Imininingwane Yomklamo We-Aluminium Alloy Shell Die Casting Tooling

Lo mbhalo uqale uhlaziye inqubo yokwakheka neyokufa kwegobolondo le-aluminium alloy, bese isebenzisa isoftware ye-UG ukuqedela ukwakhiwa kwesikhunta se-aluminium alloy shell die-casting. Kufakazelwe ngomkhuba, ukuklanywa kokufa kuklanyelwe kunengqondo, ubuso bokuphonsa okutholile bushelelezi futhi buhlanzekile, futhi ikhwalithi yomkhiqizo ihlangabezana nezidingo.

Ukuhlaziywa kwesakhiwo nenqubo yokuphonsa izingxenye ze-aluminium alloy igobolondo langemuva

- 1.1 Isakhiwo sokulingisa kungabonakala kusuka kuMdwebo 1 ukuthi isakhiwo sangemuva sokufaka igobolondo sangemuva silula, ukushuba kodonga lokulingisa ngokuyisisekelo kufana, kunezimbobo ezimbili zokuphonsa, kepha ngoba udonga lomgodi wokuphosa lukhulu kakhulu, luyashisa amabala kulula ukuvela, Ububanzi bodonga jikelele bezingxenye zokufa-zifana ngokufana. Lapho ukhetha ukushuba kodonga, kufanele kucatshangwe izinto ezahlukahlukene: ukwakheka kokufa, izakhiwo ezibonakalayo, kanye nenqubo edizayinelwe yokulingisa. Ubukhulu bodonga obuncane noma obufanayo kuphela abungahlangabezana nazo zonke izici. funa.

- 1.2 Ubuncane bodonga obukhulu bomphetho wangaphandle wokusakaza. Izimo zokwakha ezinhle zidinga ukujiya kodonga oluthile lwangaphandle. Ubudlelwano phakathi kobukhulu bedonga obunqenqemeni nokujula h ngu-s≥ (1/4 ~ 1/3) hmm. Lapho h <4.5mm, bese u-s≥1.5mm.

- 1.3 Izinto zokuphonsa okokufa Okuphonswayo kufakwa i-die-casting aluminium alloy, ibanga yi-YZAlSi9Cu4, amandla we-tensile yi-240MPa, ubulukhuni be-Brinell yi-85HBS, futhi isilinganiso sokuncipha okujwayelekile ngu-0.6%. Ingxubevange ekhethiwe imiphumela ezinhle ekubunjweni izakhiwo futhi ikakhulukazi efanelekayo die ekubunjweni.

- 1.4 I-casting fillet radius Ukuze wenze ukugeleza kwensimbi encibilike ngokushelelayo futhi kube lula ukukhipha igesi, lesi sakhiwo senzelwe ukusebenzisa izigaxa zensimbi, nokusetshenziswa kwemicu ukufaka amakhona abukhali esakhiweni nakho kungagwema imifantu. Irediyasi yamakhona ayindilinga esakhiwo esakhelwe ancike ebusongeni besakhiwo, futhi ububanzi ngokuvamile bungu-0.5 kuya ku-1 mm.

- 1.5 I-engeli yokuloba kufanele ikhethwe ngokubheka okuningiliziwe kwezici eziningi: ukusakaza i-geometry (ukujula, ukujiya kodonga, umgodi noma umgogodla), ubukhali, ukucubungula izikhombisi-ndlela zokusanhlamvu, njll. Kucatshangelwa lezi zici ezingenhla, ukwakheka kwethambeka lokudilizwa kwegobolondo kokulingiswa: α = 30 'ebusweni bangaphandle, kanye no-β = 1 ° ebusweni bangaphakathi.

