Izinhlobo Ezintathu Zokuncibilikisa Namaqhinga Okuthela Ama-Ductile Iron

Isihlabathi se-Furan resin ngokuvamile sisetshenziswa njengezinto zokubumba zezinsimbi ezinkulu ezenziwa e-China. Ikhiqizwa ngocezu olulodwa, ngesisindo esisindayo nesakhiwo esiyinkimbinkimbi. Inezidingo eziphezulu kwikhwalithi nokusebenza kokuphonswa. Okunye ukukhubazeka okusakazayo, ikakhulukazi ukukhubazeka kokuncipha, kuvame ukuvela kunqubo yokuncibilikisa. Izodala ukuthi ukusakazwa kusulwe futhi kudale ukulahleka okukhulu kwezomnotho, ikakhulukazi okokusebenza kwe-QT400-18AR, enamandla amakhulu, nokunwebeka okuphezulu, nezidingo zenani lomthelela.

Ngenkathi siqinisekisa ukwenziwa kwemishini yezingxenye ezinzima futhi ezinkulu, akulula ukugwema ukukhubazeka kwe-graphite ezintantayo nezincipha. Ngokuklanywa kokuhlolwa kwesampula, imishini yokuhlaziya ka-Elkem isetshenziselwe ukutadisha imiphumela yokwakheka kwamakhemikhali nokuthela izinga lokushisa ku-graphite entantayo, ukuncipha kanye nokunye ukukhubazeka kwesampula eliqinile elinosayizi wodonga luka-180mm. Ngemuva kwalokho isetshenziselwa ukukhiqizwa kwezingxenye ezibiyelwe zensimbi e-ductile ukuthola ama-castings asezingeni elifanele.

Izinsiza kusebenza zisetshenziselwa ukuzisebenzisa ngobumsulwa ingulube yensimbi, okusaluketshezi oluphansi lwe-manganese, i-high-magnesium spheroidizing agent, 75 # FeSi inoculant; Elkem low-magnesium spheroidizing agent, inoculant; Amathani ayi-1.5 wesithando sokuncibilika kwemvamisa emaphakathi, isikhwama se-spheroidizing esingu-500kg, isikhunta esingu-500kg. Isihlaziyi se-Elkem EPIC esishisayo, i-carbon nesalfure analyzer, i-spectrometer. Ubungako besampula eliqinile imodeli yokhuni yi-600mm × 400mm × 180mm, futhi inqubo ikhiqizwa ngecala. Ubukhulu bodonga obungu-180mm busetshenziselwa ukumboza imikhiqizo yensimbi emikhulu nene-spheroidal graphite cast iron ekhiqizwa yinkampani. Imele impela. Ifakelwe uhlelo lwe-riser ne-sprue system futhi isebenzisa ukuthululela phansi ngesisindo esithululelwayo esingu-500kg.

Uhlelo lokuncibilikisa nokuthulula lwenzelwe ukusebenzisa isithando sokuncibilikisa esiphakathi nendawo esingu-1.5t ukuncibilikisa i-1.5t iron encibilikisiwe, i-500kg isikhathi ngasinye i-spheroidizing inoculation, nokuthela ibhokisi eli-1 lezingcezu zesampula zokuhlola. Inani lamabhokisi ama-3 wezingcezu zokuhlola athelwa esithandweni esingu-1. Izinhlelo ezahlukahlukene zokuncibilikisa nezithela zenzelwe kanje:

Isilinganiso sokuqala sokushaja kwesikimu:

I-85% yensimbi yengulube, i-15% ye-low-manganese steel scrap; ukulawula ukwakheka kwamakhemikhali: sebenzisa uhlelo lokwelashwa kwe-spheroidizing inoculation: okokuqala, i-500kg yensimbi ihanjiswa ku-tundish, futhi i-1.3-1.5% ephezulu-magnesium spheroidizing ejenti, i-0.3-0.4% inoculant ne-inoculant ishunyekwe esikhwameni se-spheroidizing 0.8% esimboza i-ejenti, vula isikhwama se-spheroidization. Ngemuva kokuthi inqubo ye-spheroidization isiqediwe, indawo engaphakathi yesikhwama ithululelwa ku-inoculant yokugeleza futhi ishaywe ngokuphelele, bese isampuli lihlaziywa lihlolwe ngethuluzi le-EPIC. 1.2% Elkem spheroidizing ejenti, 0.8-1.0% ejenti ejenti, futhi 0.4% ingilazi cullet is esishunyekiwe esikhwameni spheroidizing, nensimbi akhishelwa ngqo esikhwameni spheroidizing, futhi 0.5% Elkem isitofu afakwa ngasikhathi sinye. Ngemuva kokuphothulwa kwe-spheroidization, i-Elkem yokulandelela i-inoculant efafazwe ebusweni izosampulwa futhi ihlaziywe kusetshenziswa insimbi ye-EPIC.

