Inqubo Izici Zengcindezi Ekubunjweni Okuphansi

Esikhathini ubuchwepheshe ekubunjweni kwe-aluminium alloy castings, okuvame kakhulu ukuphonsa ingcindezi ephansi. Ukuphonsa ingcindezi okuphansi kunikeza isiqinisekiso sekhwalithi enhle yamasondo ezimoto nezinye izingxenye, futhi ukuphakama kwayo okungenakubuyiselwa endaweni kuye kwabonwa iningi labakhiqizi bezimoto. Lo mbhalo ikakhulukazi wethula umlando, imigomo, izici zenqubo nezimo ezidingekayo zokuphonsa ingcindezi ephansi, kuhloswe ukunikeza inkomba ehambisanayo yabangaphakathi embonini.

Indlela yokukhipha ingcindezi ephansi isetshenziswe amashumi eminyaka ambalwa, futhi ithatha isikhundla esibalulekile ikakhulukazi ekubunjweni kwe-aluminium alloy. Indlela ephansi yokusakaza ingcindezi iyindlela ejwayelekile enemisebenzi enamandla, engakhuphula amandla wento futhi ithuthukise ukusebenza kwendaba. Ukuphonsa ingcindezi ephansi kuyindlela esebenzayo kakhulu yokusakaza. Ukujikijelwa okusakazwayo kunekhwalithi enhle, futhi indlela inezinga eliphakeme kakhulu lokuzenzakalela.

1. Umlando Wokuphonsa Ingcindezi Ephansi

Indlela yokukhipha ingcindezi ephansi inomlando weminyaka engaphezu kwekhulu. Ngawo-1920, la mazwe amabili asebenzisa indlela yokuphonsa ingcindezi ephansi ekubunjweni kwe-aluminium alloy kwakunguFrance neJalimane, kepha ayesesigabeni sesicelo sokulingwa. Ngo-1945, ukukhiqizwa komfutho ophansi kwaqala ukusetshenziswa kakhulu, ikakhulukazi ekukhiqizeni amapayipi amanzi emvula kanye neziqukathi zobhiya e-UK. Ngo-1958, abaseMelika basebenzise indlela ephansi yokucindezela ekusakazeni izingxenye zezinjini zezimoto. Leli kube yithuba lokuthi ukusakazwa kwengcindezi ephansi kusetshenziswe kabanzi. Imboni yezimoto emhlabeni iqale ukuqaphela le ndlela yokulingisa ngomlingo, futhi le ndlela yethulwa eChina ngasekupheleni kweminyaka yama-1950.

Ezweni lakithi, ukusetshenziswa kokuphonsa ingcindezi ephansi kwaqala ngo-1961. Lapho ukukhiqizwa kwamakhanda amasilinda apholisiwe emoyeni kungabonakala ngomlingo ngendlela ephansi yokuphonsa, le ndlela yaqala ukwaziswa kakhulu. Kusukela lapho, ubuchwepheshe bokuphonsa obuphansi obuphansi busetshenziswe ngokuqhubekayo embonini yezimoto, futhi isilinganiso salo sokusetshenziswa siphezulu kakhulu, ikakhulukazi ku-aluminium alloy castings, ephezulu njengengxenye yobuchwepheshe bokuphonsa obuphansi. Ikhwalithi ye-aluminium alloy castings ekhiqizwa yilobu buchwepheshe inhle kakhulu, futhi izinhlobo zemikhiqizo ekhiqizwayo zanda njalo. Ngawo-1970, ubuchwepheshe bokuphonsa obunengcindezi ephansi baqala ukusetshenziswa ekukhiqizeni amasondo ezimoto. Ezikhathini zanamuhla, abantu baqale ukunaka ukukhula okulula kwezimoto. Ubuchwepheshe bokuphonsa obunengcindezi ephansi baqala ukukhiqiza izingxenye ngokusebenza okungcono, ikhwalithi ephezulu yangaphakathi, nezakhiwo eziqinile zomshini.

