Ithonya lezinto ezintathu zokusika ekusebenzeni kahle kwemishini

Wonke umuntu uyazi ukuthi lapho kuthuthukiswa ukusebenza kahle kwemishini, ukwandisa izinto ezintathu zokusika (ukusika isivinini, ukusika ukujula, nezinga lokuphakelayo) kuyindlela elula neqonde kakhulu. Kodwa-ke, ukwenziwa ngcono kwezinto ezintathu zokusika kwamathuluzi kuvame ukukhawulwa yizimo ezikhona zomklamo wethuluzi lomshini. Ngakho-ke indlela eshibhe kakhulu ukukhetha into enhle yethuluzi.

Umthetho wokuzimisela wezinto ezintathu zokusika

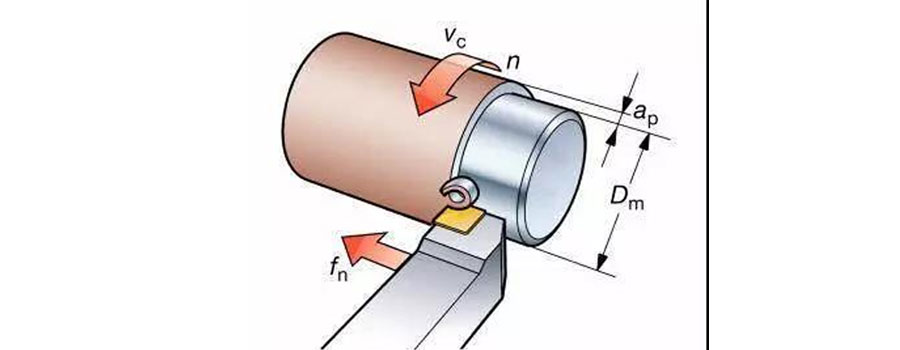

Thola ukujula kommese, inani lokuphakelayo nejubane lokusika eliqondile.

Ukusika ukujula: ngokuvamile kunqunywa ngokuya ngesabelo semishini;

Izinga lokuphakelayo: Izinga eliphakelayo lokuphakela imishini linqunywa ngamandla wethuluzi lomshini, futhi isilinganiso sokuphakela sokuqeda sinqunywa ubukhulu bendawo;

Ijubane lokusika: Kunqunywa ngokusho kwento yethuluzi nejubane lokuphotha lethuluzi lomshini.

Ngokombono wokuthuthuka ukulungisa imishini ukusebenza kahle, ukwandisa ukujula kokusika mhlawumbe kuyindlela efanele ukucatshangelwa. Esinye sezizathu ezibalulekile ukuthi izivivinyo zikhombisile ukuthi lapho ukusika kokujula kulingana nezikhathi eziyi-10 okuphakelayo, ukukhulisa ukujula kokusika kuzoba nomthelela omncane ekuqineni kwamathuluzi. Uma ijubane lokusika lenyuka, ukushintsha isivinini sokusika kuzokwenza ukuqina kwethuluzi kushintshe cishe kabili kunejubane; uma okuphakelayo kuguqulwa, ukuqina kwethuluzi nakho kungashintshwa ngokufanayo. Ngakho-ke, lapho okubizwa ngokuthi "usayizi wenetha" kungenakufinyelelwa ezikhaleni zemodi yethu yokukhiqiza ngobuningi, ukwandisa ukujula kokusika kungukukhetha okungafinyelela umjikelezo wokukhiqiza osebenza kahle ngaphandle kokubanga ukwanda okukhulu kwezindleko zamathuluzi.