1.2% Elkem spheroidizing ejenti, 0.8-1.0% ejenti ejenti, futhi 0.4% ingilazi cullet is esishunyekiwe esikhwameni spheroidizing, nensimbi akhishelwa ngqo esikhwameni spheroidizing, futhi 0.5% Elkem isitofu afakwa ngasikhathi sinye. Ngemuva kokuphothulwa kwe-spheroidization, i-Elkem yokulandelela i-inoculant efafazwe ebusweni izosampulwa futhi ihlaziywe kusetshenziswa insimbi ye-EPIC.

Isilinganiselo sesikimu sokushaja sesibili: i-65% yensimbi yengulube, ama-35% ezilahli zamanganese eziphansi; ukulawulwa kwamakhemikhali:

| C | Si | Mn | P | S | Cu | |

| Isithando sokuqala somlilo | 3.7-3.9 | 0.6-0.75 | 0.1-0.25 |

Ukwamukela uhlelo lokwelashwa kwe-spheroidizing inoculation: ngqo i-500kg yensimbi esihlokweni, esishumekiwe esingu-1.2% i-Elkem nodulizer, i-0.8-1.0% ejenti elimbozayo ne-0.4% yengilazi yokufaka ingilazi esikhwameni se-spheroidizing, bese iqondisa i-iron esikhwameni se-nodularizing. Faka u-0.5% we-Elkem inoculant. Ngemuva kokuthi inqubo ye-spheroidization isiqediwe, faka i-inoculant yokugeleza kwe-Elkem engxenyeni engaphakathi yesikhwama, uyiqede ngokuphelele, bese usebenzisa insimbi ye-EPIC yokwenza izibonelo zokwenza ukuhlaziywa nokuhlolwa.

I-500kg yensimbi ingathayithwa ngqo ku-tundish, futhi i-ejenti engu-0.95% ye-Elkem low-magnesium spheroidizing, i-0.65% i-ejenti yokumboza i-Elkem, i-0.2% yensimbi yesikhumba kanye ne-0.1% ye-slag remover efakwe esikhwameni se-spheroidizing, futhi insimbi ingathathwa ngqo ukuhlobisa iphakethe. Ngemuva kokuphothulwa kwe-spheroidization, i-Elkem yokulandelela i-inoculant ifafazwa ngaphezulu, ichithwe ngokuphelele, bese isampula lihlaziywa futhi lihlolwe ngethuluzi le-EPIC. Thepha ngqo i-iron engamakhilogremu ayi-500 esihlahleni, futhi isikhwama sokuphrinta sifakwe ku-1.2% i-Elkem nodulizer, i-ejenti yokumboza engu-0.3%, i-0.2% ye-Elkem inoculant, u-0.5% wezinsimbi zensimbi kanye ne-0.1% ye-slag remover, ngqo i-Iron esikhwameni esikhazimulayo, futhi ngasikhathi sinye wabeka u-0.35% we-Elkem inoculant.

Ngemuva kokuphothulwa kwe-spheroidization, i-Elkem yokulandelela i-inoculant ifafazwa ngaphezulu, ichithwe ngokuphelele, bese isampula lihlaziywa futhi lihlolwe ngethuluzi le-EPIC. Uhlelo lwesithathu isilinganiso sokukhokhiswa: i-65% yensimbi yengulube, i-35% yesilahli; ukulawula ukwakheka kwamakhemikhali:

