Inqubo Yesakhiwo Sokuphonsa I-Shell Body Die

Ngokuya ngezici zokwakheka kwegobolondo, inqubo yokufa yakhelwe. Ngokulingiswa kwamanani wezinhlelo ezimbili zokubamba usebenzisa isoftware ye-ProCAST, kwahlaziywa izindawo nezimbangela zokuncipha kwe-pority kanye ne-porosity, kwabe sekukhethwa uhlelo olungcono lwe-gating lokwandisa inqubo yokufa ngokuqhathanisa. Imiphumela ikhombisa ukuthi ngemuva kokusebenza kahle kwenqubo, ukusakazwa akunazimbobo zokuncipha noma ukukhubazeka kwe-porosity, futhi kuqinisekiswe ngomkhiqizo, ohlangabezana nezimfuneko zobuchwepheshe

Die ekubunjweni uhlobo ekubunjweni ubuchwepheshe m ngezinga eliphezulu ezishintshayo futhi uyakwazi ukukhiqizwa ngobuningi izingxenye nge bobunjwa eziyinkimbinkimbi. Ukujula okukhiqizwe yikhona kunezinzuzo zokuhlangana okuhle, ukucacisa okuphezulu, isabelo esincane semishini, nezakhiwo ezinhle kakhulu zemishini. Isetshenziswa ezimotweni nasemishini. I-1wl isetshenziswe kabanzi kwimishini nakweminye imikhakha. Igobolondo lekhebuli yisithwali esibalulekile sokufakwa kwezingxenye ezizenzakalelayo. Udonga lwayo lucekeceke kancane, kepha izakhiwo zalo zomshini, ukunemba, nokuqina komoya kuyadingeka ukuthi kube phezulu, futhi ukukhiqizwa ngobuningi kuyadingeka. Ngakho-ke, ingcindezi ekubunjweni igobolondo engcono yokukhiqiza. Ukukhetha.

Leli phepha lihlaziya ukwakheka kokusakazwa, lidizayine uhlelo lokusakaza, bese liyilingisa nge-software ye-PmCAST. Ngokuhlaziywa kwemiphumela yokulingisa, inqubo yenzelwa ukuqeda ukukhubazeka okufana nokuncipha kanye ne-porosity, ukuze kutholakale inqubo yokuphonsa ehlangabezana nezidingo zobuchwepheshe begobolondo.

