Ukulungiselela kanye nokusetshenziswa kwe-Die Casting Scheme ye-ETC Throttle Aluminium Shell Casting Ngokusekelwe ku-MAGMASOFT

Eminyakeni yamuva nje, ngokuthuthuka komnotho womhlaba, ukufunwa kwezingxenye zezimoto ze-aluminium zezimoto kunomthelela omkhulu kumathemba entuthuko esewonke embonini yokukhipha imboni. Lapho kubhekene nokuncintisana kwezimboni okuya ngokuya kuba nzima futhi kuncishiswa njalo kwemijikelezo emisha yokuthuthukiswa komkhiqizo, Ukulethwa kwemikhiqizo efanelekile ehlangabezana nezidingo zamakhasimende esikhathini esifushane kuzoba yinkomba entsha yokuthuthukiswa kwamabhizinisi aphonsayo; le ndatshana isebenzisa umsebenzi we-DOE we-MAGMASOFT ukwenza ukuhlaziywa kokulingisa nokuqhathanisa izinhlelo ezahlukahlukene zokuphonsa kanye nemingcele yezinqubo ezahlukahlukene kusigaba sokuqala se-ETC throttle aluminium castling castings. Futhi nokwenza kahle, ukukhetha ikhambi elihamba phambili, ngaleyo ndlela kuncishiswe umjikelezo wentuthuko, nokuqinisekisa impumelelo yesilingo sesikhathi esisodwa somkhiqizo nokukhiqizwa ngobuningi okubushelelezi nokudilivwa.

Lapho sibhekene nenkinga yokuwohloka kwesimo sezulu emhlabeni jikelele kanye nokwehla kwamandla okonga okonga ugesi, ukunciphisa ukungcola kanye nokwehliswa kokungcola, imboni yezimoto nayo izoqhubeka nokuthuthuka maqondana nokonga ugesi, ukunciphisa ukungcola kanye nobunhloli; kanye ne-electronic throttle system yazalelwa kule ndawo (i-Electronic Throttle Control System ye-ETC emfushane) yingxenye ebaluleke kakhulu futhi ebalulekile yohlelo lwamanje lwenjini yezimoto. Inquma izimo zokusebenza kwenjini ngokulawula ukungena komoya kwenjini ukuqinisekisa amandla angcono nophethiloli wemoto. Ezomnotho, ukuze kuqhutshekwe nokulawulwa kwezidingo zokuphuma. Kuyabonakala ukuthi i-throttle ye-elekthronikhi, njengobunye bobuchwepheshe obuyinhloko bezinhlelo ezithuthukisiwe zokulawulwa kwezimoto nokuphepha, ngokuqinisekile izoba namathemba amahle wokusebenzisa njengamanye ubuchwepheshe bokulawula izimoto obusezingeni eliphakeme.

Njengenye yezinto ezibaluleke kakhulu ohlelweni lwempimpi ye-elekthronikhi, ukusakazwa kwegobolondo le-ETC mpintsha nakanjani kuzothinta ukwenzeka nokuqina kohlelo; ngakho-ke, ukukhiqizwa kwe-ETC mpintsha i-aluminium castings ehlangabezana nezidingo kuzoba kubaluleke kakhulu. Kuleli phepha, ngosizo lomsebenzi we-DOE we-MAGMASOFT, esigabeni sokuqala se-ETC mpintsha i-aluminium casing castings, izinhlelo zokuthela ezahlukahlukene kanye nenqubo ehlukahlukene yokulinganisa ukulinganisa ukuqhathanisa nokwenza kahle kwenziwa uhlelo oluhle kakhulu, ngaleyo ndlela kuncishiswe intuthuko ukujikeleza nokuqinisekisa lo mkhiqizo kanye Impumelelo yemodeli yesilingo nokukhiqizwa ngobuningi okushelelayo nokudilivwa.

