Isingeniso Kwenqubo Yezimoto Ezingasindi

Njengamanje, ngokulungiswa kwesakhiwo samandla nokwenziwa ngcono kwezidingo zokuvikelwa kwemvelo, imboni yezimoto iyathuthuka ngokuya ngesisindo esincane. Idatha ikhombisa ukuthi kuko konke ukwehla ngo-10% kwekhwalithi yezimoto, ukusetshenziswa kukaphethiloli kuncipha cishe ngo-3% kuye ku-5%. Ukuthwala isisindo semoto akukwazi ukunciphisa ngempumelelo ukusetshenziswa kwamandla kuphela futhi kwandise nemisebenzi yokusetshenziswa kwezimoto, kepha futhi kunciphise izindleko zokukhiqiza futhi kuthuthukise ikhwalithi yemoto. Sekuyisiqondiso esibalulekile sokwenza imoto ukunciphisa isisindo semoto.

Indlela ebalulekile yokubona engasindi imoto

Vele, ukusindiswa kwemoto akuyona nje into elula yokwehlisa isisindo semoto, kepha ukuqinisekisa ikhwalithi yemoto, kusetshenziswa izinto ezintsha ngokwengeziwe ezingxenyeni ezisebenzayo nezakhiwe ngemoto ukwenza ukusebenza kwezingxenye zemoto kube ngaphezulu kuhle kakhulu. Ngasikhathi sinye, isisindo silula, esiqinisekisa ukuthi ukusetshenziswa kwamandla emoto kuyancipha ngesikhathi sokushayela, futhi kufinyelela imiphumela eminingi.

Ngokuhambisana nokwehla kwekhwalithi yemoto uqobo, ubuchwepheshe obulula bemoto butholakala ikakhulukazi ngalezi zindlela ezilandelayo: inani lezinto ezilula liyaqhubeka nokukhuphuka, ama-aluminium alloys, ama-magnesium alloys, ama-titanium alloys, ama-steels anamandla amakhulu, amapulasitiki , i-powder metallurgy, nezinto eziyinhlanganisela yemvelo nokusetshenziswa kobumba, njll .; ukusebenziseka kahle kwesakhiwo kanye nezinga lokwakheka kwezingxenye ezithile zezingxenye nezinto eziqhubekayo kuyaqhubeka nokuthuthuka, njengokusebenzisa idrayivu edonsa phambili, isakhiwo esiqina kakhulu kanye nesakhiwo sokumiswa se-ultra-light ukufeza inhloso yobuchwepheshe bokuhlanganiswa obulula, obusizwa yikhompyutha (kufaka phakathi I-CAD / Ukuthuthukiswa kobuchwepheshe obufana ne-CAE / CAO) kanye nokuhlaziywa kwesakhiwo kukhuthaze ukuqanjwa okuqhubekayo endleleni yokwakha nobuchwepheshe bokuxhuma embonini yokukhiqiza izimoto.

Kulezi zindlela ezintathu ezingenhla zokubona ukungasindi kwezimoto, ukucutshungulwa kwezinto ezintsha, ukwakheka nezindlela zokwakheka kwezimoto nokwenziwa kwemoduli, kanye nenqubekela phambili yobuchwepheshe bokuxhuma konke kudinga ubuhlakani obuhambisanayo bobuchwepheshe ukufeza. Phakathi kwalezi zindlela ezintathu, ukusika i-laser kanye ne-laser welding kunezinzuzo zazo ezihlukile futhi kuba izindlela ezibalulekile zobuchwepheshe zokubona ukungasindi kwezimoto.

I-Laser welding ne-laser ukusika ubuchwepheshe obusha obulula

Ukukhiqizwa kwezimoto kuwubunjiniyela besistimu enkulu obudinga uchungechunge lwezinqubo nobuchwepheshe ukuze buqedwe. Eminyakeni yamuva, ubuchwepheshe obuthuthukisiwe obumelwe yi ukusika kwe-laser, amarobhothi ezimboni, kanye nokulawulwa kwedijithali kusaqhubeka nokugqugquzela ukuthuthukiswa kwemboni yokukhiqiza izimoto. Njengendlela ethuthukisiwe yokucubungula, i-laser imiselwe ukuletha impumelelo eguquguqukayo ekuthuthukisweni kwemboni yokukhiqiza izimoto. . Njengamanje, ubuchwepheshe be-laser emkhakheni wokukhiqiza izimoto bugxile kakhulu ekusetshenzisweni okufana nokushisela nge-laser, ukusika i-laser, ukwenza buthaka kwe-laser, ukumaka nge-laser, ukunquma i-laser, kanye nokwenza kabusha i-laser.

