Izinqubo Eziyishumi Zokulingisa Ekusungulweni

Ukuhlukaniswa Kwesigaba

- Ukukhishwa kwe-Sand

- Investment asakazwe

- die thusi

- Ingcindezi okuphansi ekubunjweni

- Ukusakaza kwe-Centrifugal

- I-Gravity Die Casting

- Umshini ekubunjweni

- Cindezela ukusakaza

- Ilahlekile i-foam ekubunjweni

- Ukusakaza okuqhubekayo

1.Sand Ekubunjweni

Ukulingiswa kwesihlabathi: Indlela yokulingisa yokukhiqiza ukusakazwa esihlabathini. Insimbi, i-iron nokuningi okungafaki i-alloy castings kungatholakala ngezindlela zokuphonsa isihlabathi.

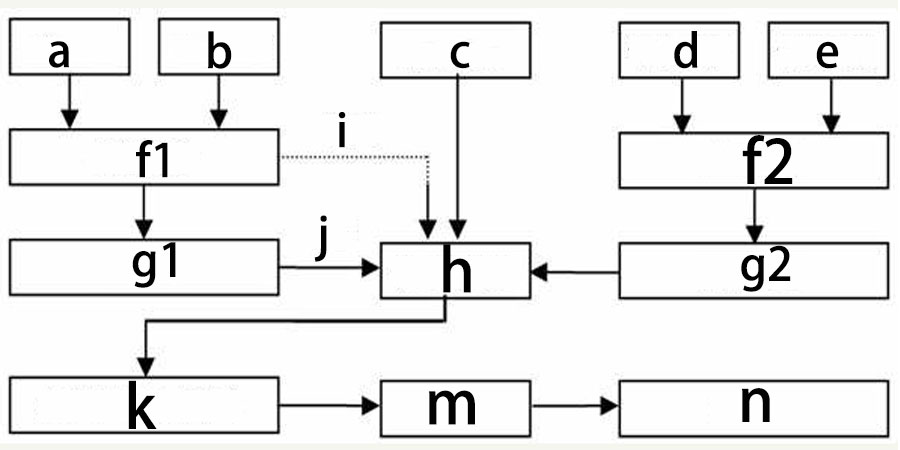

Ukugeleza kwenqubo:

- a: Ukukhiqiza Isikhunta Sample

- b: Ukulungiselela Isihlabathi Sokubumba

- c: insimbi encibilikisiwe

- d: Ukukhiqiza Isihlabathi Esiyinhloko

- e: Ukukhiqiza Ibhokisi Eliyinhloko

- i: Uhlobo olumanzi

- j: Uhlobo olomile

- f1: Isihlabathi Sokukhiqiza

- g1: Ukomisa isihlabathi

- f2: Ukukhiqiza iSand Core

- g2: Ukomisa iSand Core

- h: Isikhunta Sakhiwe Njengesikhunta

- k: Thatha ukukhishwa kwesikhunta

- m: Hlanza

- n: Izingxenye Zokuhlola

Izici zobuchwepheshe:

- Kufanelekile ukwenza izikhala ezinobujamo obuyinkimbinkimbi, ikakhulukazi ngezikhala eziyinkimbinkimbi zangaphakathi;

- Ukuzivumelanisa nezimo okubanzi nezindleko eziphansi;

- Kwezinye izinto ezine-plasticity empofu, enjenge-cast iron, ukusakazwa kwesihlabathi ukuphela kwendlela yokwakha izingxenye zayo noma izikhala.

