Izinyathelo Zokuthuthukisa Impilo Ye-Aluminium-Magnesium Alloy Die Casting Mold

Njengomshini obalulekile wokucubungula, isikhunta se-aluminium-magnesium alloy die sinomthelela oqondile kwikhwalithi yomkhiqizo nasezinzuzo zezomnotho zenkampani. Ubuchwepheshe besikhunta nokwelashwa kokushisa yizinto eziyinhloko ezithinta impilo ye-aluminium-magnesium alloy die-casting molds. Lo mbhalo uhlaziya izindlela eziyinhloko zokuhluleka kwe-aluminium-magnesium alloy die-casting molds, sethula kafushane izinsimbi zesikhunta nezindlela ezijwayelekile zokwelashwa kokushisa, futhi iveze ukuthi ukukhetha okunengqondo kwezinto zokwenziwa kanye nezinqubo zokwelashwa kokushisa kungathuthukisa kakhulu ukuzinza kwesikhunta, ukuqina , gqoka ukumelana, nokuqina kokushisa. Izici ezifana nokukhathala nokuqhuba okushisayo, ngaleyo ndlela kwandise impilo yesevisi yesikhunta.

Imodi Yokwehluleka Ye-Aluminium-Magnesium Alloy Die Casting Mold

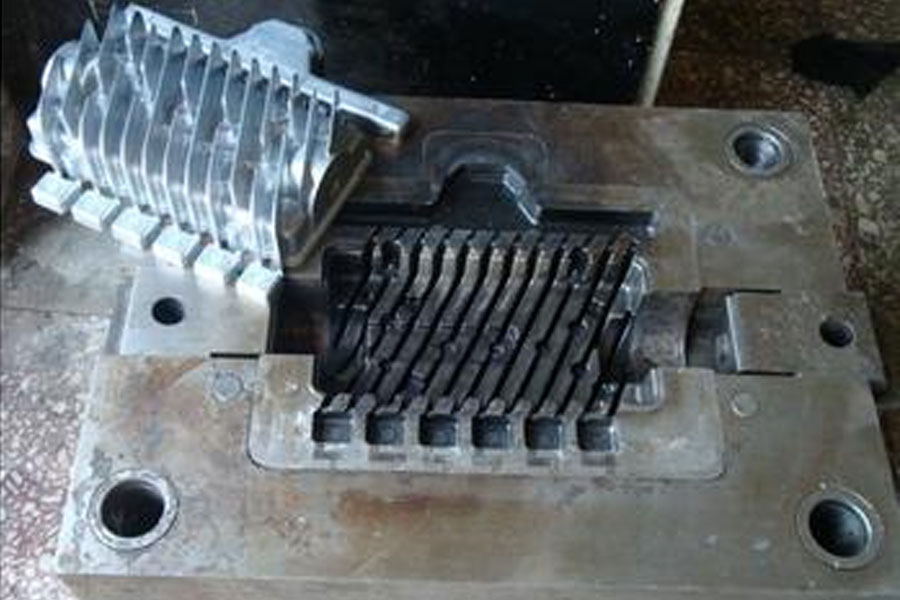

Isikhunta se-aluminium-magnesium alloy die-casting is isikhunta esakha ukusetshenziselwa ukusakaza i-aluminium-magnesium alloy castings kumshini wokuphonsa. Izinga lokushisa lomgodi lingafinyelela cishe ku-600 ℃ ngesikhathi somsebenzi, futhi uketshezi oluncibilikisiwe lwe-aluminium-magnesium alloy kulula ukunamathela ezintweni zensimbi. Ukusetshenziswa kaningi kwezingubo zokulwa nenduku emgodini wesikhunta kubangela ukushintshashintsha okukhulu ekushiseni komhlaba komgodi. Izindlela eziyinhloko zokwehluleka ukunamathela kwesikhunta, ukuguguleka komhlaba, ukukhathala nokushisa. Lapho isakhiwo sesikhunta somgogodla siyinkimbinkimbi futhi kukhona ukugxila kokucindezeleka, isikhunta sizophuka futhi sihluleke ngaphansi kwesenzo esihlanganisiwe somthwalo oshisayo nomthwalo womshini.

