Ukuhlaziywa Kwemininingwane Ye-Aluminium Die Casting Mold Crack Failure

Ukwehluleka kokuqhekeka kwemodi ye-aluminium alloy die-casting ngeke kuthinte kuphela ikhwalithi yokukhiqizwa kwesikhunta nokusebenza kahle kokukhiqiza, kepha futhi kuzokhulisa izindleko zokukhiqiza. Eqinisweni, izizathu zokuqhekeka nokwehluleka kwesikhunta se-aluminium alloy die-casting zihlukile. Isibonelo, insimbi engamanzi inemithelela ephindaphindwayo kuyo, izimo zokukhiqiza zishisa kakhulu, izinto zokukhiqiza isikhunta, kanye ne-EDM nezinye izizathu. Kuleli phepha, kwenziwa ukuhlaziywa okukhethekile kokuhluleka kokuqhekeka kwe-aluminium alloy die-casting die. Kuyathenjwa ukuthi ingadlala indima ekuheheni imibono emisha, futhi ilethe inani lesethenjwa kubasebenzi abafanele.

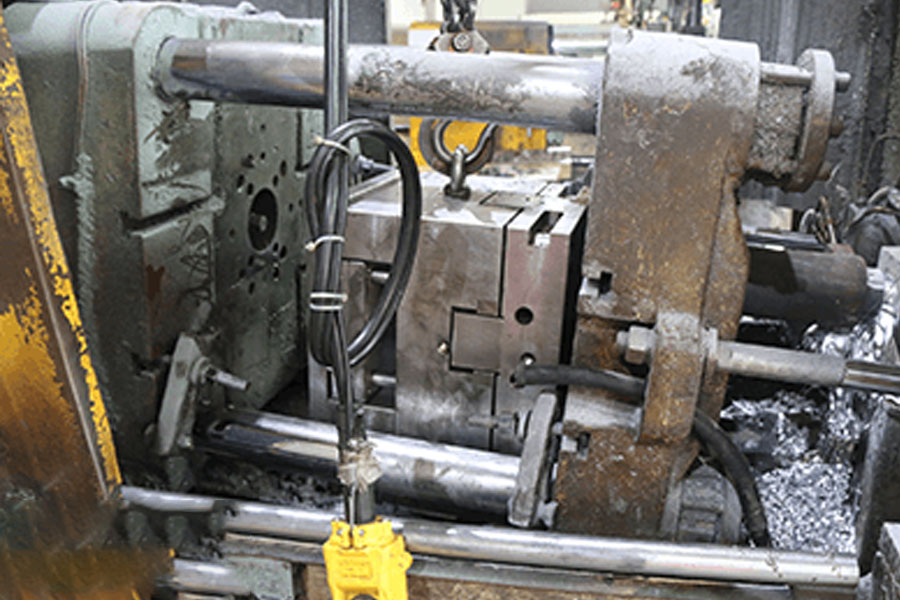

Izimo zokusebenza ze-aluminium alloy die-casting molds ziyahambisana nokushisa okuphezulu nokucindezela okukhulu. Ngasikhathi sinye, isikhunta se-aluminium alloy die-casting kwimodi yokusebenza sidinga ukumelana nomthelela ophindaphindiwe wensimbi engamanzi. Ekukhiqizweni kwangempela, ngenxa yezindleko eziphezulu ze-aluminium alloy die-casting molds, umjikelezo wokukhiqiza omude, nokwehluleka ngaphambi kwesikhathi, impilo yensizakalo izofinyezwa kakhulu. -Uma inkinga yokuqhekeka nokwehluleka kwe-aluminium alloy die-casting molds ingaxazululwa ngempumelelo, izothinta ngqo izinzuzo zezomnotho zebhizinisi lokukhiqiza. Ngalesi sizathu, abakhiqizi abaningi bokuphonsa i-aluminium alloy bakhuphule ukuhlaziywa kwabo kokuhluleka kokuqhekeka. Okuqukethwe okulandelayo kuthatha insimbi engu-H13 yensimbi eshisayo njengesibonelo, futhi kuhlanganisa inqubo yangempela yokukhiqiza ukuhlaziya izimbangela zokuqhekeka nokwehluleka kwesikhunta se-aluminium alloy die-casting kusuka kuzici ze-aluminium alloy mold material, i-microstructure kanye nogesi wokukhipha ugesi. Kuthathwe izinyathelo ezihambisanayo.