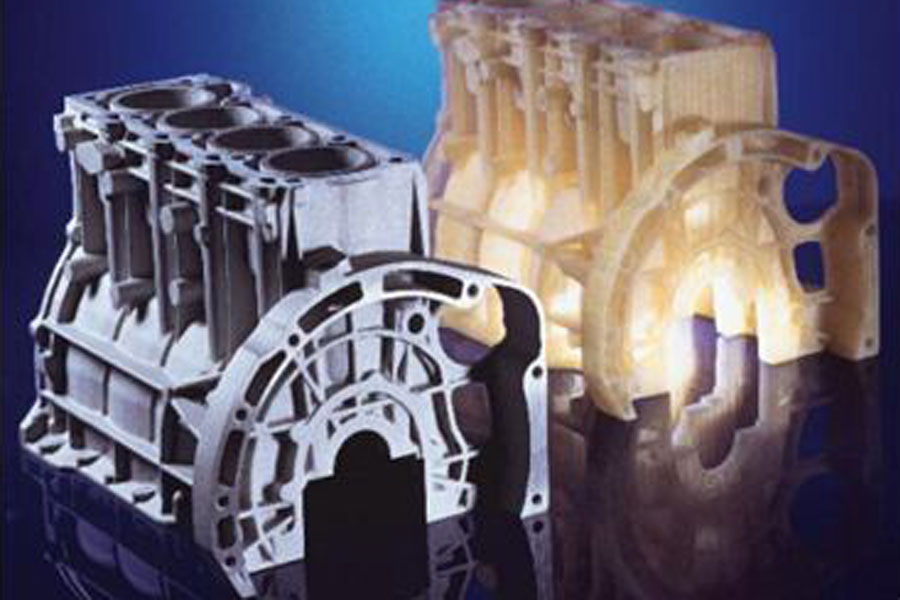

- Isicelo: imoto injini isilinda block, isilinda ikhanda, crankshaft nezinye castings

2.Investment Ukulingisa

Ukulingiswa kokutshalwa kwezimali: imvamisa kubhekiswa ekwenzeni iphethini eyenziwe ngezinto ezi-fusible, ukumboza ingaphezulu lephethini ngezingqimba eziningana zezinto eziphikisayo zokwakha igobolondo, bese kuncibilika iphethini egobolondweni ukuthola isikhunta ngaphandle kwendawo yokuhlukanisa. Ngemuva kokushisa okushisa okuphezulu Ngemuva kwalokho, ingagcwaliswa ngesihlabathi bese ithelwa. Imvamisa ibizwa ngokuthi "ukulahlwa kwe-wax".

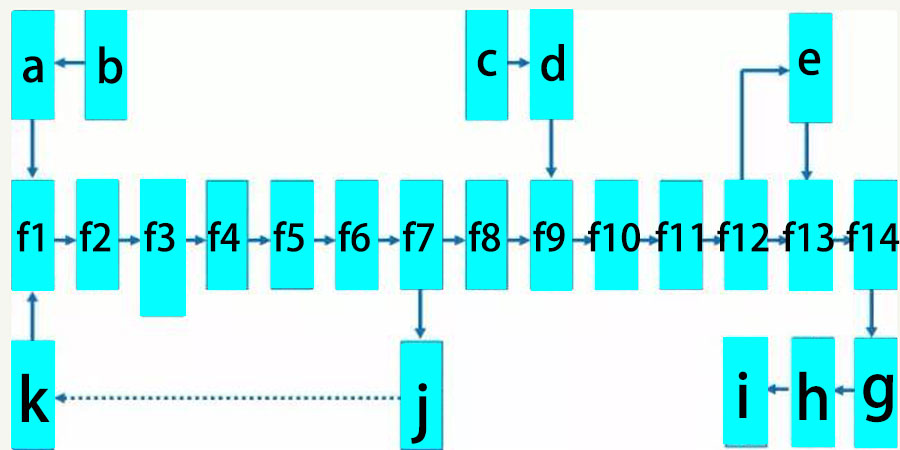

- a: Isikhunta Ukwenza

- b: Umdwebo Wokuphonsa

- c: Ukuncibilikisa

- d: Ukuhlaziywa Kwento

- e: Ukukhetha Passivation

- f1: Inaliti ye-Wax

- f2: Imodeli ye-Wax

- f3: Ukushisela i-Riser Pouring

- f4: Upende Olenga

- f5: Isihlabathi Esikhululekile

- f6: Ukuqinisa

- f7: Ukuxoshwa

- f8: Isikhunta Sokubhaka Igobolondo

- f9: Ukusakaza

- f10: Igobolondo

- f11: Hlanza

- f12: Ukwelashwa Kokushisa

- f13: Ukuhlolwa

- f14: Indawo yokugcina izimpahla

- g: Ukwenza Machining kwe-Cnc

- h: Ukuhlolwa Kwezingxenye

- i: Ukugcina izindlu

- j: I-Wax Esetshenzisiwe

- k: Ingcina

Izici zokucubungula

inzuzo:

- Ukunemba okuphezulu kwe-dimensional nokunemba kwejometri;

- Ubungqimba obuphezulu bendawo;

- Ingaphonsa ukusakaza okuyinkimbinkimbi, futhi ingxubevange yabalingisi ayikhawulelwe.