1.1 Isikhunta Esinamathelayo

Lapho izingxenye ze-aluminium-magnesium alloy kanye nobuso besikhunta zihamba, ngenxa yendawo engalingani, ingcindezi yendawo yamaphoyinti wokuxhumana idlula amandla esivuno sento yokubopha, futhi amalunga aboshiwe ayasikwa futhi aqhekeke ahlukaniswe, okwenza izinto ezingaphezulu zesikhunta Dlulisela ku-workpiece noma uwe.

1.2 Ukuguguleka kwenhlabathi

Lapho indawo yesikhunta ixhumana ne-aluminium-magnesium alloy liquid yokuhamba okuhambisanayo, i-bubble yakhiwa lapho kuthintwa phakathi kuketshezi nesikhunta kuqhekeka futhi kukhiqize umthelela osheshayo nokushisa okuphezulu, okwenza indawo yesikhunta yenze imigodi emincane nemigodi. I-aluminium-magnesium alloy liquid nezinhlayiya ezincane eziqinile ziwela ngesivinini esikhulu futhi zithinta kaningi ubuso besikhunta, zidale ukulahleka kwempahla yendawo futhi zenze imigodi nemigodi ebusweni bensimbi. Ngaphansi kwesenzo esiphindaphindwayo, imifantu yokukhathala izokhula ebusweni besifo, futhi kuzokwenzeka ngisho nokwaphuka kwendawo.

1.3 Ukukhathala Okushisayo

Ubuso besikhunta bufakwa ngokuphindaphindiwe ekushiseni nasekupholiseni ukudala ukukhathala nokwakha imifantu. Isizathu esiyinhloko sokuqhekeka kwesikhunta se-aluminium-magnesium alloy die - umehluko phakathi kokushisa okuthelayo nokushisa okushisa ngaphambili kwesikhunta. Uma kukhulu umehluko wezinga lokushisa, ngokushesha izinga lokupholisa, kuba lula ukuthi kube khona imifantu yokukhathala ezishisayo. Okwesibili, isivinini somjikelezo oshisayo, inqubo yokwelashwa kokushisa kwesikhunta kanye nokwelashwa kweSurface nakho kuhlobene kakhulu.

1.4 Gqoka

Ngoba ukungqubuzana phakathi kobuso besikhunta nezingxenye ezicutshungulwe ezinokushisa okuphezulu kwe-aluminium-magnesium alikwazi ukuthanjiswa, futhi okokusebenza okuphezulu okushisa kufakwe i-oxidized, ubuso besikhunta sesikhunta buthambile futhi buthambile, futhi ubulukhuni obuphansi buyandisa ukugqoka. Ukugqoka okunzima kuvimbela isikhunta ekusebenzeni kwemikhiqizo efanelekile. Ukuthatha umhlalaphansi akuvumelekile.

1.5 Ikhefu

Umkhuba wokuthi isikhunta se-aluminium-magnesium alloy die-casting sinemifantu emikhulu noma ukwehlukana okuncane ngesikhathi somsebenzi futhi ilahlekelwa yikhono layo elijwayelekile lokusebenza ibizwa ngokuthi ukwehluleka ukuphuka. Ukwephuka kwesikhunta kuvame ukubonakaliswa njengezicucu zendawo noma isikhunta sonke sihlukaniswe saba izingxenye eziningana.

Ukukhethwa Kwe-Aluminium Magnesium Alloy Die Casting Die Steel

Uhlobo lwento yokubumba, ukwakheka kwamakhemikhali, ukwakheka kwe-metallographic, ubulukhuni, ukuqina, isakhiwo se-hypoploid nezinye izinto ezibanzi yizizathu ezibalulekile zokwehluleka kwesikhunta se-aluminium-magnesium alloy die. Izimo zokusebenza ezingezinhle zidinga isikhunta se-aluminium-magnesium die-casting ukuze siphezulu Ukusebenza kokuqina kwe-anti-tempering nokumelana nokukhathala okubandayo nokushisa, kunokumelana okuhle nokushisa okuphezulu, umfutho ophakeme kanye nejubane elikhulu uketshezi lwe-aluminium-magnesium alloy. amandla aphezulu nokuqina.

Insimbi engu-2.1 3Cr2W8V (H21)

Iqukethe izinto eziningi ze-tungsten, i-chromium, ne-vanadium, inokuqina okuphezulu, ukuzinza kwe-tempering namandla okushisa. Kuyinto efanelekayo die-ekubunjweni isikhunta nge high eziveza umthamo, amandla okusezingeni eliphezulu ezishisayo futhi okusezingeni eliphezulu tempering ukuzinza.