| C | Si | Mn | P | S | Cu | |

| Isithando sokuqala somlilo | 3.8-4.0 | 1.1-1.4 | 0.1-0.25 |

Uhlelo lokwelashwa kwe-spheroidization inoculation luyamukelwa: i-500kg yensimbi iqoshwe ngqo esihlahleni, i-1.2% ye-Elkem low-magnesium spheroidizing agent, i-0.8% ejenti elimbozayo kanye ne-0.1% ye-slag remover efakwe esikhwameni se-spheroidizing, futhi i-iron ithephelwa ngqo isikhwama se-spheroidizing. Ngesikhathi esifanayo, i-0.55% ye-Elkem inoculant yafakwa kuyo. Ngemuva kokuphothulwa kwenqubo yokuphamba, i-Elkem's flow-through inoculant yafakwa engxenyeni engaphakathi yesikhwama, eyaphahlazeka ngokuphelele, amasampuli ahlaziywa futhi ahlolwa ngethuluzi le-EPIC. Thepha ngqo i-500kg yensimbi kusihlanganisi, esishumekwe ku-1.2% i-Elkem low-magnesium spheroidizing agent, 0.8% i-Elkem ejenti ejwayelekile, kanye ne-0.1% ye-slag remover esikhwameni se-spheroidizing, ngokuthepha ngqo insimbi esikhwameni se-spheroidizing, bese ngasikhathi sinye utshale imali engu-0.55 % I-Elkem inoculant. Ngemuva kokuphothulwa kwe-spheroidization, i-Elkem yokulandelela i-inoculant efafazwe ebusweni ichithwe ngokuphelele, futhi isampuli iyahlaziywa ihlolwe ngethuluzi le-EPIC. Thepha ngqo i-500kg yensimbi ku-tundish, ne-pre-embed 1.2% ye-Elkem low-magnesium spheroidizing ejenti, i-0.3% yokumboza i-ejenti, i-0.2% i-Elkem inoculant kanye ne-0.1% ye-slag remover esikhwameni se-spheroidizing, ngokuthepha ngqo i-iron ukwenza i-spheroidizing Package, ngenkathi ifaka ku-0.35% i-Elkem inoculant. Ngemuva kokuphothulwa kwe-spheroidization, i-Elkem inoculant efafazwe ebusweni ichithwe ngokuphelele, futhi isampuli iyahlaziywa futhi ihlolwe ngethuluzi le-EPIC. Izindlela zokuhlola zokuhlola nezindlela zokuhlaziya Okuqukethwe yikhabhoni nesibabule kwensimbi encibilikile kutholwa ngumtshina wekhabhoni nesibabule, futhi okuqukethwe kwama-alloys afana ne-P, Mn, ne-Cu kutholwa yi-spectrum analyzer; ijika lokupholisa lokwakhiwa kwamakhemikhali ahlukene ngaphambi kwesithando litholwa yimishini ye-Elkem EPIC. Isibonelo, i-LET (uketshezi lokushisa kwesigaba soketshezi), i-CE (eyi-carbon elinganayo), i-G1, i-G2, ne-G3 inamanani ahlukene wesikhawu. Imiphumela yokuhlolwa nengxoxo Imiphumela nokuxoxisana ngohlelo lokuqala:

