Izimbangela Zokukhubazeka Okuvamile EGrey Cast Iron Cylinder Blocks

Ukuvela kwengilazi yamanzi kunomlando weminyaka engaphezu kwengu-300, kepha njengesibophelelo sokwenza nokwenza okuyisisekelo, kuze kwaba ngo-1947 lapho inqubo yesihlabathi sengilazi yamanzi ne-CO2 njenge-ejenti yokuqina yenziwa nguDkt. L. Petrzela iCzech Republic. ye.

Isikhathi esingaphezu kwengxenye yekhulu leminyaka, abantu badlule ezinkambisweni ezine ezinkulu zokuphenduka ekuqondeni indlela yokuqina kwesihlabathi se-sodium silicate ocwaningweni oluqhubekayo nasekuhloleni, okungukuthi:

- 1) Umbono wokuqina kwamakhemikhali okumsulwa kwe-CO2 nguSolwazi Lias (Лясс AM) wezwe elaliyiSoviet Union ngawo-1950. Uhlukanise inqubo yokuqina ekubeni ukubola kwe-silicate, ukwakheka kwe-silica gel, kanye nokulahleka okuncane kwamanzi kusuka ku-silica gel. Ngephutha wayekholelwa ukuthi imvula ye-silicic acid nokwakheka kwe-silica gel kwakungamandla esihlabathi se-sodium silicate esiqinile. Umthombo weSole

- 2) Ngawo-1960, inqubo yokuqina kwesihlabathi sengilazi samanzi i-Worthington R yathathwa njengenhlanganisela yezindlela zokuqina kwamakhemikhali nezomzimba, okungukuthi, i-sodium silicate ebolile yaba yi-silicic acid yamahhala ngaphansi kwe-catalysis ye-CO2, yabe seyiminyaniswa i-silicon gel. Ukwehla kwamanzi emzimbeni we-gel abicah kuzoholela ku "silicone gel bonding", okuluhlobo "lokuqina kwamakhemikhali"; ukoma kwamanzi engilazini yamanzi engaphendulwanga kuzoholela ku "vitreous bonding", okungokuka "ukuqina komzimba". Kepha ukholelwa ngephutha ukuthi ukuqina kwamakhemikhali kuyindlela yokuqina eqine futhi esheshayo, ngenkathi enganaki indima ebalulekile yokuqina komzimba;

- 3) Ngasekuqaleni kweminyaka yama-1990, ingilazi yamanzi eqinile i-CO2 eyenziwe nguZhu Chunxi nabanye ezweni lami kwakuyimfundiso yokuthi "ukuqina komzimba". Ukholelwa ukuthi isihlabathi sengilazi samanzi esivunguza ukuqina kwe-CO2 kumele sibe ngaphansi kwesimo esikhetheke kakhulu, okungukuthi, ingilazi yamanzi ifakwe ebusweni bezinhlayiya zesihlabathi ukwakha ifilimu ngobukhulu bama-microns ambalwa kuphela, angakha okuhle izimo zokuphelelwa amandla kwamanzi nokukhuthaza ukuqiniswa okusheshayo kwengilazi yamanzi. , Ngakho-ke kuthiwa "ukuqina kwengilazi yamanzi empeleni ukuqina komzimba." Okubi kwalokhu kubuka ukuthi kusalandela umbono oyiphutha wokuthi i-silicic acid yamahhala iyashesha lapho i-sodium silicate iphendula nge-CO2.

- I-4) Ekupheleni kweminyaka yama-1990, uZhu Chunxi nabanye ngokususelwa kumcabango wokuthi ukuqina kwe-CO2 kungokwamakhemikhali anzima ngokomzimba, ngemuva kocwaningo olunzulu, baphakamisa ukuthi ingilazi yamanzi eqinile iluhlobo "lwengilazi yamanzi e-modulus ephezulu" . Ithiyori, okungukuthi, i-asidi ye-silicic eyenziwe ukuphendula ayikwazi ukuhlehliswa esimweni samahhala, kepha iphinde ichithwe engilazini yamanzi engaphenduliwe, ikhuphule imodulus yokugcina ukuze ibone ukuqina kwengilazi yamanzi. Isibonelo, lapho uviniga we-organic usetshenziselwa ukuqina isihlabathi se-sodium silicate, ifilimu eqine kakhulu ye-sodium silicate ene-modulus efanayo ebusweni nangaphakathi ingatholakala, esondele ku-M = 3.45. Lapho i-CO2 isetshenziselwa ukwenza lukhuni ingilazi yamanzi, ifilimu eqinile yengilazi yamanzi ene-modulus encipha kancane kancane ebusweni nangaphakathi, nge-M eseduze ne-3.79 etholakalayo.