1. Imbangela Yokuhlaziywa Kwe-Aluminium Alloy Die-Casting Mold Cracking Failure

Ukwakhiwa kwamakhemikhali

Ngokombono wokwakheka kwamakhemikhali, uhlobo lwensimbi lwe-H13 lwensimbi olushisayo luhlanganisa ikakhulu izinto ezigxile ku-C, SijMn, Mo, Cr, naku-V. Ngokombono wezici zamakhemikhali, uhlobo lwensimbi lwe-H13 lushisa insimbi ukwenza umsebenzi ophansi weSi nokuphakama kukaMo ngensimbi. Enqubeni yokukhiqiza, abakhiqizi bazonciphisa ngokufanele okuqukethwe kwe-Si noma bandise okuqukethwe kwe-Mo ensimbi ngokuya ngezidingo zangempela. Ngokunciphisa okuqukethwe kweSi, ukuchema kungancishiswa ngempumelelo

Ukuvela kwesimo semvula, nokuqhubeka ucwenga okusanhlamvu kwe-austenite, kuthuthukisa amandla nokuqina kwensimbi. Ukwandisa okuqukethwe kweMo kungathuthukisa ukuqina, ukumelana nokushisa nokuqina kokushisa kwensimbi. Futhi uvimbele ngokuphumelelayo imvula yamabele we-carbides ensimbi, kanye nokuguqulwa kwe-bainite. Ukuzijwayeza kukhombisile ukuthi i-Si ephansi ne-high Mo steel izonciphisa amathuba okuthi ungapholisi kahle ngesikhathi senqubo yokuqinisa, ngaleyo ndlela uvimbele ngempumelelo ukuvela kwama-dendrites, amakristalu we-columnar columnar nokwehlukaniswa kwe-dendrite. Ukuhlanganiswa kwezinto ze-Mo ne-V kungakha i-alloy carbides, efana ne-VC, MoC ne-Mo2C. I-alloy carbides izongena ngesimo esicoceke kahle ngaphansi kwezimo ezifanele zokushisa okuphezulu, okuzokwenza ngcono kakhulu izakhiwo ze-thermosetting zezinto zokushisa eziphakeme. Yize ngokwendlela yokwakheka kwamakhemikhali, uhlobo lwensimbi engu-H13 olushisayo lwensimbi ifa ukumelana okuqinile, ngokusebenza kwangempela, sithole ukuthi uhlobo lwensimbi olushisayo lwe-H13 luye lwahluleka ukwehla ngokushesha. Ukuze uhlaziye kangcono izimbangela zokwehluleka kokuqhekeka, kuyadingeka ukuthi uhlanganise kahle ukwakheka kwe-H13 steel hot work die steel ukuze kuhlaziyeke okunye.

Ukuqanjwa

Ukuze ucwaningisise ngokuningiliziwe ukwakheka kwe-aluminium alloy die-casting molds, le ngxenye isebenzisa izinto zesikhunta ezingazange zisetshenziswe ngemuva kokucima i-vacuum nokushisa kanye nezinto ezisetshenzisiwe zesikhunta njengezinto zocwaningo zokuhlaziya ukwakheka kwe-aluminium alloy die-casting isikhunta, bese uthola Izimbangela zokwehluleka kokuqhekeka.

Izinto Zokubumba Ezingakaze Zisetshenziswe Ngemuva Kokucima Umshini Wokushisa Nokushisa