Okumbi: izinqubo eziyinkimbinkimbi nezindleko eziphezulu

Isicelo: Kufanele ukukhiqizwa kwezingxenye ezincane ezinomumo obuyinkimbinkimbi, izidingo zokunemba okuphezulu, noma ezinye izinkinga zokucubungula, njengezinsimbi zenjini ye-turbine.

3.Die Ukulingisa

Die ekubunjweni: Isebenzisa ingcindezi ephezulu ukucindezela insimbi encibilikisiwe yenze isikhunta sensimbi ngokunemba ngesivinini esikhulu. Insimbi encibilikisiwe iyapholiswa futhi iqiniswe ngaphansi kwengcindezi yokwenza ukusakaza.

Inqubo Yokulingisa:

- Hlanza isikhunta

- Sula upende

- Ukubamba

- Kuyathulula

- ukuqinisa

- Isibungu

- Khipha

- Khipha ukusakaza

Izici zokucubungula

inzuzo:

- Okuwuketshezi kwensimbi kuthwala umfutho ophakeme ngesikhathi sokuphonsa, futhi izinga lokugeleza liyashesha

- Ikhwalithi yomkhiqizo muhle, usayizi uzinzile, futhi ukushintshana kuhle;

- Ukusebenza kahle kokukhiqiza kuphezulu, futhi isikhunta sokufa sisetshenziswa kaningi;

- Ifanele ukukhiqizwa ngobuningi ngezinzuzo ezinhle zezomnotho.

Okumbi:

- Ama-castings athambekele kuma-pores amancane kanye ne-shrinkage porosity.

- I-Die castings ine-plasticity ephansi futhi ayifanele ukusebenza ngaphansi komthwalo womthelela nokudlidliza;

- Lapho iphuzu lokuncibilika kwe-alloy ephezulu iphonswa ngokufa, impilo yesikhunta iphansi, ethinta ukunwetshwa kokukhiqizwa kokufa.

Isicelo: Ama-die castings aqale asetshenziswa embonini yezimoto nasembonini yezinsimbi, futhi ngokuhamba kwesikhathi anwetshelwa izimboni ezahlukahlukene, njengemishini yezolimo, imboni yamathuluzi omshini, umkhakha we-elekthronikhi, umkhakha wezokuvikela, ikhompyutha, imishini yezokwelapha, amawashi, amakhamera, kanye nehadiwe yansuku zonke , njll.

4.Low Pressure Ekubunjweni

Ukuphonsa ingcindezi okuphansi: kubhekisa kunqubo yokugcwalisa isikhunta ngensimbi engamanzi ngaphansi kwengcindezi ephansi (0.02 ~ 0.06MPa) nokugqamisa ngaphansi kwengcindezi yokwakha ukusakaza.

Izici zobuchwepheshe:

- Ingcindezi nesivinini ngesikhathi sokuthululela kungalungiswa, ngakho-ke kungasetshenziswa ekubunjweni okwehlukahlukene (okufana nesikhunta sensimbi, isikhunta sesihlabathi, njll.), Ukusakaza ama-alloys ahlukahlukene nokusakazwa kosayizi abahlukahlukene;

- Ukuzaliswa kohlobo lomjovo ongezansi kwamukelwa, ukugcwaliswa kwensimbi encibilikisiwe kuzinzile futhi akukho mkhuba we-splash, ongagwema ukubanjwa kwegesi nokuguguleka kodonga nomgogodla, okuthuthukisa izinga leziqu lokuphonsa;

- Ukulingiswa kugcizelela ngaphansi kwengcindezi, isakhiwo sokukhipha siminyene, uhlaka lucacile, ubuso bushelelezi, futhi izakhiwo zemishini ziphakeme, okulusizo ikakhulukazi ekusakazweni kwezingxenye ezinkulu nezincanyana ezibiyelwe;

- I-feeder riser ishiyiwe, futhi inani lokusetshenziswa kwensimbi lenyuswa laya ku-90-98%;

- Amandla aphansi okusebenza, izimo zokusebenza ezinhle, imishini elula, okulula ukuyibona imishini nokuzenzekelayo.