2. Izimiso Eziyisisekelo

Umgomo oyisisekelo wokuphonsa ingcindezi ephansi ikakhulukazi ukukhuthaza isobho elincibilikisiwe kwisikhunta ngokusebenzisa ingcindezi, futhi isobho elincibilikisiwe liyaqina kancane ngokugcwalisa kancane, futhi ukuqiniswa kwengxenye yesango yisikhathi lapho kucindezelwa khona. Abalingisi abaqiniswe ngale ndlela bazobe bephelele. Ukuqondiswa kokuqina kuqala kusuka kusiqondiso sesango, akuphikisani nengcindezi, futhi ngeke kuphazanyiswe yingcindezi, futhi inqubo yokuqinisa nokupholisa kuqedelwa ngokwemvelo nangokushelela.

3. Izici Zenqubo Yokuphonsa Ingcindezi Ephansi

Ingcindezi nesivinini ongaphakeme ingcindezi thusi kungenziwa nezimo kushintshwe ngesikhathi ethela, ukuze thusi kungenziwa ngokuya ezahlukene ekubunjweni bobunjwa. Ukuphonsa okuphansi kwengcindezi ikakhulukazi kuthatha uhlobo lokugcwaliswa kwenaliti engezansi, okungaqinisekisa ukugcwaliswa okuzinzile kwensimbi encibilikisiwe, futhi kungagwema ngempumelelo ukuphazanyiswa kwesikhala kwensimbi encibilikisiwe, futhi kugweme ukwakheka kwamaphutha ekhwalithi ngemuva kokukhishwa. Ngaphansi kwesenzo sengcindezi, ukusakazwa okubunjiwe kunekhwalithi ephezulu, indawo ebushelelezi nokusebenza okuphezulu. Ngasikhathi sinye, ukuphonsa ingcindezi ephansi kunciphisa kakhulu umfutho wabasebenzi, imvelo ingcono, futhi imishini ilula futhi iyasebenza. Uma kuqhathaniswa nezinye izindlela thusi, ongaphakeme-ingcindezi thusi has izici ezithile futhi unazo inqubo inqubo izici ezihluke kakhulu.

Izici ze-3.1 uma kuqhathaniswa nokusakaza okujwayelekile ukusakazwa okuphansi kwengcindezi kungasebenzisa isikhunta sensimbi, isikhunta sesihlabathi, isikhunta sokugaya ngamatshe, njll, futhi ububanzi baso bokusetshenziswa bukhulu kakhulu, ngakho-ke indlela yokuphonsa ingcindezi enezinzuzo eziningi izindlela ezijwayelekile zokusakaza ezinazo. Ukuphonswa okuphansi kwengcindezi kufanelekile izinsimbi ezingenayo i-ayoni nezinsimbi zensimbi, ezingatholakali ngezindlela eziningi ezivamile zokulingisa. Ukugcwaliswa kokuphonsa ingcindezi okuphansi kuzinzile kakhulu, ngoba ikakhulukazi isebenzisa uhlobo lokwakha oluphansi, ngakho ingcindezi nejubane kungalungiswa ngokuguquguqukayo. Ngaphansi kwesenzo sengcindezi, ukuqiniswa kwensimbi encibilikile kwanele kakhulu, isilinganiso sokusetshenziswa siphezulu, futhi uketshezi lungcono, futhi nekhwalithi yokusakaza ithuthukile. Lapho ukusakaza kuyinkimbinkimbi ngokwengeziwe, kungakhombisa ngokwengeziwe izinzuzo zako.

Izici ze-3.2 ziqhathaniswa nokulingiswa kokufa

Ukusakaza okuphansi kwengcindezi kungasetshenziselwa ukwenza izinhlobo eziningi zokuphonsa, futhi ukwelashwa kokushisa kungenziwa ngokuvumelana nezimo ngokusho kwesimo sangempela. Ingasetshenziselwa ukukhiqiza ukusakazwa okubiyelwe okuncane kanye nokusakazwa okujiyile, futhi kungakugwema ngokuphelele ukuphazanyiswa komoya ngesikhathi senqubo yokusakaza. , Thola ukukhishwa kwekhwalithi ephezulu, indawo ebushelelezi, isakhiwo esihle, namabhamuza amancane. Ngaphezu kwalokho, izakhiwo zemishini yokulingisa zivelele kakhulu, kunezinhlobo eziningi, eziphansi, nezindleko eziphansi.