Ngokwenza, kutholakala ukuthi kunezicubu ezingalingani ezisatshalaliswa ku-substrate yento yocwaningo ngemuva kokwelashwa kokushisa. Ngokubheka into yocwaningo ngaphansi kwesibonakhulu esinamandla amancane, sithole ukuthi inani elikhulu lama-carbide we-granular aqhephukile asatshalaliswa kumatrix futhi ahlukaniswe. Ngamanye amagama, uma iqhathaniswa ne-carbides yezicubu ezijwayelekile, le ngxenye ye-carbides Ikhudlwana ngevolumu. Ngenxa yemvula eyeqile yama-carbides kanye ne-alloy carbides, okokusebenza kwesikhunta kulahlekelwa inani elikhulu lezinto ezizungezile zekhabhoni nezakhi zensimbi. Ngaphansi kwezimo ezijwayelekile, ama-carbides ahlukanisiwe wesikhunta ngeke ancibilike kalula lapho isikhunta sishiswa ngokucima. Kodwa-ke, ngenxa yokushoda kwayo kwekhabhoni nezakhi ze-alloying, kulula ukushintshela ku-martensite ngaphansi kokushisa okushisa okuphezulu, ngaleyo ndlela kunciphise i-Tempering inkanyezi yekhwalithi, futhi kunciphisa kakhulu amandla nokuqina kwensimbi, okwenza kube lula ukuphuka njengamanje. Ngokusebenzisa imicroscope yamandla aphansi ukubuka insimbi efakiwe ngaphambi kokucima i-vacuum, sithole ukuthi i-matrix yensimbi nayo inokwehlukaniswa. Ukuvela kwalesi simo kusho ukuntuleka kokufana kwezinto zokusetshenziswa zensimbi. Futhi uma into yokuhlukaniswa ingabhekwana nayo ngempumelelo, izokwandisa ubungozi bokuqhekeka kwesikhunta nokwehluleka, futhi ithinte impilo yokugcina yokusebenza kwesikhunta.

Isikhunta Material Ngemuva Sebenzisa

Ekukhiqizweni kwangempela, isikhunta esivamile se-H13 steel hot die die molds sizovela kumazinga ahlukene okuqhekeka ebusweni besikhunta ngemuva kwezikhathi ezingaba ngu-30,000 zokusetshenziswa, ezinjengokuthi: ukuqhekeka kwangaphakathi nokuhlangana kwemifantu eminingi Ngemuva kokuxebuka, imigodi nokunye okunjalo akhiwa. Isizathu salesi simo ikakhulukazi kungenxa yokukhubazeka kwe-metallurgical ezintweni zokusetshenziswa.

EDM

I-EDM ingenye yezindlela zokucubungula ezisetshenziswa kakhulu kuma-aluminium alloy die-casting molds. Uma kuqhathaniswa nezinye izindlela zokucubungula, le ndlela yokucubungula iveza izinzuzo zokunemba okuphezulu kokucubungula, izinga eliphakeme lokuzenzekelayo nokulula kokucubungula izingxenye ezimise okungajwayelekile kwinqubo ethile yokufaka isicelo. Noma kunjalo, izinhlansi ezikhishwe ngesikhathi sokucubungula zinezici zokushisa okuphezulu nokucindezela okukhulu, futhi izinga lokushisa ketshezi lokusebenza lizoba

Ukwehla okucijile kubangele ukuthi indawo yensimbi ihlukaniswe ibe yindawo yokufudumeza ezishisayo nendawo ethinteke ekushiseni. Indawo ebizwa ngokuthi yi-thermoremelting zone isho ukuthi insimbi engaphezulu inyibilikiswa ukushisa okuphezulu okukhishwe ngesikhathi sokukhishwa. Ngoba ukuncibilika akuphonswa ngokuphelele ngaphandle, futhi ukuncibilika okugciniwe kuyaqina njengoba uketshezi olusebenzayo luphola. Indawo yokulungisa ukushisa isatshalaliswa kakhulu kungqimba olungaphezulu lwensimbi. Uma kuqhathaniswa nesendlalelo esithintwe ukushisa endaweni yokuqothula okushisayo, impahla yensimbi iyathinteka

Ngemuva kokushiswa ekushiseni okuphezulu, akubanga nencibilikisi yokuncibilika, kepha isakhiwo se-metallographic sento sashintsha ngokufanele. Ngokuzijwayeza okuningi, sithole ukuthi inqubo yesikhunta esishisayo nayo izokwandisa ubungozi bokuqhekeka kwesikhunta nokwehluleka endaweni eshisayo yokulungisa kanye nendawo ethintekayo ekushiseni. Ngemuva kokuthi isikhunta se-aluminium alloy die-casting ngemuva kokuthi i-EDM idlule esithandweni segesi, yize isakhiwo se-metallographic sesikhunta singashintshi ngokufanele, siyasuswa ngokushisa.

