Ungazithuthukisa kanjani izinyathelo zenqubo yokusakaza yesilinganiso se-spheroidization

Izinga spheroidization ezifuywayo ejwayelekile spheroidal graphite cast iron castings liyadingeka ukufinyelela ezingeni 4 noma ngaphezulu, (okungukuthi, izinga spheroidization 70%), izinga spheroidization kuzuzwe isisekelo jikelele cishe 85%. Eminyakeni yamuva, ngokuthuthukiswa kokukhiqizwa kwensimbi kwe-nodular, ikakhulukazi ezimbonini ezinezidingo eziphakeme zokukhiqizwa kwamandla omoya namandla okukhipha, izinga le-spheroidization liyadingeka ukufinyelela ezingeni 2, okungukuthi, isilinganiso se-spheroidization sifinyelela ngaphezu kuka-90%. Inkampani yombhali yahlaziya futhi yathuthukisa inqubo ye-spheroidization kanye ne-inoculation esetshenziswe ku-QT400-15, kanye ne-spheroidizing agent kanye ne-inoculant, ukuze isilinganiso se-spheroidization se-nodular cast iron sifinyelele ngaphezu kuka-90%.

1. Inqubo yokuqala yokukhiqiza

Inqubo yokukhiqiza yangempela:

- Isisetshenziswa sokuncibilikisa sisebenzisa isithando semvamisa esiphakathi nendawo esingu-2.0T kanye nesithando semvamisa sezimboni esingu-1.5T;

- Ukwakheka ketshezi lensimbi eluhlaza okungu-QT400-15 ngu-ω (C) = 3.75% ~ 3.95%, ω (Si) = 1.4% ~ 1.7%, ω (Mn) ≤0.40%, ω (P) ≤0.07%, ω ( S)) ≤0.035%;

- Umenzeli we-spheroidizing osetshenziswe ekwelashweni kwe-spheroidizing yi-1.3% kuya ku-1.5% RE3Mg8SiFe alloy;

- I-inoculant esetshenziswa ekwelashweni nge-inoculation ingu-0.7% ~ 0.9% 75SiFe-C ingxubevange. Ukwelashwa kwe-spheroidizing isebenzisa izindlela ezimbili zokuthinta nokugubha:

Okokuqala, i-55% ~ 60% yensimbi iyakhiqizwa, bese kwenziwa i-spheroidizing, bese kufakwa i-inoculant, bese kufakwa lonke uketshezi lwensimbi.

Ngenxa yendlela yendabuko yokwenziwa kwe-spheroidization kanye ne-inoculation, isilinganiso se-spheroidization esitholwe yibhulokhi eyodwa yokuhlola i-cast wedge enobukhulu obungu-25 mm ngokuvamile icishe ibe ngama-80%, okungukuthi, izinga le-spheroidization lingu-3.

2. Uhlelo lokuhlola lokuthuthukisa isilinganiso se-spheroidization

Ukuze kwandiswe isilinganiso se-spheroidization, inqubo yokuqala ye-spheroidization kanye ne-inoculation ithuthukisiwe. Izinyathelo eziyinhloko yilezi: ukwandisa inani le-ejenti ye-spheroidizing ne-inoculant, ukuhlanza insimbi encibilikisiwe, kanye nokwelashwa okuqeda amandla. Izinga le-spheroidization lisavivinywa ngebhulokhi eyodwa yokuhlola i-cast wedge engu-25 mm. Uhlelo oluthile lumi kanje:

- (1) Hlaziya isizathu sezinga eliphansi le-spheroidization lenqubo yokuqala. Bekucatshangwa ukuthi inani le-ejenti ye-spheroidizing lincane, ngakho-ke inani le-ejenti ye-spheroidizing engeziwe lenyuswe lisuka ku-1.3% laya ku-1.4% laya ku-1.7%, kepha izinga lokuphamba alihlangabezananga nezidingo. . (2) Okunye ukuqagela ukuthi isilinganiso esiphansi se-spheroidization singabangelwa ukukhulelwa okungalungile noma ukwehla kokuzala. Ngakho-ke, ukuhlolwa kukhuphule umthamo we-inoculation kusuka ku-0.7% kuya ku-0.9% kuya ku-1.1%, futhi isilinganiso se-spheroidization asihlangabezananga nezidingo.

- (3) Qhubeka uhlaziye futhi ukholwe ukuthi kunokufakwa okungaphezulu kwensimbi encibilikisiwe nezici eziphakeme zokuphazanyiswa kwe-spheroidization ezingaba imbangela yezinga eliphansi le-spheroidization. Ngakho-ke, kwenziwa ukuhlanzwa okushisa okuphezulu kwensimbi encibilikisiwe. Izinga lokushisa elihlanzekile lokushisa ngokuvamile lilawulwa ngo-1500 ± 10 ° C, kepha izinga lalo le-spheroidization alidluli ku-90%.