| C | Si | Mn | P | S | Cu | |

| 1-1 | 3.40 | 2.51 | 0.20 | 0.007 | 0.14 | |

| 1-2 | 3.45 | 1.90 | 0.18 | 0.010 | 0.14 | |

| 1-3 | 3.30 | 2.61 | 0.18 | 0.013 | 0.14 |

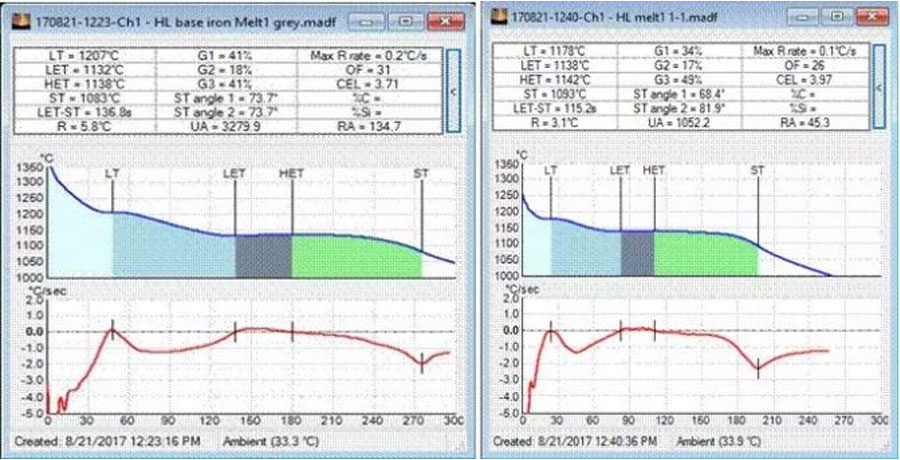

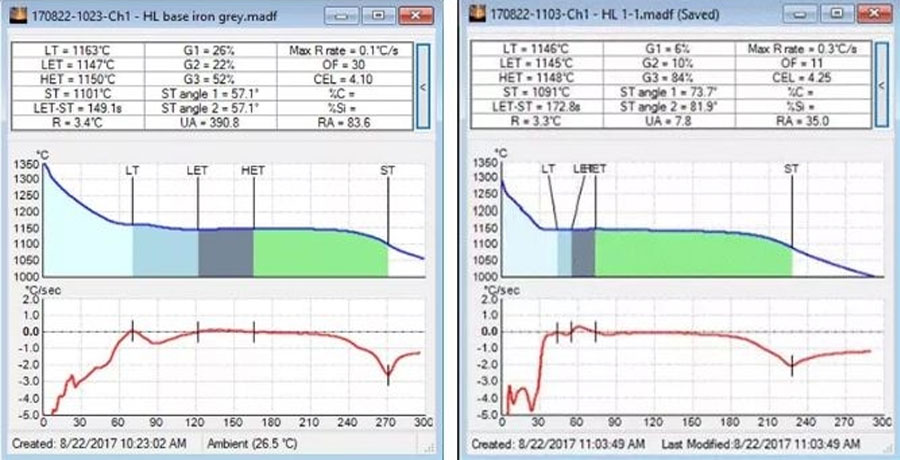

Ngokwezindlela ezahlukahlukene zokucubungula, izithombe ezitholakele ze-EPIC zimi kanje:

Ijika 1: Ijika lesithando sokuqala somlotha womlotha wensimbi oncibilikisiwe

Ijika 2: Umphumela wejika lohlelo lokuqala lwesithando A

Ijika 3: ijika lemiphumela yesikimu sokuqala somlilo B ijika 4: umphumela wejika lesikimu sokuqala somlilo C

- RomKusuka kumajika 1 no-2, siyabona ukuthi inani le-LET lesikimu sokuqala somlilo A liyakhuphuka ngemuva kwenqubo ye-spheroidization, okukhombisa ukuthi isigaba salo soketshezi Ithempelesha yomugqa iyakhula, kepha isikhawu se-G1 sise sikhulu kakhulu kuma-34%, kanti i-LET Isikhathi se--ST se-graphite precipitation yimizuzwana engu-115. Kuhlanganiswe nokwakheka kwayo kwamakhemikhali, kuyaziwa ukuthi okulingana nekhabhoni yiyona ephezulu kunazo zonke izixazululo ezintathu esithandweni sokuqala somlilo.

- RomKusuka kumajika 1 no-3, siyabona ukuthi inani le-LET lenyuka lisuka ku-1132 liye ku-1146 ° C, isikhawu se-G1 singama-36%, kanti isikhathi semvula se-LET-ST graphite amasekhondi ayi-129. Kuhlanganiswe nokwakheka kwayo kwamakhemikhali, siyazi ukuthi okulingana nekhabhoni kungokokuqala Okuphansi kunazo zonke izinketho ezintathu esithandweni esisodwa.

- RomKusuka kumajika 1 no-4, siyabona ukuthi lapho inani le-LET lenyuka lisuka ku-1132 laya ku-1140, isikhawu se-G1 singama-32%. Isikhathi semvula se-LET-ST graphite ngamasekhondi angu-139, futhi ukwakheka kwawo kwamakhemikhali okulingana nekhabethe inani eliphakathi phakathi kwezinhlelo ezintathu zesithando sokuqala somlilo.

- ④ Ukuphakama kwenani le-LET, kukhuphuka amandla ashisayo we-nucleation yensimbi, kwehlisa ukuthambekela komlomo omhlophe wokuphonsa ngaphansi kwezimo ezifanayo, namabhola we-graphite amaningi; inani le-LET-ST yisikhathi semvula se-graphite. Enqubeni yokukhiqiza izingxenye ezijiyile nezinkulu, leli nani ngokuvamile liyadingeka ukuthi libe ngaphezulu. Uma iba nkulu kangcono, kusho ukuthi i-graphite iyanqamuka phakathi nayo yonke inqubo yokuqinisa, okuzuzisa ukusebenzisa umphumela wokuzikhulisa we-graphite ukuze unciphise ukuncipha okuyingxenye; isikhawu se-G1 yisikhawu semvula se-austenite sensimbi encibilikisiwe. Okukhudlwana i-G1, kukhula kakhulu ukuthambekela kwe-iron shrinkage porosity. Kunezici ezimbili ezithinta inani le-G1. Ngakolunye uhlangothi, kungumthelela wokufaka inoculation nekhono le-nucleation yensimbi encibilikisiwe, ngakolunye uhlangothi, okulingana nekhabhoni nensimbi encibilikisiwe. Lapho okulingana nekhabhoni kufana, kuba ngcono umthelela wokufaka inoculation, kwehlise inani le-G1, futhi kuncane ukuthambekela kokuncipha.

