Izindlela Nezinyathelo Zokunyathela I-Die Design

Kunezinhlobo eziningi zesikhunta, ezingahlukaniswa zibe:

- Izikhunta zensimbi ezisuselwa kuzinhloso zokucubungula namasu wokucubungula.

- Icubungula isikhunta esingeyona insimbi ne-powder yokusansimbi.

Namuhla, umhleli ukhuluma ngendlela kanye nenqubo yokugxiviza ukwakhiwa kwediski.

Ukuhlaziywa kwenqubo yokugaya izingxenye zezingxenye

Izingxenye zokunyathela kufanele zibe nobuchwepheshe obuhle kakhulu bokufaka isitampu ukuze kukhiqizwe izingxenye ezifanelekayo zokushaya izitayela ngendlela elula futhi eyonga kakhulu. Ukuhlaziywa kwenqubo yezingxenye zokunyathela kungaqedwa ngokuya ngezindlela ezilandelayo:

- Funda imidwebo yezingxenye. Ngaphezu kokuma nobukhulu bezingxenye, kubalulekile ukuqonda izidingo zokunemba kwezingxenye nobukhulu bendawo.

- Hlaziya ukuthi ukwakheka nokuma kwezingxenye kufanelekile yini ukucubungula isitembu.

- Hlaziya ukuthi ukukhethwa kwesithenjwa nokufakwa amalebuli esikalini kwezingxenye kunengqondo yini, nokuthi ingabe isilinganiso, ukuma kanye nokunemba kokuma kufanelekile ukucubungulwa kwesitampu.

- Ukuthi izidingo zobukhulu besimo sengxenye yengxenye engenalutho ziphakeme kakhulu.

- Noma ngabe kunenqwaba enkulu yokukhiqiza eyanele.

Uma ukwenziwa kwengxenye kukubi kakhulu, kufanele uxoxisane nomhleli bese uhlongoza uhlelo lokubuyekeza uhlelo. Uma iqoqo lokukhiqiza lincane kakhulu, ezinye izindlela zokukhiqiza kufanele zicatshangelwe ukucubungula.

Ukunyathela Ukuhlelwa Kwenqubo Nokwakheka Kwenqubo Okufanele

- Ngokwakheka nangobukhulu bezingxenye zokugxivizwa, qala ukuthola uhlobo lwenqubo yokugxiviza, njengoku: ukushaya isibhakela, amazombe, ukudweba okujulile, ukuqhuma, ukuguqula kabusha nezinye izindlela zokuhlela nokufa. Stamping izindlela zokuhlela ukufa nezinqubo.

- Bala izinga lokujula kwendlela ngayinye yokwakha isitampu. Uma izinga lokuzisola lidlula umkhawulo wokusonteka, inani lezibhakela kule nqubo kufanele libalwe.

- Ngokuya ngezici zokumosheka nezidingo zekhwalithi zenqubo ngayinye, hlela ukulandelana okuthembekile kokushaya isitampu. Ukunakwa kufanele kunikezwe ukuqinisekisa ukuthi indawo yokukhubazeka enqubeni ngayinye yindawo ebuthakathaka. Ingxenye esivele yakhiwa (kufaka phakathi imbobo ebunjiwe noma umumo) ngeke ibambe iqhaza ekuguqulweni kwenqubo elandelayo. Ingxenye ye-zigzag ye-polygonal kufanele igobeke kuqala ngaphandle bese igotshwa Ngaphakathi, kuyadingeka ukuhlela izinqubo nezinqubo ezisizayo ezidingekayo njengokulolonga, ukulinganisa, nokwelashwa kokushisa.

- Esimeni sokuqinisekisa ukunemba kwezingxenye, thola inqubo yenhlanganisela enengqondo ngokuya ngenqwaba yokukhiqiza kanye nokuma okungenalutho nezidingo zokuhambisa.

- Ukuhlela izinhlelo ezimbili noma ngaphezulu zenqubo, bese uqhathanisa ikhwalithi, izindleko, izinga lokukhiqiza, ukucija nokulungisa isikhunta, impilo yesikhunta nokuphepha kokusebenza, njll., Ukukhetha uhlelo oluhle kakhulu lwenqubo.

- Qala ukunquma imishini yokushaya ngenqubo ngayinye.

Ukuhlelwa okungenalutho nokwakheka kwezingxenye zezingxenye

- Ngokwezinhlobo zezingxenye zokugxiviza, bala ubukhulu bezikhala bese wenza imidwebo engenalutho

- Ngokwemvelo nangezinga lokungenalutho, hlela umdwebo wesakhiwo bese ubale isilinganiso sokusetshenziswa kwedatha. Ukuhlela izinhlelo ezahlukahlukene zokuhlelwa, khetha uhlelo oluhle kakhulu phakathi kwabo ngokuqhathanisa.