- (4) Inani eliphakeme lama-ω (S) lisebenzisa ngokungathi sína umthamo wokuphamba futhi lisheshisa ukwehla kwe-spheroidization. Ngakho-ke, ukwelashwa kwe-desulfurization kuyakhuphuka ukunciphisa uketshezi lwensimbi lwangempela ω (S) kusuka ku-0.035% kuye ngaphansi kuka-0.020%, kepha isilinganiso se-spheroidization naso sifinyelelwe ku-86% kuphela. Imiphumela yokuhlolwa kwalezi zinhlelo ezine ezingenhla ikhonjisiwe kuThebula 1. Isakhiwo nezinto zokwenziwa kwebhulokhi lokumisa okwakhekiwe azihlangabezananga nezidingo.

3. Uhlelo lokugcina lokuthuthuka lwamukelwa

3.1 Izinyathelo ezithile zokwenza ngcono

- Izinto zokusetshenziswa ziyinsimbi yengulube, imfucumfucu engagqokile noma encane egqwalile nezinto zokuvuselela;

- Ukwehliswa kwesimbi kwensimbi ebunjiweyo eluhlaza ngokufaka umlotha wesoda (Na2CO3) esithandweni somlilo;

- Sebenzisa i-ejenti yokwelashwa kwe-Foseco 390 ukwenza i-deoxidize ngaphambili esikhwameni;

- Ukwelashwa nge-spheroidizing nge-Fozco Nodulizer;

- Kusetshenziswa i-silicon carbide ne-ferrosilicon inoculation ehlangene.

Ukulawulwa kwensimbi encibilikisiwe koqobo kwenqubo entsha: ω (C) = (3.70% ~ 3.90%, ω (Si) = 0.80% ~ 1.20% [casting ω (Si final) = 2.60% ~ 3.00%], ω ( Mn) ≤ 0.30%, ω (P) ≤0.05%, ω (S) ≤0.02%. Lapho insimbi yokuqala encibilikisiwe ω (S) idlula u-0.02%, kusetshenziselwa i-soda ash yezimboni ukwenza i-desulfurization phambi kwesithando somlilo, ngoba Ukusabela kwe-desulfurization kuyindlela yokuphela komzimba, Ukushisa kwe-desulfurization kuyadingeka ukuthi kulawulwe cishe nge-1500 ° C, futhi inani le-soda ash added lilawulwa ku-1.5% ~ 2.5% ngokuya ngenani lama-ω (S) ngesikhathi sokuncibilika esithandweni .

Ngasikhathi sinye, iphakheji yokwelashwa nge-spheroidizing isebenzisa iphakheji ejwayelekile yokwelashwa kohlobo lwedamu. Okokuqala, engeza u-1.7% we-Foseco NODALLOY7RE brand spheroidizing agent ohlangothini lwedamu ezansi kwephakeji, icwecwe futhi icwecwe, bese usebenzisa u-0.2% we-silicon carbide no-0.3% omncane Inqwaba ye-75SiFe imbozwe ungqimba ngalunye ngokulandelana , futhi ngemuva kokunyathela, imbozwa ngensimbi yokucindezela, kuthi kufakwe i-0.3% ye-Foseke 390 inoculant kolunye uhlangothi lweladi lensimbi encibilikisiwe. Lapho uthinta i-iron, i-55% ~ 60% yenani eliphelele lensimbi encibilikisiwe iqala ukufuthwa. Ngemuva kokuphothulwa kokuphazanyiswa kokuphothulwa, kufakwa i-1.2% 75SiFe-C inoculant bese kufakwa insimbi encibilikisiwe esele, bese kuthelwa i-slag.