Ngakho-ke, ingilazi yamanzi eqinile luhlobo lwengilazi yamanzi e-modulus ephezulu, engenziwa iqine ngokulahleka kwe-alkali namanzi.

Ngo-2008, uJalimane C. Wallenhorst et al. bakholelwa ukuthi imodi yokuphendula enzima yesihlabathi se-sodium silicate ingahlukaniswa ngezinhlobo ezimbili ezilandelayo, njengoba kukhonjisiwe ku-Figure 1.

Imodi 1.1

Lapho kukhona isisombululo esine-asidi noma i-ejenti ephulukisayo (i-CO2 noma i-organic ester), izinga lokukhula kwezinhlayiya ze-colloidal engilazini yamanzi lihamba kancane, kepha lihlangana ngqo libe yi-gel yenethiwekhi enezinhlangothi ezintathu.

1.2 Imodi B

Ngaphansi kwesimo sesisombululo se-alkaline ngaphandle kwe-ejenti yokwelapha (ngaphansi kokushisa), izinhlayiya ze-colloidal zikhula kuqala futhi zakhe isakhiwo se-sol; futhi izinhlayiya zomuntu ngamunye zingakha isakhiwo senethiwekhi esiyizinhlangothi ezintathu kuphela ngaphansi kwesenzo sokuxhuma se-accelerator.

Izinhlayiya ze-silicic acid ezingazodwana zingakhula zibe yizinhlayiya ezinkulu ze-colloidal (imodi B), noma zingahlangana zibe yizinhlaka nezakhiwo zejel zenethiwekhi (imodi A). Kulezi zindlela ezimbili zokuphendula ezilukhuni, indlela yokusabela yamakhemikhali iyefana-ngokusebenzisa ukusabela kokuncipha phakathi kwamaqembu asebenzayo e-silanol, ukungabi namanzi emzimbeni nokuxhuma kunhlanganisela entsha ye-siloxane.

"Kungabonakala ukuthi imodi yokuphendula elukhuni yengilazi yamanzi incike kakhulu kunani le-pH lesisombululo se-binder. Ngenani eliphansi le-PH (phambi kwe-CO2 noma i-organic ester elapha i-ejenti) isisombululo se-silicic aqueous, kuyasiza imodi yokuphendula eqina A. Ngalesi sikhathi, isivinini sokuphendula esiqinile sihamba kancane kakhulu, futhi izinhlayiya ze-colloidal zihlanganisana zakha isakhiwo sejel esinegatsha, esinamafutha.

Lapho inani le-pH lesisombululo se-aiclicic acid aqueous> 7 (akukho CO2 noma ama-organic esters nokuqaliswa kokushisa), imodi yokuphendula enzima B iyaqhubeka nokwakha isakhiwo senhlayiya enkulu. Endabeni yesisombululo esinenani eliphakeme le-pH, ama-molecule akhula ngokushesha okukhulu kangangokuba ukusabela kokuqina ikakhulu kubangelwa ukukhula okuqhubekayo kwezinhlayiya ze-colloidal ngaphezu kokwakhiwa kwesakhiwo se-gel. Eqinisweni, isimo sokuhlanganiswa kwesakhiwo senethiwekhi sivinjelwe.

Lapho isihlabathi sengilazi samanzi esine-accelerator sifudunyezwa futhi siqiniswa, indlela yokuphendula eqina imi kanjena:

Ngemuva kokuthi ingilazi yamanzi eyisihlabathi ishubile futhi yavuselelwa, iyaqhubeka ngokuya ngemodi yokusabela ebukhali B (bheka Umfanekiso 1), nezinhlayiya ze-colloidal ziyakhula futhi zakhe isakhiwo se-sol. Ngalesi sikhathi, njengoba ukusabela kokuqina kuqhubeka, kungakhiwa isakhiwo esiyimbudumbudu esifana kakhulu noma isakhiwo esinamaphutha athile singakhiwa. Inani lamaphutha lizothinta ngqo ukusebenza kwalo okulandelayo, njengokumelana nomswakama wengqimba yesihlabathi.

