nezimbobo ukuba zibe khona, ukusatshalaliswa kwezimbobo nezimbobo kusakazeka kakhulu, futhi kunezincazelo eziqinile nezidingo zosayizi. Ngokuxhuma kwekhanda lesilinda, isikhundla se-camshaft sihambisana nokutholwa kwephutha. Ngemuva kokucubungula, ubukhulu bomgodi kufanele buhlangabezane nezidingo zokuqapha futhi buhlangabezane namazinga wokuqapha aphansi. Kulolu hlobo lwento, kuletha ubunzima obukhulu ekwakhiweni nasemsebenzini wokukhiqiza, futhi kuthinta kakhulu ukusebenza kahle komklamo nokusebenza kahle kokukhiqiza. Ubuchwepheshe nenqubo yokulingiswa akukwazi ukubheka ngokuphelele izixhumanisi ezahlukahlukene nezikhundla zabo bonke abalingisi, futhi ayihambelani kangako nezixhumanisi zokukhiqiza kanye nezixhumanisi zokwakhiwa kwenqubo. Ezinye izindonga zezibungu zihambisana nezinto ezibushelelezi, futhi ukujula kwezindonga zezibungu kukhulu, kuhambisana nezinkinga zokungcoliswa komoya. Okwesibili, kukhona nokunye ukungalungi okufana nama-pores axhumanisa izimbotshana zomoya nezimbotshana zokuncipha.

1.2 Yenza inqubo yokuxilongwa okuphelele nokuhlaziywa kanye nokuhlaziywa kokufaniswa kwesithombe

Izinto nezinto ezithengwe ngaphandle, ukungasebenzi kahle, inqubo yokwenziwa kokunciphisa, nokusetshenziswa okusebenzayo kwamadivayisi wemishini, njll., Konke kunomthelela omkhulu ekuphepheni kokuphonswa kwezimoto, okuholela ekuguqulweni kwekhwalithi, futhi amacala abucayi azoholela ekusakazweni kwezicucu. Izici ezichazwe ngenhla zonke zinezici zokuhlukahluka, futhi ngenxa yalokho zinomthelela omkhulu kwikhwalithi yabalingisi. Noma yiluphi ushintsho kunoma yisiphi isixhumanisi luzoletha ukwehla kwekhwalithi yokulingiswa. Akulula ukuthola izizathu ezisemqoka zoshintsho kwikhwalithi yokulingisa elethwe yizinto nezinto ezithengwe ngaphandle, ukungasebenzi kahle, inqubo yokunciphisa ukwenziwa, nokusetshenziswa okusebenzayo kwamadivayisi wemishini. Ebhekene nalesi simo, kuyadingeka ukwandisa ukulandelela okuqhubekayo nokuphenya kokuqanjwa kokuqanjwa kanye nenqubo yokuxhumanisa. Okokuqala, kufanele sigcine futhi sihlaziye izinsuku zokukhiqizwa kwabasiki abahlukahlukene, sisungule ukuhlelelwa kwesikhathi okulinganiselwe, simise ikhwalithi yabalingisi njengenhloso eqondisayo, futhi siqaphele futhi siqhubeke nokubona lokhu kuncishiswa okulandelayo. Kubandakanya ukuqapha okuphelele nokulandela ngomkhondo izinto zokusetshenziswa ezingavuthiwe, izinto ezisizayo, izixhumanisi zokuncibilikisa, ukuklama imidwebo nenqubo yokukhiqiza yenqubo, ukuqapha ikhwalithi nezinye izixhumanisi [21. Ukuhlaziywa kokufaniswa kwesithombe, ukukhubazeka okuyinhloko kwe-castings kubonakala egumbini lamagiye. Izici ezinkulu ezinomthelela kulokhu kukhubazeka ithonya lokushintsha kwegesi nokuncipha, okuletha ukukhubazeka okukhulu emigodini. Okokuphonsa, igesi ekhiqizwayo itholakala kakhulu ngaphakathi kokuncibilika negesi etholakala kumenzeli wokukhishwa. Igesi engalindelekile evela kunqubo yokusakaza. Irhasi ekhiqizwa kusixazululo ihlobene kakhulu nohlobo nezakhiwo zento yokuphonsa, futhi ihlobene kakhulu nobuchwepheshe bokuncibilikisa bokuphonsa.