- ⑤ Ngakho-ke, kubonakala sengathi esithandweni sokuqala ngemuva kokwelashwa kwensimbi encibilikisiwe, inketho C iyona engcono kakhulu, inketho B ingeyesibili, futhi inketho A yimbi kakhulu.

Imiphumela nengxoxo ngenketho yesibili

| C | Si | Mn | P | S | Cu | |

| 2-1 | 3.70 | 2.36 | 0.18 | 0.007 | - | |

| 2-2 | 3.66 | 2.39 | 0.19 | 0.005 | - | |

| 2-3 | 3.46 | 2.65 | 0.18 | 0.005 | - |

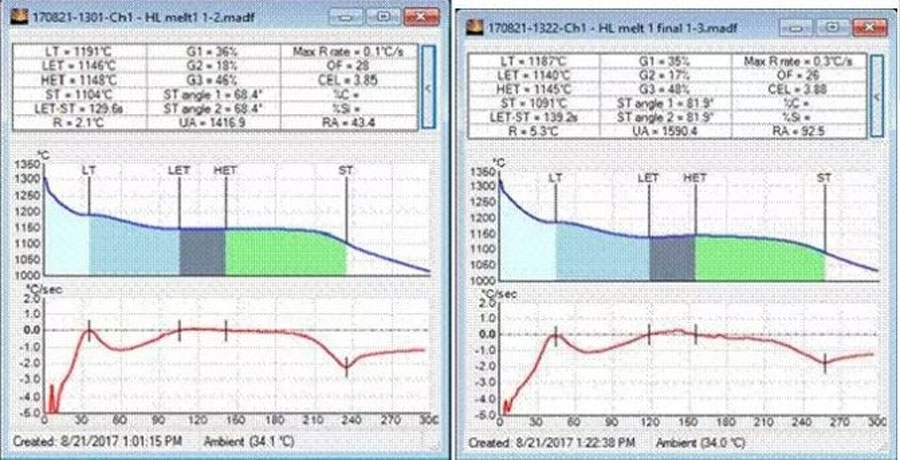

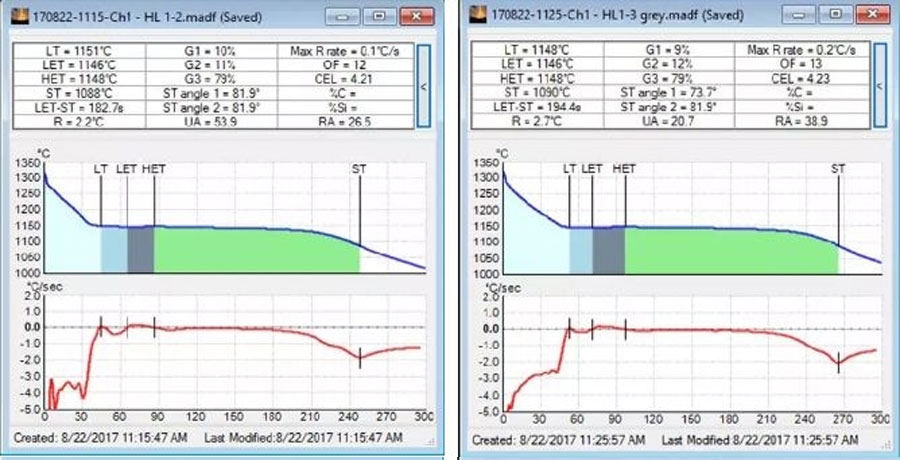

Ngokwezindlela ezahlukahlukene zokucubungula, izithombe ezitholakele ze-EPIC zimi kanje:

Ijika 5: Ijika lesithando sesibili sesampula yomlotha wensimbi encibilikisiwe

Ijika 6: Umphumela wejika lesithando sesibili somlilo u-A

Ijika 7: Umphumela wejika lesithando sesibili somlilo B

Ijika 8: Umphumela wejika lesithando sesibili somlilo uC

- CanKungabonakala kusuka ejikeni 5 nakujika 6 ukuthi inani le-LET lehlisiwe lisuka ku-1149 laya ku-1141 ℃, isikhawu se-G1 singama-20%, kanti isikhathi semvula se-LET-ST graphite yimizuzwana eyi-146. Ihlanganiswe nokwakheka kwayo kwamakhemikhali, kuyaziwa ukuthi okulingana nekhabhoni kuyisithando sesibili somlilo. Ukuphakama kwezinhlelo ezintathu. Ngemuva kokuhlaziywa, inani eliphansi le-LET lejika lomgodi wensimbi elincibilikisiwe lokuqala belingenxa yokwengezwa kwe-ferrosilicon kanye ne-graphitizing recarburizer, okuholele ekutheni kube namandla we-nucleation aqinile ngokushesha wensimbi encibilikisiwe.

