Ubuchwepheshe Bokukhiqiza Bensimbi Yensimbi

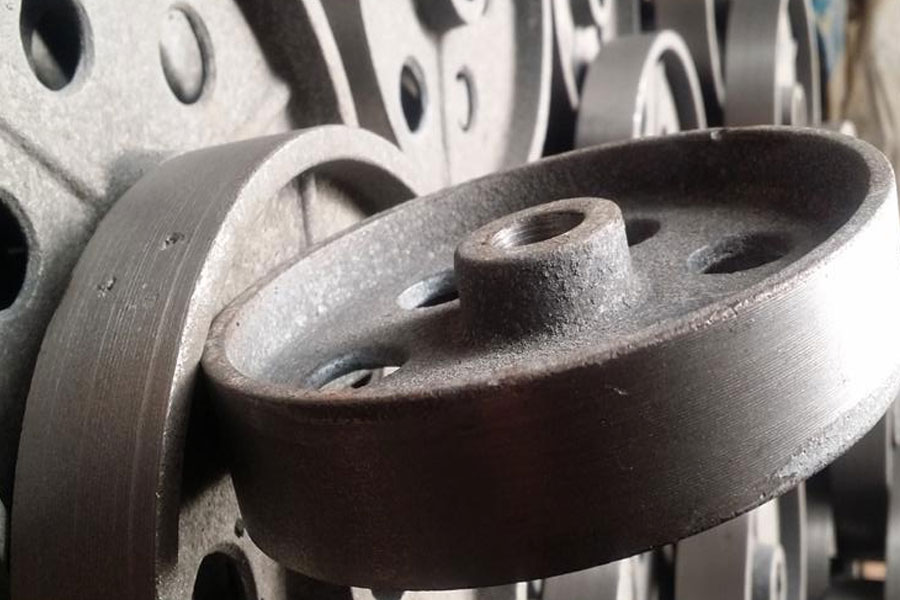

Ezingxenyeni zomshini ezidinga amandla aphakeme, ipulasitiki nobulukhuni, kudingeka izinsimbi zensimbi. Okukhishwa kwabasiki bensimbi kungokwesibili kuphela ekubunjweni kwensimbi, okubalwa cishe u-15% wokukhishwa okuphelele kokuphonswa.

Ngokwakheka kwamakhemikhali, insimbi yensimbi ingahlukaniswa ngezigaba ezimbili: i-carbon cast iron ne-alloy cast cast. Phakathi kwazo, i-carbon cast steel iyona esetshenziswa kakhulu, ebala ngaphezu kuka-80% wokukhishwa okuphelele kwensimbi yensimbi.

1.Carbon Sakaza Insimbi

Ngokuvamile, i-carbon-low steel ZG15 inephuzu eliphakeme lokuncibilika nokusebenza okungalungile kokuphonsa, futhi isetshenziselwa kuphela ukwenza izingxenye zezimoto noma izingxenye ze-carburized; medium-carbon steel ZG25, ZG45 inezakhiwo eziphelele eziphakeme kunazo zonke izinhlobo zensimbi yensimbi, okungukuthi, amandla aphezulu nokusebenza okuhle kakhulu. Ngenxa yokuqina kwepulasitiki nobulukhuni bayo, ilungele ukukhiqiza izingxenye ezinokuma okuyinkimbinkimbi, izidingo zamandla aphezulu nokuqina, njengamasondo esitimela, ukwakha izitendi zesando nama-anvils, ama-rolls kanye nama-valve anomfutho ophezulu. Luhlobo olusetshenziswa kakhulu lwensimbi yekhabhoni; Insimbi yekhabhoni ephezulu i-ZG55 inendawo encibilika kancane, futhi ukusebenza kwayo ekubunjweni kungcono kunalokho kwensimbi enekhabhoni ephakathi, kepha ubulukhuni bayo nokuqina kwayo kubi, futhi kusetshenziselwa kuphela ukwenza izingxenye ezimbalwa ezingamelana nokugqoka.

2.I-Alloy Cast Steel

Ngokwenani eliphelele lezinto ezi-alloying, i-alloy cast iron ingahlukaniswa ngezigaba ezimbili: i-alloy steel low kanye ne-high alloy steel.

- Insimbi ene-alloy ephansi, izwe lethu lisebenzisa kakhulu uchungechunge lwe-manganese, uchungechunge lwe-manganese silicon kanye nochungechunge lwe-chromium. Efana ne-ZG40Mn, ZG30MnSi1, ZG30Cr1MnSi1, njll. Isetshenziselwa ukwenza izingxenye ezinjengamagiya, amasilinda asebenza ngomshini wokubacindezela kanye nama-rotor turbine rotors, kanti i-ZG40Cr1 ijwayele ukusetshenziselwa ukwenza izingxenye ezibalulekile zokuxineka njengamagiya anamandla amakhulu kanye nemiphini enamandla amakhulu .