Idizayini yenqubo yokuphonsa inqubo

2.1 Ukukhethwa komshini wokuphonsa lapho kukhethwa khona umshini wokufa, amandla okubamba kufanele anqunywe kuqala. Amandla okubopha anemisebenzi emibili: owodwa usetshenziselwa ukulinganisa ingcindezi yangemuva ukufeza injongo yokukhiya indawo yokuvalelisa; okunye ukuvimbela ukuqhuma kwensimbi encibilikisiwe ukufeza inhloso yokufeza ukunemba kobukhulu besilinganiso. Akukho mandla wokunwetshwa ngokwengxenye ekubunjweni okwenzelwe, ngoba lesi sikhunta asinakho ukudonsa okusemaceleni (ukusakazwa kokufa akunazimbobo zohlangothi nezinciphisi). Ngakho-ke, ukukhiya kuka-F ≥ KF okuyinhloko = 1.25 × 1288.352 = 1610.44kN. Ngokuya ngesibalo esingenhla, inani lamandla okubamba kanye nesisindo sokuphonsa kuyatholakala. Ngokuya ngalezi zinto ezimbili eziyinhloko, kukhethwa umshini wokuphonsa okokufa, futhi imodeli yokugcina ekhethiwe yilezi: umshini wokuphonsa umshini wokubanda obandayo (2500kN) ——— Uhlobo lwe-J1125, imingcele eyinhloko:

- VolumeIvolumu enkulu ethela ivolumu yensimbi ——— 3.2Kg,

- Ubukhulu oldMold ———— 250 ~ 650mm,

- OvingMoving isikhunta isihlalo ipuleti unhlangothi ———— 400mm,

- Force Amandla okujova—— —143 ~ 280kN.

2.2 Ingcindezi yokuphonsa Die-casting ingcindezi ingenye yemingcele eyinhloko kunqubo yokufa. Ngakho-ke, kubaluleke kakhulu ukuqonda inguquko yengcindezi yensimbi engamanzi ngesikhathi se- ukufa-okusakaza inqubo, nokulawula ngokufanele ingcindezi esigabeni ngasinye senqubo yokufa:

- ① Thola ukusakazwa okufanelekile—— -Inhlangano eminyene, uhlaka olucacile;

- CalIsibalo sokuqala somfutho othile womjovo - Bala ngokuya ngamandla akhethiwe omjovo. Ingcindezi ethile yomjovo nayo ihlobene nesikhala sesikhala sesikhunta, ukushuba kodonga lokusakaza, inqubo yensimbi encibilikisiwe nezinye izinto. Ukuhlanganisa imingcele ethile yesikhunta esenzelwe kanye nenani lokuqala, ingcindezi ethile yomjovo yalesi sikhunta sokuphonsa ekugcineni isethwe ku-90MPa.

2.3 Ijubane lokuphonsa okhethwayo Ukukhethwa kwejubane lokuphonsa kufa kunezici ezimbili ezilandelayo: ukukhethwa kwejubane lomjovo nokugcwaliswa kokukhethwa kwejubane. Ukukhethwa kwezivinini ezimbili kubaluleke kakhulu, okunquma ngqo ikhwalithi yangaphakathi nangaphandle nencazelo yomugqa wokusakaza. Izici ezizocatshangelwa lapho kukhethwa ijubane lokugcwalisa:

- Usayizi wokusakaza,

- ComplexUbunzima besakhiwo sokuphonsa,

- Uhlobo lwe-alloy olukhethiwe ekusakazweni,

- Izinga lomfutho womjovo.

Izinketho ezithile:

- CastThe castings okulula ukugcwalisa --- ukusakazwa ngobukhulu bodonga obulula noma izidingo zekhwalithi yangaphakathi ephakeme, khetha: isivinini esiphansi, ingcindezi ephezulu ethile, isango elikhulu;

- FillingUkugcwaliswa okusheshayo kuyadingeka --- okuyindilinga enezindonga ezincane noma Okokuphonsa ngezidingo zekhwalithi ephezulu, khetha: isivinini esikhulu, ingcindezi ephezulu ethize. Ukucutshungulwa okuphelele, ngokusho kwezici ezithile zalesi sigaba sokufa-isakhiwo silula, khetha isivinini esiphakathi, ibanga lingu-20 ~ 90m / s.