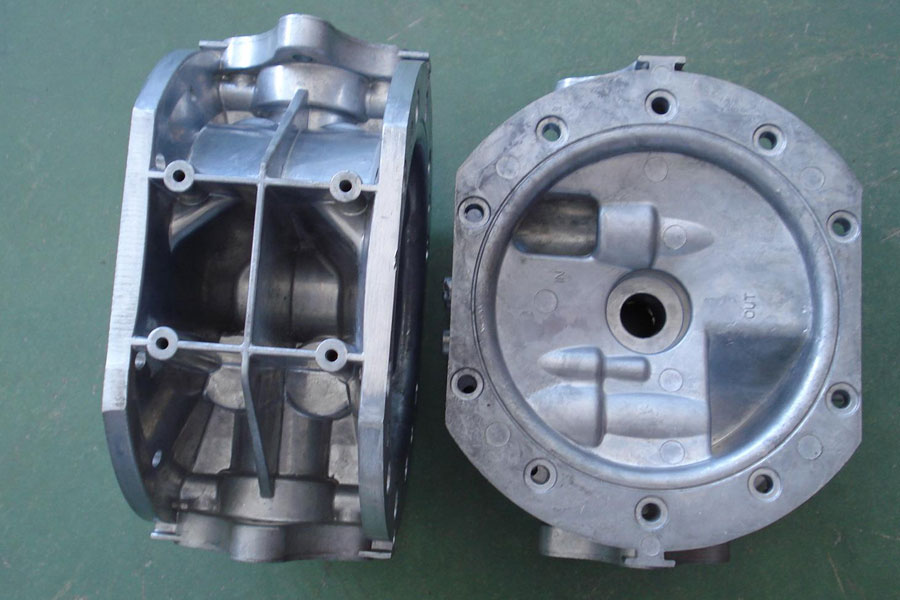

Ukusakazwa okusacwaningwa kuyizitokisi zezingxenye zemoto ezikhiqizwa inkampani ethile. Umdwebo wayo wokumodela kathathu ukhonjisiwe kuMdwebo I. Indawo emnyama ingumshini wokulingisa wokusakaza, isabelo semishini ngu-0.5 mm, nosayizi wohlaka wokuphonsa Ungu-103 mm x 98 mm x 89 mm, ukusakaza ivolumu ingu-234 108 mn r ', ubukhulu bungu-632 g, udonga olugqinsi lungu-5.5 mm, udonga oluncane kakhulu lungu-2.5 mm, futhi ubukhulu besilinganiso sobudonga bungu-3 mm. Izinto zokusakaza ziyi-Al-Si-Cu alloy YL113 enokufudumala okuhle, ukuqina komoya okuhle, nokumelana nokugqoka okuphezulu. Ukwakheka kwalo kwe-alloy kuboniswa kuThebula lw. Ama-castings adingeka ukuthi abe nobuso obushelelezi, i-engeli esalungiswa akufanele yeqe u-1.5 °, isilinganiso sokuncipha se-0.6%, futhi akufanele kube khona ukukhubazeka kwangaphakathi okufana nezimbobo zokuncipha kanye ne-porosity.

Ekuklanyweni kwesikhunta, inqubo yokufa ifa ibaluleke kakhulu, ethinta ngqo ikhwalithi yokusakaza, ukukhiqizwa kanye CNC machining izindleko, nobunzima bokwenza isikhunta. Inqubo die ekubunjweni kuhlanganisa ukukhethwa kokuvaleka komhlaba, ukwakheka kohlelo lwesango, ukwakheka kokuchichima nohlelo lokukhipha

- Ukuma kwesitokisi kunzima kakhulu, futhi kudingeka indlela yokudonsa eyinhloko. Ngakho-ke, kunzima ukwenza isikhunta. Ngakho-ke, lo thusi usebenzisa eyodwa-isikhunta-eyodwa-umgodi thusi indlela. Ngokwesimiso esiyisisekelo sokukhetha indawo yokuhlukanisa indawo, khetha indawo enkulu kunazo zonke yendawo ekhonjisiwe. Kunezindlela ezimbili zokubeka indawo zokubeka lokhu kusakaza. Njengoba kukhonjisiwe kuMdwebo 2, kusetshenziswa indawo yokuvalelisa a, kudingeka eyodwa kuphela indlela yokudonsa, kepha ukusakazwa kunembobo ejulile namandla amakhulu wokuqinisa, futhi ukuphonsa akulula ukuwa; Okwesibili, udonga lokusakaza luncane, futhi akulula ukufaka indlela yokukhipha. Nge ukuvaleka kobuso b, ukusakaza kudinga ukufakelwa izindlela eziningi zokudonsa okuyisisekelo, futhi ukukhiqizwa kwesikhunta kuyinkimbinkimbi, kepha ukusakazwa ngokuyisisekelo kuyalingana phezulu naphansi, futhi ukusakazwa kugcwaliswe kahle. Okwesibili, kulula ukusetha indlela yokukhipha, enenzuzo ekusethweni kwe-groove echichimayo ne-groove ye-exhaust, futhi isebenza kangcono Ukuhlangabezana nezidingo zenqubo yokufa, i-S text castings khetha indawo yokuhlukanisa b.

- Isango langaphakathi lingahlukaniswa libe: isango elingaphakathi eliyisicaba, isango eliseceleni kobuso bokugcina, isango langaphakathi maphakathi, isango langaphakathi eliyiminyaka, njll. 16]. Igobolondo lingelohlobo lwama-cylindrical. Ukuze kugwenywe umthelela oqondile wensimbi encibilikisiwe engxenyeni kanye nokuvela kokunamathela, lezi zinhlelo ezimbili zokufaka igeyithi zamukela ukuphakelwa kwangaphakathi kwesango okunethezeka, okungukuthi, umgijimi oyiminyaka usethwe ohlangothini lokusakaza, futhi okuncibilikisiwe insimbi iyagcwaliswa Ngemuva kokuthi umgijimi we-annular engena emgodini, insimbi encibilikisiwe ingathola cishe ijubane elifanayo kumjikelezo we-annular, ukuze insimbi encibilikisiwe igcwalise kahle futhi igesi esemgodini ikhishwe kalula. Okwesibili, kungenzeka futhi ukufaka induku yokududula esangweni elingaphakathi ukugwema imikhondo yenduku yohlelo ekusakazweni.

