Izizathu ze-Aluminium Die Casting Tooling Ukuqhekeka Okulula

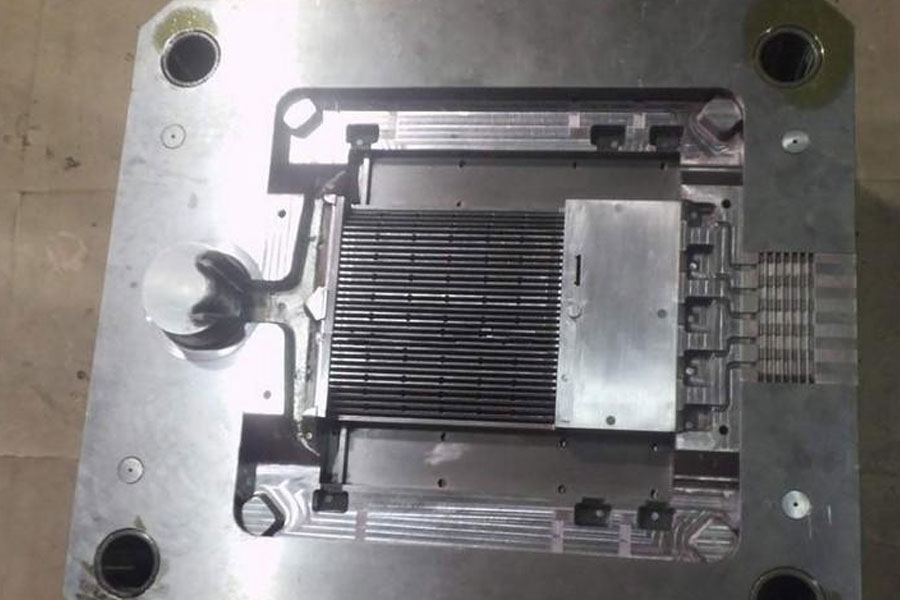

Njengoba sonke sazi, i-aluminium alloy die die-casting die izoba nemifantu ngemuva kwesikhathi sokukhiqizwa.

Izizathu eziyinhloko zalesi simo zimi kanje:

- Izinga lokushisa lesikhunta liphezulu kakhulu futhi ukucindezeleka kukhulu kakhulu

- Isikhunta core impahla isebenzisa 8407, skd61

- Ubulukhuni bokulashwa kwesikhunta buphezulu kakhulu

- Ukugcinwa njalo, 5k times1 ukufuthelana, izikhathi eziyi-15k1 ukufuthelana izikhathi ezingama-30k ……

Ukuvimbela die-ekubunjweni isikhunta nokuqhekeka nokwandisa impilo service amazwe isikhunta steel

Amaphuzu alandelayo kufanele enziwe:

- 1. Izidingo zokwelashwa kokushisa kwengxenye eyakha isikhunta sokufa (ukuhamba, umnyombo wesikhunta ongaguquki, umnyombo): ubulukhuni kumele buqinisekiswe ukuthi yi-HRC43 ~ 48 (okubalulekile kungaba yi-SKD61 noma i-8407)

- 2. Isikhunta kufanele sishiswe ngokuphelele ngaphambi kokukhiqizwa kokufa. Imisebenzi yayo imi kanje:

- 2.1 Yenza isikhunta sifinyelele ibhalansi engcono yokushisa, yenza isilinganiso sokuqina sokuqina futhi senze ukudluliswa kwengcindezi.

- 2.2 Gcina uketshezi lwe-alloy die-casting lapho igcwalisiwe, unokuqina okuhle futhi uthuthukise ikhwalithi ephezulu yokusakaza.

- 2.3 Nciphisa ukukhubazeka kokuqala kokukhiqiza futhi uthuthukise ukukhiqizwa kokufa.