Isikhathi se-die-casting sinquma isikhathi sokufa, esiqukethe izingxenye ezintathu zesikhathi esidingekayo: isikhathi sokugcwalisa, isikhathi sokubamba nesikhathi lapho ingxenye yokulingisa ihlala kusikhunta sokufa. Kunezici eziningana ezihlanganisiwe ukukhiqiza lo mphumela: ingcindezi, isivinini, izinga lokushisa, izici zensimbi encibilikisiwe, kanye nesakhiwo sokusakaza (ikakhulukazi ukushuba kodonga nevolumu) nokwakheka kwesikhunta (ikakhulukazi uhlelo lokubiyela kanye nokhipha uhlelo) nezinye izinto. Isikhathi sokugcwalisa siphakathi kuka-2.4 no-0.01s. Ubude bunqunywa ngosayizi wokuphonsa nobunzima besakhiwo: ukusakaza okunesakhiwo esilula nevolumu enkulu kudinga isikhathi sokugcwalisa eside; ukusakaza okunesakhiwo esiyinkimbinkimbi nobukhulu bodonga obuncane kudinga isikhathi esifushane. Ngemuva kokuhlolwa okusebenzayo, isikhathi sokugcwalisa sisethwe cishe ku-0.2s, okunengqondo ngokuphonsa okuphakathi nencane kwe-aluminium alloy die yakhelwe kuleli phepha. Umsebenzi wokubamba isikhathi sengcindezi ngukuthi: isibhakela somjovo sinesikhathi esanele sokufaka ingcindezi sensimbi engaqinisekisiwe, ukuze inqubo ye-crystallization yenziwe ngaphansi kwengcindezi, ethuthukisa ukondla futhi ithole ngempumelelo isakhiwo esinyene. Izici ezithinta ubude besikhathi: iphuzu lokuncibilika kwe-alloy ekhethiwe, ibanga lokushisa kwe-crystallization kanye nobukhulu bodonga lokusakaza. Ama-castings anephuzu eliphakeme lokuncibilika, ububanzi obukhulu nobukhulu bodonga obukhulu budinga isikhathi eside, ama-0.2 ~ 2s; lapho isikhathi esinqunyiwe sifushane kakhulu, i-shrinkage izovela, kepha ayinamphumela obonakalayo uma isikhathi sokubamba silulwa. 3 ~ 1s ibanga lesikhathi sokubamba ngokujwayelekile. Ubukhulu bodonga obuphakathi bokuphonsa kulo mklamo ngu-2mm. Ngokubheka ukwakheka kwayo nezakhiwo ze-alloy, ama-3 akhethwe njengesikhathi sokubamba. 3 Izinga lokushisa lokusakaza Inqubo yemingcele esemqoka yokuqinisekisa ukusakazwa okufanelekile — izinga lokushisa elithululelwayo lensimbi encibilikisiwe kanye nezinga lokusebenza lokushisa kwesikhunta. Kunezici eziningi eziyithintayo: ukwakheka kokujula, ukujiya kodonga, ingcindezi yokugcwalisa, isivinini nezinhlobo ze-alloy. Kuyadingeka ukucubungula ngokuphelele imingcele engenhla ukuqinisekisa ukuthi izinga lokushisa lokufa lizinzile ngaphakathi kwebanga elifanele futhi linikeze izimo ezinhle zokugcwaliswa. Uma izinga lokushisa lokuthela lingekho ebangeni elifanele, ikhwalithi yomkhiqizo izokwehliswa noma ingafaneleki:

TemperatureUkushisa okuthe xaxa - kuzodala ukuncipha okukhulu ngesikhathi sokupholisa, umkhiqizo uthambekele ekuqhekekeni, okusanhlamvu okukhulu, nasekusebenzeni kahle kwemishini, futhi kubangele ukunamathela kwesikhunta, kunciphise impilo yesikhunta;

Temperature Amaphutha okushisa okushisa aphansi kakhulu afaka phakathi umgoqo obandayo, iphethini yomhlaba nokuthululwa okunganele. Ukuze uthole ukusakazwa okufanelekile, ngaphezu kokushisa okuthululelwayo, ingcindezi, ukushisa kwesikhunta sokufa, isivinini sokugcwalisa kanye ne-alloy ekhethelwe ama-castings kufanele futhi kubhekwe ngasikhathi sinye. Izingxenye zokuphonsa zenziwe nge-aluminium-silicon alloy. Ngokuya ngobuningi baso nobusikhunta, i-620 ℃ ikhethwa njengezinga lokushisa lokuphonsa.