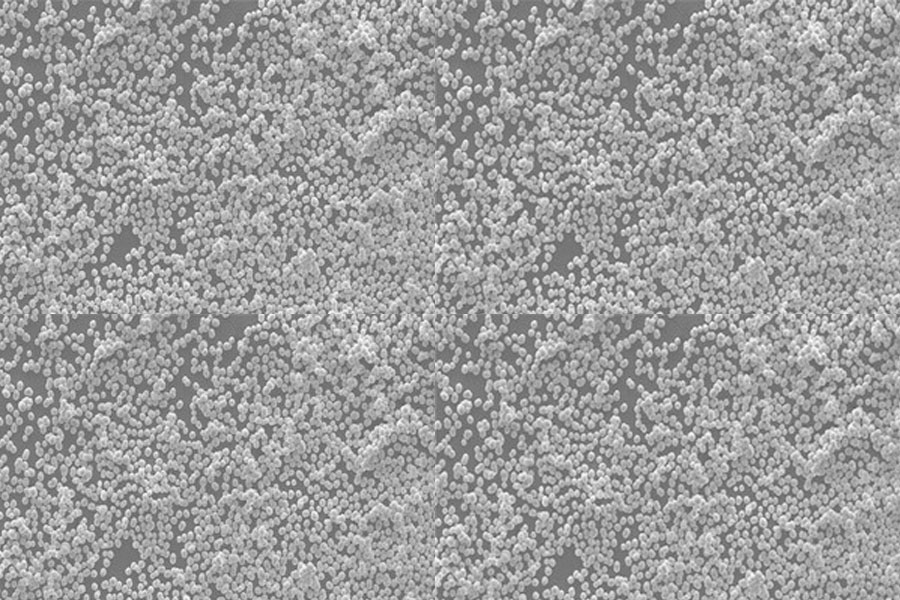

3.2 Imiphumela Yokuhlolwa

Ukwakheka kwensimbi yokuqala encibilikisiwe ngaphambi nangemva kokuchithwa komhlaba, izakhiwo zemishini kanye nesakhiwo se-metallographic se-25mm single cast wedge emise isivivinyo, kanye nendlela yokuhlola yezinga le-spheroidization esakhiweni se-metallographic itholwa ngokuzenzakalela ngohlelo lwe-metallographic image analysis system .

4. Ukuhlaziywa kwemiphumela

4.1 Umthelela wezinto ezisemqoka kusilinganiso se-spheroidization

- I-C, i-Si: C ingakhuthaza i-graphitization futhi yehlise ukuthambekela komlomo omhlophe, kepha inani eliphakeme le-ω (C) lizokwenza i-CE ibe phezulu kakhulu futhi ibangele kalula i-graphite ukuthi intante, ngokuvamile ilawulwa ku-3.7% ~ 3.9%. I-Si ingaqinisa ikhono le-graphitization futhi iqede i-cementite. Lapho i-Si ifakwa njenge-inoculant, inganciphisa kakhulu amandla we-supercooling wensimbi encibilikisiwe.Ukuze kuthuthukiswe umphumela we-inoculation, inani le-ω (Si) ensimbi yokuqala encibilikisiwe lehlisiwe lisuka ku-1.3% laya ku-1.5% laya ku-0.8% kuya ku-1.2%, kanti inani le-ω (final Si) lalilawulwa ku-2.60% kuya ku-3.00%.

- Mn: Ngesikhathi senqubo yokwenziwa kwamakhristali, uMn wandisa ukuthambekela kwensimbi eyakhiwe ngokweqile futhi akhuthaze ukwakheka kwama-carbides (FeMn) 3C. Enkambisweni yokuguqulwa kwe-eutectoid, uMn unciphisa izinga lokushisa lokuguqulwa kwe-eutectoid, aqinise futhi acwenge i-pearlite. UMn akanayo ithonya elikhulu ezingeni le-spheroidization. Ngenxa yethonya lezinto zokusetshenziswa, ngokuvamile lawula ω (Mn) <0.30%.

- P: Lapho ω (P) <0.05%, incibilika ngokuqinile ku-Fe, futhi kunzima ukwenza i-phosphorus eutectic, engenamthelela omncane ezingeni le-spheroidization lensimbi ye-ductile.

- S: S iyinto enesithunzi. U-S usebenzisa i-Mg ne-RE kumenzeli we-spheroidizing ngesikhathi sokuphendula okukhazimulayo, okuvimba i-graphitization nokunciphisa isilinganiso se-spheroidizing. I-Sulphide slag nayo izobuyela esulphur ngaphambi kokuthi insimbi encibilikisiwe iqine, iphinde isebenzise izinto ezi-spheroidizing, isheshise ukwehla kwe-spheroidization, iphinde iqhubeke nokuthinta isilinganiso se-spheroidizing. Ukuze kuzuzwe izinga eliphakeme le-spheroidization, inani lama-ω (S) ensimbi eluhlaza kufanele lehliswe libe ngaphansi kuka-0.02%.

Ukwelashwa kwe-Desulfurization

Ngemuva kokuthi icala licibilikiswe, thatha amasampuli bese uhlaziya ukwakheka kwamakhemikhali. Lapho inani lama-ω (S) lingaphezulu kuka-0.02%, ukwenziwa kwe-desulfurization kuyadingeka.