- Ingxubevange ephezulu yensimbi yensimbi, enezici ezikhethekile njengokuqina kokugqoka, ukumelana nokushisa noma ukumelana nokugqwala. Isibonelo, insimbi ephezulu ye-manganese i-ZGMn13 uhlobo lwensimbi yokulwa nokugqoka, ikakhulukazi esetshenziselwa ukwenza izingxenye ezisetshenziswa ngaphansi kwezimo zokusebenza ezomile, njengodonga lwangaphambili nokubamba amazinyo abembayo, abakhasi bamagandaganda namathangi, njll .; i-chromium-nickel insimbi engagqwali i-ZG1Cr18Ni9 ne-chromium insimbi engagqwali i-ZG1Cr13 ne-ZGCr28, njll., inokumelana nokugqwala okuphezulu ku-nitric acid, futhi isetshenziselwa kakhulu ukwenza izingxenye zamakhemikhali, i-petroleum, i-fiber fiber kanye nezinsimbi zemishini yokudla.

Ekubunjweni inqubo izici yensimbi cast

Izici zemishini yensimbi yensimbi ziphakeme kune-cast iron, kepha izakhiwo zayo zokusakaza zimbi kakhulu kune-cast iron. Ngenxa yokuncibilika okuphezulu kwensimbi yensimbi, insimbi encibilikisiwe kulula ukuyifaka i-oxidize, uketshezi kwensimbi encibilikile kubi, futhi ukuncipha kukhulu. Izinga lokuncipha komzimba wayo lingu-10-14% kuthi ukuncipha komugqa kungu-1.8-2.5%. Ukuze uvikele ukukhubazeka njengokuthela okunganele, ukwahlukana okubandayo, ukuncipha kanye ne-porosity, imifantu nesihlabathi kunamathele izinsimbi zensimbi, izinyathelo zenqubo eziyinkimbinkimbi ukwedlula insimbi yensimbi kufanele zamukelwe:

- 1. Ngenxa yokungabi namanzi okusansimbi okuncibilikisiwe, ukuvimbela izithiyo ezibandayo nokuthululelwa ngokwanele kwezinsimbi zensimbi, ubukhulu bodonga bezinsimbi zensimbi akufanele bube ngaphansi kuka-8mm; ukwakheka kohlelo lokuthela kufanele kube lula futhi usayizi ohlukanisiwe kufanele ube mkhulu kunowensimbi eyakhiwe; ukusakaza okomile kuyasetshenziswa Noma isikhunta esishisayo; ukwandisa ngokufanele ukushisa kokuthela, ngokuvamile ngo-1520 ° ~ 1600 ° C, ngoba izinga lokushisa elithululayo liphezulu, insimbi encibilikisiwe inezinga eliphezulu lokushisa ngokweqile, futhi isimo samanzi sigcinwa isikhathi eside, futhi uketshezi kungathuthukiswa. Kodwa-ke, uma izinga lokushisa lokuthela liphezulu kakhulu, kuzodala ukukhubazeka okunjengokusanhlamvu okuluqhafuqhafu, imifantu eshisayo, izimbotshana nokunamathela kwesihlabathi. Ngakho-ke, izinga lokushisa lokusakazwa kokuphonswa okuncane, okunemiduli emincane nokuyindida kumayelana nokushisa kwamaphuzu okuncibilika kwensimbi + 150 ° C; ithempelesha yokusakaza yokuphonsa okukhulu, okubiyelwe ngodonga cishe kungu-100 ° C ephakeme kunephuzu layo lokuncibilika.

- 2. Njengoba ukuncipha kwensimbi eyinsimbi kudlula kakhulu okwensimbi yensimbi, ukuze kuvinjelwe izimbotshana zokuncipha kanye nokukhubazeka kokuncipha ekubunjweni, izinqubo eziningi zokuphonsa zamukela izindlela ezinjengokuvuka, insimbi ebandayo, kanye noxhaso ukuze kuzuzwe ukuqina okulandelanayo. , ukuvimbela ukuvela kwemigodi yokuncipha, i-shrinkage porosity, ama-pores kanye nemifantu ekusakazweni kwensimbi, ubukhulu bodonga kufanele bufane, amakhona abukhali nezakhiwo ze-angle efanele kufanele kugwenywe, i-sawdust ingezwa esihlabathini sokuphonsa, i-coke iyangezwa kuya emgodini, futhi ama-cores angenalutho nama-cores sand cores asetshenziselwa ukuthuthukisa ukubuyela emuva nokungena komoya kwesikhunta sesihlabathi noma ama-cores. Iphuzu lokuncibilika lensimbi lensimbi liphezulu, futhi izinga lokushisa lokusakaza kwalo liphakeme ngokufanayo. Ukusebenzisana phakathi kwensimbi encibilikisiwe nezinto zokubumba ekushiseni okuphezulu kungaveza kalula ukukhubazeka kwesihlabathi okunamathelayo. Ngakho-ke, isihlabathi se-quartz esenziwe ngokufakelwa okuphezulu kufanele sisetshenziswe njengesikhunta, futhi ingaphezulu lesikhunta kufanele lihlanjwe ngengubo eyenziwe nge-quartz powder noma i-zirconium sand powder. Ukuze wehlise umthombo wegesi, uthuthukise uketshezi lwensimbi encibilikisiwe namandla esikhunta, iningi lezinsimbi zensimbi ziphonswa ekubunjweni okomile noma kokumisa okusheshayo, njenge-CO2 lukhuni isikhunta sesihlabathi se-silicate.