1 Ukuhlaziywa kwesakhiwo soMkhiqizo nezidingo zobuchwepheshe

Ibanga le-die-casting material le-ETC mpintsha ye-aluminium ekubunjweni okufundwe kuleli phepha yi-AlSi12Cu1Fe, futhi ubukhulu bayo bohlaka bungu-111mm * 109mm * 84mm. Ukushuba okumaphakathi kwalokhu kusakazwa kungu-4mm, futhi ukushuba kobukhulu bodonga obukhulu ngu-13mm. Isakhiwo jikelele somkhiqizo siyinkimbinkimbi ngokwengeziwe. , Kunezimbambo eziningi ezikude ezihlukanisiwe, ezingakulungele ukugcwaliswa okuhlelekile kwe-aluminium encibilikisiwe; ubukhulu bezindonga zezinye izikhundla buhluke kakhulu, futhi indawo enezindonga ezincanyana izoqala iqine ibe isimo esiqinile, okulingana nokuhlukanisa ingxubevange encibilikisiwe ibe maningi Indawo encane ebiyelwe yakha indawo yesigaba samanzi esingalodwa odongeni olujiyile. Lapho inqubo yokuncibilikisa insimbi encibilikisiwe nenqubo yokuncipha kulezi zindawo ezihlukanisiwe zesigaba soketshezi ingeke yanezelwa, inkinga yemigodi yokuncipha ne-porosity izokwenzeka nakanjani ngaphakathi.

Ngenxa yendawo yokusebenza eyinkimbinkimbi ye-ETC mpintsha ye-aluminium castling castling, ukuqhuma kwesibhamu kuyadingeka ukuqinisa ikhwalithi yesimo sokusakaza nokwenza ngcono ukumelana kwayo nokugqwala; isikhundla sokumataniswa komkhiqizo sinezidingo eziphakeme zokubekezelelana kwejometri nobukhulu; Qinisekisa ukuthi ivolumu yokuvuza ekucindezelweni kokuhlolwa kokuvuza kwe-3bar ingaphansi noma ilingana no-3cc / min, futhi ubukhulu bomgodi wokuncipha endaweni yendawo yomkhiqizo awuvunyelwe ukudlula u-0.7mm, inani eliphelele ingeqi ku-5, isikhala asikho ngaphansi kuka-10mm, futhi asidluli u-10% wendawo isiyonke. ; Ngakho-ke, kulokhu kusakazwa kokufa, izidingo zokuklanywa kwenqubo ephezulu kakhulu ziyadingeka ukuqinisekisa ukuthi ikhwalithi yangaphakathi yokusakaza ingahlangabezana nezinga lokwamukelwa kwamakhasimende;

2 Umkhiqizo die-thusi scheme futhi inqubo design design

2.1 Umklamo wokuphonsa umkhiqizo wokufa

Isixhumanisi sokuklanywa kwesango esibaluleke kakhulu kubuchwepheshe bokukhiqiza bokufa sinquma ikhwalithi yezingxenye zokufa, ukufeza ukukhiqiza ukusebenza kahle, impilo yesikhunta, ukusika nokuhlanza izingxenye zokuphonsa, ukukala izinga lama-alloys wokuphonsa, namandla kagesi imishini die-ekubunjweni. Inomthelela ofinyelela kude; ngakho-ke, ukwakheka kwesikhundla esinengqondo sesango, ubukhulu besango nosayizi, nobuningi besango kuyizikhiye zokuqinisekisa ikhwalithi yokulingisa yokufa efanelekayo; kusukela ekuhlaziyweni kwezici zesakhiwo somkhiqizo nesipiliyoni sokwakheka kwenqubo, izindlu ze-ETC mpintsha zikhona izindlu ezintathu zokuphonsa ezifanele ukwakhiwa kwendawo yokuphakelayo; ngakho-ke, le ndatshana izoklama izikimu ezintathu zokuthululela ukufa. Kusukela enkambweni yokugcwaliswa kwemfundiso kanye nebanga lokugeleza, izinhlelo ezahlukahlukene zokuthela zizokhiqiza imiphumela ehlukile yokugcwalisa, ngakho-ke zidinga ukususelwa kumiphumela yesoftware yokulingisa ye-MAGMA iqhathaniswa futhi ihlaziyelwe ukuqinisekiswa;