Inzuzo ebaluleke kakhulu ye-laser ekukhiqizeni izimoto yindlela yayo yokucubungula engeyona yokuxhumana ehamba phambili, edlala indima ebalulekile emisha yokucubungula ubuchwepheshe emkhakheni wezimoto zomzimba ezimhlophe, i-electronics yezimoto, ukucutshungulwa kwensimbi nokunye. Ekusetshenzisweni kwezinto ezintsha ezifana ne-aluminium alloys, ama-magnesium alloys, ama-titanium alloys, ukusika kwe-laser kuyashesha futhi kunembe kakhulu kunezindlela zangaphambilini zokusika. Kulezi zinto ezilukhuni ukucubungula, ukusika i-laser kulula ukukufeza. Ukuthuthuka kobuchwepheshe kuphinde kwaguqula ukusetshenziswa kwalezi zinto ezintsha kusuka kokuhle kuya kokuyiqiniso, ukuze izinto ezintsha zitholakale ekusindisweni kwezimoto.

Ukwakheka nokwenziwa kwemoduli ukuhlanganiswa kwezingxenye ezihlakazekile nezakhi ekukhiqizeni kwendabuko yezimoto ukubona imisebenzi yasekuqaleni yemoto isiyonke, ngaleyo ndlela kuncishiswe isisindo futhi kuqaphele isisindo esincane. Ukufezekiswa kokuhleleka nokwenziwa kwemoduli kuncike kakhulu enqubekweni yetheknoloji yokuxhuma. Ezinye zezindlela zokukhiqiza zendabuko zifakwa ngezikulufo, kanti ezinye zixhunywe ngeglue. Izindlela zendabuko azikwazi ukuhlangabezana nezidingo zokunemba nokuqina ekukhiqizeni izimoto zanamuhla, futhi ukusetshenziswa kwezinto ezintsha nakho kwenza izindlela zendabuko zibe yimbi kancane. I-Laser welding ayixhumani nayo. Ngesikhathi sokucubungula, i-welding ngokunemba ingatholakala ngaphandle kokuthinta umkhiqizo. Ithole inqubekela phambili eya phambili ekuqineni, ekuthungeni, ekucaceni nasekuhlanzekeni kokuxhuma. Iba indlela ebalulekile yokubumba esikhathini esizayo.

Ubuchwepheshe be-Laser budlale indima ebalulekile ekusindisweni kwezimoto, ngaleyo ndlela kuthuthukisa kakhulu ukusebenza nokuphepha kwezimoto. Ngokuzayo, ubuchwepheshe be-laser bunamathemba abanzi wohlelo emkhakheni wezimoto.

Sicela ugcine umthombo nekheli lale ndatshana ukuze uphinde uprintwe: Isingeniso Kwenqubo Yezimoto Ezingasindi

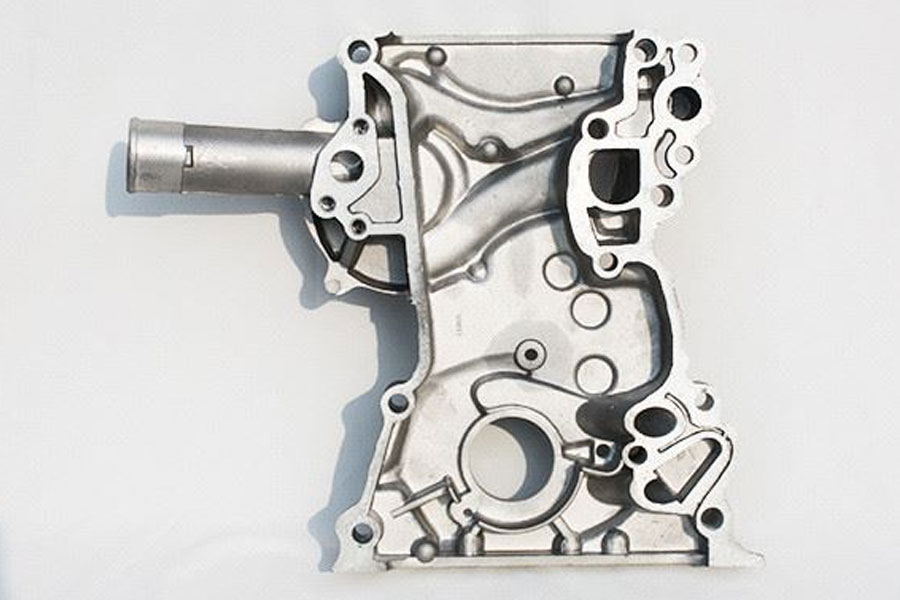

UMinghe Inkampani yeDie Casting anikezelwe ekukhiqizeni nasekuhlinzekeni ikhwalithi nokusebenza okuphezulu Izingxenye Zokulingisa (izingxenye zensimbi zensimbi zokufa zisebenza ikakhulukazi zibandakanya I-Thin-Wall Die Casting,I-Hot Chamber Die Casting,Cold Chamber die Casting), Insizakalo Eyindilinga (Insiza Yokulingisa,ICnc Machining,Ukwenza Okubandayo, Surface Treatment) .Noma ikuphi ukusakazwa kwe-Aluminium die, i-magnesium noma i-Zamak / zinc die casting nezinye izidingo zokuphosa zamukelekile ukuxhumana nathi.