Isicelo: Ikakhulukazi imikhiqizo yendabuko (isilinda ikhanda, isondo ihabhu, isilinda ifreyimu, njll).

5.Centrifugal Ekubunjweni

Ukusakazwa kwe-Centrifugal: kuyindlela yokusakaza lapho insimbi encibilikisiwe ithelwa kusikhunta esijikelezayo, bese isikhunta sigcwaliswa ngaphansi kwesenzo samandla we-centrifugal ukuqinisa nokubumba.

Izici zokucubungula

inzuzo:

- Cishe akukho ukusetshenziswa kwensimbi ohlelweni lokufaka amasango kanye nohlelo lokukhuphuka, okuthuthukisa izinga lokukhiqiza lenqubo;

- Akudingekile ukusebenzisa umnyombo lapho kukhiqizwa ukusakazwa okungenalutho, ngakho-ke ikhono lokugcwalisa insimbi lingathuthukiswa kakhulu lapho kukhiqizwa ukusakazwa okuude kwe-tubular;

- Ama-castings anokuqina okuphezulu, ukukhubazeka okumbalwa njengama-pores kanye ne-slag inclusions, nezindawo eziphakeme zemishini;

- Kuyinto elula ukukhiqiza umphongolo nomkhono wokuhlanganiswa kwensimbi.

Okumbi:

- Kunemikhawulo ethile lapho isetshenziswa ekukhiqizeni ukusakazwa okumise okhethekile;

- Ububanzi bomgodi wangaphakathi wokuphonsa awunembile, ubuso bomgodi wangaphakathi buqhathaniswa, ikhwalithi ayibi, futhi isabelo semishini sikhulu;

- Ama-Castings athambekele ekuhlukanisweni kwamandla adonsela phansi athile.

Isicelo:

Ukusakaza kwe-Centrifugal kwaqala ukusetshenziswa ekukhiqizeni amapayipi okusakaza. Ekhaya nakwamanye amazwe, ukukhishwa kwe-centrifugal kwakusetshenziswa ekusetshenzisweni kwensimbi, izimayini, ezokuthutha, ukuchelela kanye nemishini yokuhambisa amanzi, ezokundiza, ezokuvikela izwe, izimoto nezinye izimboni ukukhiqiza insimbi, i-iron ne-non-ferrous carbon alloy castings. Phakathi kwabo, ukukhiqizwa kokuphonsa okufana namapayipi wensimbi we-centrifugal, imishini yenjini yomlilo yangaphakathi yomlilo nemikhono ye-shaft yiyona evame kakhulu.

6.Gravity Die Ukulingisa

I-Gravity Die Casting: isho indlela yokubumba lapho insimbi engamanzi igcwele isikhunta sensimbi ngaphansi kwesenzo samandla adonsela phansi futhi selehlile futhi yaqina kusikhunta ukuthola ukusakaza.

Izici zokucubungula

inzuzo:

- Ukuqhutshwa okushisayo namandla okushisa kwesikhunta sensimbi makhulu, izinga lokupholisa liyashesha, isakhiwo sokukhipha siminyene, futhi izakhiwo zemishini zicishe zibe yi-15% ngaphezulu kunaleso sokuphonsa isihlabathi.

- Ama-castings anokunemba okuphezulu ngokweqile kanye namanani aphansi wokuqina angatholakala, futhi ukuzinza kwekhwalithi kuhle.

- Ngenxa yokuthi ama-cores esihlabathi awasetshenziswa futhi akavamile ukusetshenziswa, imvelo iyathuthukiswa, uthuli namagesi ayingozi ancishisiwe, namandla ezisebenzi anciphile.

Okumbi:

- Isikhunta sensimbi uqobo asinakho ukungena emoyeni, futhi kufanele kuthathwe izinyathelo ezithile ukuthola umoya osemgodini kanye negesi eyenziwe yingqimba yesihlabathi;

- Isikhunta sensimbi asinakho ukuhlehla, futhi ukusakaza kuthanda ukuqhekeka lapho kuqiniswa;

- Umjikelezo wensimbi yokwenza isikhunta mude futhi izindleko ziphakeme. Ngakho-ke, kuphela ekukhiqizweni okukhulu, ingakhombisa imiphumela emihle yezomnotho.