2.1.1 Uhlelo lokuthela idizayini eyodwa

Njengoba kukhonjisiwe kulesi sibalo, inani lamasango kuhlelo lokuqala lokuthela lenzelwe imicu ephindwe kabili, eklanywe ngokulandelana endaweni yodonga eseceleni yesimo sokufakwa kwezimoto nendawo yokufakwa kwepuleti ye-valve. Kukhethwe ipunch yomjovo enobubanzi obungu-60mm, kanti isilinganiso sejubane lomjovo ngu-1: 14; Inzuzo yalolu hlelo lokuthela ukuthi ukugeleza kwensimbi encibilikisiwe kufushane, okunomthelela omncane kunani lokunciphisa izinga lokushisa ngesikhathi senqubo yokugcwalisa; ukwakheka kweziteshi ezintathu zokugeleza kunikela ekudlulisweni kwengcindezi kanye nokondliwa kwensimbi encibilikisiwe, okusizayo ukunciphisa inqubo yokukhiqiza yakamuva Ubungozi bokukhubazeka kokuncipha bunomphumela othile omuhle; Ububi bayo ukuthi ngenxa yokuhlukaniswa komkhiqizo nezizathu zesakhiwo, umgijimi kumele aklanywe ngezinyathelo ezithile nezindawo ezinodonga oluncane. Lezi zikhundla zivame ukumboza igesi ngesikhathi senqubo yokugcwalisa kamuva. Ngaphezu kwalokho, indawo yokufakwa kwezimoto yalo mkhiqizo ayicutshungulwa, futhi ukwakhiwa kwesango kulapha, okulula ukuwasha ngqo ingqikithi yangaphakathi kwodonga nokushisa endaweni yesango. Ephakeme, kulula ukudala ukukhubazeka kokufa nokuguguleka endaweni yokufaka izimoto; futhi ukuma kwesango akulungiswa, okunomthelela othile ongemuhle ekunciphiseni nasekuhlanzweni kokuphonswa kwabafa kamuva;

2.1.2 Ukwakhiwa kohlelo lwesibili lokuthela

Njengoba kukhonjisiwe kulesi sibalo, inani lamasango ohlelweni lwesibili lokuthela lenzelwe ukuba libe linye, futhi isikhundla senzelwe endaweni eyimbobo eyindilinga eseceleni kwendawo yokufakwa kwepuleti ye-valve. Kukhethwe ipunch yomjovo enobubanzi obungu-60mm, kanti isilinganiso sejubane lomjovo ngu-1: 30; lokhu kuthelwa Inzuzo yesixazululo ukuthi umgijimi angadizayinwa ngoshintsho olubushelelezi, oluzuzisa ukugcwaliswa kwensimbi encibilikisiwe futhi kunciphise isimo sokugcwala kwegesi ngesikhathi senqubo yokugcwalisa, futhi kunciphise ukukhubazeka okubangelwa igesi alethwe umgijimi; isango lenzelwe endaweni yokucubungula. Nciphisa umthwalo wokucheba nokuhlanza ama-die castings, futhi unciphise izindleko zokukhiqiza; isango elilodwa lomucu lingavimbela imicu eminingi yensimbi encibilikisiwe ukuthi ingene emgodini futhi ibangele i-vortex, intrainment, ne-oxidation. Okubi ukuthi kusekugcineni kwesango. Umphumela wokuphakelwa kwendawo eshisayo ushoda ngokuyisisekelo, futhi ezinye izikimu zokudla ezisizayo zidinga ukucatshangelwa; futhi ukugeleza kwensimbi encibilikisiwe kukude ngokwedlulele, okunomthelela othile ongemuhle ekushiseni kwensimbi encibilikisiwe ngesikhathi senqubo yokugcwalisa, kanye nokukhubazeka kwempahla ebandayo kungenzeka ezindaweni zendawo. ;