Lapho umgogodla wesihlabathi sengilazi yamanzi uqiniswa yigesi ye-CO2, noma lapho i-organic ester isenziwa lukhuni, i-sol ion eyodwa izoqhubeka ngokuya ngemodi yokusabela eqina A, nezinhlayiya ze-colloidal zizohlangana zihlangane zenze isakhiwo sejel . Uma kungekho-ejenti elaphayo kusixazululo se-aliclic acid, izinhlayiya ze-silica gel zingaba khona ngokuqinile kusixazululo se-alkaline. Lokhu kungenxa yokuthi ubuso bezinhlayiya ze-colloidal bunomphumela kagesi woqweqwe oluphindwe kabili lukagesi lwama-ion e-sodium akhokhiswe kahle. Umphumela wezinhlayiya ze-colloidal ziyaphikisana futhi azihlanganiswa. Uma kukhona i-accelerator engaphili enqubeni yokuqina kwesihlabathi se-sodium silicate, ingasebenza njenge-ejenti yokuxhumanisa phakathi kwezinhlayiya ze-colloidal, okungukuthi, i-accelerator engaphiliyo ingaxhuma izinhlayiya ze-sol ngazinye ngamaqembu asebenzayo asebenzayo ebusweni bayo . Ngokubambisana, inethiwekhi enezinhlangothi ezintathu yamathambo e-silicate yakhiwa, ukuze isibopho siqiniswe ngokushesha nezinhlayiya zesihlabathi ziboshwe futhi zakheke.

Uma ingekho i-accelerator engajwayelekile engezwa, ukwakheka kwamathambo e-silicate esakhiweni senethiwekhi kuhamba kancane ngesikhathi senqubo yokuqina kwasesekondari, futhi umgogodla wesihlabathi olungiselelwe ukhombisa ukushiyeka okufana namandla aphansi ngokushesha kanye nokumelana nomswakama omubi.

Ngokuhlaziywa kwendlela yokuqinisa ingilazi yamanzi engenhla, kungabonakala ukuthi yize kunezindlela ezahlukahlukene zokuqinisa isihlabathi se-sodium silicate, zingahlukaniswa ngokujwayelekile zibe ukuqina komzimba kanye nokuqina kwamakhemikhali, futhi inqubo yokwenza lukhuni iyahambisana futhi ihlangene. ka. Okusho ukuthi, indlela yokuqina kwe-organic ester yesihlabathi se-sodium silicate inendlela efanayo yokuqina njengenqubo yokuqina kwe-CO2, egxile kakhulu ekuqineni komzimba okungaphendulwa kokuphela kwengilazi yamanzi, okuyisizathu esikhulu samandla we isikhunta (umongo) wesihlabathi; ukukhiqiza i-silicon Ukuqina kwamakhemikhali kwejel kulekelelwa ukuqina okusheshayo kwesihlabathi se-sodium silicate, ukusungulwa kwamandla okuqala, ukwenziwa ngcono kokumelana nomswakama nokuqina kokugcina kwesihlabathi, kanye nenqubo yokusebenzisana kokuqina kwamakhemikhali nokuqina komzimba .

Ngokususelwa ekuhlaziyweni okujulile kwendlela yokwenza lukhuni kwesihlabathi esingenhla se-sodium silicate ngezindlela ezahlukahlukene zokuqina (indlela ye-CO2, indlela ye-organic ester nokushisa + indlela yokusheshisa, njll.), Uphinde uhlole ithonya lamandla okuhlanganisa ingilazi yamanzi nomswakama ukumelana okuvela ezingeni lesakhiwo samangqamuzana Izici eziyinhloko ezinomthelela phakathi kwengilazi yamanzi nokusebenza okugoqekayo, ukuze kuguqulwe ukwakheka ne-morphology yengilazi yamanzi ngokombono wamangqamuzana, futhi kuthuthukiswe ukuqina okusha kokuqinisa + i-accelerator ingilazi yamanzi isihlabathi inqubo entsha, ukuze thuthukisa amandla okubopha isihlabathi sengilazi yamanzi. Inhloso yokwandisa ukumelana kwayo nomswakama nokwenza ngcono ukusebenza kwayo okuwohloka ukuqhubeka nokuthuthukisa nokwenza ngcono ukusebenza kwenqubo yesihlabathi se-sodium silicate ngenkathi iqhubeka ngokunqoba ukushiyeka kwayo okungokwemvelo, ngaleyo ndlela kube ukusakaza okuluhlaza okwethembisayo kakhulu ngekhulu lama-21. Hlanza okunamathelayo.

2 Inqubo yokusebenza kwesihlabathi esisha esingajwayelekile

2.1 Ukusebenza kwamandla ebond

Ngokulungiselela i-amorphous phosphate nokuyisebenzisa ukuguqula ingilazi yamanzi, amandla okubopha we-binder engaphiliyo ayathuthukiswa.

