Inqubo Yokwelashwa Kokushisa Ingxoxo Ye-Aluminium-Magnesium Alloy Die-casting Mold

Ukusetshenziswa kokwelashwa okuqinisayo nenqubo yokwelashwa yokuqinisa indawo kuyindlela ebalulekile yokukhiqiza yokwenza ngcono ukusebenza nempilo yesikhunta.Ngokuya kwezimo zokusebenza nezidingo zokusebenza kwe-aluminium-magnesium alloy die-casting molds, lesi sihloko sihlaziya izici zesikhunta ukwelashwa kokushisa nezinqubo ezijwayelekile ngokuningiliziwe, futhi kukhombisa ukuthi ukwakheka okufanele kwenqubo yokwelashwa kokushisa kungaqinisekisa ubulukhuni besikhunta, ukugqoka ukumelana, amandla ayisisekelo nobulukhuni, futhi kuvimbele ukugqwala kwensimbi ketshezi. Ukunamathela kusikhunta kunganciphisa ngempumelelo isilinganiso sezinto ezilahliwe futhi kukhulise kakhulu impilo yenkonzo yesikhunta.

Ama-alloys e-Aluminium-magnesium asetshenziswa kabanzi nangaphezulu ngenxa yobuningi bawo namandla awo aphezulu. Phakathi kwabo, i-aluminium-magnesium alloy die-casting technology, njengenqubo yokusika esezingeni eliphakeme, inezici zokusebenza kahle kokukhiqiza, ukonga izinto zokusetshenziswa, ukunciphisa izindleko zokukhiqiza, ukusebenza kahle komkhiqizo, nokunemba okuphezulu. , Isetshenziswa kakhulu ku-elekthronikhi, izimoto, izinjini, izinto zasendlini nezinye izimboni, okunye ukusebenza okuphezulu, ukucacisa okuphezulu, ukuqina okuphezulu imikhiqizo ye-aluminium-magnesium alloy nayo isetshenzisiwe ezindizeni ezinkulu, emikhumbi nakwezinye izimboni ezinokuqhathaniswa izidingo zobuchwepheshe eziphakeme.

Izimo zokusebenza nezidingo zokusebenza kwe-aluminium-magnesium alloy die-casting molds

Aluminium-magnesium alloy die-casting mold is a molding die used to die-cast aluminium-magnesium alloy castings on a die-casting machine. Iphuzu lokuncibilika kwe-aluminium alloy lingu-600 ~ 750 ℃, futhi iphuzu lokuncibilika kwe-magnesium alloy lingu-600 ~ 700 ℃. Izinga lokushisa elisebenza ngokujwayelekile lingakhuphukela ku-500 ~ 600 ℃. Ubuso bomgodi, i-mandrel kanye nombhobho konke kubhekene nokushintshashintsha okukhulu kwezinga lokushisa, futhi ubuso besikhunta bujwayele imifantu yokukhathala okushisayo. Ngaphezu kwalokho, i-aluminium-magnesium alloy kulula ukunamathela ebusweni besikhunta ngesikhathi senqubo yokufa, ethinta ukusebenza okuqhubekayo kokukhiqizwa kokufa. I-liquid aluminium-magnesium alloy inomphumela oqinile wokuguguleka ebusweni besikhunta. Ngakho-ke, ukwenza isikhunta se-aluminium-magnesium alloy die-casting, okokusebenza kwesikhunta kuyadingeka ukuze kube nokuqina okuphezulu kokushisa nokumelana nokukhathala okubandayo nokushisa cishe ngo-600 ° C, futhi kumelane nokushisa okuphezulu, umfutho ophakeme, isivinini esikhulu, nokumelana nokuguguleka okuphezulu kwama-alloys e-liquid aluminium-magnesium. Amandla nobulukhuni besikhunta, futhi ngasikhathi sinye, ukwelashwa okufanelekile kokushisa kuyadingeka ukuthepha amandla wento yokubumba nokwenza ngcono impilo yenkonzo yesikhunta. Njengamanje, izinsimbi ezi-die-casting die-casting die-casting die zihlanganisa: 3Cr2W8V steel, 4Cr5MoSiV1 steel, 4Cr3Mo3SiV steel, 4Cr5MoSiV steel, kanye nezinhlobo ezintsha zensimbi i-4Cr5Mo2MnSiV1 steel ne-3Cr3Mo3VNb steel.