Isicelo: Metal isikhunta thusi is hhayi kuphela efanelekayo ukukhiqizwa ngobuningi non-ayoni ingxubevange Castings ezifana aluminium Alloys futhi magnesium Alloys nge bobunjwa eziyinkimbinkimbi, kodwa futhi efanelekayo ukukhiqizwa yensimbi nensimbi yensimbi castings futhi ingots.

7.Vacuum Die Ukulingisa

Umshini thusi: An advanced die-thusi inqubo ukuthi aqede noma kakhulu kunciphisa izimbotshana futhi amagesi ziyoncibilika izingxenye die-ekubunjweni ngokususa igesi kusukela die-ekubunjweni isikhunta umgodi ngesikhathi inqubo die-thusi, ngaleyo ndlela ngcono izakhiwo mechanical kanye ebusweni ikhwalithi yezingxenye zokufa.

Izici zokucubungula

inzuzo:

- Qeda noma wehlise izimbotshana ngaphakathi kokuphonswa kokufa, uthuthukise izakhiwo zemishini nekhwalithi ebusweni bokuphonsa okufa, futhi uthuthukise ukusebenza kwesilayidi;

- Ukwehlisa ingcindezi yangemuva yomgodi, ingcindezi ethile ephansi kanye nama-alloys anezinto eziphansi zokuphonsa kungasetshenziswa, futhi kungenzeka ukuthi ufe-cast castings ezinkulu ngomshini omncane;

- Izimo zokugcwaliswa ziyathuthukiswa, futhi ukusakazwa okuncane kungasakazwa;

Okumbi:

- Isakhiwo sokubekwa kwesikhunta siyinkimbinkimbi, futhi kunzima ukukhiqiza nokufaka, ngakho izindleko ziphakeme;

- Uma indlela ye-vacuum die-casting ilawulwa ngendlela engafanele, umphumela awubalulekanga kakhulu.

8.Ukucindezela i-Die Casting

Cindezela ukukhipha: kuyindlela yokuqinisa, ukugeleza nokwakha insimbi eqinile noma eqinile ngaphansi kwengcindezi ephezulu ukuthola izingxenye noma izikhala ngqo. Inezinzuzo zokusetshenziswa okuphezulu kwensimbi engamanzi, inqubo eyenziwe lula nekhwalithi ezinzile. It is a energy-saving metal ukwakha ubuchwepheshe obunamandla okusebenzisa amathuba.

- Direct cindezela thusi: fafaza upende, cast ingxubevange, isikhunta close, pressurize, ubambe ingcindezi, ukukhululwa ingcindezi, uqhekeko isikhunta, demold blank, kabusha;

- Cindezela ngokungaqondile ukusakaza: ukumboza isifutho, ukubopha isikhunta, ukondla, ukugcwalisa, ukucindezela, ukubamba ingcindezi, ukukhululeka kwengcindezi, ukuhlukaniswa kwesikhunta, ukugoqa okungenalutho, ukusetha kabusha.

Izici zobuchwepheshe:

- Ingasusa ukukhubazeka kwangaphakathi okufana nama-pores, izimbobo zokuncipha kanye ne-shrinkage porosity;

- Ubukhulu besimo esiphansi nokunemba okuphezulu;

- Kungavimbela ukwenzeka kokuphonsa imifantu;

- Kulula ukubona imishini nokuzenzekelayo.

Isicelo: Ingasetshenziselwa ukukhiqiza izinhlobo ezahlukahlukene zama-alloys, njenge-aluminium alloy, zinc alloy, copper alloy, ductile iron, njll.

9.Lost Foam Ekubunjweni

Ukulahlwa kwe-foam elahlekile (okwaziwa nangokuthi isikhunta esigcwele): Ukuhlanganisa upharafini we-wax noma amamodeli we-foam anosayizi ofanayo nomumo kuma-castings akha amaqoqo. Ngemuva kokuxubha kanye nokomisa okubhangayo okukhanyayo, bangcwatshwa esihlabathini esomile se-quartz sokwenza imodeli yokudlidliza. Luhlobo olusha lwendlela yokuphonsa lapho isikhunta senziwe vaporized ngokuthululela ngaphansi kwengcindezi, insimbi ketshezi ithatha isikhundla sesikhunta, futhi ukwakheka kwakheka ngemuva kokuqina nokupholisa.