2.1.3 Ukwakhiwa kohlelo lwesithathu lokuthela

Njengoba kukhonjisiwe kulesi sibalo, inani lamasango amathathu kusikimu sokuthela lenzelwe ukuthi libe linye, futhi isikhundla sisethwe ohlangothini lomgodi oyindilinga wesikhundla sokufakwa kwepuleti le-valve. Kukhethwe ipunch yomjovo enobubanzi obungu-60mm, kanti isilinganiso sejubane lomjovo ngu-1: 30; Ubuhle besango ukuthi isango lenzelwe endaweni yokucubungula indawo, enganciphisa umthwalo wokusika nokuhlanza umshini wokuphonsa, futhi unciphise izindleko zokukhiqiza. Isango lenzelwe isitayela sokugcwalisa okuqondile, okunganciphisa ukushaywa kokugcwaliswa kwe-aluminium encibilikile kanye nelahleko lokushisa kwe-aluminium encibilikisiwe. Inani liyancipha; ibanga phakathi kwesibhakela nesango lifushane, elingaqinisekisa ukudluliswa okusebenzayo kwengcindezi ye-punch; Okubi ukuthi ukuguquguquka kwemingcele yokulungiswa kokukhiqizwa kwakamuva kubi, futhi ikhwalithi yomkhiqizo ayikwazi ukwenziwa ngcono ngokulungisa amapharamitha wokufa.

Inqubo yomklamo wenqubo yomkhiqizo

Ngokuya ngokuhlaziywa kwesakhiwo kanye nezidingo zekhwalithi ye-ETC mpintsha i-aluminium castling castings, lo mkhiqizo usebenzisa umshini wokulingisa we-350T, isikhunta esisodwa nedizayini eyodwa, futhi ingcindezi yokusakaza isethwe ku-100MPa ukuqinisekisa ukondleka kahle kokudla nokunciphisa ukubukeka kokukhubazeka kokuncipha esikhathini esizayo. ; Izinga lokushisa elithelelwayo lenzelwe ukuba libe ngu-660-680 ℃, futhi ama-cores wesikhunta ahambayo futhi ahleliwe afudunyezwa abe ngu-180-200 ℃; ngesikhathi sokugcwalisa, isivinini esiphansi sisethelwe ku-0.25m / s, isivinini esikhulu sisethelwe ku-3m / s, futhi amaphuzu wokushintsha ngesivinini esikhulu ahlolwa ku-340mm naku-350mm ngokulandelana. Isikhundla sisetshenziselwa ukucacisa isimo sokugcwalisa esizinzile kakhulu sensimbi encibilikisiwe kanye nesimo esibi esibi kakhulu samanje nesokufaka; ngasikhathi sinye, uhlelo lokulawula izinga lokushisa lokupholisa ulayini kanye nokupholisa iphuzu kusetshenziselwa ukuqinisekisa ukulinganisela okuhle kokushisa kwesikhunta;

3. ukumbumbuluzwa kwamanani nokuhlaziywa kokuqhathanisa kokungenisa ngokuchofoza okukodwa

Inqubo yokugcwalisa nokuqinisa inqubo yokusakaza inethonya elinqumayo kwikhwalithi yokusakaza okufa, kepha njengoba lezi zinqubo ezimbili ziphothulwa endaweni evaliwe nengabonakali ngesikhathi senqubo yokukhiqiza, akunakwenzeka ukugcina nokuhlaziya ngqo noma ngokungaqondile, ngakho-ke inani langaphambilini Ukulingisa kubaluleke kakhulu; ngokusebenzisa umsebenzi we-MAG code DOE, ukungenisa ngokuchofoza okukodwa kwalezi zinhlelo ezintathu zomjovo ezingenhla nezindawo ezimbili zokuhlola ukushintsha isivinini esikhulu, ukubalwa kwesikhathi esisodwa kwezinhlelo eziningi, isibikezelo esisheshayo sendawo enesici, futhi uthole uhlelo oluhle kakhulu lokuthuthuka ikhwalithi yangaphakathi yemikhiqizo, yehlisa imijikelezo yentuthuko, futhi yehlise izindleko zokukhiqiza.