Inqubo yokukhiqiza ye-aluminium-magnesium alloy die-casting mold

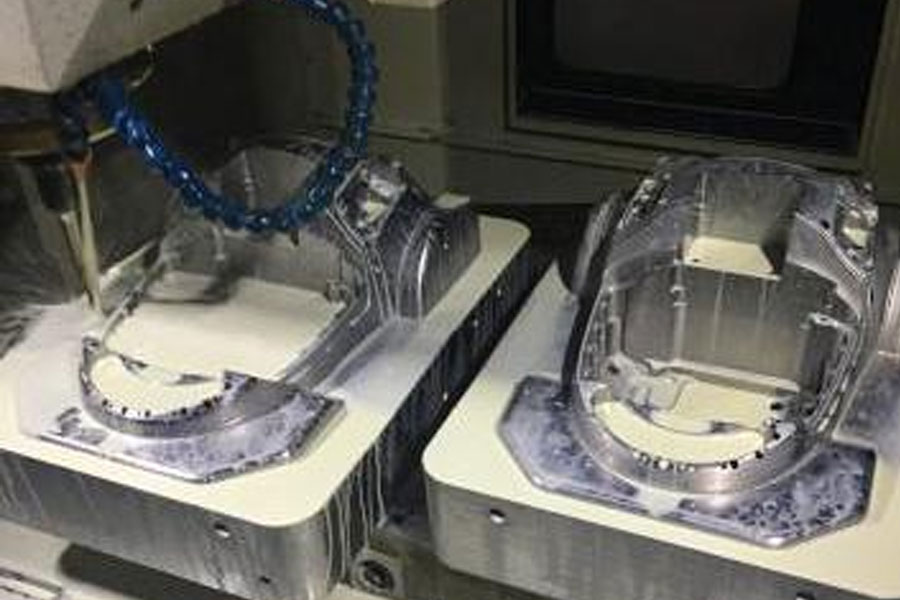

Inqubo yokukhiqiza ye-aluminium-magnesium alloy die-casting mold is: blanking → ekwakheni → spheroidizing annealing → machining → quenching, tempering → repairing, grinding, polishing → nitriding (nitrocarburizing) → assembly and use.

Ukuqinisa nokuqinisa inqubo yokwelashwa kwe-aluminium-magnesium alloy die-casting mold

Ukwelashwa okuqinile kwesikhunta se-aluminium-magnesium die-casting ukuguqula ukwakheka kwensimbi ukuthola isakhiwo esidingekayo nokusebenza kwesikhunta. Ukwelashwa ngokushisa kufanele kususelwe kokuqukethwe kwesikhunta, ukwakheka kwesikhunta, usayizi, kanye nobunzima ukucacisa inqubo yenqubo yokwelashwa kokushisa.

Ukwelashwa kwangaphambi kokushisa

Ukwelashwa kwangaphambi kokushisa kwesikhunta sokuphonsa kungamukela izinqubo ezintathu: ukufakelwa okuqhubekayo, ukufakelwa kwe-isothermal kanye nokuqeda ukwelashwa kokushisa. Inhloso ukuthola isakhiwo esifanayo kanye ne-carbide ehlakazekile ngaphambi kokwelashwa kokugcina kokushisa ukwenza ngcono ukuqina kwensimbi. Inqubo eqhubekayo yokuncisha umbhobho ilula, futhi nesakhiwo esingcono se-granular pearlite singatholakala. Okwembumbulu lokuphonsa ngokufa okunobunzima obuyinkimbinkimbi kanye nezidingo eziphakeme, ukufakwa kwe-isothermal kungasetshenziswa ukuthola isakhiwo se-pearlite esihle kakhulu.