2.2 4Cr5MoSiV1 (H13) insimbi

Inokuqina okuphezulu nokumelana nokukhathala okubandayo nokushisa, futhi akulula ukukhiqiza imifantu yokukhathala okushisayo. Noma kuvela imifantu yokukhathala okushisayo, mincane futhi imifushane, futhi akulula ukuyinweba. Akunasidingo sokufudumeza ngaphambi kokusetshenziswa, futhi kungapholiswa ngamanzi ompompi. Amandla okushisa.

2.3 4Cr5Mo2MnSiV1 (Y10) insimbi

I-Molybdenum enengxenyenamba yesisindo engaba ngu-2% ingeziwe, ingezelelwa ngezinto ezifana ne-vanadium nodaka ukwenza ngcono ukuzinza okushisayo, futhi amanani afanele we-silicon ne-manganese ayengezwa ukukhulisa amandla e-matrix, ngokusebenza kahle kokukhathala nokushisa nokumelana ukugqwala kwensimbi encibilikisiwe.

2.4 4Cr5MoSiV (H11) Insimbi

Ngeyetungsten hot hot die die. Inokuqina okuhle ngaphansi kwezimo zokushisa okuphakathi, amandla amahle wokushisa, ukusebenza kokukhathala okushisayo nokuqina okuthile kokugqoka. Kuphefumula umoya nokushisa kushiswa ngaphansi kwezimo zokushisa eziphansi. I-deformation incane, ukuthambekela kokukhiqiza isikali se-oxide ngesikhathi sokucima umoya kuncane, futhi kungamelana nomphumela wokuguguleka kwe-aluminium encibilikisiwe.

2.5 3Cr3Mo3VNb (HM3) Insimbi

Uhlobo olusha lwamandla aphezulu nobulukhuni obushisayo bokwakha insimbi yensimbi, enezela umkhondo we-elementi Nb ngaphansi kwesimo sokuqukethwe kwekhabhoni ephansi ukwenza ngcono ukumelana nokuqina namandla okushisa, inomphumela osobala wokuqina okuqinile, futhi inganqoba ngempumelelo isikhunta Ukwehluleka kokuqala ngenxa ukugqoka okushisayo, ukukhathala okushisayo, ukuqhekeka okushisayo, njll.

2.6 4Cr3Mo3SiV (H10) Insimbi

It has ubulukhuni ephakeme, ukushisa ukumelana futhi bafake ukumelana at lokushisa ukusebenza ka 500 ~ 600 ℃, futhi has a hardenability enhle kakhulu futhi ubunzima, high ukumelana tempering nokuzinza ezishisayo kukhona ephakeme ukwedlula H13 steel, umthelela ubulukhuni Ubulukhuni nokuqhekeka ubunzima kuphakeme kunalokho wensimbi engu-3Cr2W8V. Lapho izinga lokushisa lokushisa lidlula i-260 ℃, ubunzima bensimbi buphakeme kunobo bensimbi engu-H13. Ukusetshenziswa kwezinto ezinamandla amakhulu futhi ezinzima zesikhunta kuyindlela ebaluleke kakhulu yokwenza ngcono ukusebenza kwe-aluminium-magnesium alloy die-casting molds nokwelula impilo yenkonzo yesikhunta. Isibonelo, isikhunta esithile sicutshungulwa ngqo ngensimbi engu-3Cr2W8V. Ubukhulu φ180x85mm, ubulukhuni imfuneko 42 ~ 46HRC, kungaba kuphela die-cast 249 ekukhiqizweni nasekusebenziseni,

Izingcezu ezingama-900. Kamuva, yenziwa nge-4Cr3Mo3SiV, futhi impilo yenkonzo yakhushulwa yaba izingcezu eziyi-1000.000.

Ukukhethwa Kwenqubo Yokwelapha Ukushisa Kwe-Aluminium-Magnesium Alloy Die-casting Mold

Ukwelashwa kokushisa kwesikhunta se-aluminium-magnesium die-casting ukushintsha ukwakheka kwensimbi yesikhunta, ukuze isikhunta sikwazi ukuthola isakhiwo esidingekayo nokusebenza, futhi sikwazi ukunweba impilo yenkonzo yesikhunta. Incazelo yenqubo yokwelashwa kokushisa kufanele inqunywe ngokuya ngezinto zokubumba, ukwakheka kwesikhunta, usayizi nobunzima.