2 Izindlela zokusebenzisa nokwenza ngcono

2.1 Ukuphathwa nokulingiswa kwesithombe

Okokuphonsa, igesi ekhiqizwayo itholakala kakhulu ngaphakathi kokuncibilika negesi etholakala kumenzeli wokukhishwa. Igesi engalindelekile evela kunqubo yokusakaza. Irhasi eyenziwe ngesisombululo ihlobene kakhulu nohlobo nezakhiwo zento yokuphonsa, futhi ihlobene kakhulu nobuchwepheshe boncibilikisi bokuphonsa [41. Irhasi ekhiqizwa yi-ejenti ekhishwayo ihlobene eduze nokukhethwa kwesixhumanisi senqubo yokulingisa kanye nemodeli yesixhumanisi sokucindezela. Ngenxa yalokhu kusilela ekwakhiweni kokuphosa, ukusetshenziswa kokulungiswa ekubunjweni kobuchwepheshe bokuncibilikisa nokulungiswa kobuchwepheshe bokufafaza kungasetshenziselwa ukuthuthukisa nokwenza ngcono. Kunobudlelwano obuseduze phakathi kokungalungi kwegesi okulethwe ukusakazwa kunqubo yokucindezela nefomu lokusebenza kwensimbi engamanzi. Izithiyo zokunwetshwa nokusikwa kokuphonsa zihlobene kakhulu nethempelesha nokuqina kokuphonsa. Ngemuva kokucacisa uhlelo lokuklanywa lokusakaza, unganweba ukwakheka nokulungiswa komgijimi, usethe umugqa wokukhipha nemishini yokugcwala, usethe izinga lokushisa lesikhunta sokusakaza, bese usetha i-coefficient yabezindaba. Lapho kuklanywa futhi kulungiswa ama-coefficients kanye nemingcele yezingxenye zokucindezelwa, kufanele kucatshangwe ifomu lokugeleza kwensimbi ewuketshezi emzimbeni wokuphonsa, kufanele kuncishiswe inani le-liquid solid, inani le-shrinkage cavity, futhi umkhawulo kufanele kuncishisiwe. Ngaphezu kwalokho, ukulingisa isithombe kungasetshenziselwa ukuhlaziywa kulesi sixhumanisi. Indlela yokulingisa isithombe iyindlela esemqoka yokuhlaziya umthetho wabalingisi futhi uqonde ukwakheka kwayo njengamanje, futhi unikeze isisekelo sesayensi ngesizathu samaphutha we-castings. Shintsha imodeli yesikhathi bese uyethula ngendlela engunxantathu, bese unikeza uhlelo lokulingisa lobuchwepheshe bayo nenqubo, bese uhlukanisa ifomethi yefayela le-STL. Ngemuva kokuhlonza, sebenzisa isoftware kaMsgmasoft ukuqala ukuhlukaniswa kwenethiwekhi. Inike izindawo eziyizinkulungwane eziyikhulu zenethiwekhi ezinamasistimu okusakaza nokuthulula. Ngemuva kocwaningo olunzulu nokuhlaziywa kwesoftware yakwaMsg-masoft, kanye nokusebenza kwayo okusebenzayo, kutholakala ukuthi ukusetshenziswa kwesoftware yakwaMsgmasoft kunokusebenziseka okusebenzayo, okungaguqula futhi kuvuselele isikhunta senqubo yokuphonsa, futhi kubeke isisekelo senkolelo yokwakha ukusakaza isikhunta nezinqubo. .