3.2 Ukucima nokushisa

I-die-casting isikhunta sensimbi ikakhulu ingxubevange yensimbi enokuqhuba okungahambi kahle kokushisa. Izinyathelo zokushisa kuqala zivame ukuthathwa ngesikhathi sokucima nokushisa. Inani lokushisa nokushisa lincike ekwakhiweni kwensimbi yokufa kanye nezidingo zokuguqulwa kwesikhunta. Kwisikhunta esinokushisa okuphansi okucimayo, ukuma okulula kanye nezidingo eziphansi zokukhubazeka, kudingeka ukushisa (800 ~ 850 ℃) ngesikhathi sokucima nokushisa ngaphandle kokuqhekeka. Okokubumba okunokushisa okuphezulu kokushisa, ubujamo obuyinkimbinkimbi nezidingo eziphakeme ze-deformation, ukushisa kwesibili (600-650 ° C, 800-850 ° C) kuyadingeka. Inhloso ukunciphisa ukucindezeleka okwenziwe ngesikhathi senqubo yokushisa futhi ngasikhathi sinye wenze ukwakheka okuphelele komfaniswano wesikhunta.

3.3 Ukucima ukushisa

Izinga lokushisa elicishayo lesikhunta sokufa lingasetshenziswa ngokuya ngemininingwane ecisha ukushisa yebanga ngalinye lensimbi. Isibonelo, izinga lokushisa lokucisha lensimbi le-3Cr2W8V lingu-1050 ~ 1150 ℃, kanti izinga lokushisa lokucisha lensimbi le-H13 lingu-1020 ~ 1100 ℃. Ukunyusa izinga lokushisa lokucisha ama-steels amabili kungakhuphula amandla okushisa aphezulu kanye nokuqina kokukhathala okushisayo kwesikhunta sokuphonsa, kepha kuzokwandisa ukuguqulwa kwesikhunta. Lapho kufudunyezwa esithandweni sokugeza sikasawoti, ukuze kugwenywe ukwehla kwe-oxidative ebusweni besikhunta, kufanele kusetshenziswe indawo yokugeza usawoti i-barium chloride ene-deoxidation enhle, futhi kufanele kwenziwe i-deoxidation njalo. Lapho kufudunyezwa esithandweni sebhokisi lokumelana nebhokisi, kufanele kuvunyelwe isimo sokuvikela; noma ukufudumeza esithandweni sebhokisi lohlobo lokumelana nomshini ngemuva kokupakisha. Ukuze kuqinisekiswe ukuchithwa okugcwele kwe-carbides, thola i-austenite efanayo, futhi uthole ukusebenza okuhle okushisa okuphezulu, isikhathi sokucima nokushisa sokubamba isikhunta sokufa kufanele sandiswe ngokufanele. Ngokuvamile, ukushisa okuphethe ukushisa esithandweni sokugeza sikasawoti kungu-0.8-1.0 min / mm.

3.4 Qeda ukupholisa

Izinga lokucima uwoyela liyashesha futhi ukusebenza okuhle kungatholwa, kepha ukuthambekela kokukhubazeka nokuqhekeka kukhulu. Ngokuvamile, isikhunta sokuphonsa u-oyela opholile ngamafutha ngobunjwa obulula nezidingo eziphansi zokusonteka kuyasetshenziswa; ukuthola isikhunta sokufa esinezimo eziyinkimbinkimbi nezidingo eziphakeme ze-deformation, ukucisha ubuholi kufanele kusetshenziselwe ukuvimbela ukuguqulwa kwesikhunta nokuqhekeka. Ukupholisa ukucima kufanele kube kuhamba kancane ngangokunokwenzeka ukunciphisa ukucinywa kwe-quenching, ukufudumeza nokucisha esithandweni sokumelana nomshini, ukupholisa kungamukelwa kucisha igesi. Ukushisa nokuqeda endaweni yokugeza kasawoti, futhi ukucisha ukulinganisa kungenziwa lapho kupholile. Lapho isikhunta sicinyiwe futhi selehlile, ngokuvamile sipholile sibe ngu-150 ~ 200 ℃ bese sithanjiswa ngokushesha ngemuva kokucwila. Akuvunyelwe ukupholisa ekamelweni lokushisa.