Kodwa-ke, kuzoqhekeka okuncane endaweni, kuthi lapho imifantu inweba ifike endaweni ethinteke ekushiseni, ibanga le-micro-crack lizophinda lenyuke futhi, nalo elandisa izinga lokwehluleka kokuqhekeka kwesikhunta.

Izindlela Zokuzivikela Zokulwa Nokwehluleka Ukwehluleka Kwe-Aluminium Alloy Die-Casting Mold

- 2.1 Ukwandisa inani lamasampuli okuhlolwa kwe-metallographic kwezinto zokusetshenziswa zesikhunta se-aluminium alloy die-casting Enkambisweni yangempela yokukhiqiza, abakhiqizi abaningi abakwenzanga ngokugcwele ukuhlolwa kwensimbi okuthengiwe kwezinto zokusetshenziswa ezithengiwe ukuze kusheshiswe uhlelo lokukhiqiza. Ukuze kuncishiswe ukwenzeka kwemifantu nokwehluleka kwesikhunta se-aluminium alloy die-casting, abakhiqizi badinga ukukhulisa inani lokuhlolwa kwensimbi okusetshenzisiwe emasampulini aluhlaza ezifundeni ezifakiwe nezincishisiwe ezicishiwe nezomoya, ukuze kuqinisekiswe ukuthi izinto zesikhunta ziyahlangabezana umkhiqizo wangempela udinga ngezinga elikhulu kakhulu. Lapho kukhishwa amasampula wezinto zesikhunta, umkhiqizi udinga ukukhetha indawo eyisampuli ngokwesayensi nangokunengqondo. Ekusampuleni isikhunta se-aluminium alloy die-casting, ukuze kuqinisekiswe ubuqotho bengxenye ezenzakalelayo engaguquki futhi kutholwe ikhwalithi enembile yezinto zokwenziwa zesikhunta, abakhiqizi ngokuvamile basebenzisa isango njengendawo eyisibonelo.

- 2.2 Xazulula ngempumelelo indawo yokulungisa ezishisayo ebangelwe yi-EDM: Indawo yokuxhuma ezishisayo edalwe ukukhishwa kwemishini kagesi inobulukhuni obuphakeme nokuqina okukhulu, futhi ama-microcracks athanda ukuvela ngesikhathi senqubo yokuchofoza. Ikakhulukazi kunqubo yokuthosa ilangabi, amathuba okuqhekeka okuncane makhulu. Ukuze ugweme imifantu nokwehluleka kwe-aluminium alloy die-casting molds, kuyadingeka ukuvikela ngokwesayensi nangokufanelekile ukuvela kwendawo eshisayo yokulungisa. Ngemuva kwe-EDM, indawo yokulungisa eshisayo idinga ukususwa ngesikhathi, futhi isikhunta kufanele sithanjiswe ngesikhathi ukuze kuqedwe kakhulu ukucindezela okusele koqweqwe oluthintekile. .

- 2.3 Ngendlela efanele gwema lo mkhuba wokwehluleka kokuqala kokuqhekeka: Ukwehluleka kokuqhekeka kwe-aluminium alloy die-casting isikhunta kwenzeka ekuqaleni, okubangelwa kakhulu ukushisa okwenziwe ngokweqile kokuklama okungenalutho. Ukwehluleka kokuqhekeka okubangelwa yilesi sizathu kuyiphutha elingenakulinganiswa. Ngakho-ke, ngenkathi kwenziwa umkhiqizo ongenalutho, umkhiqizi udinga ukulawula ngokuqinile izinga lokushisa elenziwe. Esigabeni sokucima ukucisha, kuyadingeka futhi ukuhlela isikhathi sokushisa ngokwesayensi nangokufanelekile ukulawula ngempumelelo ukushisa kokushisa nokuvimbela ukwenzeka kwe-decarburization. Esigabeni sokucima nokupholisa, kuyadingeka ukulawula kahle isikhathi sokupholisa, futhi ulwele ukuqedela inqubo yokuqeda nokupholisa ngesikhathi esifushane nangesivinini esisheshayo. Ngokwesiteshi samanzi sokupholisa, umklami udinga ukugcina ibanga phakathi kwalo nephrofayili namakhona amakhulu ngokwanele ukuqinisekisa ukuqhubeka kwenqubo yokupholisa.