- 3. Ukwelashwa ngokushisa kokufakwa kwensimbi: Zonke izinsimbi zensimbi kufanele zisetshenziswe ngemuva kokwelashwa kokushisa. Ngoba kukhona ukukhubazeka kokuphonsa okufana ne-porosity, imifantu, imbobo yokuncipha kanye ne-shrinkage porosity, okusanhlamvu okuluhlaza, ukwakheka okungalingani kanye nengcindezi yangaphakathi eyinsalela ekusakazweni kwensimbi ku-as cast cast, amandla, ikakhulukazi i-plasticity nobulukhuni be-castings yensimbi kwehliswe kakhulu.Ukuze ucwenge okusanhlamvu, ukwakheka okufanayo futhi uqede ukucindezeleka kwangaphakathi, ukusakazwa kwensimbi kufanele kusebenze ngokujwayelekile noma kufakwe. Insimbi evamile inezakhiwo eziphakeme zemishini nezindleko eziphansi kunezensimbi ezifakiwe, ngakho-ke inezicelo eziningi. Kodwa-ke, ngoba ukwelashwa okujwayelekile kuzodala ukucindezeleka okukhulu kwangaphakathi kunokuncishiswa, kulungele kuphela ukusakazwa kwensimbi okunekhabhoni engaphansi kuka-0.35%. Ngoba ukusakazwa ngensimbi engaphansi kwekhabhoni kunepulasitiki enhle, akulula ukuqhekeka ngesikhathi sokupholisa. Ukuze unciphise ukucindezeleka kwangaphakathi, ukusakazwa kwensimbi kufanele kufudumale ekushiseni okuphezulu ngemuva kokujwayelekile. Okokukhishwa kwensimbi ngokuqukethwe kwekhabhoni ≥ 0.35%, ukwakheka okuyinkimbinkimbi futhi okulula ukuqhekeka, ukwelashwa okunamathisela kuphela okungenziwa. Ukufakwa kwensimbi akufanele kucishwe, kungenjalo kuzoqhekeka kalula.

- 4. ukuncibilika kwensimbi yensimbi: Ukuncibilikiswa kwensimbi yensimbi kuvame ukusebenzisa iziko elivulekile leziko, amakhekhe kagesi kagesi namakhandlela okufakwa. Iziko elivulekile libonakala ngomthamo walo omkhulu, ukusetshenziswa kwensimbi eyisigaxa njengezinto ezingavuthiwe, ikhono lokulawula ngokunembile ukwakheka kwensimbi kanye nekhono lokuncibilikisa insimbi esezingeni eliphakeme nensimbi ene-alloy ephansi. Isetshenziselwa kakhulu ukuncibilikisa insimbi encibilikisiwe yokusakazwa kwensimbi enkulu enezidingo ezisezingeni eliphakeme.

Isithando somlilo se-arc esinezigaba ezintathu kulula ukuqala nokumisa isithando somlilo, kungaqinisekisa ukwakheka nekhwalithi yensimbi encibilikisiwe, izidingo zekhokhiso aziqinile kakhulu, futhi kulula ukuzifudumeza, ngakho-ke zingenza phezulu -quality steel, ibanga eliphakeme le-alloy steel nensimbi ekhethekile, njll Kuyinto yokubumba okukhiqizwayo okokusebenza okujwayelekile kokuphonswa kwensimbi.

Ngaphezu kwalokho, imvamisa yamandla noma isithando sokungeniswa semvamisa esiphakathi singasetshenziselwa ukuncibilikisa izinsimbi nezinsimbi ezahlukahlukene eziphakeme kakhulu ezinokuqukethwe kwekhabhoni ephansi kakhulu. Isithando somlilo sinesivinini sokuncibilikisa esisheshayo, ukulahleka okushisayo kwe-alloy element, ukusetshenziswa kwamandla okuphansi, kanye nekhwalithi ephezulu yensimbi encibilikisiwe, okungukuthi, okuqukethwe ukungcola okuphansi kanye nokufakwa okumbalwa. Ifanele amashabhu wokufundisa okusansimbi amancane.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ubuchwepheshe Bokukhiqiza Bensimbi Yensimbi

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off