3.5 Ukushisa

Ubulukhuni isikhunta die-ekubunjweni kufinyelelwa tempering, futhi ubulukhuni die-ekubunjweni isikhunta umgodi ngqo kuthinta ashisayo nabandayo ukuphila ukukhathala isikhunta. Izinto ezahlukahlukene, ukushisa okuhlukile okucimayo, nokushisa okushisa nakho kwehlukile. Ngokwesibonelo, ubulukhuni 3Cr2W8V steel aluminium-magnesium ingxubevange die-ekubunjweni isikhunta ngokuvamile 42 ~ 48HRC, futhi tempering ithempelesha yayo ngokuvamile kukhethwe phakathi 560 ~ 620 ℃, kodwa uma high lokushisa eqeda isetshenziswa, izinga lokushisa tempering kuyinto phezulu njengoba 670 ℃. Ubulukhuni ngemuva kokucima ku-1150 ° C nokushisa ku-650 ° C yi-45HRC; ngenkathi ubunzima ngemuva kokucima ku-1050 ° C nokushisa ku-650 ° C kungu-35HRC. Ubulukhuni be-H13 steel aluminium-magnesium alloy die-casting mold is required to be 44 ~ 50HRC. Ukuphakama kwesibili kwensimbi ye-H13 kuvela lapho kufutheliswa ku-500 ℃, kepha ubukhulu besiqongo buhlobene nokushisa okucimayo. Izinga lokushisa elifudumele ngokuvamile liyi-560 ~ 620 ℃. Ukushisa kufanele kwenziwe izikhathi ezimbili kuya kwezi-2. Izinga lokushisa lokuqala lingaba ngaphansi. Ngemuva kokubamba kokuqala, linganisa inani lobulukhuni. Uma imfuneko ubulukhuni kufinyelelwa, izinga lokushisa tempering kufanele sehliswe 3 20 ℃ ukugwema Ubulukhuni kuyehla. Uma ubulukhuni buphakeme kakhulu, lungisa ithempelesha yokushisa ngokufanele ukuhlangabezana nemfuneko yobulukhuni ngokusho kobulukhuni obuphakeme. Ithempeli lesithathu ukuthuthukisa ukuqina, izinga lokushisa lokushisa kufanele libe ngaphezulu kunelesibili

Izinga lokushisa lesibili lingu-30 ~ 50 ℃ ngaphansi. Isikhathi esivuthayo nesokubamba kufanele sanele ukuqeda ukucindezela okwenziwe ngesikhathi sokucima nokunciphisa ukwakheka kwemifantu yesikhunta. Isikhathi sokubamba ukufutheka ngakunye ngu-2h, futhi isikhathi sokubamba isikhunta esikhulu sinwetshiwe ngokufanele. Ngenxa yengcindezi ephezulu yokushisa nokushisa kwe-microstructure ye-die-casting die ngemuva kokucima, idayivu ivamise ukufuthelana ngokushesha ngemuva kokupholisa iye ku-150-200 ° C.

Inqubo yokwelashwa eqinisa ukwenziwa kwesikhunta se-aluminium-magnesium alloy die

Ngemuva kokucima nokushisa, ubukhulu bendawo ye-aluminium-magnesium alloy die-casting die ayiphezulu kakhulu. Ukuze uthole ubulukhuni obuphakeme futhi ugqoke ukumelana ebusweni besikhunta, ngenkathi ingxenye eyinhloko isalokhu inamandla anele nokuqina, nokwenza ngcono ukusebenza okulwa nokunamathela kwesikhunta se-aluminium-magnesium alloy kungenziwa ngesikhunta. Ukwelashwa kweCarburizing.

4.1 Ukwelashwa kwe-Nitriding

I-Nitriding inqubo yokwelapha ukushisa ye-nitriding ebusweni bensimbi ukukhulisa ukuhlushwa kwe-nitrogen kusendlalelo esingaphezulu. Inhloso ye-nitriding ukunciphisa ukuguqulwa kwezingxenye zesikhunta, ukuthuthukisa ubulukhuni bomhlaba, ukugqoka ukumelana, amandla okukhathala nokumelana nokuqina kwesikhunta se-aluminium-magnesium alloy die-casting, sithuthukise ukumelana nokubola kwesikhunta ngokumelene nomoya nomoya oshisayo, futhi uthuthukise ukumelana nokushisa nokuthamba. Ukuzwela kwe-notch. I-nitriding eqinile, i-nitriding ewuketshezi kanye negesi nitriding izindlela ezivamile ze-nitriding. Ubuchwepheshe obusha obufana ne-ion nitriding, i-vacuum nitriding, i-electrolytic nitriding ne-high-frequency nitriding inganciphisa kakhulu umjikelezo we-nitriding, ithole ungqimba lwekhwalithi ephezulu ye-nitriding, futhi ithuthukise ukusebenza kahle kwezomnotho kwamabhizinisi, ngakho-ke asetshenziswa kakhulu ekukhiqizeni.