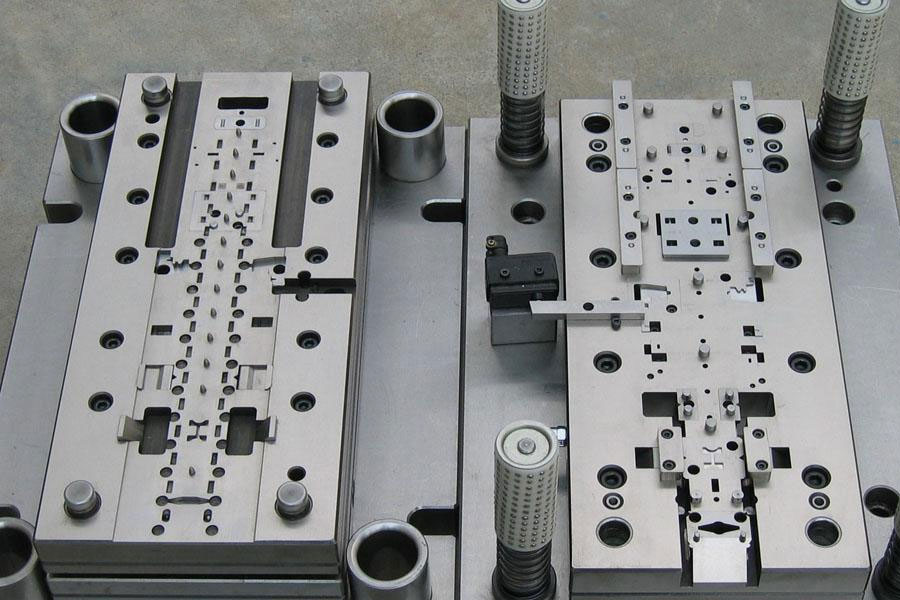

Wokushaya die design

1. Thola indlela yesakhiwo sesikhunta senqubo ngayinye yokunyathela isitembu, bese wenza umdwebo wesikimu wesikhunta.

2. Yenza ukuhlela okuqondile kokuhleleka kwesikhunta senqubo ebekiwe engu-1-2, bese wenza imidwebo yokusebenza kwesikhunta.

Indlela yokuhlela imi kanje:

- Thola uhlobo lwesikhunta: ingabe isikhunta esilula, isikhunta esiqhubekayo noma isikhunta esihlanganisiwe.

- Isikhunta sokusebenza kokuhlela izingxenye: bala ubukhulu be-convex ne-concave die edge nobude be-convex kanye ne-concave molds, thola isakhiwo se-convex ne-concave molds kanye nezindlela zokuxhuma nezingqinamba.

- Thola indawo nebanga lendawo engenalutho, bese uhlela ukuma okuhambisanayo nezingxenye zebanga.

- Thola izindlela zokucindezela, ukwehlisa, ukukhipha kanye nokucindezela izingxenye, bese uhlela amapuleti okubamba ahambisanayo, ukhulula amapuleti, kanye nezindawo zokucindezela.

- Isisekelo sesizinda sokuhlela: kufaka phakathi ukuhlelwa kwezisekelo zesikhunta ezingenhla nezansi nezindlela zokuqondisa, futhi izisekelo zesikhunta ezijwayelekile nazo zingakhethwa.

- Ngokwesisekelo sokuphothulwa kwemisebenzi engenhla, umdwebo wokusebenza kwesikhunta wenziwa ngokuya ngesilinganiso. Okokuqala sebenzisa umugqa onamachashazi amabili ukwenza okungenalutho, bese wenza izingxenye ezisebenzayo, bese wenza izingxenye zokuma nezindawo zebanga, usebenzise izingxenye zokuxhuma ukuxhuma izingxenye ezingenhla, futhi ekugcineni wenze izingxenye ezicindezelayo nezothulwayo endaweni efanele. Ngokuya ngezimo ezithile zesikhunta, ukulandelana okungenhla kungalungiswa ngokufanele.

- Umdwebo wokusebenza kufanele ukhombise ubukhulu bengqimba yangaphandle yesikhunta, ukuphakama kokuvalwa kwesikhunta, isikali sokubambisana, kanye nendlela yokubambisana yohlobo lokunyathela ukuhlela isikhunta nenqubo yokuhlela isikhunta. Imephu yomsebenzi kufanele ikhombise izidingo zokunemba kokukhiqizwa kwesikhunta nezimo zobuchwepheshe. Imephu yomsebenzi kufanele yenziwe ngokuya ngamazinga kazwelonke wokudweba, ngomugqa wetayitela ofanelekile nohlu lwamagama oluningiliziwe. Uma kungukufa okungenalutho, yenza umdwebo wesakhiwo ekhoneni eliphezulu elingakwesokunxele lomdwebo womsebenzi.

- Bala isikhungo sengcindezi sesikhunta bese uhlola ukuthi isikhungo sengcindezi nomugqa ophakathi kwesibambo sesikhunta uhambelana yini. Uma zingahambelani, yenza ukulungisa okuhambisanayo nemiphumela yesikhunta.

- Bala amandla okushaya, bese ekugcineni ukhethe okokunyathela, bese ubheka ubukhulu obufanele bemishini yokufa neyokunyathela (ukuphakama okuvaliwe, indawo yokusebenza, isibambo sedivayisi yokufa, njll.).

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Izindlela Nezinyathelo Zokunyathela I-Die Design

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off