2.2 Khulisa ukuphathwa kwamagesi ancibilikile

Lapho igiya lesikhathi lisebenza emsebenzini wokuncibilikisa, ukukhokhiswa kwegumbi lamagiya kufaka phakathi i-50% yediphozi ye-aluminium kanye ne-39% yesithando somlilo. Ngoba umswakama nezinye izinto zizoqhubeka nokwanda ngesikhathi sokusebenza kabusha kwesithando somlilo, esizokwandisa okuqukethwe kwegesi, bese lokho okuqukethwe kufanele kuphathwe futhi kulawulwe ngesikhathi ukunciphisa okokuncibilika kwento futhi kuyengezwe futhi kususwe ngaphambi kwento ufakwa esithandweni somlilo. Ukuze kutholakale igesi noketshezi, ukuqapha nokubhekwa kokuqukethwe kwegesi kwandisiwe. Ngasikhathi sinye, inqubo kufanele iguqulwe futhi yenziwe ngcono, ubuchwepheshe bokujova kufanele benziwe ngcono, futhi ulayini womjovo kufanele ulungiswe ukuze kuqinisekiswe ukusebenza kahle kwe-degassing futhi kuthuthukiswe ukusebenza kahle kwe-degassing. Qinisekisa ukuthi okuqukethwe igesi amagremu ayikhulu we-aluminium impahla icishe ibe ngu-0.2ml.

2_3 Khulisa ukuhleleka kwamapharamitha wenqubo futhi ulungiselele izimo zokulingisa

Ngokuphathelene nokuhleleka kwamapharamitha enqubo, okokuqala, ngokusho kwemiphumela yokuqapha, izinqubo zenqubo kanye nobudlelwano bekhwalithi obungathinta ukusakazwa kufanele kuhlolisiswe futhi kufundwe, futhi ikhwalithi yabalingisi ingakhuphuka ngaphandle kokushintsha izimo zokulingisa. Ukuze kuqinisekiswe ubungqingili bemingcele yenqubo, inqubo yokujova ingasetshenziselwa ukukhulisa ukubumbana kokuphonswa, ingcindezi yegesi yokugcwalisa kule nqubo, njll., Ukwandisa ukuqonda kwenqubo yokusakaza. Okwesibili, kubalulekile ukukhulisa izinga lokunakwa kwezimo zokuphonsa, ukuqinisekisa ukusebenza kwenqubo, ukukhulisa izinga lokunaka emigodini, ukulungisa usayizi womgijimi, bese ufaka ipayipi lokukhipha lapho kuhlangana khona amanzi. Emisebenzini yangempela yokukhiqiza nokuklama yabalingisi, kuyadingeka ukukhulisa ukubonwa kwemigodi yokusakaza ukubona ukuthi kukhona yini ukukhubazeka nokushiyeka, nokubona ubukhulu bayo nokusabalala kobubanzi. Lokhu kubukwa kokuphonswa ikakhulukazi ukuqapha ukusebenza kwangempela kwabaphosayo ukubona ukuthi ngabe kumele kusulwe futhi kuvuselelwe. Bamba izixhumanisi ezinesici sokuphonsa futhi uphinde wenze kabusha izingxenye ezingalungile ukuqinisekisa ukuthi ziyahlangabezana nezidingo zokuphonsa okujwayelekile futhi zikhulise ukusebenza kwazo okusebenzayo. Ngokusakazwa okuqediwe, naka ukubonwa kodonga lomgodi ukubona ukuthi udonga lomgodi lumangele yini. Odongeni olunemigodi eqinile, ikakhulukazi ikhombisa ubunjalo bamagatsha ezihlahla. Uma usebenzisa i-microscope ukubheka nokuhlaziya, phansi kungatholakala Ukuqhubeka kungcono, kuhambisana nokwehla kanye nokuxegisa izibungu.

Amazwi okuphetha ayi-3

Ukuphatha ukukhubazeka kwekhwalithi yokuphonswa kwezimoto ze-aluminium alloy die, kufanele siqale sikhulise ukuphathwa kwegesi elichithakele, siguqule futhi sisebenzise inqubo, sandise ukucabanga kwamapharamitha enqubo, ukwandise izimo zokuphonsa, ukuqapha nokugcina ukusakazwa ukubona ukuthi zidinga ukuba yi-Scrap futhi zivuselele. Phinda usebenzise izingxenye ezingaphelele ukuqinisekisa ukuthi ziyahlangabezana nezidingo zokuphosa okujwayelekile. Ukufanekisa isithombe nokuhlaziywa kwamaphutha amakhulu wezindawo zesikhathi sokusakaza, ungasebenzisa ukulungiswa kobuchwepheshe bokusakaza ukuncibilikisa nokulungiswa kobuchwepheshe bokufafaza.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ukuxilongwa Okuphelele Nokulawulwa Kwekhwalithi Yezimoto ze-Aluminium Die Castings

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off