- 2.4 Ukwelashwa kokushisa kwesayensi futhi okunengqondo kwesikhunta: Ikhwalithi yezinto zokusetshenziswa zesikhunta sokufa-ithinta impilo yesevisi ye-aluminium alloy die-casting molds ngezinga elikhulu. Ngakho-ke, abasebenzi badinga ukukhetha izinto zokubunjelwa ezifanelekile ezisuselwa kuzidingo zangempela. Ngemuva kokuthi isisebenzi sinqume izinto zokusetshenziswa zesikhunta se-aluminium alloy die-casting, kuyadingeka ukuqhuba ukwelashwa kokushisa ngesikhathi. Ngasikhathi sinye, kuyadingeka ukwenza umsebenzi omuhle kunqubo yokusiza ekucindezelekeni esigabeni sokukhiqiza ukuvimbela ukugxila kwengcindezi, nokulawula i-R angle. Umsebenzi weSystem. -Ngokujwayelekile, lapho isikhunta se-aluminium alloy die-casting sisetshenziselwa izikhathi ezingaba ngu-10,000 XNUMX, sidinga ukufuthwa ngesikhathi ukususa ingcindezi, ukuze kuvinjelwe ngempumelelo ukugxila kokucindezela kungabangeli isikhunta ukuqhekeka futhi kwehluleke. Ukuze wandise isikhathi sokusebenzisa isikhunta sonke, izindlela eziningi zokuphefumula nokucindezela zingasetshenziswa.

- 2.5 Ngokwesayensi nangokufanelekile ukulawula izinga lokushisa enqubeni yokukhiqiza isikhunta se-aluminium alloy die: Ngakho-ke, kubaluleke kakhulu ukulawula ngokwesayensi nangokufanelekile izinga lokushisa enqubeni yokukhiqiza. Enqubeni yokukhiqiza, umkhiqizi angasebenzisa i-thermometer efanelekile ukubala izinga lokushisa eliphakeme kunqubo yokuphonsa futhi athathe izinyathelo ezisebenzayo zokulawula ukushisa ngaphakathi kwama-degree angama-650.

3. Isiphetho

Ngamafuphi, ngokuthuthuka okusheshayo komnotho wezwe lami, abakhiqizi be-aluminium alloy die-casting mold bakhule ngokushesha ngokuya ngenani nesikali sokukhiqiza. Kodwa-ke, ngenxa yokutshalwa kwemali enkulu ezindlekweni zokukhiqiza isikhunta se-aluminium alloy die-casting, uma ikhwalithi yokukhiqiza ingenakuqinisekiswa ngempumelelo, izothinta ngqo ukusebenza kahle komkhiqizo kanye nokuncintisana kwemakethe komenzi. Enqubeni yokukhiqiza, ukwehluleka kokuqhekeka kuyinkinga ejwayelekile yekhwalithi ye-aluminium alloy die-casting molds. Lokhu akugcini ngokuheha ukunakwa okubanzi ngabakhiqizi, kodwa futhi kusetshenziswe kabanzi ukuthinta abathengi. Ngalesi sizathu, kubaluleke kakhulu ukukhulisa ucwaningo ngokuhluleka kokuqhekeka kwe-aluminium alloy die-casting molds. Okuqukethwe okungenhla kuhlaziya izimbangela zokuqhekeka kwe-aluminium alloy die-casting molds, futhi kuphakamisa izinyathelo zokuvimbela ekuqhekekeni ukwehluleka kwe-aluminium alloy die-casting molds ngalesi sizathu. Kuyathenjwa ukuthi ingaletha inani elithile lesethenjwa kubasebenzi abafanele futhi ikhuthaze intuthuko esimeme, esheshayo nenempilo yezimboni zezimboni ze-aluminium alloy die-casting.

Imibhalo Yohlobo Olufanayo: Izizathu ze-Aluminium Die Casting Tooling Ukuqhekeka Okulula

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ukuhlaziywa Kwemininingwane Ye-Aluminium Die Casting Mold Crack Failure

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off