- 2.4 Nciphisa ukushisa okushisayo kwesikhunta futhi ukwandise impilo yenkonzo yesikhunta. Ukucaciswa okulandelayo kungokulandelayo: Ingxubevange yohlobo lwe-Aluminium alloy / Zinc alloy Mold preheating temperature (℃) 180 ~ 300 150 ~ 200

Ngemuva kokuthi isikhunta esisha sikhiqizwe isikhathi esithile

Ukuqoqwa kwengcindezi eshisayo kuyimbangela eqondile yokuqhekeka okuyisisekelo kwesikhunta. Ukuze kuncishiswe ukucindezelwa okushisayo, umnyombo wesikhunta nesilayida kufanele kutholakale ukuze kuqedwe ukucindezela okushisayo ngemuva kokufakwa ekukhiqizeni isikhathi esithile. ethize

Izindlela zokukhiqiza ezidinga ukuqeda ukucindezelwa okushisayo zingokulandelayo:

| Uhlobo lwe-Mold | Ukushisa kokuqala | Ukushisa kwesibili | Ukushisa okwesithathu |

| aluminium ingxubevange | <Izikhathi zesikhunta ezingama-2000 | <Izikhathi zesikhunta ezingama-10000 | <Izikhathi zesikhunta ezingama-30000 |

| I-alloy alloy | <Izikhathi zesikhunta ezingama-10000 | <Izikhathi zesikhunta ezingama-20000 | <Izikhathi zesikhunta ezingama-50000 |

Amathiphu angama-22 okwenza isikhunta sifinyelele impilo ende

- 1. Izinto ezisezingeni eliphakeme zesikhunta

- 2.Yakha ngokufanelekile isikhunta sodonga lobukhulu nezinye izilinganiso zesikhunta

- 3. Zama ukusebenzisa okufakiwe

- 4. Khetha ikona R elikhulu kunawo wonke angaba khona ngaphansi kwezimo ezingaba khona

- 5. Ibanga phakathi kwesiteshi samanzi sokupholisa nephrofayili nekona kufanele libe likhulu ngokwanele

- 6. Ukucindezela ukufuthelana kufanele kususwe ngemuva kwemishini emibi

- 7. Ukwelashwa ngokushisa kufanele, futhi ukucima nokupholisa kufanele kusheshe ngokwanele

- 8. Pholisa ngokuphelele bese ususa ungqimba lwesikhafu se-EDM

- 9. Iphrofayili akufanele ipholishwe kakhulu

- 10. Ubuso besikhunta kufanele bufakwe i-oxidized

- 11. Uma i-nitriding ekhethiwe, ungqimba lokungena akufanele lujule kakhulu

- 12. Hlangisa isikhunta emazingeni okushisa anconyiwe ngendlela efanele

- 13. Isivinini sesando esisheshayo kufanele sisetshenziselwe ukuqala ukusakaza izingcezu ezi-5-10

- 14. Ngesisekelo sokuthola imikhiqizo efanelekayo, zama ukunciphisa izinga lokushisa le-aluminium encibilikisiwe ngangokunokwenzeka

- 15. Ungasebenzisi ijubane elikhulu kakhulu lomjovo we-aluminium liquid

- Qinisekisa ukuthi isikhunta selehlile kahle, futhi izinga lokushisa lamanzi okupholisa kufanele ligcinwe ku-16 ~ 40 ℃

- 17. Ngokucisha okwesikhashana, zama ukuvala isikhunta futhi unciphise inani lamanzi okupholisa ukugwema ukushaqeka okushisayo kusikhunta lapho uqala kabusha

- 18. Isipholisi kufanele sicishwe lapho indawo yemodeli isezingeni lokushisa eliphakeme kakhulu

- 19. Hhayi kakhulu i-ejenti yokukhipha isifutho

- 20. Ngemuva kwenani elithile lokusakazwa kokufa, ukukhululeka kwengcindezi nokushisa

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Izizathu ze-Aluminium Die Casting Tooling Ukuqhekeka Okulula

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off