- CanKungabonakala kusuka ejikeni 5 nakujika 7 ukuthi inani le-LET lehlisiwe lisuka ku-1149 laya ku-1139 ℃, isikhawu se-G1 singama-24%, kanti isikhathi semvula se-LET-ST graphite yimizuzwana eyi-146. Ihlanganiswe nokwakheka kwayo kwamakhemikhali, kuyaziwa ukuthi okulingana nekhabhoni kuyisithando sesibili somlilo. Maphakathi nezinhlelo ezintathu. Isizathu sokwehla kwe-LET siyefana naleso esingenhla.

- CanKungabonakala kusuka ejikeni 5 nakujika 8 ukuthi inani le-LET lehlisiwe lisuka ku-1149 laya ku-1138 ° C, isikhawu se-G1 singama-33%, kanti isikhathi semvula se-LET-ST graphite amasekhondi ayi-144. Ihlanganiswe nokwakheka kwayo kwamakhemikhali, kuyaziwa ukuthi okulingana nekhabhoni kuyisithando sesibili somlilo. Okuphansi kunezinketho ezintathu.

- Ngokuvamile, uhlelo lwesibili lwesithando somlilo A esinamandla amakhulu we-nucleation sinenani eliphakeme le-LET, ukuthambekela okuncane kakhulu ukubuye kube uhlelo lwesithando sesibili u-A, futhi inani le-G1 lincane kakhulu. Kukhombisa ukuthi ukwanda kwenani le-CE kunganciphisa ukuthambekela kokuncipha futhi kuthuthukise ikhono le-nucleation.