4.2 I-Nitrocarburizing

INitrocarburizing i-ammonia kanye nophuzo oludakayo (i-methanol, i-ethanol) kanye nemithombo yezindaba ehlangene enjenge-urea, i-formyl glue ne-triethanol glue. Ukuphendula kokubola okushisayo kwenzeka ezingeni lokushisa elithile ukukhiqiza i-nitrogen ne-carbon athomu esebenzayo, efakwa ngama-alloys e-aluminium-magnesium. Ngemuva kokumunwa kobuso besikhunta, buyahluka futhi bungene kungqimba lwesikhunta ukuze kutholwe ungqimba lwe-nitrocarburizing olususelwa ku-nitrogen, ukuze isikhunta sithole ubulukhuni obuphezulu, ukumelana nokukhathala, ukugqoka ukumelana nokumelana nokugqwala. Izindlela zeNitrocarburizing zifaka izindlela zoketshezi negesi, futhi izindlela eziningi ezisetshenziswayo ekukhiqizeni yigesi i-nitrocarburizing. Isikhunta se-H13 steel aluminium alloy die-casting sishiswa ngezigaba ezimbili zokwelashwa ngaphambi kokushisa ku-550 ℃ × 40min naku-850 ℃ × 40min esithandweni sokushisa sikasawoti esisezingeni eliphakeme, sicinyiwe ngo-1030 ℃, sithanjiswe ngo-600 ℃, bese sihanjiswa ukwelashwa igesi nitrocarburizing ukushisa at 580 ℃. Ubulukhuni ngenhla 900HV, ubulukhuni matrix kuyinto 46 ~ 48HRC, ukumelana bafake, ukukhathala ukumelana, futhi ukugqwala ukumelana isikhunta ngcono kakhulu, futhi akukho adhesion, uyaxebuka, imihuzuko kanye ukugqwala, okuyinto ngempumelelo kuthuthukisa impilo isikhunta.

Isiphetho

Njengomshini obalulekile wokucubungula, isikhunta se-aluminium-magnesium alloy die sinomthelela oqondile kwikhwalithi yomkhiqizo nasezinzuzo zezomnotho zenkampani. Ukuphenya kanye nezibalo kukhombisa ukuthi ukwehluleka kwesikhunta ngenxa yenqubo engafanele yokwelashwa kokushisa kubangela cishe amaphesenti angama-50 okwehluleka okuphelele. Ngakho-ke, ukukhetha okunengqondo kokuqiniswa nokuqinisa ukwelashwa kanye nezinqubo zokwelashwa eziqinisa indawo nokulawulwa okuqinile kokucaciswa kwenqubo yokwelashwa kokushisa kuyizindlela ezibalulekile zokwenza ngcono ukusebenza kwesikhunta nempilo. Ekukhiqizeni isikhunta se-aluminium-magnesium alloy die-casting, kuyadingeka ukuhlaziya nokutadisha ukwehluleka izimbangela ngokuya ngezimo zokusebenza kwesikhunta, futhi kuqondwe kahle izinqubo zokwelashwa kokushisa ukuqinisekisa ubulukhuni besikhunta, ukugqoka ukumelana, amandla ayisisekelo nobulukhuni, ukuvimbela insimbi ukugqwala ketshezi nokunamathela kwesikhunta, futhi kunciphise ngempumelelo inani lokwenqatshwa, Kakhulu kuthuthukise impilo yesevisi yesikhunta.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Inqubo Yokwelashwa Kokushisa Ingxoxo Ye-Aluminium-Magnesium Alloy Die-casting Mold

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off