3.3 Okubi Okuthintwe indawo nobuningi bamasango, kanye nokushuba kodonga lwangaphakathi, umkhiqizo uzobekwa ngaphansi kwemikhawulo ethile. Ukuze ukhombise ngokugcwele ukushelela okuhle kwensimbi encibilikisiwe futhi uqinisekise ukuthi ukuqiniswa kuqala esangweni, umjikelezo wokusakaza uzokwandiswa futhi nezinga lokuqina nalo lizokwehla. Lapho insimbi encibilikile igcwalisa umgodi, izakhiwo zomshini wensimbi encibilikisiwe zizokhawulwa.

4. Izimo Ezidingekayo Ekuphonseni Ingcindezi Ephansi

Ukushisa okungu-4.1

Ukushisa kwesobho esincibilikisiwe kuzothinteka ngohlobo nokuma, kepha umehluko ophelele ngeke ube mkhulu kakhulu. Ukuthi ukushisa kwalo kufanelekile noma cha kuzothinta ngqo ikhwalithi nobuhle bomkhiqizo, ngakho-ke izinga lokushisa kufanele lilawulwe ebangeni elifanele. Kumele kuqashelwe ukuthi izinga lokushisa lesikhunta alinakunakwa nakho.

Ngokombono wokuqiniswa kwensimbi encibilikisiwe, ukusatshalaliswa kwamazinga okushisa kwesikhunta ikakhulukazi kusuka esangweni kuya esiqondisweni esibheke phezulu kuyehla kancane, kepha ngoba lokhu kuzokwandisa umjikelezo wokusakaza futhi kuthinte izinga lokuqina, ngakho ukupholisa okuphezulu nokuvundlile kufanele kwenziwe . Umjikelezo wokukhiqiza, ukushisa kwensimbi encibilikisiwe nezinye izici kudinga ukucatshangelwa ngokucophelela futhi kulungiswe, okuzothinta ngokujulile ikhwalithi yangaphakathi nangaphandle yokusakaza, ngakho-ke umehluko wokushisa kwesango ungakhuphuka ngokuya ngesimo sangempela, ukuze isimo esikhona singaguqulwa.

Isikhathi se-Pressurization

Isikhathi se-Pressurization ikakhulukazi sibhekisa esikhathini esithathwa yinsimbi encibilikisiwe ukusuka ekugcwaliseni kuya ekuqiniseni esangweni. Isikhathi sokucindezela singathinteka yizinto ezahlukahlukene, ezidinga ukucatshangelwa isikhathi sekhanda lesilinda. Isandiso kufanele sibe yinde ngangokunokwenzeka, futhi isisekelo sokwelulwa sisekelwe kakhulu esisindweni. Isikhathi sokucindezela sithinteka kalula yizimo zokushisa. Uma izinga lokushisa lizinzile, isikhathi sokucindezela sizophinde sizinze kakhulu.

Isikhathi sokuqina kwensimbi encibilikisiwe singase singazinzile ngenxa yezinguquko ekushiseni nasekunciphiseni kwezinga lokushisa. Ngoba inani labaphoswayo lizoqhubeka nokukhuphuka, izinga lokushisa lizozinza kakhulu, futhi ngasikhathi sinye, indawo enqamulelayo yesango izokwehla, okuzodala ukuthi isikhathi sokuqina siguquke, okuholele ekulimaleni kwangaphakathi ikhwalithi yabalingisi. Ngakho-ke, kufanele sinake kakhulu ithonya lezinto ezinjengokushisa, isango nepayipi lokuphakela ohlelweni lwesobho.