3.1 Ukwelashwa kwangaphambi kokushisa

Ukwelashwa kwangaphambi kokushisa kwesikhunta sokuphonsa kungamukela izinqubo ezintathu: ukufakelwa okuqhubekayo, ukufakelwa kwe-isothermal kanye nokuqeda ukwelashwa kokushisa. Inhloso ukuthola isakhiwo esifanayo kanye ne-carbide ehlakazekile ngaphambi kokwelashwa kokugcina kokushisa ukwenza ngcono ukuqina kwensimbi. Inqubo eqhubekayo yokuncisha umbhobho ilula, futhi nesakhiwo esingcono se-granular pearlite singatholakala. Okwembumbulu lokuphonsa ngokufa okunobunzima obuyinkimbinkimbi kanye nezidingo eziphakeme, ukufakwa kwe-isothermal kungasetshenziswa ukuthola isakhiwo se-pearlite esihle kakhulu.

3.2 Ukucima Nokushisa

I-die-casting isikhunta sensimbi ikakhulu ingxubevange yensimbi enokuqhuba okungahambi kahle kokushisa. Izinyathelo zokushisa kuqala zivame ukuthathwa ngesikhathi sokucima nokushisa. Inani lokushisa nokushisa lincike ekwakhiweni kwensimbi yokufa kanye nezidingo zokuguqulwa kwesikhunta. Okwabumba abanokushisa okucimayo okuphansi, ukwakheka okulula, nezidingo eziphansi ze-deformation, kufanele kwenziwe ngaphambi kokushisa (800 ℃ ~ 850 ℃) ngesikhathi kucishwa ukushisa ngaphandle kokuqhekeka. Okokubumba okunokushisa okuphezulu kokushisa, ubujamo obuyinkimbinkimbi nezidingo eziphakeme ze-deformation, ukushisa kwesibili (600 kuya ku-650 ° C, 800 kuye ku-850 ° C) kuyadingeka. Inhloso ukunciphisa ukucindezeleka okwenziwe ngesikhathi senqubo yokushisa futhi ngasikhathi sinye wenze ukwakheka okuphelele komfaniswano wesikhunta.

3.3 Ukucima Ukushisa

Izinga lokushisa elicishayo lesikhunta sokufa lingasetshenziswa ngokuya ngemininingwane ecisha ukushisa yebanga ngalinye lensimbi. Isibonelo, izinga lokushisa lokucisha lensimbi le-3Cr2W8V lingu-1050 ~ 1150 ℃, kanti izinga lokushisa lokucisha lensimbi le-H13 lingu-1020 ~ 1100 ℃. Ukuze kuqinisekiswe ukuchithwa okuphelele kwama-carbides, thola i-austenite efanayo, futhi uthole ukusebenza okuhle okushisa okuphezulu, isikhathi sokucima nokushisa sokubamba isikhunta sokufa kufanele sandiswe ngokufanele. Ngokuvamile, ukushisa okuphethe ukushisa esithandweni sokugeza sikasawoti kungu-0.8 ~ 1.0min / mm.

3.4 Ukucima Nokupholisa

Izinga lokucima uwoyela liyashesha futhi ukusebenza okuhle kungatholwa, kepha ukuthambekela kokukhubazeka nokuqhekeka kukhulu. Ngokuvamile, ukupholisa uwoyela kusetshenziselwa isikhunta sokufa ngokuma okulula nezidingo eziphansi zokusonteka; ukuthola isikhunta sokufa esinezimo eziyinkimbinkimbi nezidingo eziphakeme ze-deformation, ukucisha ubuholi kufanele kusetshenziselwe ukuvimbela ukuguqulwa kwesikhunta nokuqhekeka. Ukupholisa ukucima kufanele kube kuhamba kancane ngangokunokwenzeka ukunciphisa ukucinywa kwe-quenching, ukufudumeza nokucisha esithandweni sokumelana nomshini wokupholisa, ukupholisa kungamukelwa kucisha igesi. Ukushisa nokuqeda endaweni yokugeza kasawoti, futhi ukucisha ukulinganisa kungenziwa lapho kupholile. Lapho isikhunta sicinyiwe futhi selehlile, kufanele sithanjiswe ngokushesha ngemuva kokuthi sifakwe futhi sipholile sibe ngu-150 ~ 200 ℃, futhi asivunyelwe ukupholisa ekamelweni lokushisa.