Inqubo flow: pre-amagwebu → amagwebu → ekushoniseni enamathela → omiswe → ukumodeliswa → ethela → awe phansi → yokuhlanza

Izici zobuchwepheshe:

- Ukulingiswa kunokunemba okuphezulu futhi akukho mhlabathi wesihlabathi, okunciphisa isikhathi sokucubungula;

- Ayikho indawo yokuvaleka, idizayini eguquguqukayo nezinga eliphezulu lenkululeko;

- Ukukhiqizwa okuhlanzekile, akukho ukungcola;

- Nciphisa izindleko zokutshala imali nezokukhiqiza.

Ukufaka isicelo Efana grey cast iron engine box, indololwana yensimbi ephezulu ye-manganese, njll.

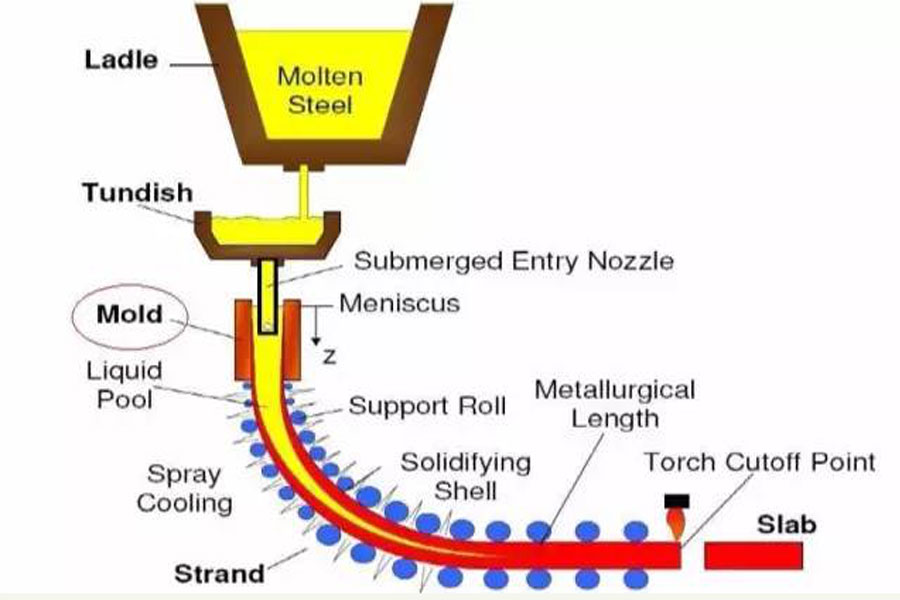

10.Casting Okuqhubekayo

Ukulingiswa okuqhubekayo: Kuyindlela ephakeme yokulingisa. Umgomo wawo ngukuqhubeka uthele insimbi encibilikisiwe esikhunjeni esikhethekile sensimbi esibizwa ngokuthi isikhunta. Ukuqina (okuqhekekile) ukusakazwa kususwa ngokuqhubekayo kusikhunta. Khipha umkhawulo owodwa, ungathola noma yikuphi ubude noma ubude obuthile bokuphonsa.

Inqubo Yokulingisa Eqhubekayo:

Izici zobuchwepheshe:

- Ngenxa yokupholisa okusheshayo kwensimbi, i-crystal iminyene, isakhiwo siyalingana, futhi izakhiwo zemishini zingcono;

- Gcina insimbi futhi wandise isivuno;

- Inqubo yenziwa lula, futhi ukumodeliswa nezinye izinqubo kuyasuswa, ngaleyo ndlela kuncishiswe ukuqina kwabasebenzi; indawo edingekayo yokukhiqiza nayo incishiswe kakhulu;

- Ukukhiqizwa okuqhubekayo kokukhipha kulula ukubona imishini nokuzenzekelayo, futhi kuthuthukise ukusebenza kahle kokukhiqiza.

Isicelo: Ukulingiswa okuqhubekayo kungasetshenziswa ukwenza insimbi, insimbi, ama-alloys ethusi, ama-alloys e-aluminium, ama-alloys we-magnesium namanye ama-castings amade anamajamo we-cross-sectional, njengama-ingots, ama-slabs, ama-billets, amashubhu, njll.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Izinqubo Eziyishumi Zokulingisa Ekusungulweni

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off