Ngaphansi kokulawulwa kwe-ISO9001 ne-TS 16949, Zonke izinqubo zenziwa ngamakhulu emishini esezingeni eliphakeme yokufa, imishini ye-5-axis, nezinye izikhungo, ezisukela kuma-blasters kuya kumishini yokuwasha ye-Ultra Sonic.Minghe akagcinanga ngemishini esezingeni eliphezulu kepha futhi unobuchwepheshe iqembu lonjiniyela abanolwazi, ama-opharetha nabahloli ukwenza ukwakheka kwekhasimende kugcwaliseke.

Umenzi wenkontileka yokufa kwabasikiwe. Amandla afaka izingxenye ezibandayo ze-aluminium die casting ezivela ku-0.15 lbs. kuye ku-6 lbs., Ukusetha ushintsho olusheshayo, nemishini. Izinsizakalo ezingezwe ngenani zifaka phakathi ukupholisha, ukudlidliza, ukuphazamisa, ukuqhumisa ngokudubula, ukupenda, ukuhlobisa, ukumboza, ukuhlangana nokusetshenziswa kwamathuluzi. Izinto zokusebenza ezisetshenzisiwe zifaka ama-alloys afana no-360, 380, 383, no-413.

I-Zinc die casting design usizo / izinsizakalo zobunjiniyela ezihambisanayo. Umenzi wangokwezifiso we-precision zinc die castings. Ukusakazwa okuncane, ukukhishwa kwengcindezi ephezulu, ukusikeka kwesikhunta esiningi, ukujikijelwa kwesikhunta okuvamile, ukufefa kwamayunithi kanye nokuzimela okuzimele kanye nokuvalwa okuvaliwe komgodi kungenziwa. Ama-Castings angenziwa ngobude nobubanzi obufinyelela ku-24 in. Ku +/- 0.0005 in. Ukubekezelelana.

I-ISO 9001: Umkhiqizi oqinisekisiwe ka-2015 we-die cast magnesium, Amandla afaka i-high-pressure magnesium die casting up to 200 ton chamber hot & 3000 ton cold chamber, designing designing, polishing, molding, machining, powder & liquid paint, QA full with CMM amakhono , inhlangano, ukupakisha nokulethwa.

Kuqinisekiswe i-ITAF16949. Insiza Eyengeziwe Yokulingisa Faka ukukhipha utshalomali,ukuphonsa kwesihlabathi,Ukuphonswa kwamandla, Lost Foam Ekubunjweni,I-Centrifugal Casting,Ukuphoswa Kokuqothula,Permanent Isikhunta Ukulingisa, Amakhono afaka i-EDI, usizo lobunjiniyela, ukumodeliswa okuqinile nokucutshungulwa kwesibili.

Izimboni Zokulingisa Izingxenye Zamacala Ezifundo Zezimoto: Izimoto, Amabhayisikili, Izindiza, Izinsimbi Zomculo, I-Watercraft, Amadivayisi we-Optical, Izinzwa, Amamodeli, Amadivayisi we-elekthronikhi, Ukuvaleka, Amawashi, Imishini, Izinjini, Ifenisha, Ubucwebe, AmaJig, Telecom, Ukukhanyisa, Amadivayisi Wezokwelapha, amadivayisi wezithombe, Amarobhothi, okubaziwe, okokusebenza komsindo, okwezemidlalo, i-Tooling, Amathoyizi nokuningi.

Yini esingakusiza ukuthi uyenze ngokulandelayo?

∇ Iya ekhasini eliyisiqalo For I-Die Casting China

→Izingxenye Zokusakaza-Thola esikwenzile.

→ Izeluleko Ezilinganisiwe Mayelana Izinsizakalo Zokufa Zokusakaza

By Umkhiqizi weMinghe Die Casting | Izigaba: Izindatshana Eziwusizo |Material Omaka: I-Aluminium Casting, Zinc Ukulingisa, Ukulingiswa kweMagnesium, I-Titanium Casting, Insimbi Engagqwali, Brass Ekubunjweni,Ukulingiswa kweBronze,Isakaza ividiyo,Umlando wenkampani,I-Aluminium Die Casting | Amazwana Off