3.5 Ukushisa

Ubulukhuni isikhunta die-ekubunjweni kufinyelelwa tempering, futhi ubulukhuni die-ekubunjweni isikhunta umgodi ngqo kuthinta ashisayo nabandayo ukuphila ukukhathala isikhunta. Izinto ezahlukahlukene, ukushisa okuhlukile okucimayo, nokushisa okushisa nakho kwehlukile. Ngokwesibonelo, ubulukhuni 3Cr2W8V steel aluminium-magnesium ingxubevange die-ekubunjweni isikhunta ngokuvamile 42 ~ 48HRC, futhi tempering yayo lokushisa ngokuvamile akhethiwe phakathi 560 ~ 620 ℃, kodwa uma high lokushisa eqeda isetshenziswa, izinga lokushisa tempering kuyinto phezulu njengoba 670 ℃. Ubulukhuni ngemuva kokucima ku-1150 ° C nokushisa ku-650 ° C yi-45HRC; ngenkathi ubunzima ngemuva kokucima ku-1050 ° C nokushisa ku-650 ° C kungu-35HRC.

Ukwelashwa Okuqinisa Indawo

Emva isikhunta die-ekubunjweni icishiwe futhi omnene, ubulukhuni ebusweni akuyona ephezulu kakhulu. Ukuze uthole ubulukhuni obuphakeme futhi ugqoke ukumelana ebusweni besikhunta sokufa, ngenkathi ingxenye eyinhloko isalokhu igcina amandla nokuqina okwanele, nokwenza ngcono ukusebenza okulwa nokunamathela kwesikhunta se-aluminium-magnesium i-nitriding ingenziwa kusikhunta sokufa. Noma ukwelashwa kwe-nitrocarburizing. Ukusetshenziswa kokwelashwa okuqinisayo nenqubo yokwelashwa yokuqinisa indawo kuyindlela ebalulekile yokwenza ngcono ukusebenza nempilo yesikhunta. Isibonelo, i-nitrocarburizing heat treatment medium ye-H13 die-casting mold is ammonia gas + ethanol, kanti inqubo ingu-580 ℃ x4.5h. Ngemva eqeda 1030 ° C futhi tempering at 600 ° C futhi 580 igesi nitrocarburizing ukushisa ukwelashwa, ebusweni ubulukhuni isikhunta ngenhla 900HV, ubulukhuni matrix kuyinto 46 ~ 48HRC, futhi bafake ukumelana, ukukhathala ukumelana futhi ukugqwala ukumelana isikhunta athuthukiswe kakhulu. .

Isiphetho

Ekukhiqizeni isikhunta se-aluminium-magnesium alloy die-casting, kubalulekile ukuhlaziya nokutadisha izimbangela zokwehluleka ngokuya ngezimo zokusebenza kwesikhunta, ukhethe kahle izinto zesikhunta, bese wenza inqubo yokwelashwa yokushisa efanelekile ukuqinisekisa isikhunta ukuqina kobuso, ukugqoka ukumelana, amandla ayisisekelo nobulukhuni, futhi kuvimbele ukugqwala ketshezi lensimbi nokunamathela kwesikhunta. , Nciphisa ngempumelelo inani lokwenqatshwa futhi wandise kakhulu impilo yesevisi yesikhunta. Umkhuba wokukhiqiza ukhombisile ukuthi ukushisa isikhunta se-aluminium-magnesium die-casting ekushiseni okusebenzayo nokonga kunganciphisa umehluko wezinga lokushisa phakathi kwesikhunta nendawo yokusebenza, kunciphise ukukhiqizwa kokuqhekeka kwesikhunta, kwandise impilo yenkonzo yesikhunta, futhi kwandise umkhiqizo. Vele, ngesikhathi sokusebenzisa isikhunta se-aluminium-magnesium alloy die-casting, ukusetshenziswa okulungile, ukuphathwa okunengqondo, nokugcinwa ngokucophelela nakho kuyizinyathelo ezisebenzayo zokunciphisa ukwehluleka kokuqala kwesikhunta futhi kwandise impilo yokusebenza kwesikhunta.

Amakhasi ahlobene:isikhunta yokukhiqiza

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Izinyathelo Zokuthuthukisa Impilo Ye-Aluminium-Magnesium Alloy Die Casting Mold

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off