Sakhiwo design die ekubunjweni die ekubunjweni igobolondo emuva

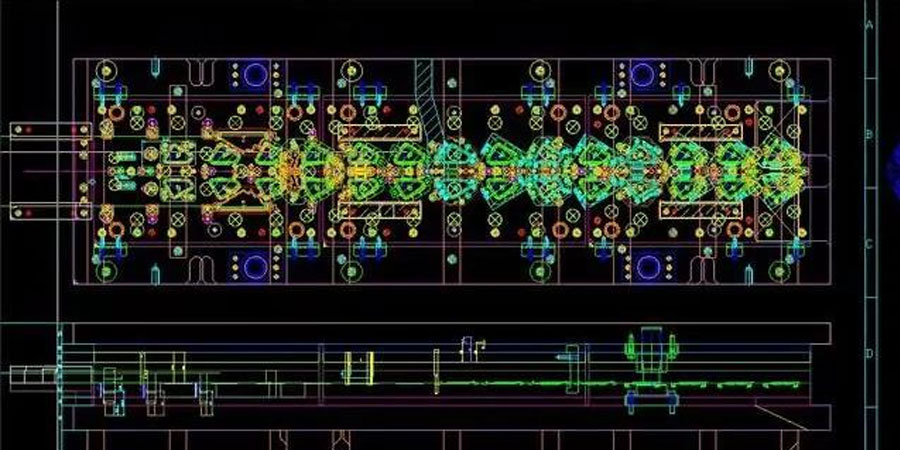

3.1 Ukunqunywa kwendawo yokuhlukanisa ingxenye inesakhiwo esilula. Ngokomgomo wokuhlukaniswa kokukhethwa kwendawo, isigaba esikhulu kunazo zonke sokuqagela kufanele sikhethwe, njengoba kukhonjisiwe kuMfanekiso 2.

3.2 Idizayini yohlelo lokufaka amasango Uhlelo lokungena luqukethe izingxenye ezine:

- Run umgijimi oqondile

- Ner umgijimi ovundlile

- Gate isango langaphakathi,

- Hole imbobo ye-slug ebandayo.

Idizayini ethile:

- ChamberIgumbi lengcindezi elihlanganayo —— indlela yokuxhuma yegumbi lengcindezi kanye ne-sprue bushing;

- ShapeUkuma kwesigaba esiphambanayo somgijimi —— i-flat trapezoid;

- Isango langaphakathi —— isango elisehlangothini eliyindilinga;

- IdeSide uthela Umlomo-uhlelwe endaweni yokuhlukanisa ukusakaza;

- Mold Isikhunta esisodwa esinemigodi emine, uMdwebo 3 ukhombisa ukwakheka okuthile.

3.3 Idizayini yethangi lokuchichima kanye nohlelo lokukhipha impahla Ukwakheka kwethangi lokuchichima kuyenziwa, futhi ukwakheka kwesigaba esiphambanweni esikhethwe ngokucutshungulwa okuphelele kwezici ezahlukahlukene yi-trapezoidal (Umfanekiso 4). Isakhiwo esizwakalayo sinemisebenzi elandelayo:

- MpThuthukisa ibhalansi eshisayo yesikhunta-lungisa izinga lokushisa kuyo yonke indawo kusikhunta, unciphise amamaki okugeleza, izithiyo ezibandayo nokuthululwa okunganele kokuphosa, ukudlulisa izimbotshana zokuncipha, i-porosity ye-shrinkage, nokufakwa kwe-vortex;

- ② ukukhishwa Igesi esemgodini iphela ngokushesha nge-groove yokukhipha;

- Ukugcinwa koketshezi lwensimbi olubandayo olungcolile - ingxube yensalela kapende negesi.