Ukuze uqhubeke nokuthuthukisa amandla okuhlanganisa isihlabathi se-sodium silicate, kuye kwakhiwa i-accelerator ephilayo. Ngokuxhuma kwamakhemikhali nokuqina, amandla asheshayo esihlabathi se-sodium silicate angathuthukiswa kakhulu. Lapho i-accelerator ephilayo ifakwa ku-1.5%, amandla wokuqina osheshayo Amandla angafinyelela ku-1.8MPa.

2.2 Ukumelana nomswakama wesihlabathi esiyisisekelo

Ngokuvamile, amandla esihlabathi sengilazi yamanzi aqiniswe umoya oshisayo azokwehla kancane kancane endaweni enomswakama. Ukuze kuthuthukiswe ukumelana nomswakama kwesihlabathi se-sodium silicate, ngakolunye uhlangothi, okuqukethwe umswakama okusele esihlabathini kususwa ngokuphelele ngemuva kokuqina, ngakolunye uhlangothi, kusetshenziswa indlela yokuxhuma nokuqina kwamakhemikhali. Lapho i-accelerator ingezwa ku-1.5%, amandla okuqina esihlabathi se-sodium silicate ngeke anciphe, kepha izokwanda kancane ngemuva kokubekwa ku-20 ° C naku-80% umswakama ohlobene namahora angama-24

2.3 Izici zokugeleza kwesihlabathi esiyinhloko

Ukungezwani kobuso bengilazi yamanzi uqobo kukhulu ngokwedlulele, okwenza ukuba manzi phakathi kwengilazi yamanzi nesihlabathi se-silica kube kubi, futhi i-viscosity yengilazi yamanzi yokusakaza imikhulu kakhulu kakhulu, ukuze i-viscosity yesihlabathi sengilazi yamanzi ngemuva ukuxuba kukhulu kakhulu, futhi izinhlayiya zesihlabathi zinamathela engilazini yamanzi. Ukumelana nokunyakaza kukhulu kakhulu, kuholele ekungangeni kahle kwesihlabathi se-sodium silicate, futhi ekugcineni kunciphise kakhulu ukuhlangana komgogodla wokudutshulwa. Kulolu vivinyo, ama-surfactants kanye nama-lubricants aqinile afakwa ukuthuthukisa kakhulu ukuswakama kwesihlabathi sokubumba.

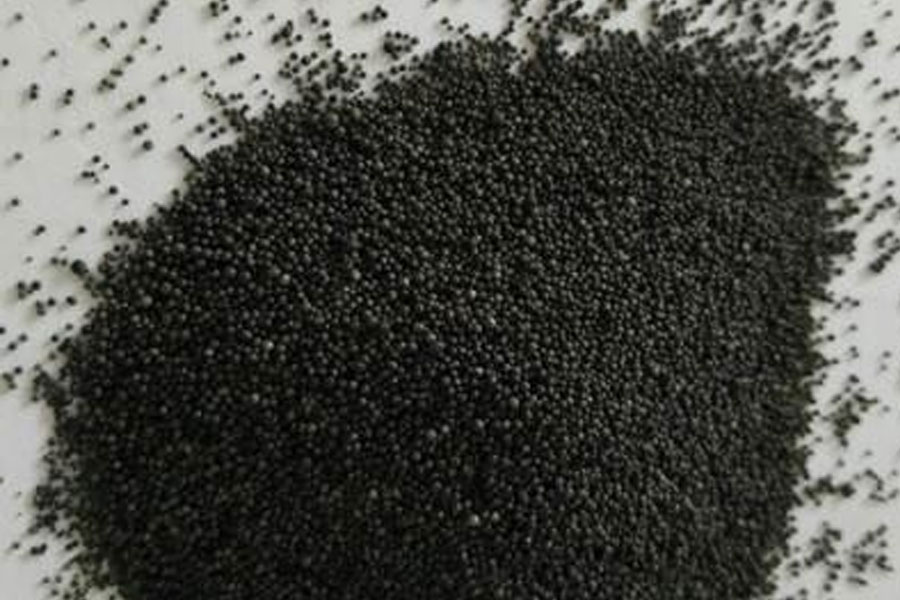

Ngokuya ngokusetshenziswa kwama-surfactants nezinto zokugcoba eziqinile, lesi silingo sakha i-accelerator eyindilinga, eyathuthukisa kakhulu uketshezi kwesihlabathi sengilazi samanzi.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Izimbangela Zokukhubazeka Okuvamile EGrey Cast Iron Cylinder Blocks

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off