- Umgijimi uyisiteshi esiguqukayo sensimbi encibilikisiwe kusuka ku-sprue kuya esangweni elingaphakathi. Ngokuphonswa okwehlukile kokufa, umgijimi unezakhiwo ezahlukahlukene, nangenxa yokuphonswa kwamasilinda, isakhiwo esinenkontileka se-arc samukelwa. Ukuze uvimbele ingcindezi engemihle lapho insimbi encibilikisiwe igeleza, indawo enqamulelayo yomgijimi kufanele yehliswe kancane kancane

- I-sprue iyisiteshi esiyinhloko sensimbi encibilikisiwe ukungena emgodini ovela kumshini wokulingisa. Usayizi wayo uhlobene nobubanzi begumbi lokucindezela lomshini wokulingisa wokufa. Kulolu cwaningo, ububanzi begumbi lokucindezela liyi-60 mm, ubukhulu bezinto ezisele busethwe ku-10 mm, futhi i-engeli esalungiswa ingu-10 °.

- Ngenisa ukumodeliswa kwe-3D kusoftware yokulingisa i-ProCAST yokuhlukaniswa kwegridi, setha usayizi weyunithi yokusakaza yegridi ibe ngu-2 mm, nosayizi weyunithi yegridi yesikhunta ibe ngu-10 mm

- Ukuze kwenziwe ukusakaza kuqiniswe ngokufanayo ekujiyweni kodonga, lolu cwaningo lusethe isiteshi samanzi sokupholisa ngqo ngaphansi kwe-porosity shrinkage kanye nendawo yomgodi wokuphonsa, bese usetha izindawo ezimbili zokuchichima endaweni lapho i-shrinkage porosity ne-shrinkage Indawo yomgodi igxiliwe ukuyenza iqede ngokuphelele igesi nokufakwa, ukudluliswa kwezikhundla zokuncipha, futhi uhlelo lwenqubo elungiselelwe luboniswa ku-Figure 10. 2 / (• K), neminye imingcele ihlala ingashintshiwe

- Ngokwakheka kwegobolondo, izinhlelo ezimbili zokubiyela zokuphonsa zenzelwe, futhi isoftware yeProCAST isetshenziselwa ukwenza ukulingiswa kwamanani kuzo. Imiphumela ikhombisa ukuthi abaphosayo banemigodi yokuncipha kanye nokukhubazeka kokuncipha odongeni; isango elingaphakathi lihlelwe ngogqinsi lodonga olude. Kunezimbobo ezimbalwa zokuncipha kanye nokukhubazeka endaweni. Ukuhlaziywa kutholakale ukuthi isizathu sokuncipha komgogodla kanye ne-porosity yokusakaza ukuthi ukusakazwa kuqiniswa ngokungalingani ebangeni lobonda, futhi ingxenye yendawo iqhelelene futhi ayinakondliwa.

Ngokusebenzisa inqubo, ukukhishwa kwenziwa mahhala ngezimbobo zokuncipha kanye nokukhubazeka kwe-porosity, futhi inqubo elungiselelwe isetshenziselwa ukuqinisekisa ukukhiqizwa. Ngokuhlolwa, kutholakala ukuthi azikho izimbobo zokuncipha kanye ne-shrinkage porosity defects ngaphakathi kwe-castings, futhi ihlangabezana nezidingo zobuchwepheshe, ezingasetshenziswa ukuqondisa ukwakheka kwenqubo efanayo yokuphonsa inqubo yokuphonsa.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Inqubo Yesakhiwo Sokuphonsa I-Shell Body Die

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off