Umgomo we-soda ash desulfurization uwukuthi: faka inani elithile le-soda umlotha ku-ladle, sebenzisa ukugeleza kwensimbi encibilikisiwe ukugeleza nokugovuza, i-soda ash ibola ekushiseni okuphezulu, ifomula yokusabela yi-Na2CO3 = Na2O + CO2 ↑: i-Na2O eyenziwe ensimbi encibilikisiwe futhi Ukugcotshwa nokwakheka kwe-Na2S, (Na2O) + [FeS] = (Na2S) + (FeO).

INa2CO3 yehlukanisa futhi ixazulule i-CO2, idale ukuyaluza okunodlame kwensimbi encibilikisiwe, egqugquzela inqubo yokonakaliswa komhlaba. I-Soda ash slag kulula ukugeleza nokuntanta ngokushesha, futhi isikhathi sokuphendula se-desulfurization sifushane kakhulu. Ngemuva kokushiswa kwesulfure, i-slag kufanele isuswe ngesikhathi, kungenjalo izobuyela kusulfure. Ukwelashwa kwe-pre-deoxidation, ukwelashwa kwe-spheroidization kanye nokwelashwa kwe-inoculation I-ejenti yokwelashwa kwe-Foseke 4.3 idlala indima yokwelashwa kwangaphambi kokukhishwa kwe-deoxidation esikhwameni, futhi ngasikhathi sinye kwandisa umnyombo we-graphite nucleation kanye nenani lama-graphite spheres endaweni ngayinye, futhi ukwandisa izinga lokumunca iMg. Thuthukisa ngokuphawulekayo ikhono lokumelana nokwehla kwamandla omnotho futhi wandise izinga le-spheroidization. I-Fochke inoculant iqukethe ω (Si) = 390% ~ 60%, ω (Ca) = 70% ~ 0.4%, ω (Ba) = 2.0% ~ 7%, lapho uBa anganweba isikhathi esisebenzayo sokufukamela. Ibanga le-NODALLOY11RE le-Fozco Nodulizer liyakhethwa, futhi i- ω (Si) = 7% ~ 40%, ω (Mg) = 50% ~ 7.0%, ω (RE) = 8.0% ~ 0.3%, ω (Ca) = 1.0 % ~ 1.5%, ω (Al) <2.5%. Njengoba insimbi encibilikisiwe ithola ukwelashwa kwe-desulfurization kanye ne-pre-deoxidation, izinto ezidla ama-nodulizers ensimbi encibilikile zincishisiwe kakhulu, ngakho-ke kukhethwa i-nodulizer enenani eliphansi le-ω (RE) ukunciphisa ukonakala kwe-spheroidal graphite morphology ngu-RE. ; Isici esiyinhloko sesenzo nguMg; ICa no-Al bangadlala indima ekuqiniseni ukufukamela. Usebenzisa i-silicon carbide ne-ferrosilicon ukwelashwa okuhlangene kwe-inoculation, iphuzu lokuncibilika kwe-silicon carbide cishe liyi-1.0 ° C, futhi i-graphite crystal nucleus yanda ngesikhathi sokuqina, futhi imithamo emikhulu ye-ferrosilicon isetshenziselwa inoculation, engavimbela i-spheroidization ekunciphiseni.

Isiphetho se-5

Ekukhiqizeni i-ferritic nodular cast iron, lapho isilinganiso se-spheroidization sidingeka ukufinyelela ngaphezu kuka-90%, kungalandelwa izinyathelo ezilandelayo:

- (1) Khetha ukukhokhiswa kwekhwalithi ephezulu ukunciphisa izakhi ze-de-spheroidization ekukhokhisweni.

- (2) Khetha i-ejenti yokuphamba ngenani eliphansi le-ω (RE) ukunciphisa umphumela owohlokayo we-RE ku-morphology ye-spheroidal graphite.

- (3) Okuqukethwe kwe-ω (S) kwensimbi yokuqala encibilikisiwe kufanele kube ngaphansi kuka-0.020%, okunganciphisa ukusetshenziswa kwama-nodulizers, ikakhulukazi izinto ezi-nodulized ezisetshenziswa ukwenziwa kwesulfurization kwesibili kwe-sulfide slag.

- (4) I-pre-deoxidize insimbi encibilikisiwe, yenyusa inani lemikhakha ye-graphite endaweni yunithi ngayinye, ikhuphule izinga le-spheroidization, ithuthukise kakhulu ikhono lokumelana nokwehla kwamandla omnotho, futhi yandise isikhathi sokufakelwa okusebenzayo.

- (5) Nciphisa inani le-ω (Si) kusimbi yensimbi encibilikisiwe, ukhuphule inani le-ejenti ye-spheroidizing, i-inoculant kanye nama-ejenti aqala ukwelashwa, futhi uqinise ukwelashwa kokufakwa.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Ungazithuthukisa kanjani izinyathelo zenqubo yokusakaza yesilinganiso se-spheroidization

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off