Ukulingiswa nokuhlaziywa kwenqubo yokugcwalisa

Njengoba kukhonjisiwe kuMdwebo 3, umphumela wokulingisa womugqa wokuqala wesithombe isikhathi sokugcwalisa. Indawo yokushintsha ngesivinini esikhulu kwezinhlelo ezintathu zokuqala ingu-340mm, kanti isikhathi sokugcwalisa sifushane. Indawo yokushintsha ngesivinini esikhulu kwezinhlelo ezintathu zokugcina ingu-350mm, kanti isikhathi sokugcwalisa side. Ukuma kombala okukhanyayo indawo yokugcina yokugcwalisa yezikimu ezintathu zomjovo;

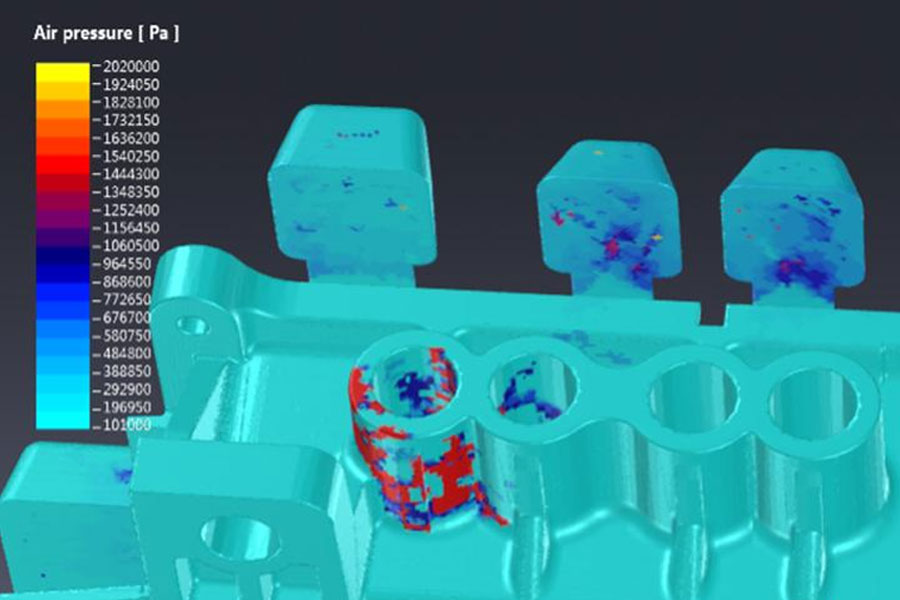

Umphumela womugqa wesibili wesithombe ungumphumela omkhulu womfutho womoya. Umbala okhanyayo wemiphumela yokulingisa isikhundla somfutho ophakeme womoya, futhi ubungozi be-stomata bukhulu. Ngokuqhathanisa, kutholakala ukuthi inani lomfutho womoya weSikimu 2 kanye neSikimu 5 liphansi kakhulu, futhi ubungozi be-stoma buncane;

Umphumela womugqa wesithathu wesithombe ungumphumela wevolumu yokugcwalisa. Umphumela wokulingisa unokuqukethwe okuphezulu komoya endaweni ekhanyayo nengozi enkulu yokuvuza. Ngokuqhathanisa, kutholakala ukuthi inani levolumu yesibili neyesihlanu yesikimu liphansi kakhulu, futhi ubungozi bokuvuza buncane;

Ukuhlaziywa okuphelele kwemiphumela yokulingisa yenqubo yokugcwalisa kukhombisa ukuthi ingcindezi yomoya nokufakwa kwenketho yesibili neyesihlanu kuncane kakhulu, futhi indawo yesibili yokushintsha ijubane iphambili, futhi isikhathi sokugcwalisa sifushane, ngakho konke ukuhleleka kuhle.