4.3 Ukubeka Isikhathi

Isikhathi sokuqinisa sibhekisa esikhathini esivela ekuqedeni ukucindezela kuya ekubhujisweni komkhiqizo. Ngemuva kokuthi ukujikijelwa kwehlisiwe, akuqediwe impela, kepha ukuqinisekisa ukuthi ukusakaza akukhubazekile futhi nekhwalithi yokuphonsa iqinisekisiwe. Isikhathi esidingekayo sale ngxenye kumele sengezwe esikhathini esidingekayo sokuqinisa. Isikhathi sokuqina ngeke sithathe isikhathi eside, sihlobene nokushisa, futhi isivinini sokuqina sizoshesha kunesikhathi sokucindezela. Ukuze unciphise isikhathi sokuqina, izinga lokupholisa lingakhuphuka.

Izimo ezinezingcindezi

Ukuze uqinisekise ukusebenza kokugcwaliswa, naka ukulungisa isivinini sokucindezela, ukushesha kakhulu noma ukuhamba kancane kuzothinta umphumela wokugcwalisa nekhwalithi yokusakaza. Ngokuqondile, uma ijubane lihamba kancane, lizodala inkinga yokungabi bikho kahle kwesobho esincibilikisiwe; uma isivinini sishesha kakhulu, umkhiqizo uzophazamiseka yigesi futhi ubangele ukukhubazeka kwekhwalithi. Ngakho-ke, kubalulekile ukulungisa ijubane lokucindezela. Njengoba isilinganiso sokugeleza sizothinteka ngomehluko ekubunjweni kwendlela yokugeleza, kuyadingeka ukulawula ijubane ngokuya ngesimo sangempela.

5. Isiphetho

Ngamafuphi, ingcindezi yokukhipha ubuchwepheshe obuncane inezinzuzo ezinkulu futhi ubuchwepheshe bokujula obujwayelekile be-aluminium alloy castings. Uma kuqhathaniswa nezinye izindlela zokulingisa, lobu buchwepheshe bunezinhlobo ezahlukahlukene zezinhlelo zokusebenza, ezinekhwalithi ephezulu yokulingisa, ukucacisa okuphezulu, ukusebenza okuhle nezinga eliphakeme lokuzenzakalela. Ingcindezi okuphansi ekubunjweni ubuchwepheshe inomlando weminyaka eyikhulu selokhu yasungulwa, futhi ithonya imboni ye-alloy ekubunjweni ngentuthuko engcono.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Inqubo Izici Zengcindezi Ekubunjweni Okuphansi

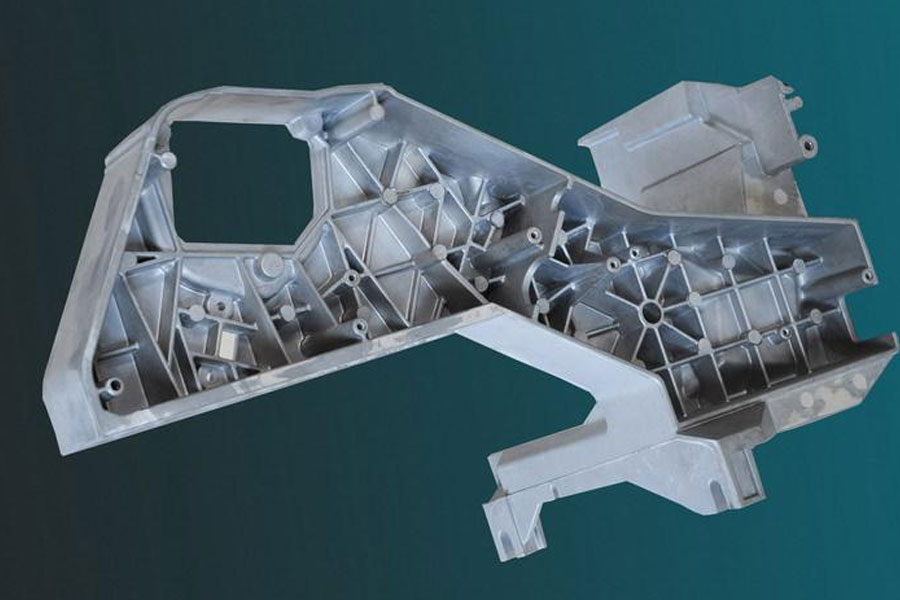

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off