3.4 Idizayini yohlelo lokukhipha Inqubo yokufa, ngemuva kokuba umjikelezo ophelele wokwakha usuphothuliwe, okufayo kudinga ukuvulwa ukuze kuthathwe ingxenye yokufa, kuthi ingxenye esongelwe ngokufa izotholakala ohlangothini lwe isibhakela, esidinga ukususwa. Lo msebenzi udinga uhlobo olungeziwe lwendlela ephezulu yokwenza. Uhlelo lwe-ejector luthathe isikhundla esibalulekile ekwakhiweni kwesakhiwo sesikhunta. Kunezingxenye ezintathu eziyinhloko zohlelo lwe-ejector:

- Ject khipha,

- ② setha kabusha

- ③ umhlahlandlela. Lesi setha sesikhunta sisebenzisa izindlela ezimbili zokukhipha i-ejector, ezisetshenziselwa ukusakaza nokukhipha i-sprue. Ububanzi bezikhonkwane ze-ejector bungu-6mm no-8mm ngokulandelana.

Amadivayisi wokukhawulela umklamo ohlelweni:

- ① umkhawulo block,

- ② setha kabusha isigwedlo ukwenza ngcono ukunemba kokusetha kabusha kwemishini futhi uvimbele unhlangothi ukuba weqe umkhawulo ngesikhathi sokuhamba kwezinto zomshini.

3.5 Ukubalwa kobukhulu bengxenye eyakhiwe

I-3.5.1 Cavity nosayizi oyisisekelo:

3.5.2 Bala ibanga lesikhungo nosayizi wesikhundla: lapho: L-ibanga maphakathi lengxenye yokwakha nosayizi wesilinganiso sendawo (mm); L-usayizi omaphakathi webanga lokufa ekubunjweni kokufa nendawo (mm).

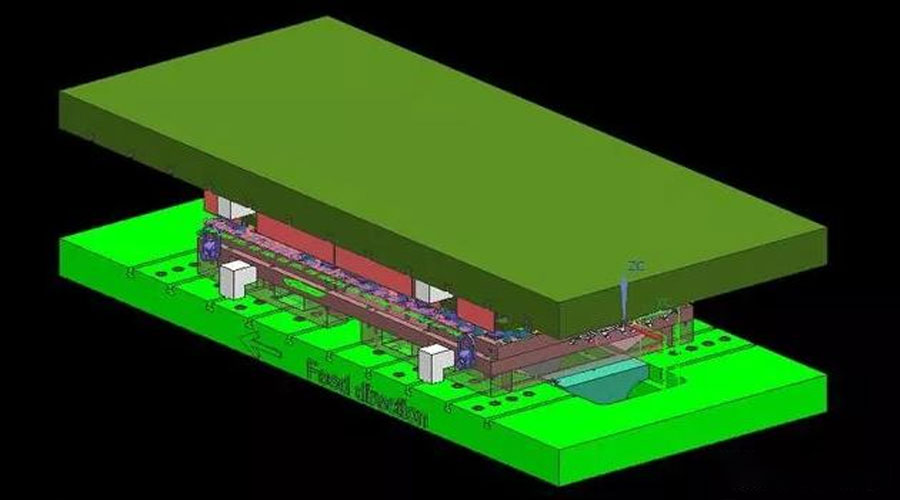

3.6 Ukwakheka kohlelo lokupholisa kukhetha indlela yokupholisa esebenza kahle futhi elula ukulawulwa — ukupholisa amanzi ukuthola ukusakazwa kwekhwalithi ephezulu nempilo yesikhunta ende. Umphumela wokupholisa wokupholisa amanzi uncike ekuhlelweni kwesiteshi sokupholisa, esihlelwe emgodini:

- Izinga lokushisa eliphakeme kakhulu,

- Ukushisa kugxilwe kakhulu,

- Ngaphansi kwesikhunta,

- Uhlangothi olubhekene ne-opharetha. Ukuze uthuthukise ukufakwa okulula kwephayiphu yokulethwa kwamanzi, kuyadingeka ukuhlanganisa ubukhulu bejometri lobubanzi obungaphandle besiteshi samanzi. Ukuhlelwa kwayo kwesakhiwo kuboniswe kuMdwebo 5.