3.2 Ukulingisa nokuhlaziya inqubo yokuqinisa

Njengoba kukhonjisiwe kuMdwebo 4, umphumela womugqa wokuqala wesithombe yinkambu yokushisa okubandayo. Imiphumela yokulingisa ikhombisa ukuthi isikhathi sokuqina kwesango langaphakathi lesikimu 3 nohlelo 6 yinde kakhulu, futhi isikhathi sokudla kwengcindezi yinde kakhulu; isikimu 1 kanye nesikimu 4 kungokwesibili, futhi isikhathi sokudla kwengcindezi siphakathi; isikhathi sokuqina kwesango langaphakathi lesikimu 2 nohlelo 5 Isikhathi esifushane nesifushane kakhulu sokunikezwa kwengcindezi;

Umphumela womugqa wesibili yisikhathi sokudla esisebenzayo sejoyini elishisayo, futhi umbala ogqamile womphumela wokulingisa isikhundla sejoyinti elishisayo lomkhiqizo, okuyisikhundla lapho isakhiwo somkhiqizo siwugqinsi futhi ekugcineni siqinile. Izindawo zezinhlelo 1, 2, 4, no-5 ngokufanayo ziyefana. ISikimu 3 neSikimu 6 sinamasango angaphakathi aminyene ngokuqhathaniswa, ngakho-ke uma izindawo ezimbili ezishisayo esangweni elingaphakathi zixhunywe ndawonye, izindawo ezishisayo zizokwanda;

Umphumela womugqa wesithathu umphumela wokuncipha. Ngenxa yokuphakelwa ingcindezi, isimo sokuncipha kwesikimu 3 nohlelo 6 yiso esincane kunazo zonke, futhi ukuncipha kwezinye izinhlelo ezine kuyafana ngokuyisisekelo. Uma kuqhathaniswa, isikimu 2 nesikimu 5 mancane amanye.

Kususelwa ekuhlaziyweni kwemiphumela yokulingisa yenqubo yokuqinisa, indawo yokuncipha yesikimu 3 nohlelo 6 incane kunazo zonke, kepha ilunga elishisayo esangweni elingaphakathi likhulu kakhulu, futhi imiphumela yokuhlangana yokushisa nokuncipha kohlelo 2 nohlelo 5 lungcono kakhulu.

4. Ukuqinisekisa kokukhiqiza

Ukuhlaziywa okuphelele kokulingisa, indlela yesibili yokusakaza isetshenziselwa ukukhiqiza. Umdwebo 5 ukhombisa isithombe sokukhiqizwa kwe-ETC mpintsha i-aluminium casing castings; ngokuhlolwa komkhiqizo nokuhlolwa kwe-X-ray, ukusakazwa akubonisanga ama-pores kanye ne-shrinkage defects eyeqe izidingo zekhwalithi yekhasimende; futhi Kuphumelele izidingo zokuvuza ohlangothini, akukho ukuvuza okwenzekile; ubuso bokusakaza bekukhanyayo, bekungekho ukukhubazeka okusobala kwezinto ezibandayo nokuthululwa okunganele, umphumela jikelele uhlangabezane ngokugcwele nezidingo zokuhlolwa kwekhwalithi yekhasimende, nokukhiqizwa ngobuningi okubushelelezi.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ukulungiselela kanye nokusetshenziswa kwe-Die Casting Scheme ye-ETC Throttle Aluminium Shell Casting Ngokusekelwe ku-MAGMASOFT

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off