Imiphumela nengxoxo ngenketho yesithathu

| C | Si | Mn | P | S | Cu | |

| 3-1 | 3.72 | 2.36 | 0.24 | 0.008 | - | |

| 3-2 | 3.76 | 2.45 | 0.24 | 0.009 | - | |

| 3-3 | 3.78 | 2.37 | 0.24 | 0.008 | - |

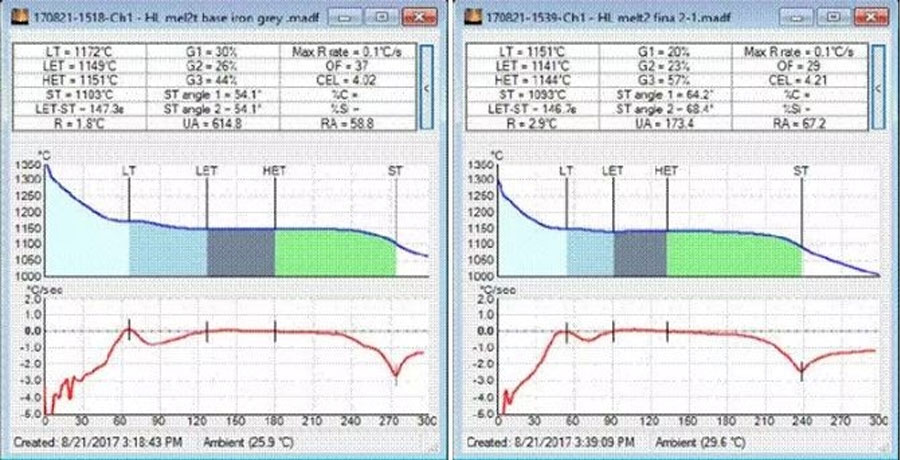

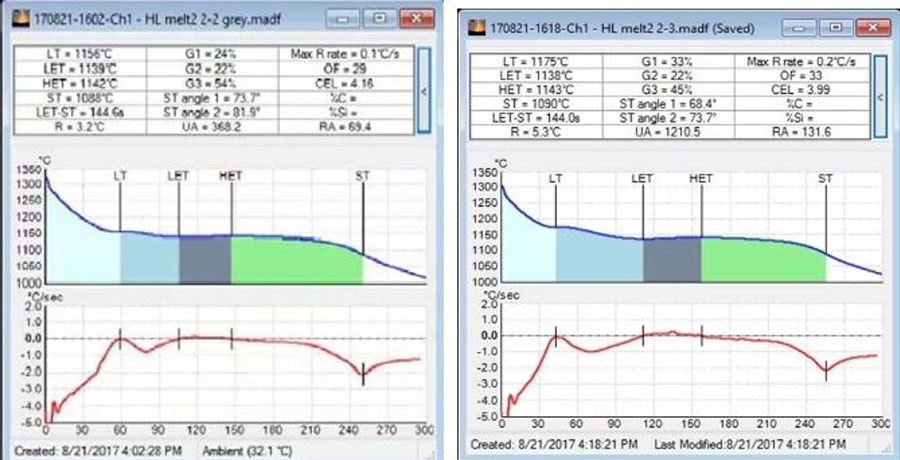

Ijika 9: ijika lesithando sesithathu sesampula yomlotha wensimbi encibilikisiwe

Ijika 10: Umphumela wejika lesithando somlilo sesithathu u-A

Ijika 11: Umphumela wejika lesithathu lesithando somlilo B

Ijika 12: Umphumela wejika lesithathu lesithando somlilo uC

- RomKusuka kujika 9 nejika 10, kungabonakala ukuthi inani le-LET lehlisiwe lisuka ku-1147 laya ku-1145 ℃, inani le-G1 lingu-6%, i-LET-ST graphite Isikhathi semvula amasekhondi ayi-172.8, kuhlangene nokwakheka kwamakhemikhali, kuyaziwa ukuthi okulingana nekhabhoni yikhona okuphansi kakhulu phakathi kwamaqhinga amathathu esithandweni sesithathu somlilo.

- CanKungabonakala kusuka ejikeni 9 nakujika 11 ukuthi inani le-LET lehla lisuka ku-1147 liye ku-1146 ° C, inani le-G1 lingu-10%, kanti isikhathi semvula se-LET-ST graphite yimizuzwana engu-182.7. Ihlanganiswe nokwakheka kwayo kwamakhemikhali, kuyaziwa ukuthi okulingana nekhabhoni kuyisithando sesithathu somlilo. Ukuphakama kwezinhlelo ezintathu.

- CanKungabonakala kusuka ejikeni 9 nakujika 10 ukuthi inani le-LET lehlisiwe lisuka ku-1147 laya ku-1146 ℃, inani le-G1 lingu-9%, kanti isikhathi semvula se-LET-ST graphite yimizuzwana engu-194.4. Ihlanganiswe nokwakheka kwayo kwamakhemikhali, kuyaziwa ukuthi okulingana nekhabhoni kuyisithando sesithathu somlilo. Maphakathi nezinhlelo ezintathu.

- Overall Inani eliphelele le-G1 lenketho yesithathu liphansi ngokuqhathaniswa, okukhombisa ukuthi insimbi encibilikisiwe encishiswe yile nketho inokuthambekela okuphansi kakhulu kokuncipha. Ngokukhuluma okuphelele, umehluko phakathi kwensimbi encibilikisiwe emithathu ayinkulu. Ngokukhulumayo, inketho yesithathu yesithando somlilo inomthelela omuhle kakhulu. Isiphetho sesivivinyo sesampula ukusebenzisa inani elilinganayo lekhabhoni ukulungisa isilinganiso sokushaja ngensimbi encibilikisiwe yethala lokuqala nelesibili.

Inani le-LET lensimbi yokuqala encibilikisiwe yesithando sesibili liphakeme kunaleso lesithando sokuqala somlilo, kanti inani le-G1 lincane kunelesithando sokuqala. Ngokulungisa isilinganiso sokushaja samathambo wesibili nowesithathu, ukufaka esikhundleni imvuthuluka emsulwa ye-low-manganese ngensimbi eyisigaxa, inani le-LET seliseduze, futhi inani le-G1 lehliswa kakhulu ngemuva kokuphindwa kabusha. Ngakho-ke, ukwandisa okuqukethwe kwekhabhoni kungathuthukisa ikhono le-nucleation yensimbi yokuqala encibilikile futhi kunciphise.