Ukukhethwa kweThuluzi

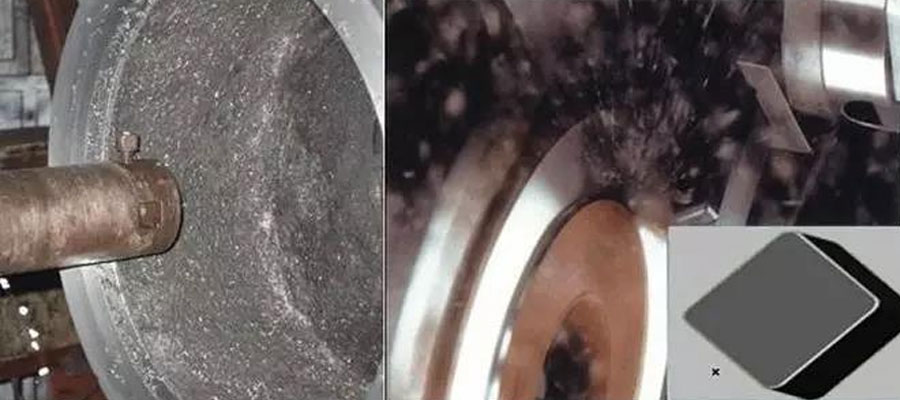

Amathuluzi we-carbide ahlanganisiwe angamathuluzi amakhulu emakethe yamathuluzi yamanje. Wonke umuntu ujwayelene naleli thuluzi. Ungaguqula izinto ezintathu zokusika zamathuluzi we-carbide aqinisiwe ngokuya ngezimo zangempela zesayithi lokucubungula, ukuze wandise impilo yethuluzi nokusebenza kahle kokusebenza. Kodwa-ke, i-cubic nitrogen Ukwenziwa kwamathuluzi asuselwa ku-boron bekungekude, futhi abantu abaningi abakaze bathinte amathuluzi anjalo. Kodwa-ke, ngokuvela kwezinto ezilukhuni nezinto zokwenzelwa umshini onzima, amathuluzi ama-cubic boron nitride avele kancane kancane emkhakheni wokubuka wawo wonke umuntu. Kepha abantu abaningi bavame ukucabanga ukuthi amathuluzi we-cubic boron nitride anqunyelwe ezinqubweni zokusika nokuqedela okusheshayo.

Eqinisweni, nge-R & D eqhubekayo kanye nomkhakha wethuluzi lezinto ezibonakalayo ogqamile, amathuluzi we-cubic boron nitride asetshenziswe kabanzi ezinqubweni zemishini emibi nezimo zokusika ezimaphakathi. Ukukhethwa kwamathuluzi we-cubic boron nitride kuyefana namathuluzi we-carbide aqinisiwe. Ngokuya ngezinto ezahlukahlukene zokusebenza, kukhethwa amamaki wethuluzi ahlukile kanye nezakhiwo zamathuluzi.

Ikholomu ye-cubic boron nitride blade isetshenziselwa inqubo yokuqeda. Inengxenye esezingeni eliphansi kuphela yezinto ezibonakalayo ze-cubic boron nitride, kanti i-matrix iyi-matrix ye-carbide eqinisiwe. Ukujula kommese kulawulwa ngaphakathi kwe-0.5mm, ngakho-ke kungasetshenziswa kuphela Ekuqedeni izinqubo, kulabo abanamamaki amakhulu nezindawo ezingajwayelekile, khetha i-cubic boron nitride blade. Umzimba wonke wenziwe nge-cubic boron nitride. Ukujula kokusika kungu-1-10mm, futhi impilo yethuluzi imvamisa amahora ama-3 / onqenqemeni lokusika.

Ngenqubekela phambili yocwaningo yamathuluzi we-cubic boron nitride kanye nezidingo zangempela ekucubunguleni, ukuqedwa kwejubane eliphakeme koqobo kuye kwasungulwa kwaba okufika ngezikhathi ezithile, oku-rough kanye ne-semi-finish, futhi kungasetshenziswa kumathuluzi wemishini ejwayelekile; izindleko zokusebenzisa nazo zibiza kakhulu.

Ukufunda Okwengeziwe

Ububanzi bemishini yamathuluzi we-cubic boron nitride namathuluzi we-carbide aqinisiwe ayahlangana. Isibonelo, i-grey cast iron, amathuluzi we-carbide aqinisiwe namathuluzi we-cubic boron nitride wonke angacutshungulwa. Ungakhetha ukonga okwengeziwe futhi okungabizi kangako ngamathuluzi, i-carbide eqinisiwe ngokuya ngezidingo zebhizinisi. Ngenxa yokulinganiselwa kokusebenza kwayo, isivinini esikhulu somugqa sethuluzi singafinyelela ku-350m / min, kanti ithuluzi le-cubic boron nitride lingafinyelela ku-1500m / min. Ngasikhathi sinye, ukuqina kwethuluzi le-cubic boron nitride liphindwe izikhathi ezingama-30-50 kunalelo lamathuluzi ajwayelekile aqinisiwe we-carbide. Izikhathi ezingama-5-15 impilo yethuluzi le-carbide eligqinsiwe.

Kodwa-ke, izinkampani azikhethi ngobumpumputhe amathuluzi we-cubic boron nitride ukucubungula i-iron cast iron. Ngemuva kwakho konke, inani lamathuluzi we-cubic boron nitride liphakeme kunalelo lamathuluzi we-carbide aqinisiwe. Ngakho-ke, kunconywa ukuthi ukhethe ukukhiqizwa ngobuningi kanye nezidingo zokucubungula okuphezulu. Kumathuluzi okusika ama-cubic boron nitride, uma ukusebenza kahle kungaphakeme futhi kunemisebenzi embalwa, kuyonga kakhulu futhi kubiza izindleko ukukhetha amathuluzi okusika we-carbide aqinisiwe.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe:Ithonya lezinto ezintathu zokusika ekusebenzeni kahle kwemishini

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off