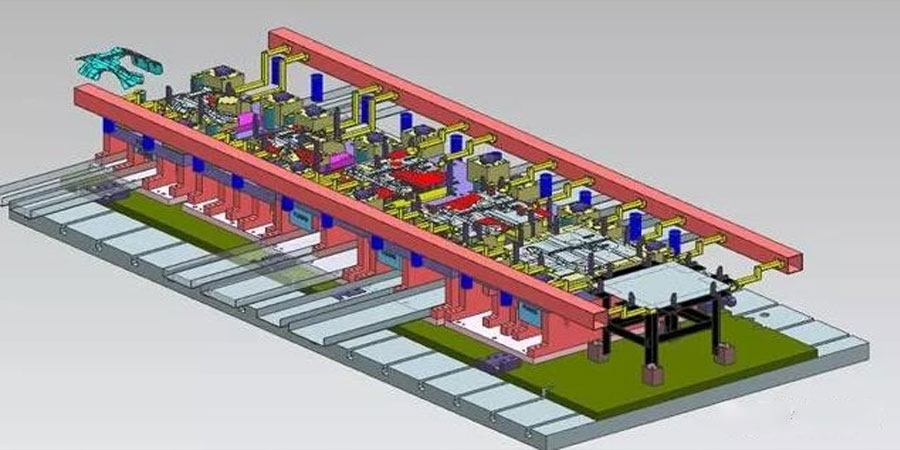

3.7 General Assembly Drawing of Die-casting Mold Yenza umdwebo womhlangano jikelele wesikhunta sokuphonsa esembozweni segobolondo langemuva (Umfanekiso 6). Isikhunta sokuphonsa sakhiwa izingxenye ezimbili: isikhunta esinqunyiwe nesikhunta esihambayo. Isikhunta esinqunyiwe simile futhi sitholakala kupuleti elingaguquki lesikhunta. Isikhunta esihambayo sihamba nepuleti lomlandeli futhi sitholakala kupuleti lomlandeli ipuleti elungisiwe. Isikhunta sivaliwe futhi sivulwa ngokuhamba kwesikhunta esihambayo ngokuya kwesikhunta esihambayo.

Amp Ukubamba isikhunta: lezi ezimbili zivaliwe ukwakha umgodi, futhi umgodi ugcwele insimbi encibilikisiwe ngaphansi kwengcindezi ephezulu kusetshenziswa uhlelo lokubamba; Ukuvulwa kwesikhunta

Lo mbhalo usebenzisa isoftware ye-UG ukumodela izingxenye zekhava yangemuva, bese uqedela ukuhlaziywa kwenqubo, ufe imingcele yenqubo yokuphonsa kanye nokwakheka kwesakhiwo sesakhiwo sezingxenye zangemuva. Umgodi unqunyelwe yizici ezilandelayo: ukukhiqiza, inqubo nokukhiqiza ukusebenza kahle, njll., Uma kubhekwa lezi zici ezingenhla ngokuqondakalayo, kunqunywa njengokwakheka okunembayo okukodwa kwesakhiwo sesine. Ukukhiqizwa okusebenzayo kukhombisa ukuthi kukhethwa ingcindezi ethile yokufa kwe-90MPa, ijubane lokuphonsa likhethiwe ebangeni lama-20-90m / s, isikhathi sokulingisa esingu-0.2s, isikhathi sokubamba ama-3s, nokulingisa izinga lokushisa lika-620 ℃, ikhava yangemuva egoqekile egobekile inendawo ebushelelezi futhi ihlangabezana nezidingo zekhwalithi yomkhiqizo.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Imininingwane Yomklamo We-Aluminium Alloy Shell Die Casting Tooling

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off