Ukuthambekela kokuncipha kunoshintsho oluncane ngohlobo lwezinto ezilahlwayo. Inqubo efanele yokwelashwa kwe-spheroidizing inoculation itholakala ngokuqhathanisa isithando sokuqala se-A nohlelo lwe-B kanye nohlelo lwe-C. I-ejenti ye-spheroidizing efektri kanye ne-inoculant yamukela indlela yokwelashwa ekhona, futhi ukuthambekela kokuncipha nekhono le-nucleation yensimbi encibilikisiwe kungcono. Mpofu; Ngokwecebo lesibili lesithando somlilo A, uhlelo B nohlelo C, lapho isilinganiso somenzeli we-spheroidizing singu-1.2% kanti umthamo we-inoculant ungu-0.5, umphumela wokwelashwa yiwona ohamba phambili, futhi umehluko phakathi kokufaka okushumekiwe nokuthekiwe akuwona mkhulu; kudlulile Ukuqhathanisa izikimu zesithando sesithathu u-A, B, no-C, awukho umehluko osobala emiphumeleni yezinhlelo ezintathu zokwelashwa.

Imbangela yenguquko yinani le-CE lensimbi yokuqala ebunjiwe. Ngamafuphi, ngenani eliphakeme le-CE (C3.7-3.9, Si2.1-2.4), usebenzisa i-Elkem nodulizer inoculant, isilinganiso se-nodulizer 1.2%, i-Elkem inoculant 0.5% ne-flow inoculant ingathola ukuma okuphezulu Insimbi encibilikisiwe enamandla enuzi futhi Ukuthambekela okuphansi kwe-shrinkage kwenza kube lula ukuthola ama-ductile iron castings ahlangabezana nezidingo zekhwalithi. Iziphetho zesicelo sokukhiqiza Sebenzisa iziphetho zokuhlolwa kwesampula zokukhiqizwa kwezingxenye ezibiyelwe zensimbi e-ductile. Uhlelo lumi kanjena: ukuncibilika kwesisindo 20t, isilinganiso sengulube yensimbi engu-65%, insimbi eyisigaxa engu-35%, i-Elkem nodulizer 1.2%, i-Elkem inoculant 0.5% + ene-Flow inoculant, insimbi yokuqala encibilikisiwe i-C3.7-3.9, i-Si2.2- 2.5, Mn≤0.3, P≤0.05, S < 0.02, ekukhiqizweni, thatha ibha yokuhlola yokusakaza enamathiselwe ekusakazweni kokuhlolwa, bese usika futhi ubheka umzimba wokusakaza. Ngemuva kokuhlukaniswa, indawo yokucubungula ihlolwe, futhi akubanga khona ukukhubazeka kwe-graphite nokuncipha ngemuva kokucutshungulwa, futhi uhlelo luphumelele.

Ngamafuphi

- 1. Izingxenye zensimbi eziqinile ezi-ductile kunzima ukuzilawula ekukhiqizeni i-ductile iron. Zinezici zobukhulu bodonga obukhulu, ukupholisa okuhamba kancane, okuqukethe uMg nezinye izinto, nokuthambekela okuphezulu kokuncipha. Amaphutha nezinto ezilahlekile ngesikhathi sokukhiqiza kwenzeka kalula, okudala ukulahleka komnotho. Ikakhulukazi ekubunjweni kwebanga le-QT400-18AR, izidingo zalo zokusebenza: ukusebenza ngokuqina Rm≥390; amandla isivuno Re≥240; ukunwebeka A≥18; inani lomthelela omaphakathi i-KV2≥14, inani eliphansi lomthelela KV2≥11, nezidingo eziphakeme.

- 2. Ngokuhlolwa kwenqubo yesampula encane, ucezu lwesampula lwesampula oluthelwa luhlolwa izingxenye ezahlukahlukene zamakhemikhali nezindlela ezahlukahlukene zokwelashwa kwe-spheroidization inoculation. Isisetshenziswa se-Elkem EPIC sithola ukuthambekela kokuncipha kwensimbi encibilikisiwe, sinquma ukwakheka kwamakhemikhali okufanelekile kanye nendlela efanele yokwelashwa kwe-nodularization inoculation, futhi ingathola insimbi encibilikile enokuthambekela okuncane kakhulu kokuncipha.

- 3. Faka imininingwane etholwe ekuhlolweni kwenqubo yesampula encane ekukhiqizweni kwangempela ukwakha uhlelo lokukhiqiza olucacile noluzinzile lokukhiqizwa kwezingxenye ezibiyelwe zensimbi e-ductile. Ngokuhlolwa kwebha yokuhlola yokusakaza enamathiselwe nokubukwa komhlaba okwakheka komzimba, kunqunywa ukuthi uhlelo luyasebenza futhi ukukhiqizwa kuyenziwa. Ikhwalithi inhle futhi ihlangabezana nezidingo zekhwalithi.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Izinhlobo Ezintathu Zokuncibilikisa Namaqhinga Okuthela Ama-Ductile Iron

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off